Patents

Literature

48 results about "Support worker" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

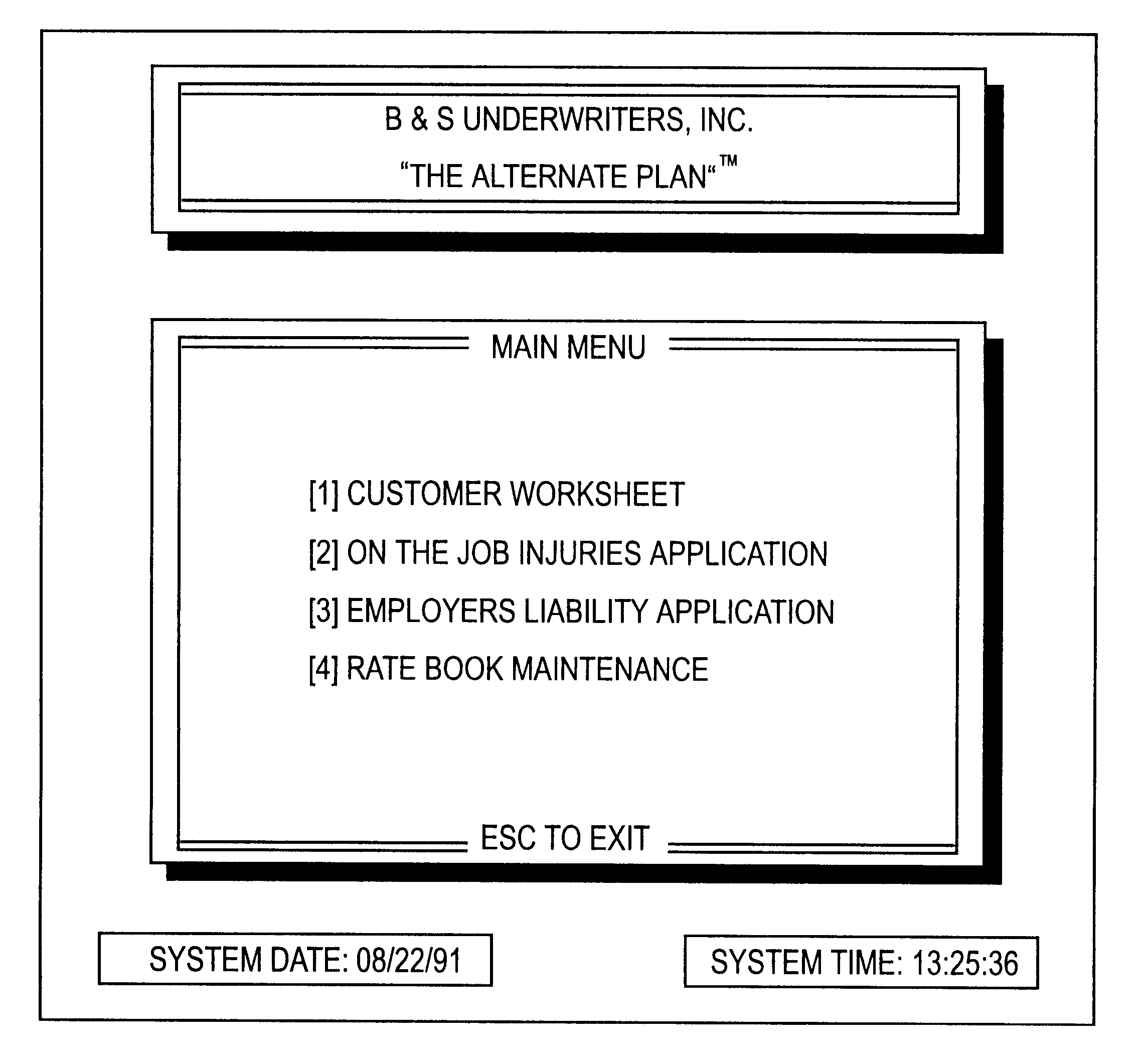

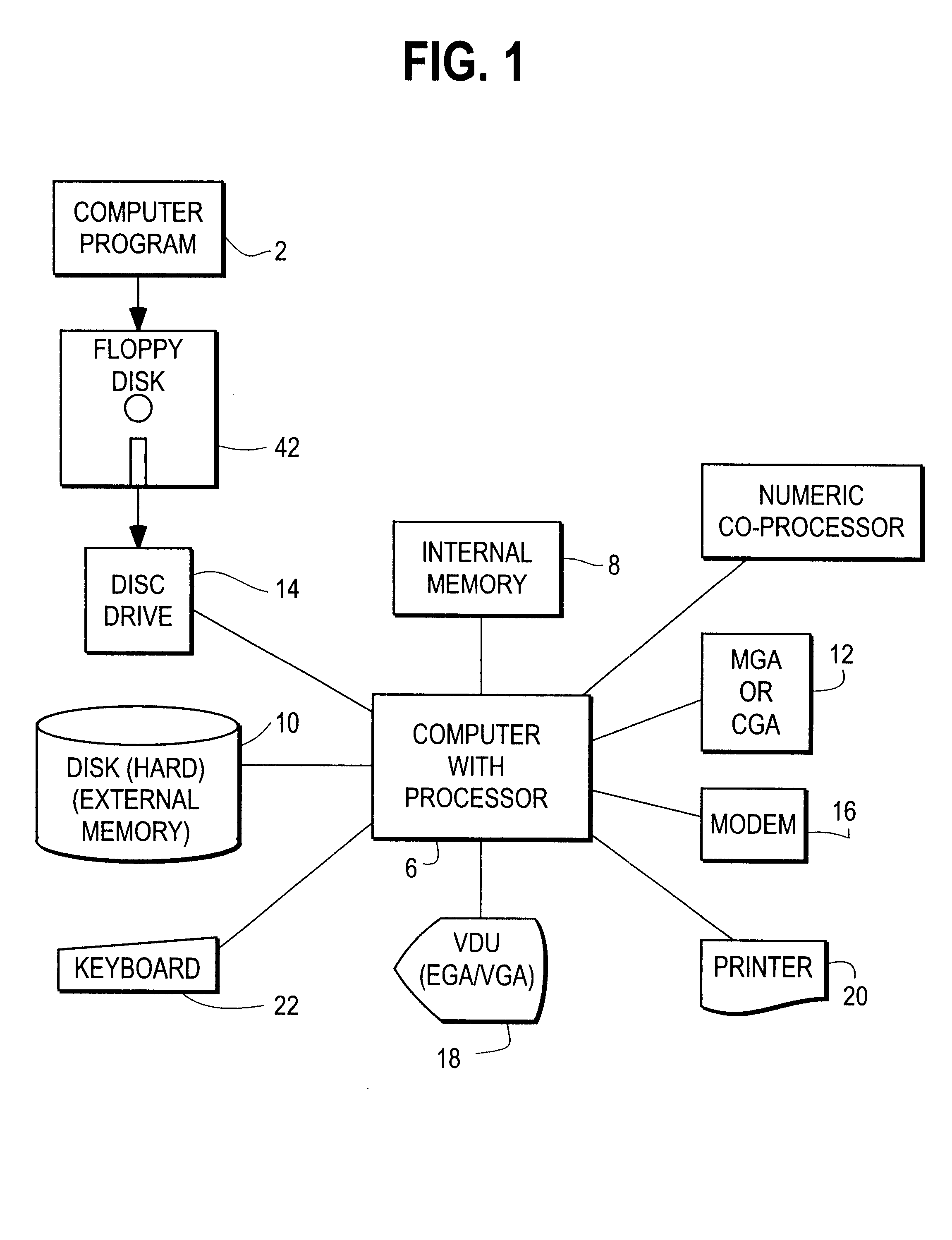

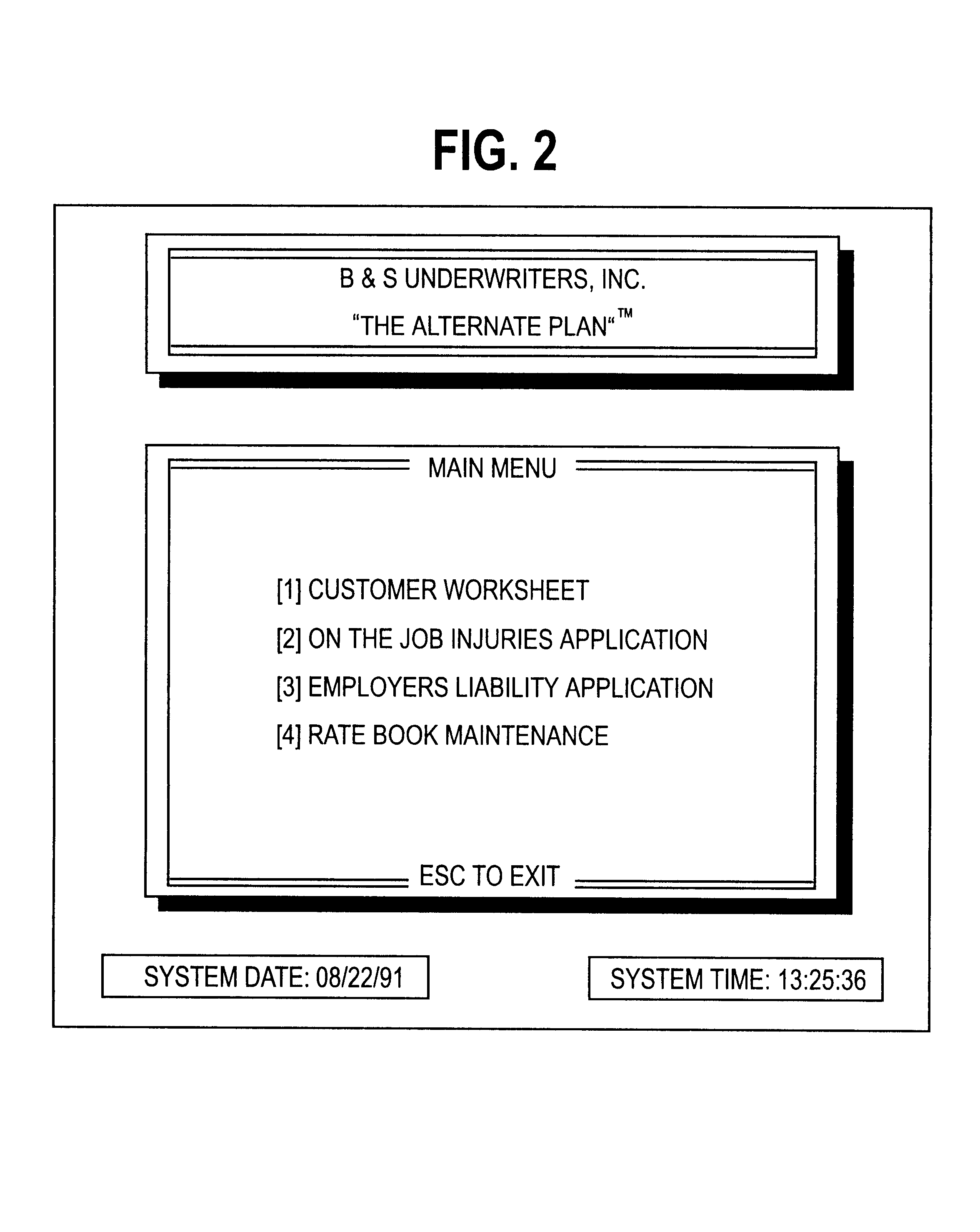

Computer system and methods for supporting workers' compensation/employers liability insurance

An automated system and method of computing rates to be charged for insurance coverage equivalent to that provided by a standard workers' compensation policy includes coordinating a workers' compensation insurance policy with an employers liability insurance policy to provide the coverage of a standard workers' compensation policy; determining one set of rates for insuring employees in pre-determined employment classifications for the workers' compensation policy and another set of rates for insuring the employees in other pre-determined employment classifications for said employers liability coverage; entering the sets of rates in a memory accessible by a digital computer; computing with the digital computer a first number, representing the amount of premium to be paid for workers' compensation coverage, by multiplying an employer's payroll for the employees in a one of the pre-determined employment classifications times a corresponding rate from the one set of rates, and computing with the digital computer a second number, representing the amount of premium to be paid for employers liability coverage, by multiplying the employer's payroll for employees in a one of the other pre-determined employment classifications times a corresponding rate from the second set of rates, to compute the rates to be charged for insurance coverage equivalent to that provided by the standard workers' compensation policy.

