Net laying device and method for fully-mechanized coal mining face

A fully-mechanized mining face and mesh laying technology, which is applied to mining equipment, earthwork drilling, mine roof supports, etc., can solve problems that affect the safety of the withdrawal operation environment, affect the efficiency of coal mining work, and threaten the safety of operators. Achieve the effects of reducing the possibility of being torn, shortening working hours, and reducing labor intensity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

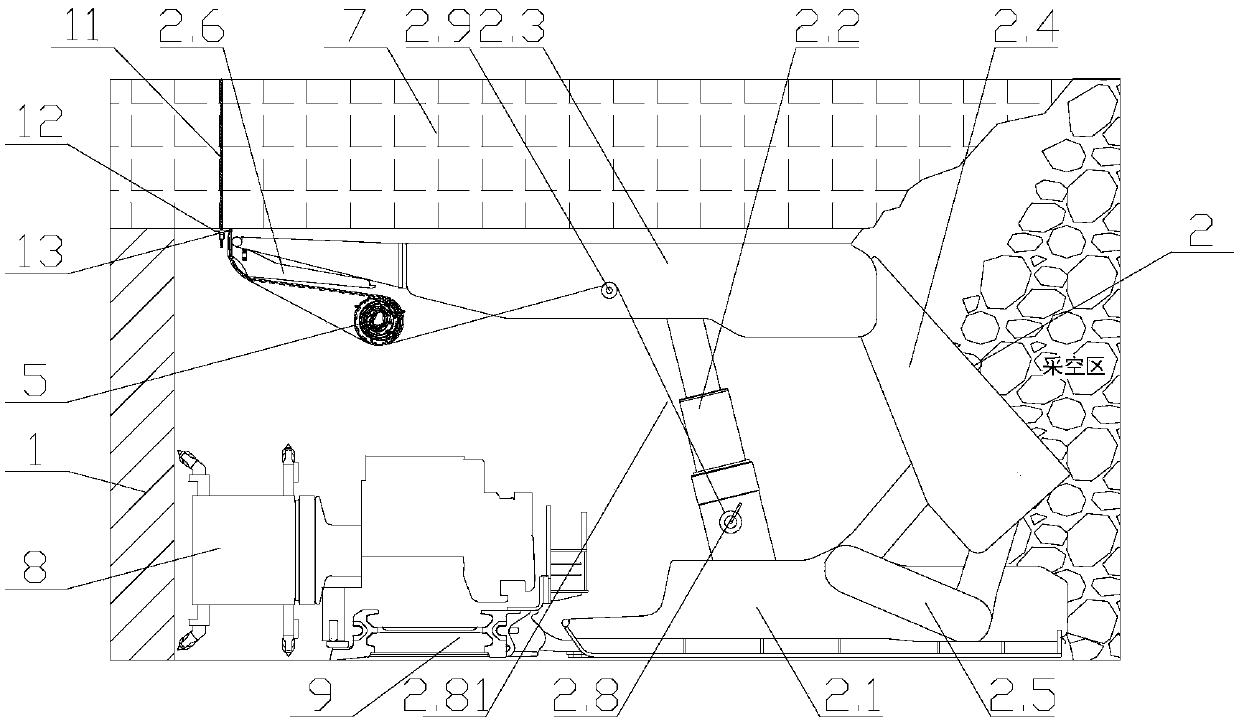

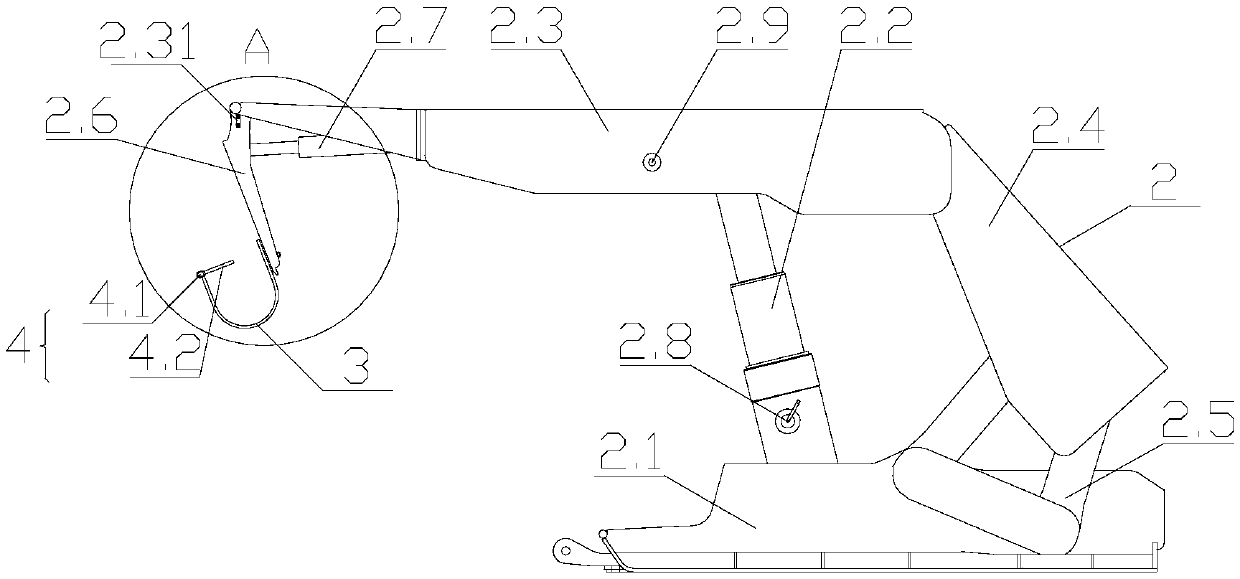

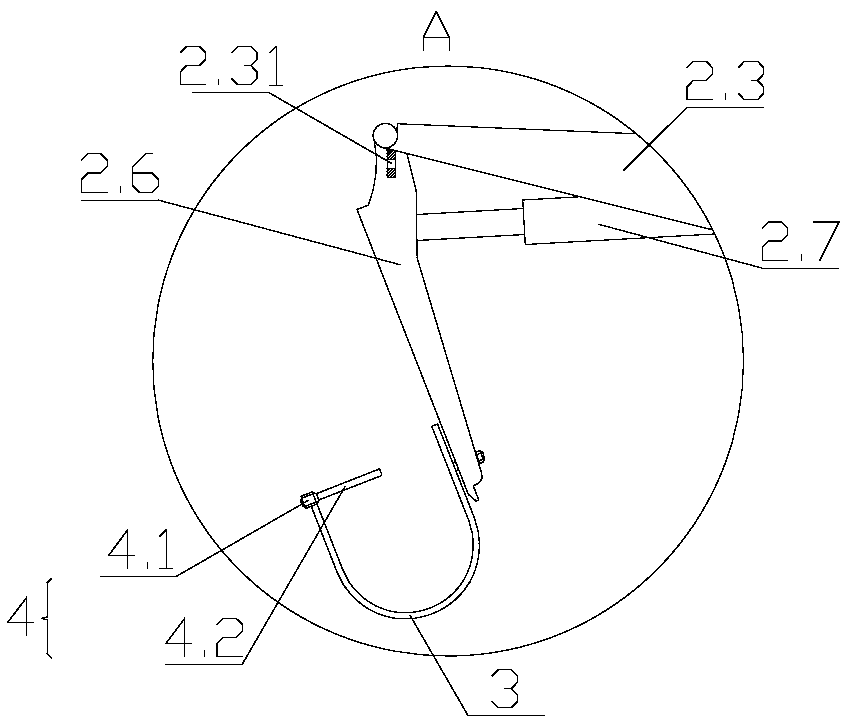

[0033] Embodiment 1: as Figure 2 to Figure 3 As shown, a net laying device for fully mechanized mining face, which includes a plurality of hydraulic supports 2 and net storage hooks 3 arranged along the fully mechanized mining face 1, the hydraulic support 2 includes a base 2.1, a hydraulic prop 2.2, a top beam 2.3, Tail beam 2.4, four connecting rods 2.5, side guard 2.6, telescopic rod 2.7, winch 2.8 and fixed pulley 2.9; hydraulic prop 2.2 is arranged on base 2.1; the bottom end of hydraulic prop 2.2 is movable hinged with base 2.1, and hydraulic prop 2.2 The top of the top beam is articulated with the top beam 2.3; one end of the top beam 2.3 is articulated with the upper part