Superheater protecting device with thermal expansion eliminating function

A protection device and superheater technology, which is applied in steam superheating, lighting and heating equipment, steam generation, etc., and can solve problems such as easy cracking of welds at the joints of headers and serpentine pipes

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

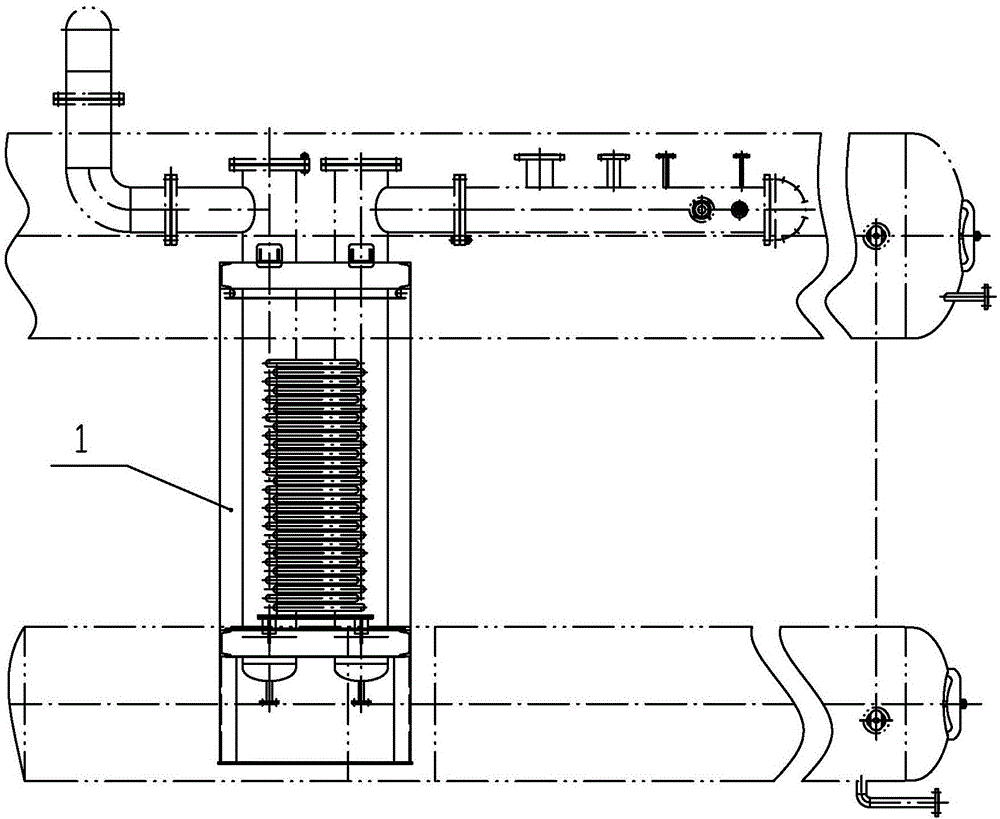

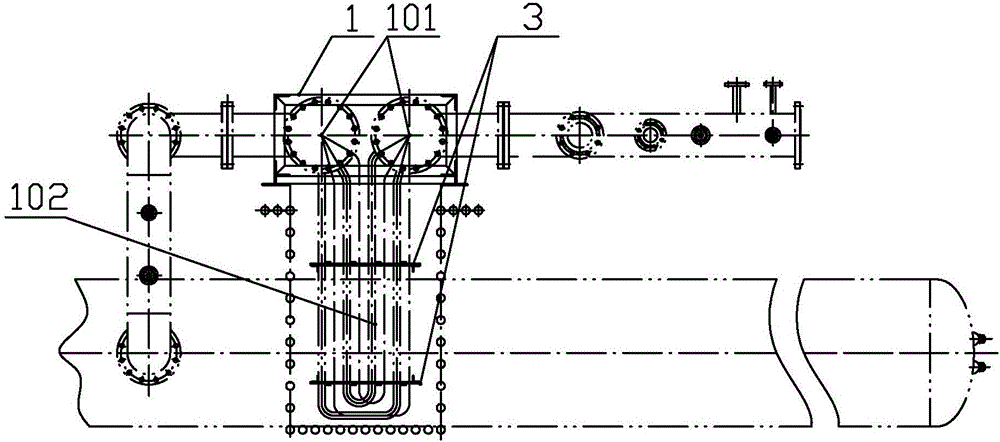

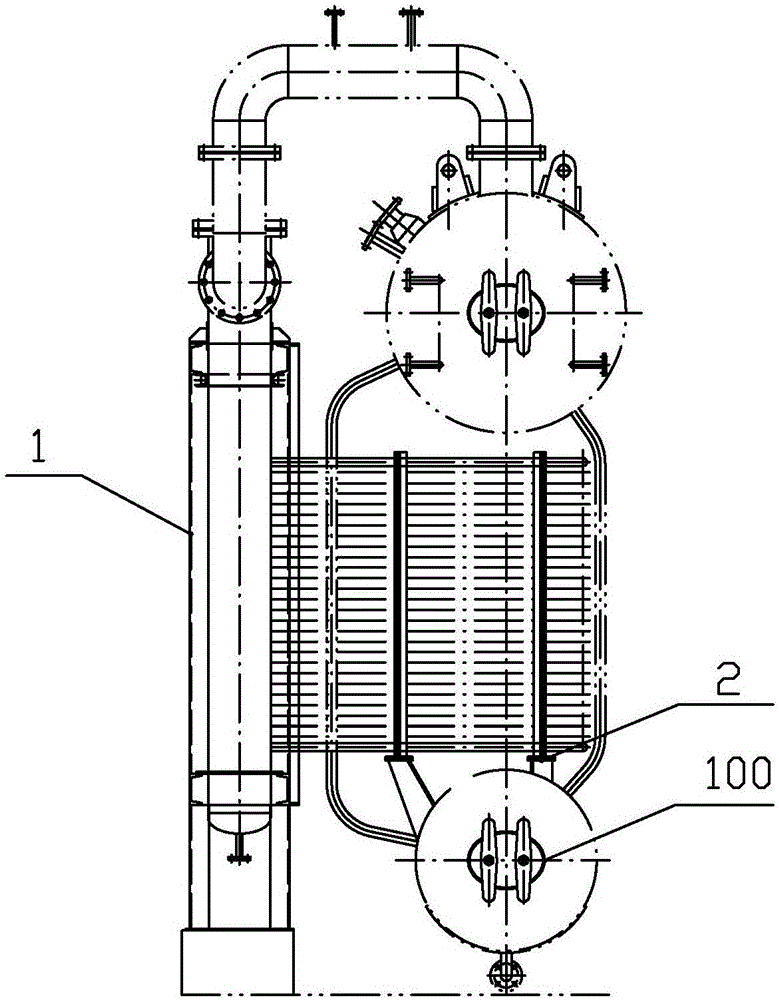

[0030] Specific implementation mode one: combine Figure 1 to Figure 13 Describe this embodiment, a superheater protection device with the function of eliminating thermal expansion, which includes a vertical bracket 1, a horizontal bracket group 2 and a tube bundle fixing device 3, and the tube bundle fixing device 3 is connected to the lower drum 100 through the horizontal bracket group 2 Support positioning, the vertical support 1 is a closed cubic structure, the header 101 and its connection with the serpentine tube 102 are located in the vertical support 1 and sealed by the vertical support 1, the serpentine tube 102 passes through the tube bundle fixing device 3 fixed.

[0031] A sealing frame 4 is fixed on the side of the vertical support 1 close to the tube bundle, and the sealing frame 4 is a rectangular frame surrounded by four steel plates, which is used for sealing the connection between the superheater and the boiler.

specific Embodiment approach 2