Owner:LIFECOMP

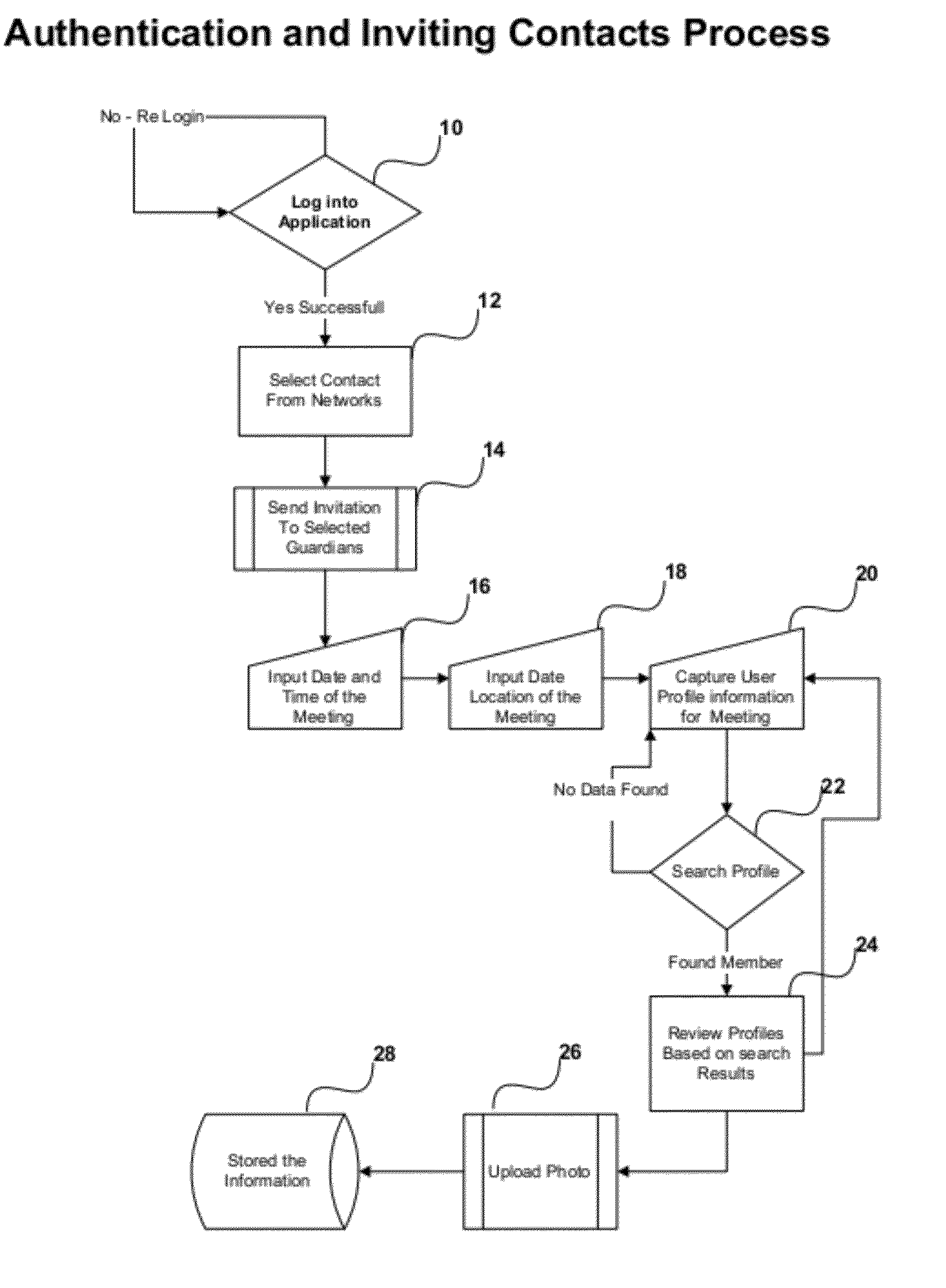

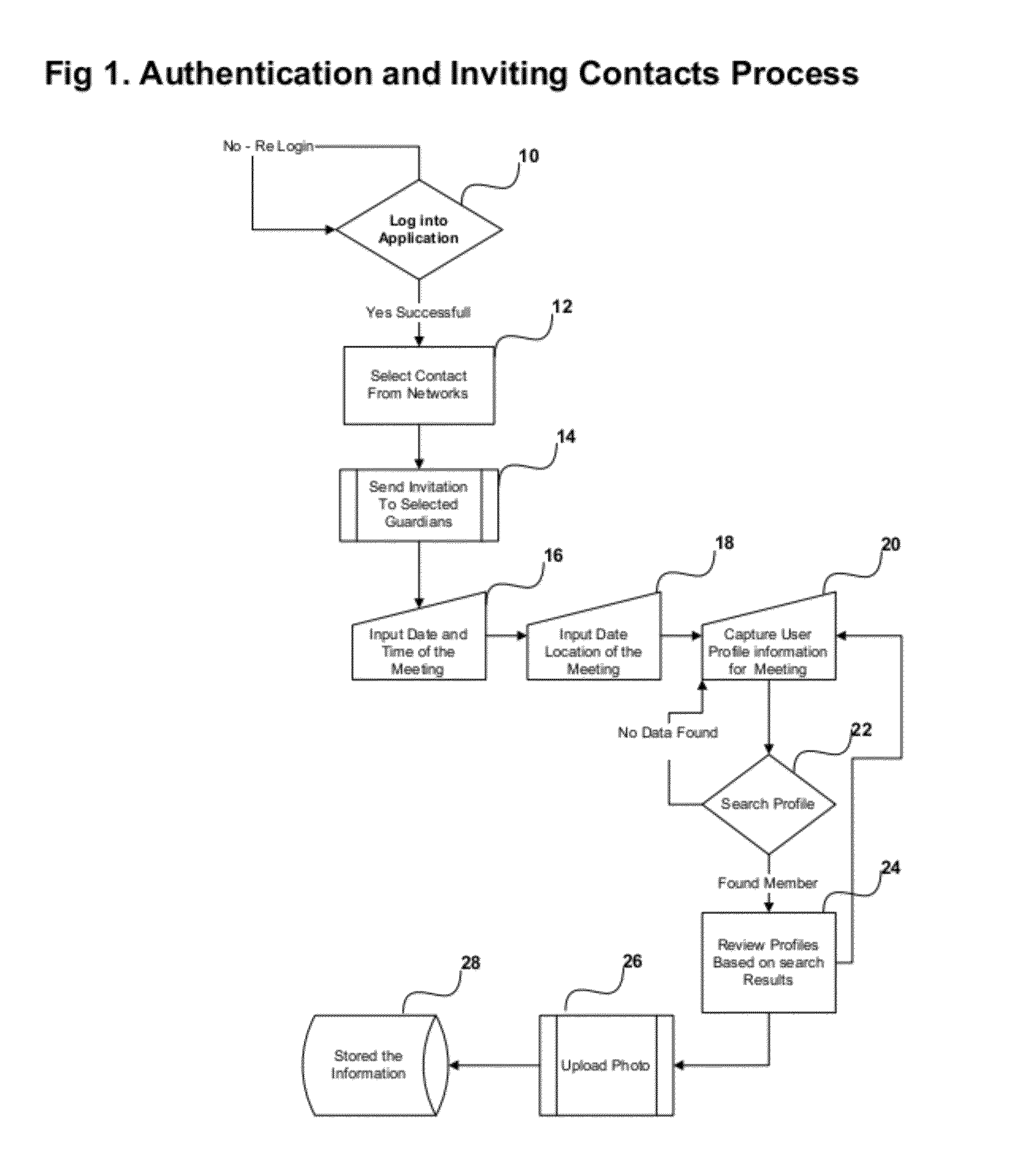

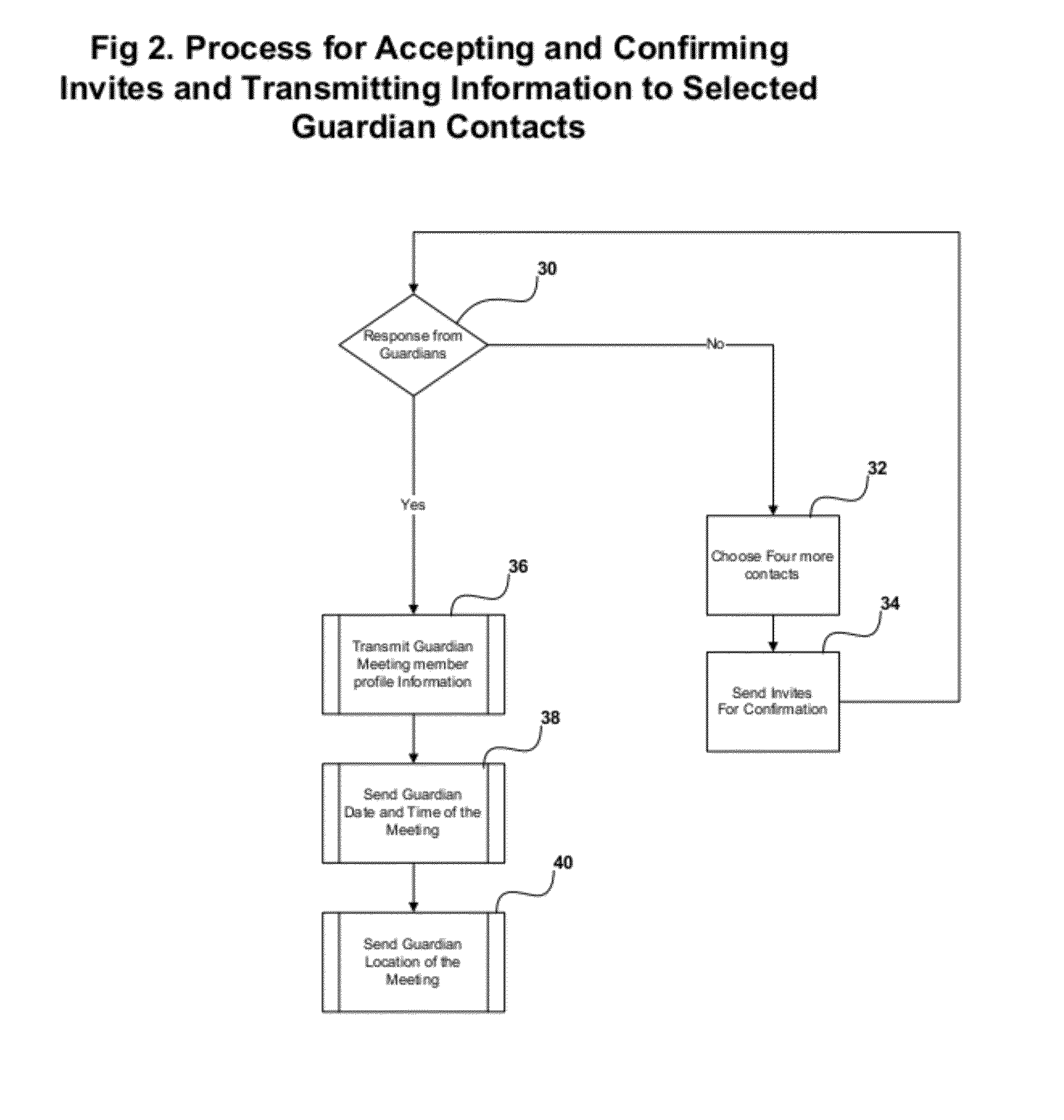

Method and Apparatus to Enable Safer Meetings and Dates

InactiveUS20120246089A1Improve performanceFacilitates capturing dataData processing applicationsSignalling system detailsSecurity MeasureApplication procedure

A method and apparatus for verifying persons' profiles that reside within the databases of online dating, location-based and social networking sites, platforms and applications. The method includes an interface for inputting and modifying settings, including inviting selected contacts, transmitting data about the individual whom the user will be meeting, the scheduled date, time and location for the meeting, and messaging delivered at requested times and intervals. Said user also may auto-transmit pre-set messages at determined times, visually record a meeting for real-time delivery to selected contacts, and utilize a Blue-tooth-enabled device to activate a distress signal and messaging via his or her mobile communication device, as well as transmitting pre-created messages to contacts that reside on directories or support workers. The invention also facilitates utilizing nearby user contacts, as a peer-to-peer buddy network, to render aid and to escalate security measures wherein the user may be in distress.