of the tail beam 2.4, and the lower part of the tail beam 2.4 is connected with the base 2.1 through four connecting rods 2.5; the other end of the top beam 2.3 is provided with a lifting hole 2.31 , the other end of the top beam 2.3 is also provided with a side panel 2.6, and a telescopic rod 2.7 is...

Embodiment 2

[0036] Embodiment 2: as Figures 4 to 6 Shown, use embodiment 1 to the method for fully mechanized mining face laying net, comprise the following steps:

[0037] (1) Set up net volume 5:

[0038] First pass the free end of each winch wire rope 2.81 through the corresponding lifting hole 2.31, and fix the free end of the winch wire rope 2.81 on the unfolded net at a distance of 1.1m from the free edge of the net roll 5; then operate the winch 2.8 to tighten the winch Wire rope 2.81, after the free end of capstan wire rope 2.81 is hoisted to hoisting hole 2.31, stop operating winch 2.8, and the net at the free end of winch wire rope 2.81 is fixed on the hoisting hole 2.31;

[0039] Then the free end of the winch wire rope 2.81 is released from the net, and then the free end of the winch wire rope 2.81 is moved down and fixed on the rolled net roll 5, the winch 2.8 is operated to tighten the winch wire rope 2.81, the net roll 5 is improved, and the net The volume 5 is placed in...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com