[0032] Specific implementation mode two: combination Figure 1~6 To illustrate this embodiment, the vertical support 1 includes a positioning frame 1-1, a sealing support frame 1-2, an upper end seal 1-3, a lower end seal 1-4 and four side sealing plates 1-5, and the sealing support frame 1 -2 is fixedly connected to the body frame of the superheater through the positioning frame 1-1, the sealing support frame 1-2 has a cubic structure, and the four sides of the sealing support frame 1-2 are respectively sealed by four side sealing plates 1-5, And the sealing support frame 1-2 is fixedly connected with the body frame of the superheater through four side sealing plates 1-5, the header 101 is located in the sealing support frame 1-2, and the lower end seal 1-4 includes a horizontal fixed connection on the sealing support frame 1 -2 The first steel plate 1-41 at the bottom, the upper end seal 1-3 includes a U-shaped expansion joint 1-31 and a second steel plate 1-32 horizontally ...

specific Embodiment approach 3

[0033] Specific implementation mode three: combination Figure 1~6 To illustrate this embodiment, the sealing support frame 1-2 includes four angle steels arranged vertically and eight channel steels arranged horizontally, and the four angle steels and eight channel steels are assembled into a cubic structure. Such design can reduce the weight of the structure while ensuring the stability of the structure. Other composition and connection relations are the same as the second specific method.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com