Rotation-based combined desulfurization and denitrification distribution system

A desulfurization and denitrification, rotary type technology is applied in the field of combined desulfurization and denitrification layout system, which can solve the problems of difficult desulfurization product treatment, large ammonia escape, limited load capacity of units, etc., and achieves saving operation and maintenance costs, simple system layout, and consumption The effect of low electricity rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] The present invention will be further described in detail below in conjunction with the accompanying drawings.

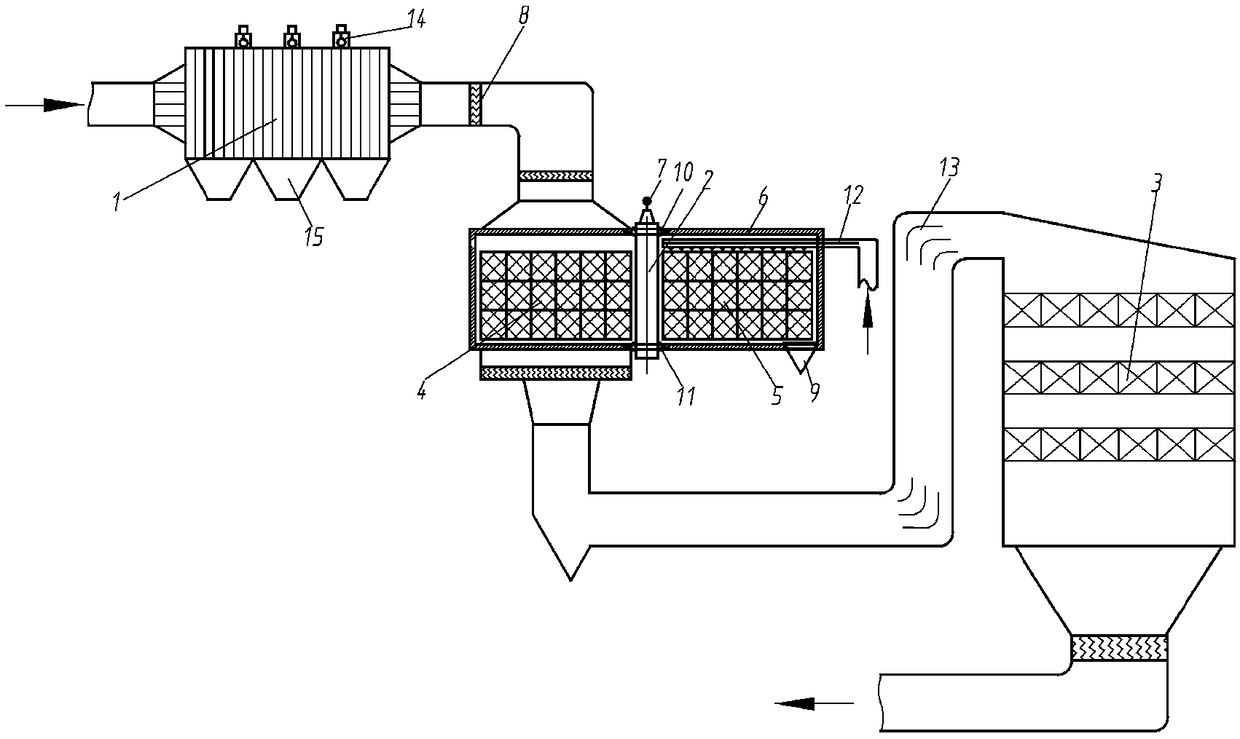

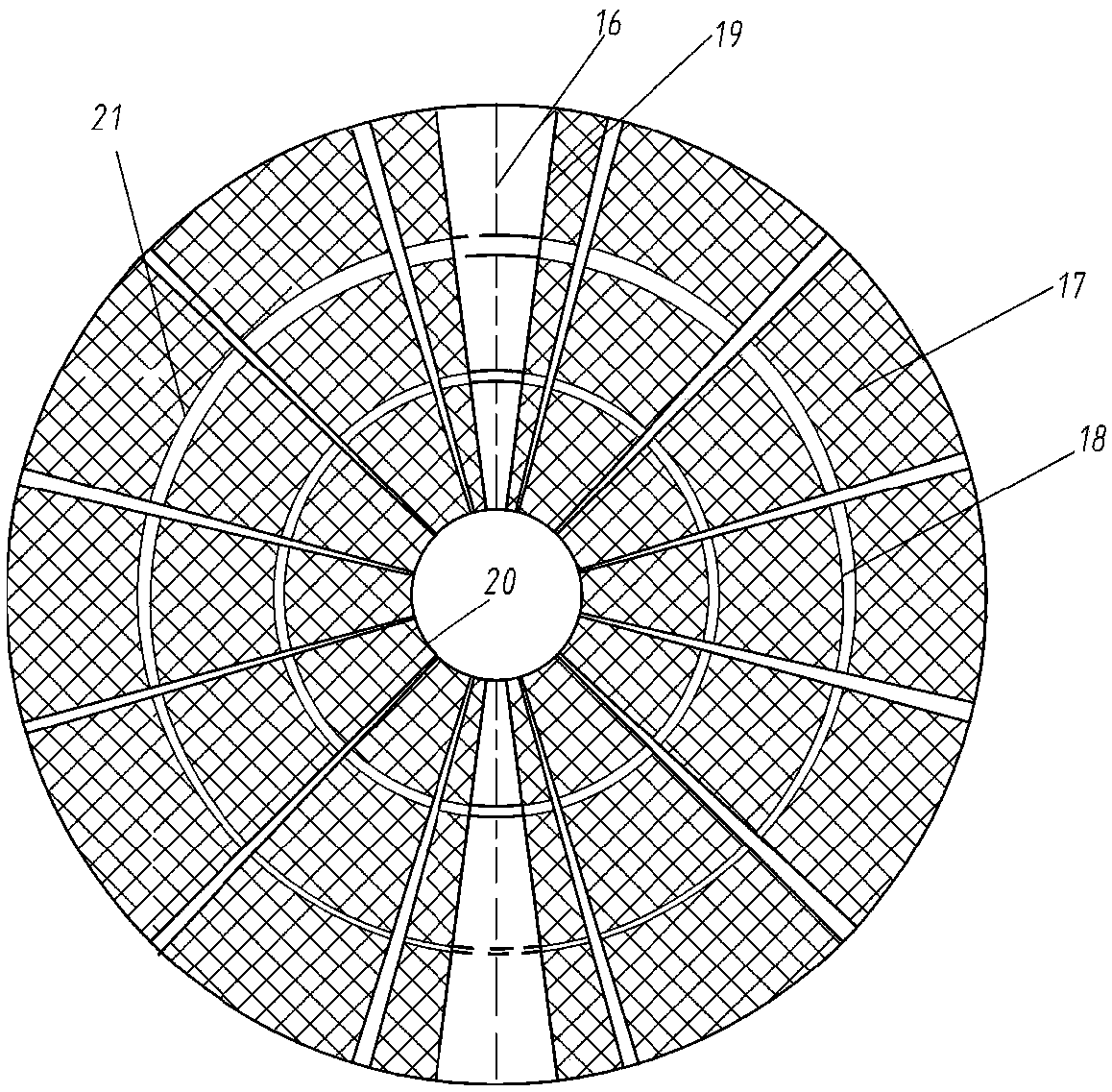

[0029] see figure 1 , The present invention proposes a new type of combined desulfurization and denitration system, the main features of which are: (1) A high-temperature electrostatic precipitator and a desulfurization device are arranged in front of the SCR denitration device, which can prevent ammonia escape from the SCR denitration device and SO2 2 The reaction generates ammonium hydrogen sulfate, which effectively solves the problems of air preheater, low and low temperature economizer, and induced draft fan equipment corrosion and ash blocking, and ensures long-term efficient and stable operation of the unit. (2) Activated carbon fibers adsorb SO in oxygen atmosphere 2, NO experimental results show that activated carbon fibers have poor adsorption capacity for NO, but NO helps activated carbon fibers to absorb SO. 2 Gas adsorption, within 90 minutes o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com