Owner:QUESTCOURSE

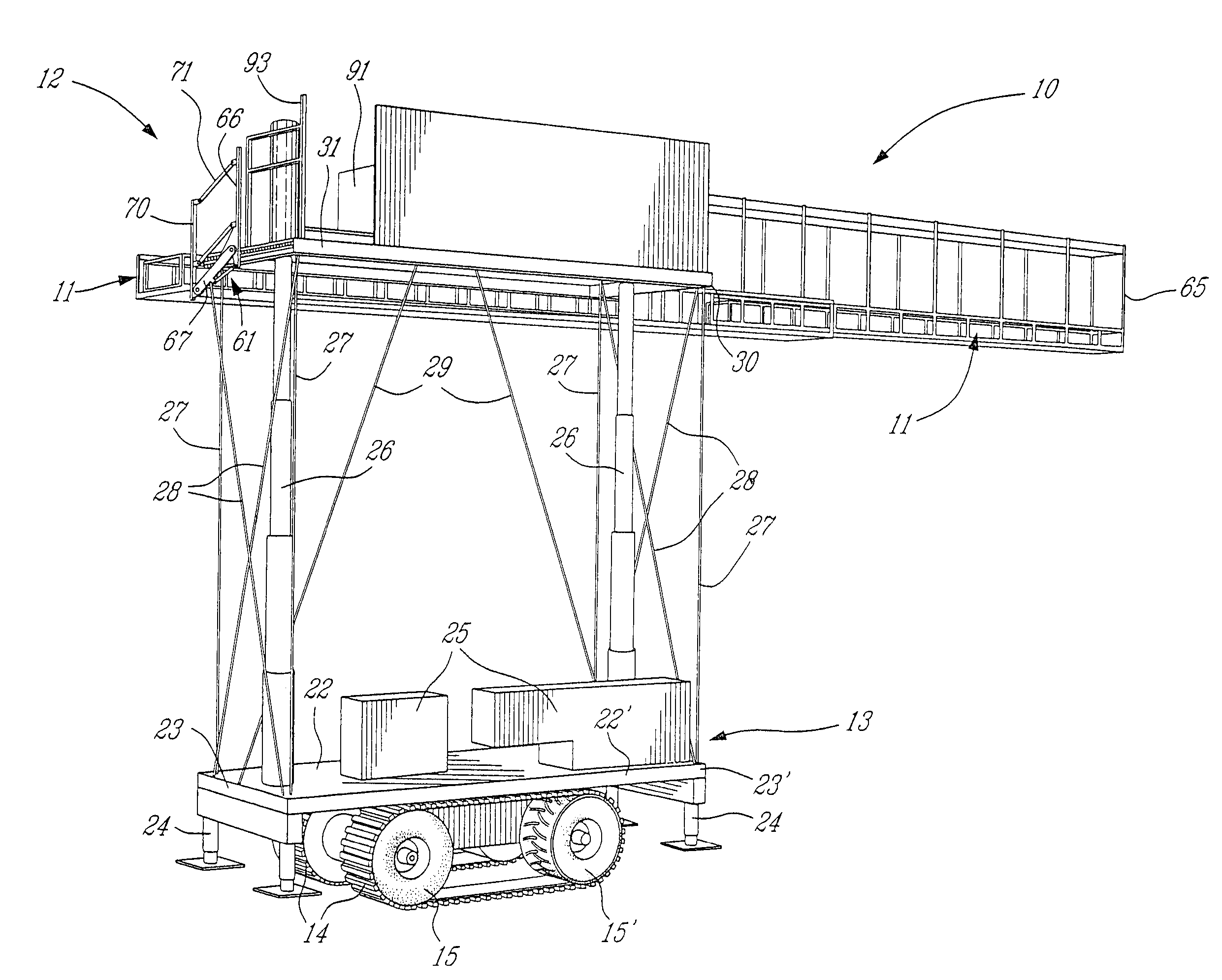

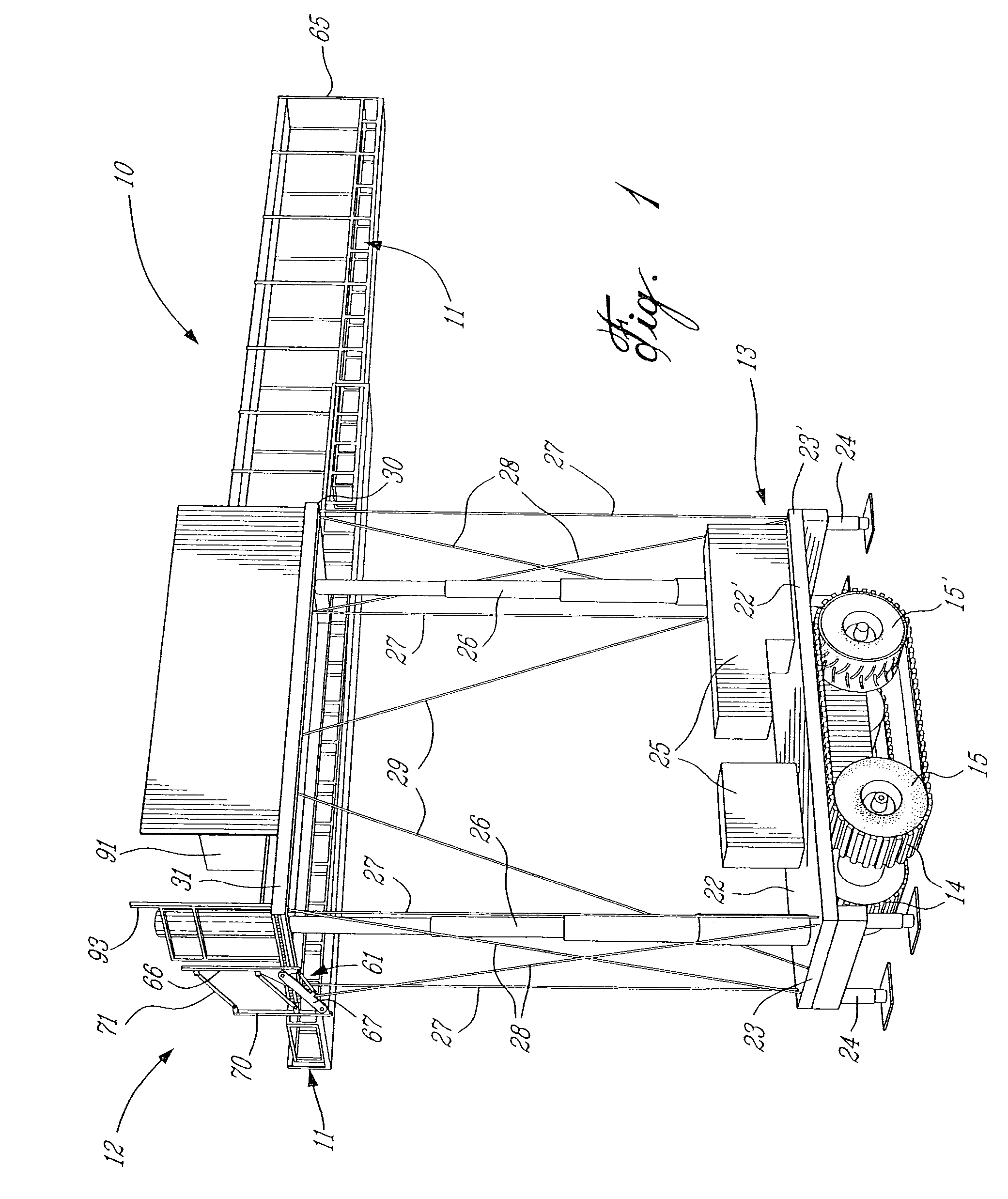

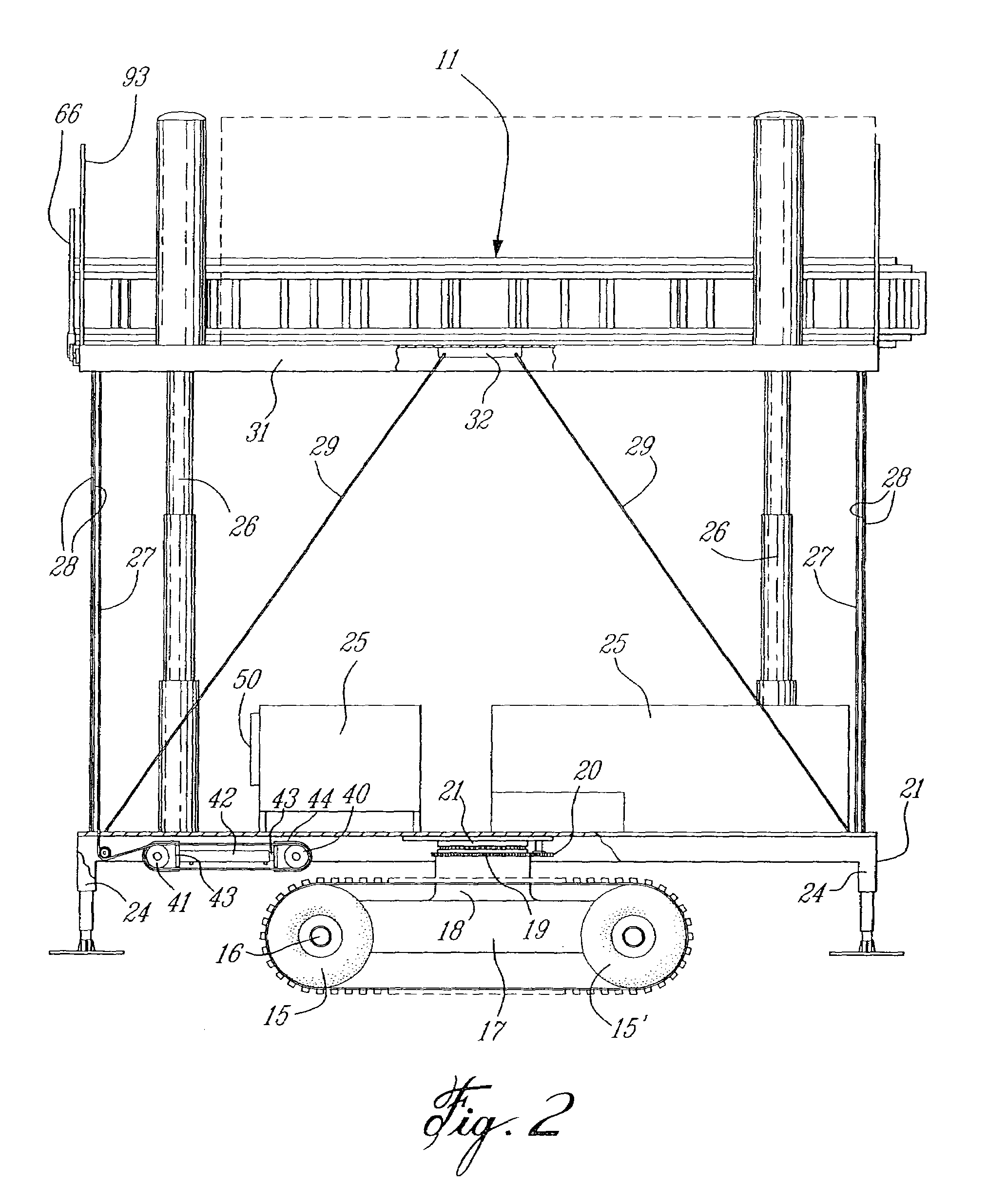

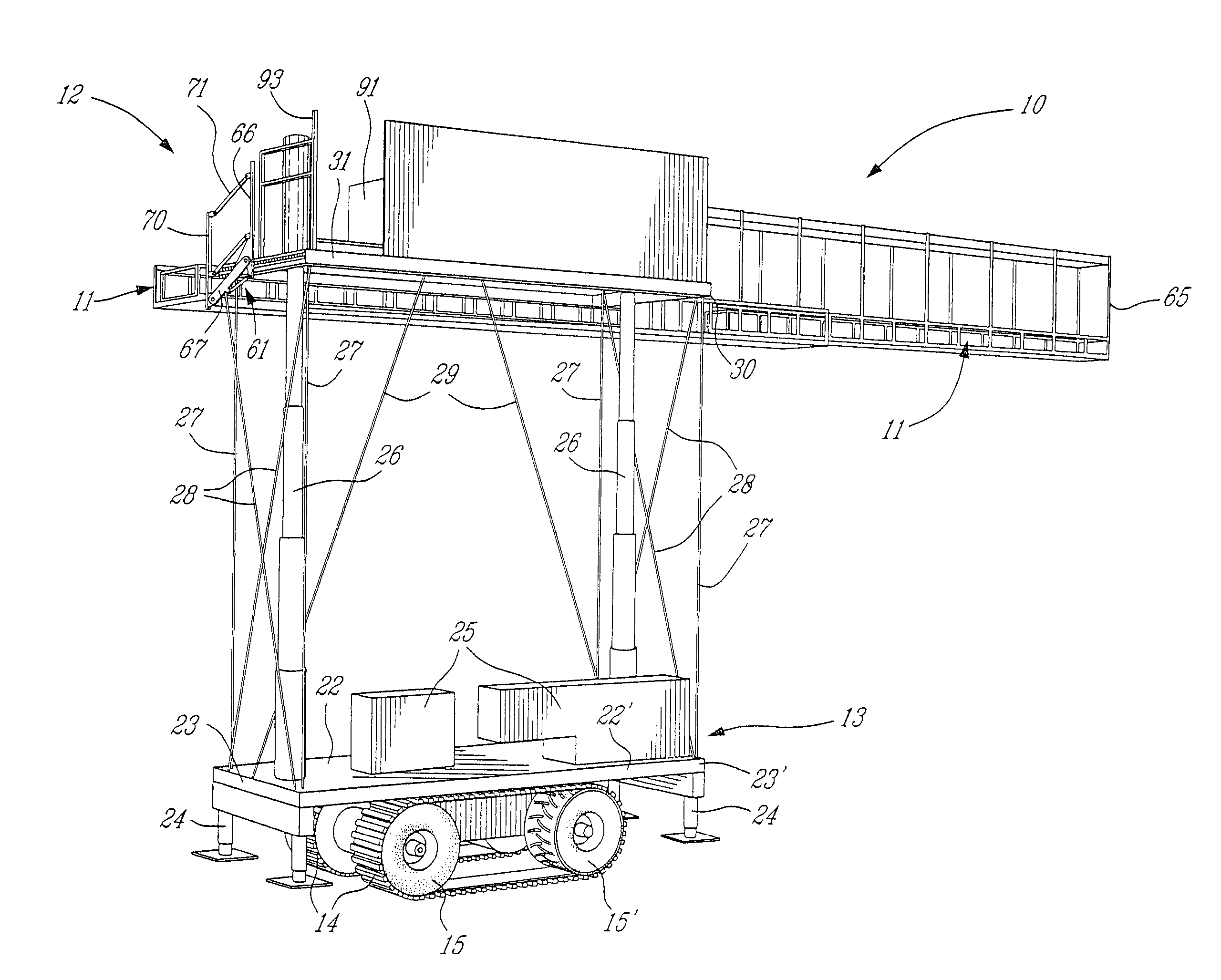

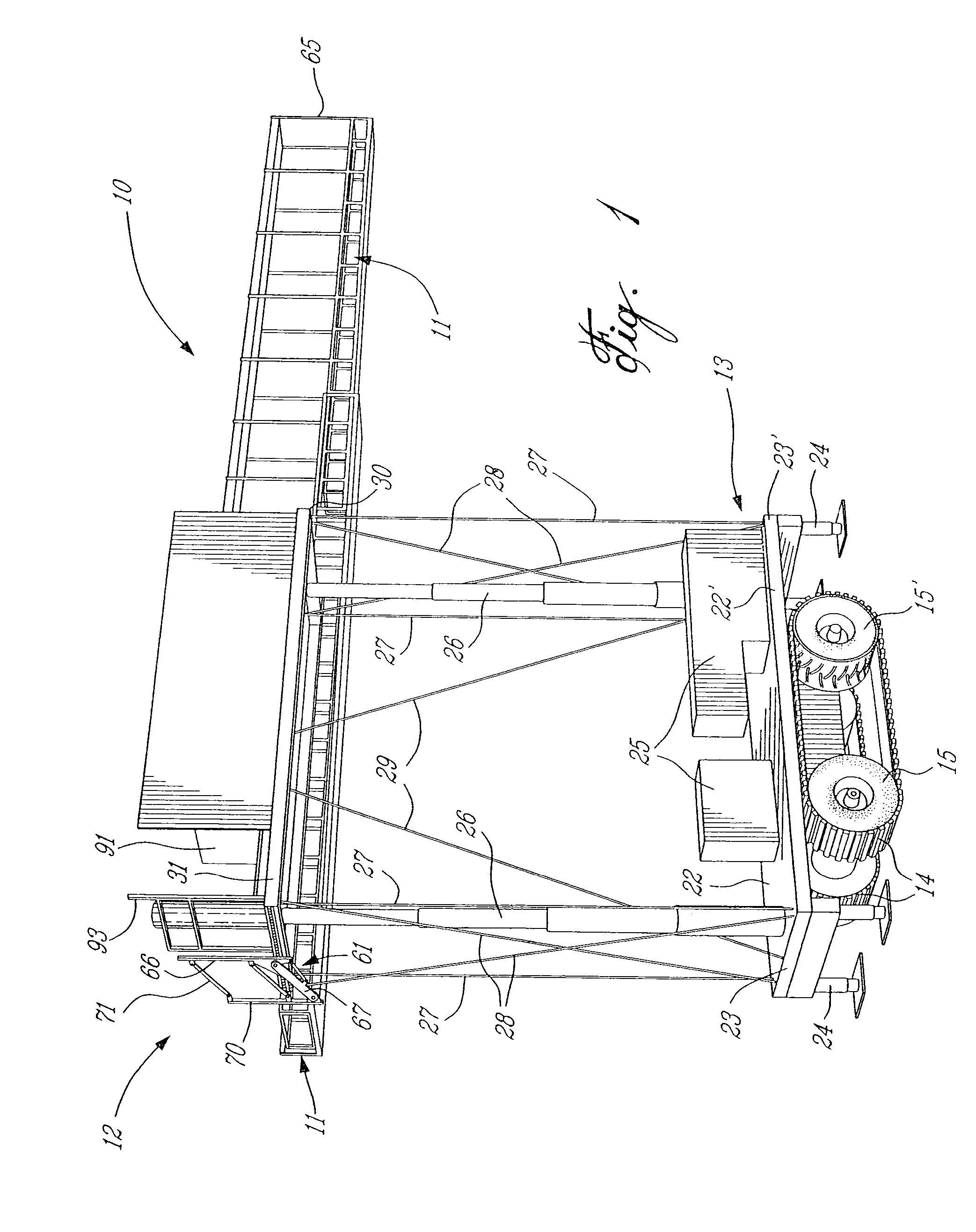

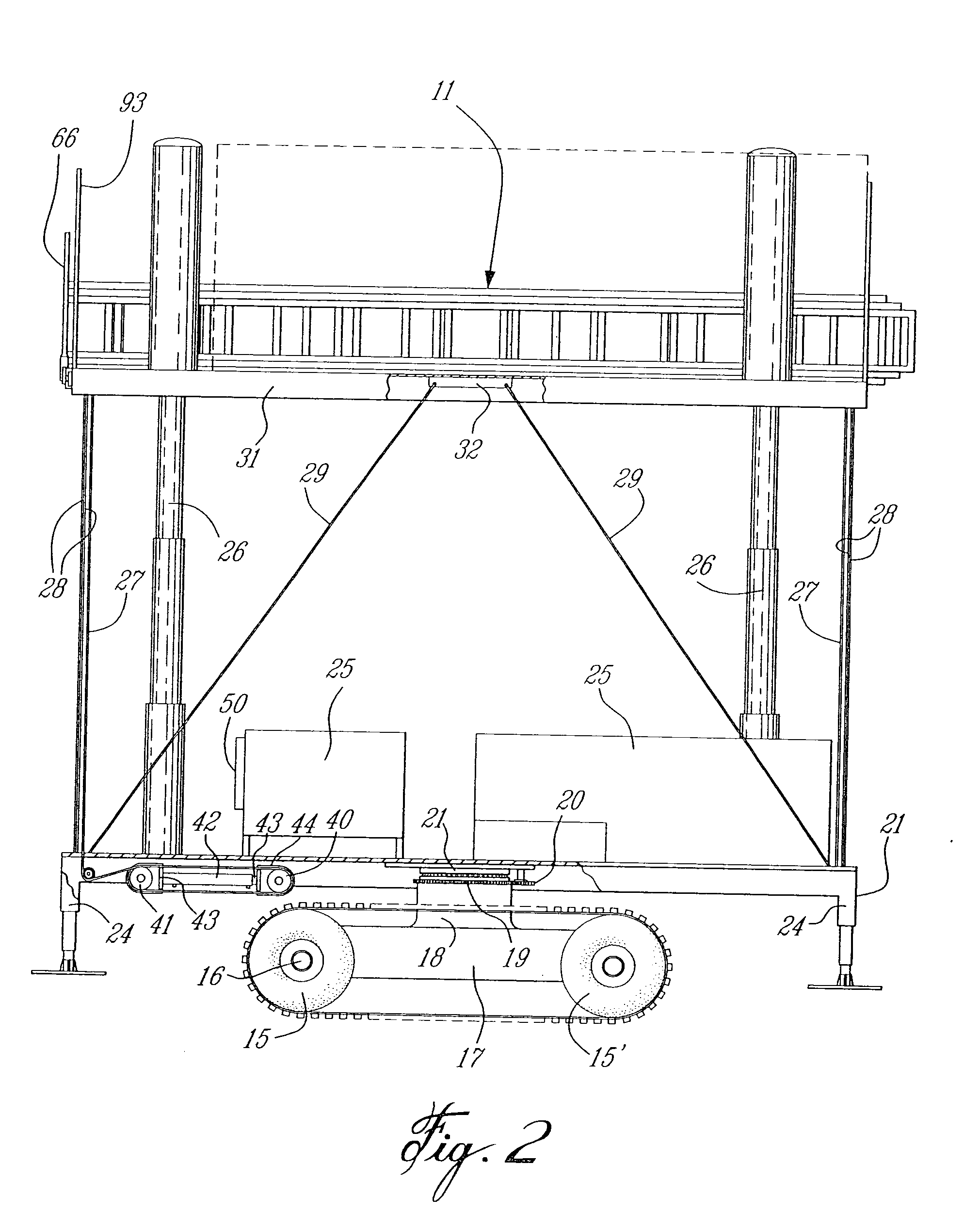

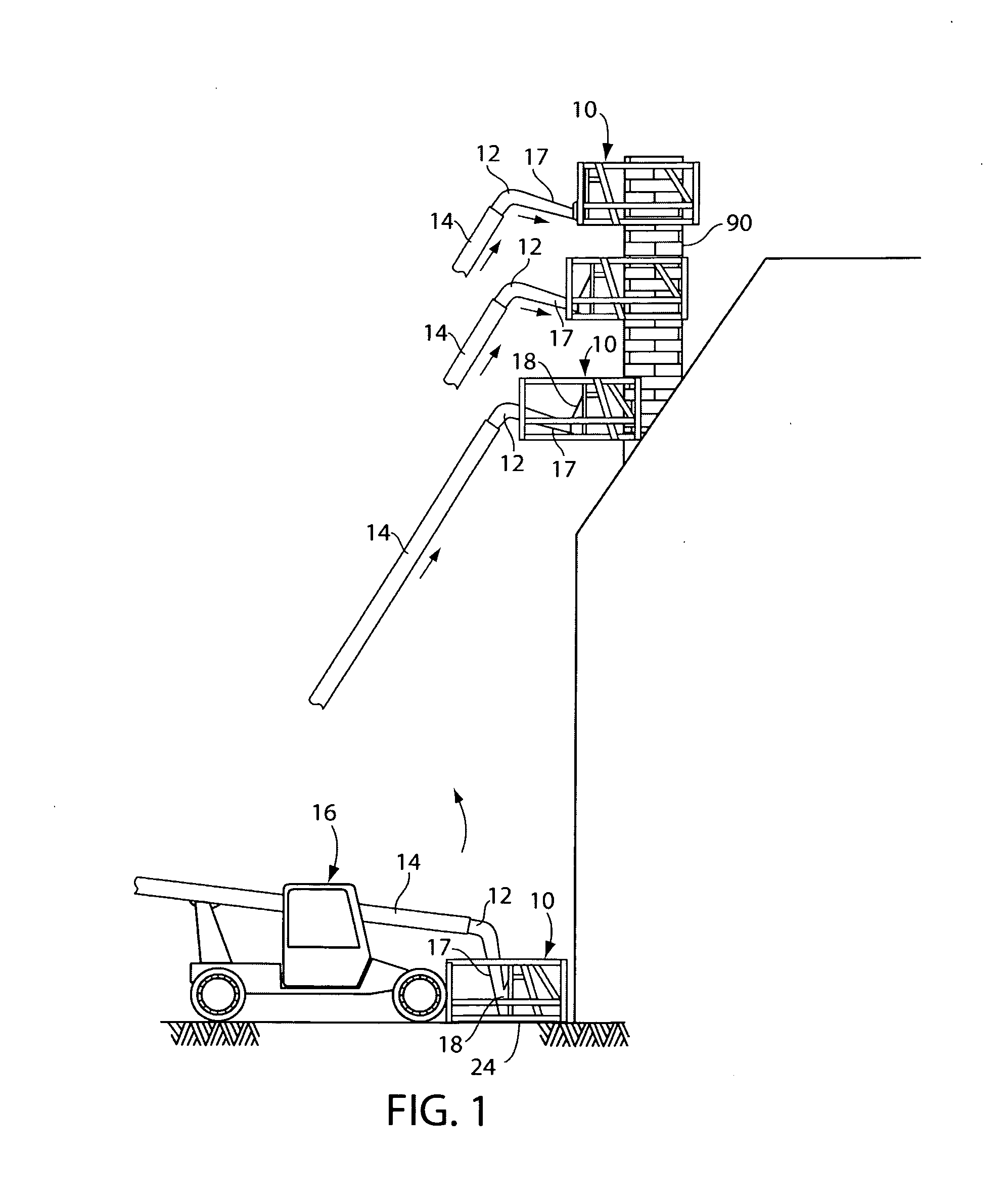

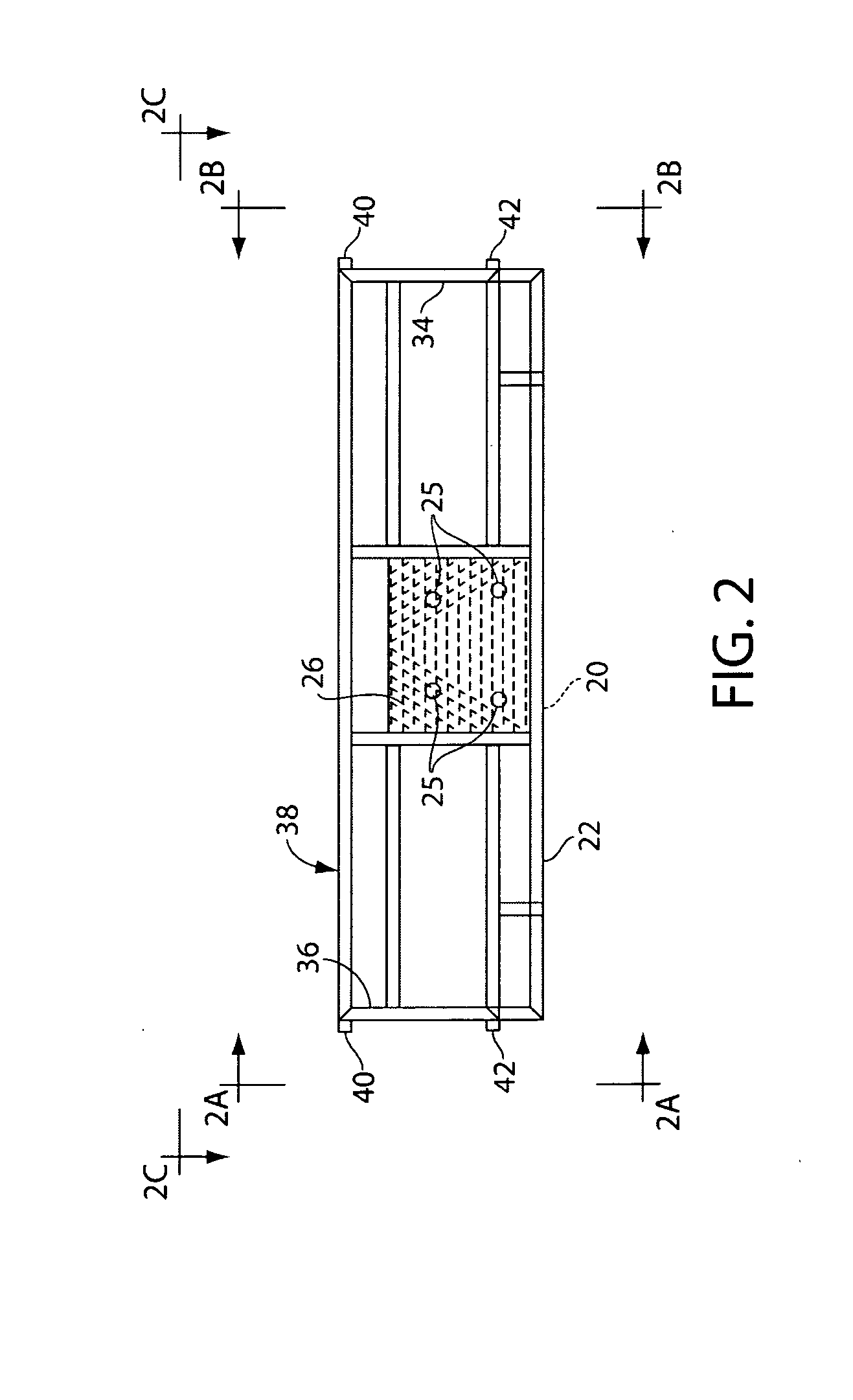

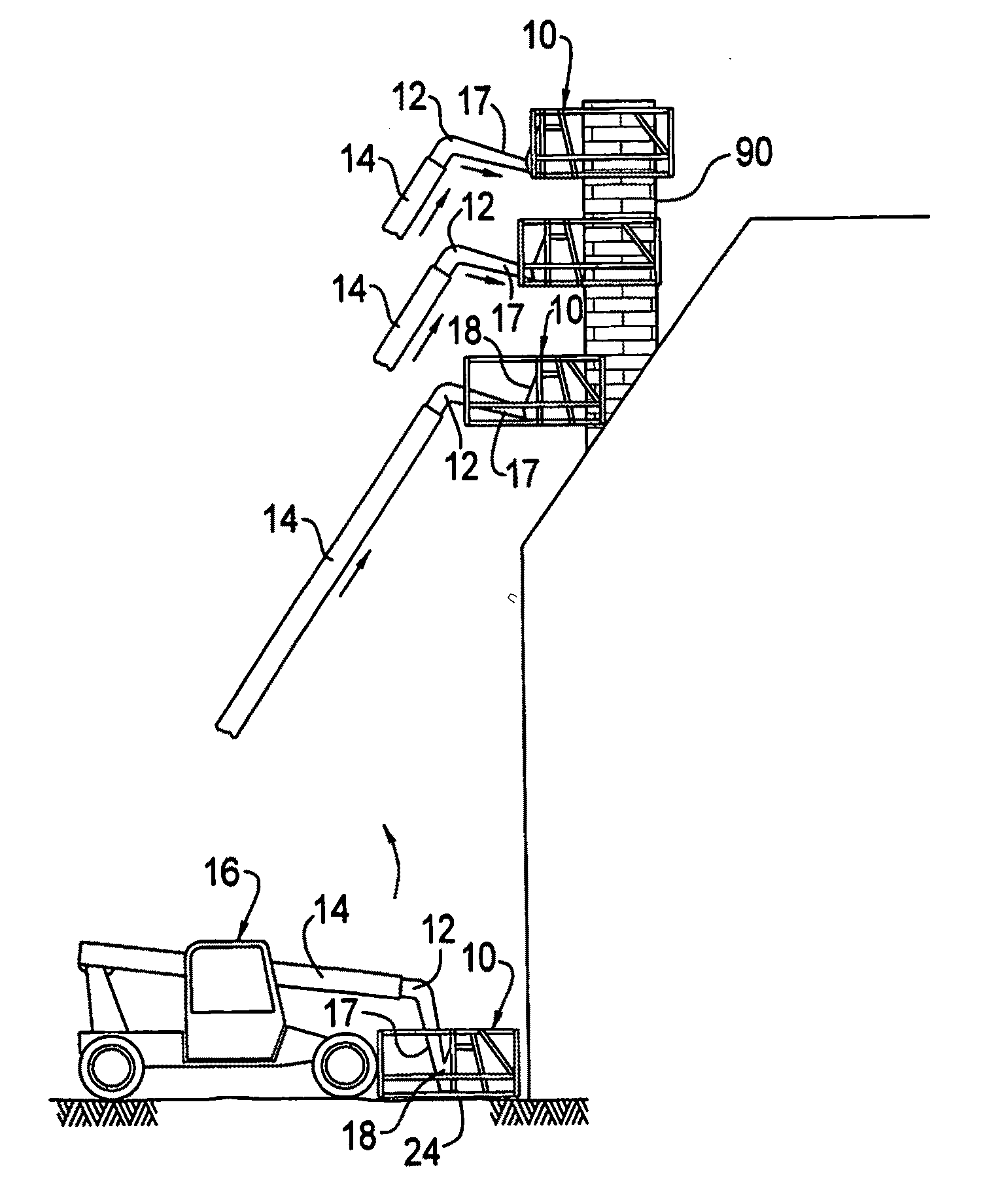

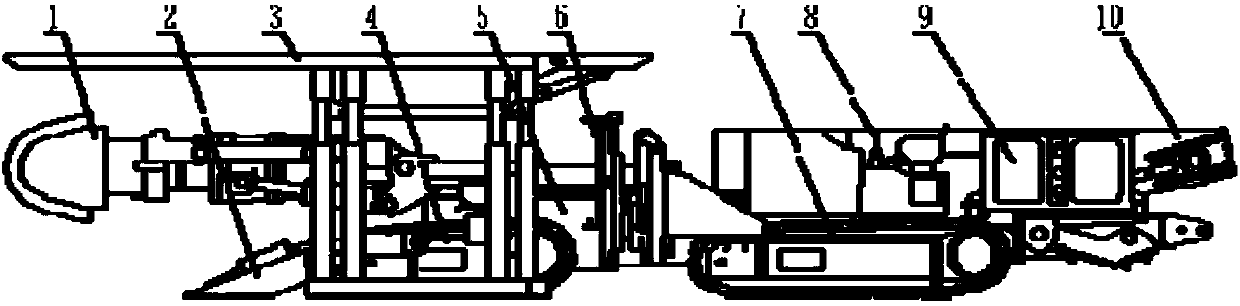

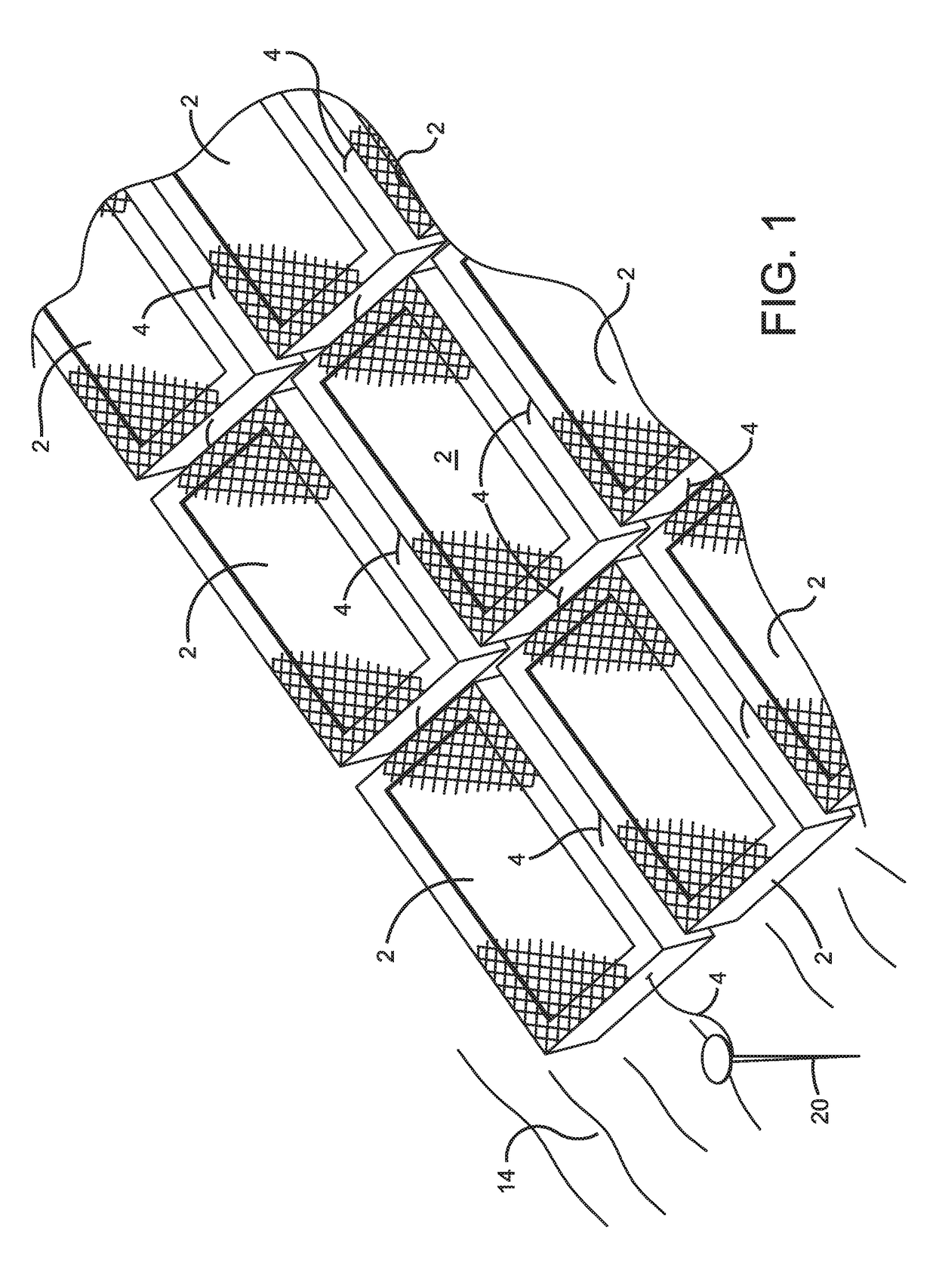

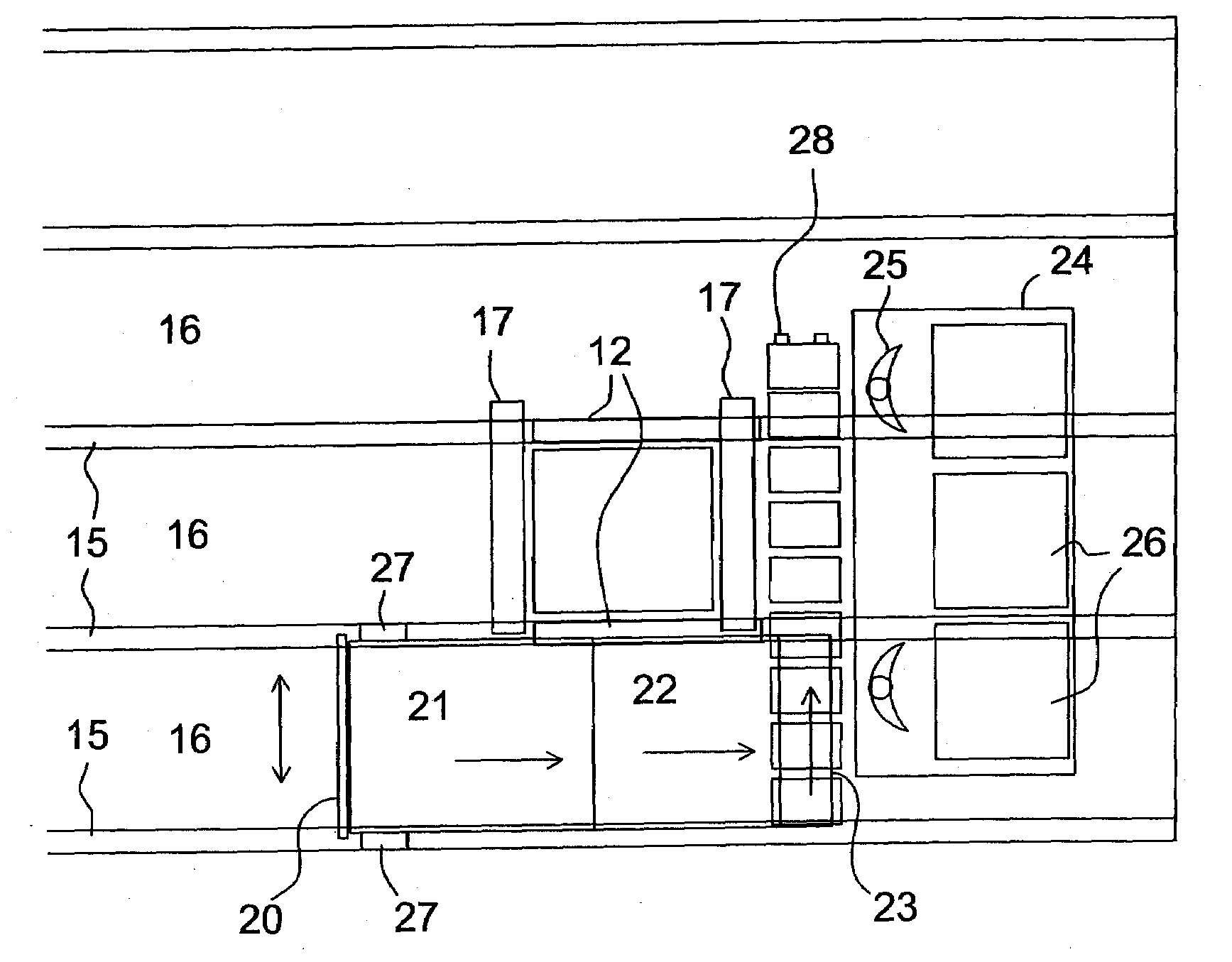

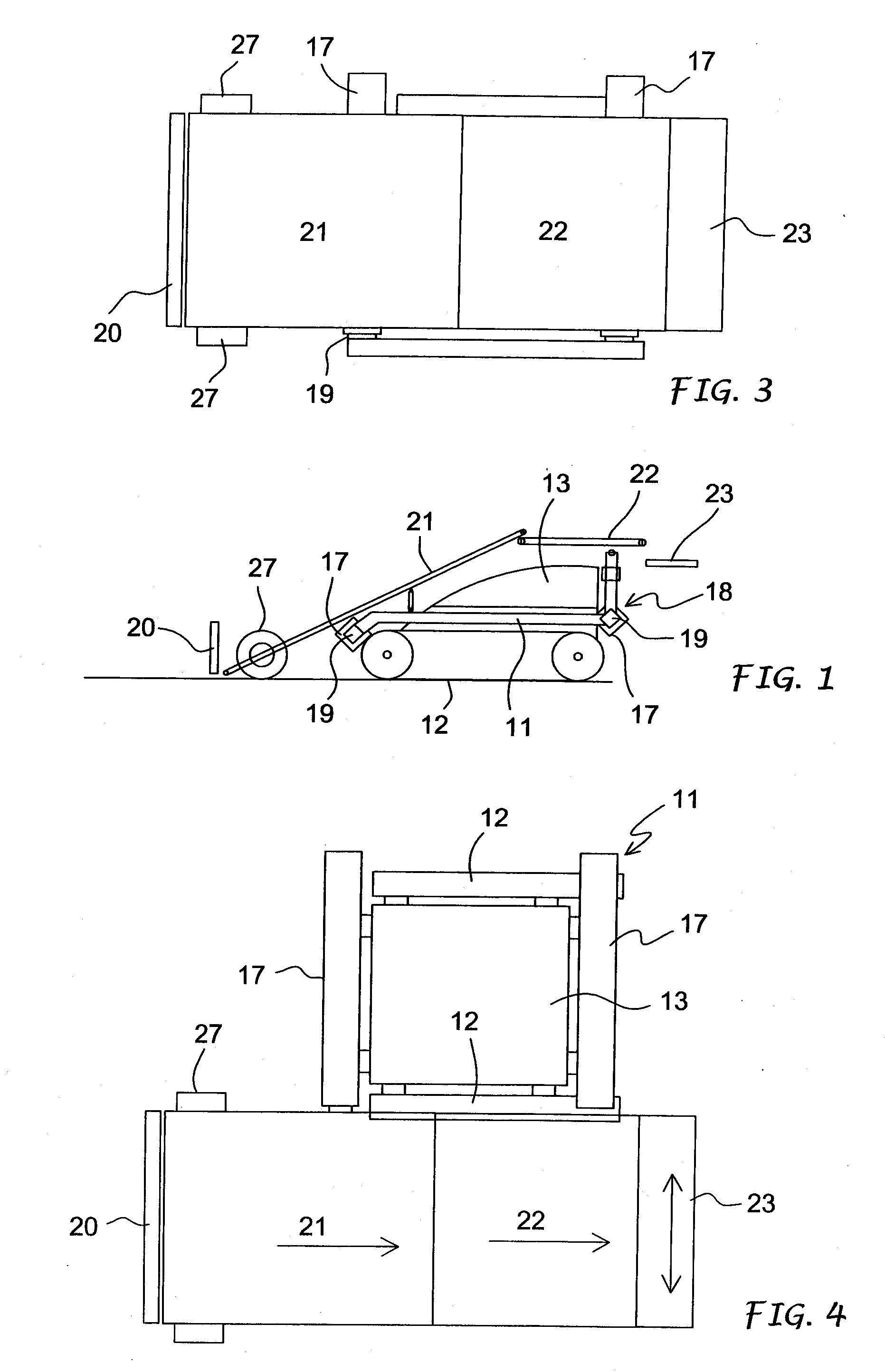

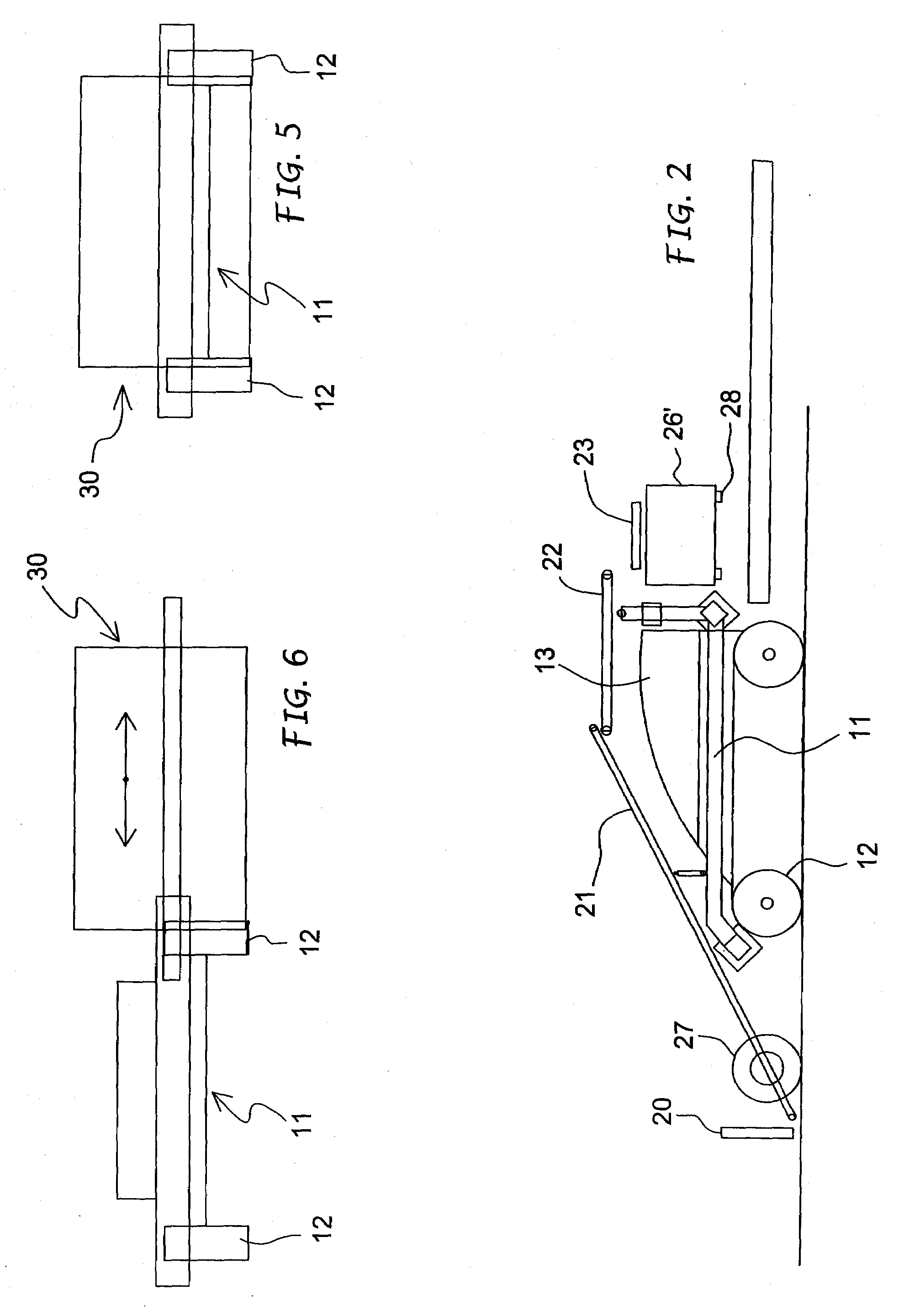

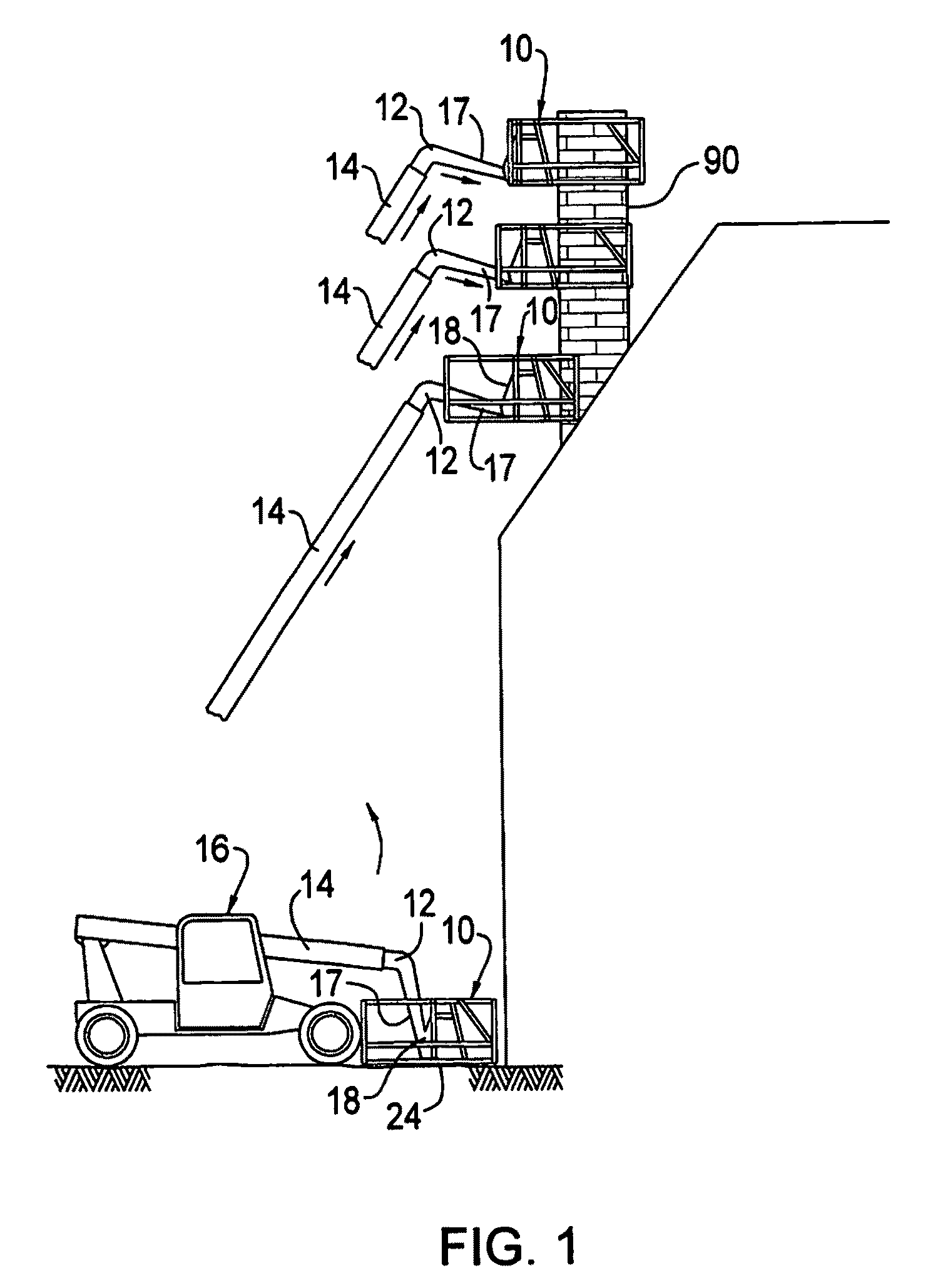

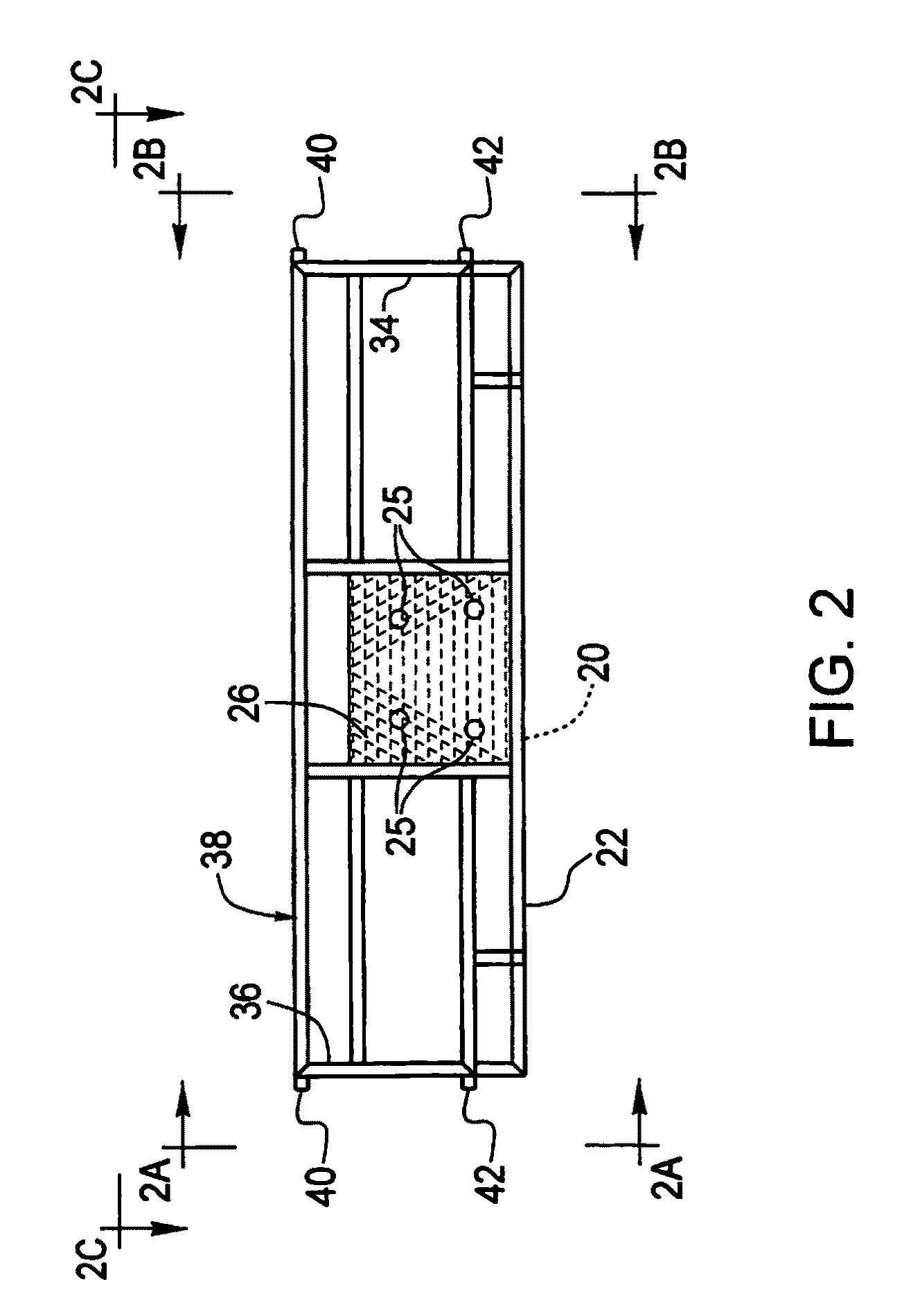

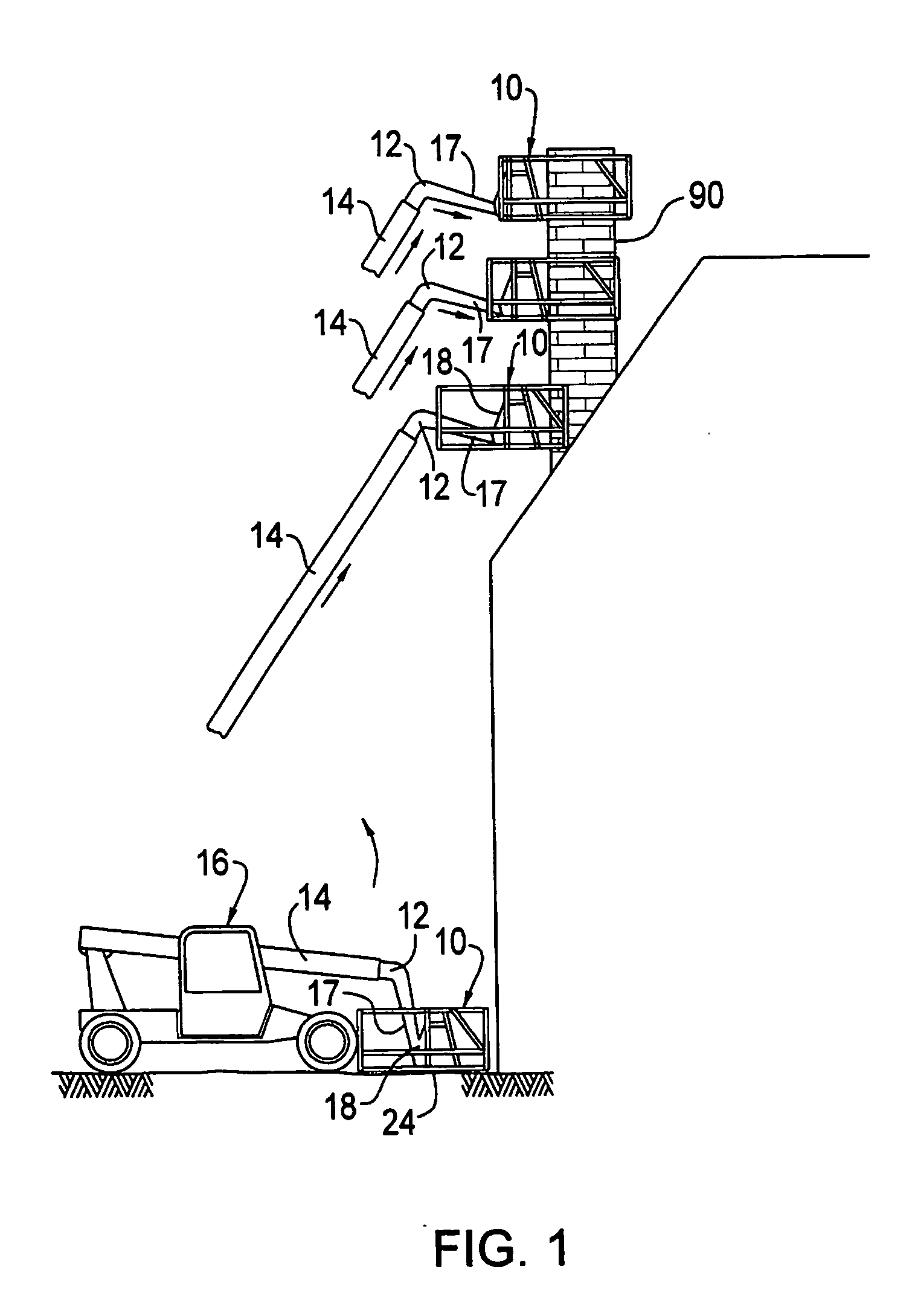

Motorized scaffold with displaceable worker support platform

InactiveUS7004286B2Avoid displacementLifting devicesBuilding reinforcementsEngineeringMechanical engineering

A motorized scaffold for self-displacement on land is comprised of a support base mounted on a pair of traction belts. Jacks are provided to immobilize and level the support base at a desired location. A platform assembly is secured over the support base on extendable supports. Braces are secured between the support base and the platform assembly and are extendable with the movement of the platform assembly over the base whereby to maintain the platform assembly substantially stable during its displacement and at a stationary desired working elevation with respect to the support base. A displaceable worker support platform is secured to the platform assembly for supporting workers thereon.

Owner:FREDETTE JEAN PAUL

Motorized scaffold with displaceable worker support platform

ActiveUS20050056484A1Avoid displacementLifting devicesBuilding reinforcementsEngineeringMechanical engineering

A motorized scaffold for self-displacement on land is comprised of a support base mounted on a pair of traction belts. Jacks are provided to immobilize and level the support base at a desired location. A platform assembly is secured over the support base on extendable supports. Braces are secured between the support base and the platform assembly and are extendable with the movement of the platform assembly over the base whereby to maintain the platform assembly substantially stable during its displacement and at a stationary desired working elevation with respect to the support base. A displaceable worker support platform is secured to the platform assembly for supporting workers thereon.

Owner:FREDETTE JEAN PAUL

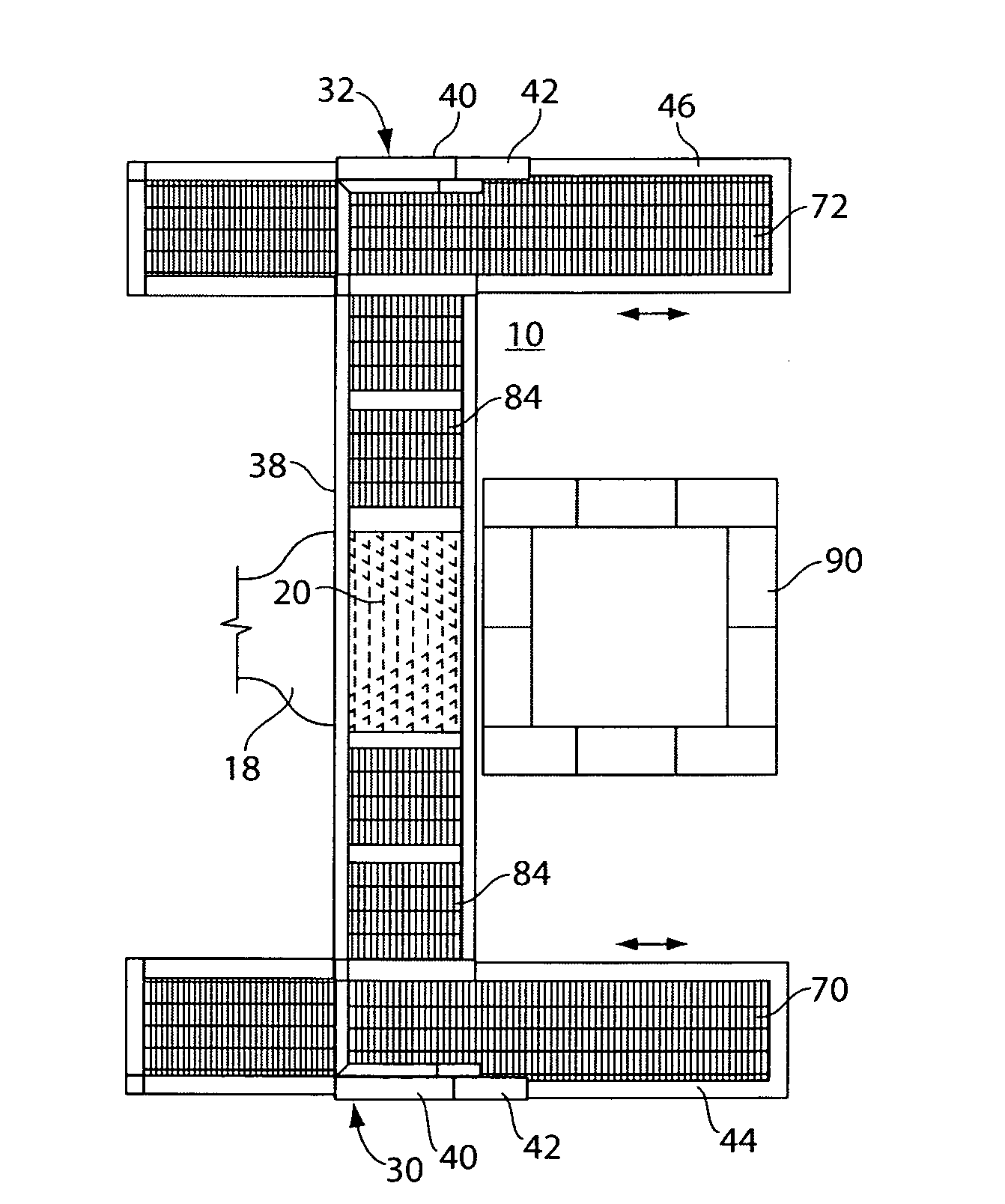

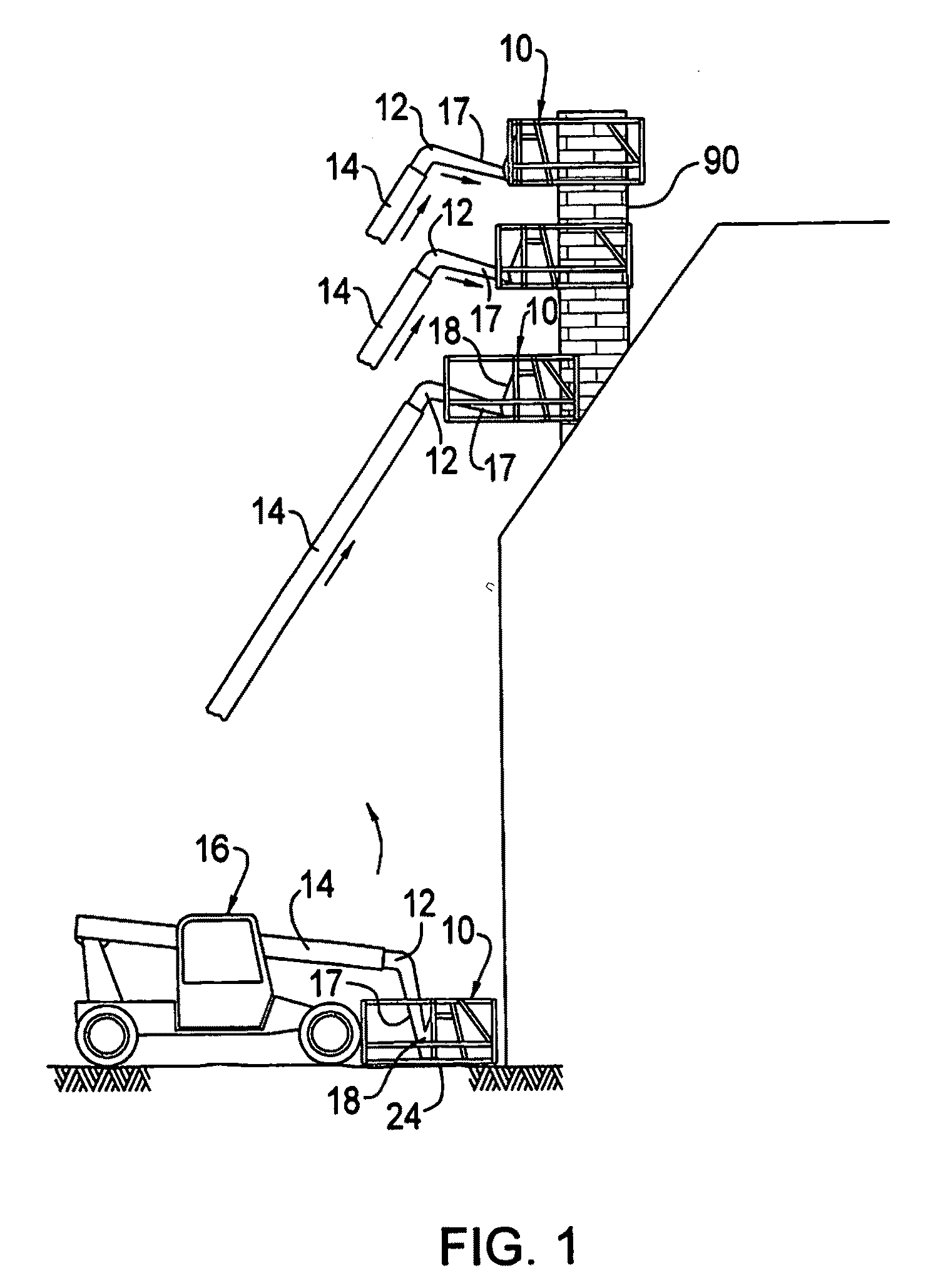

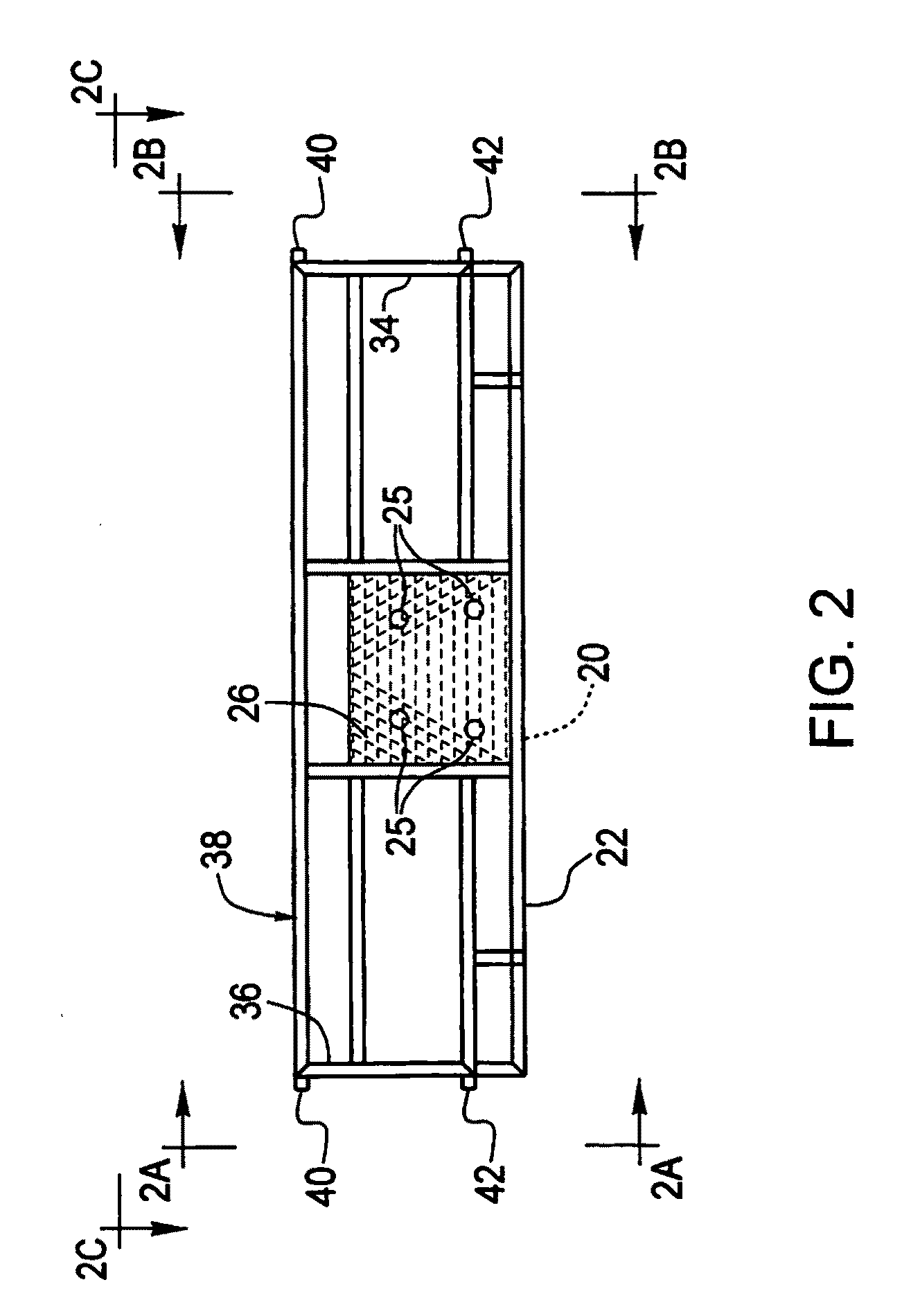

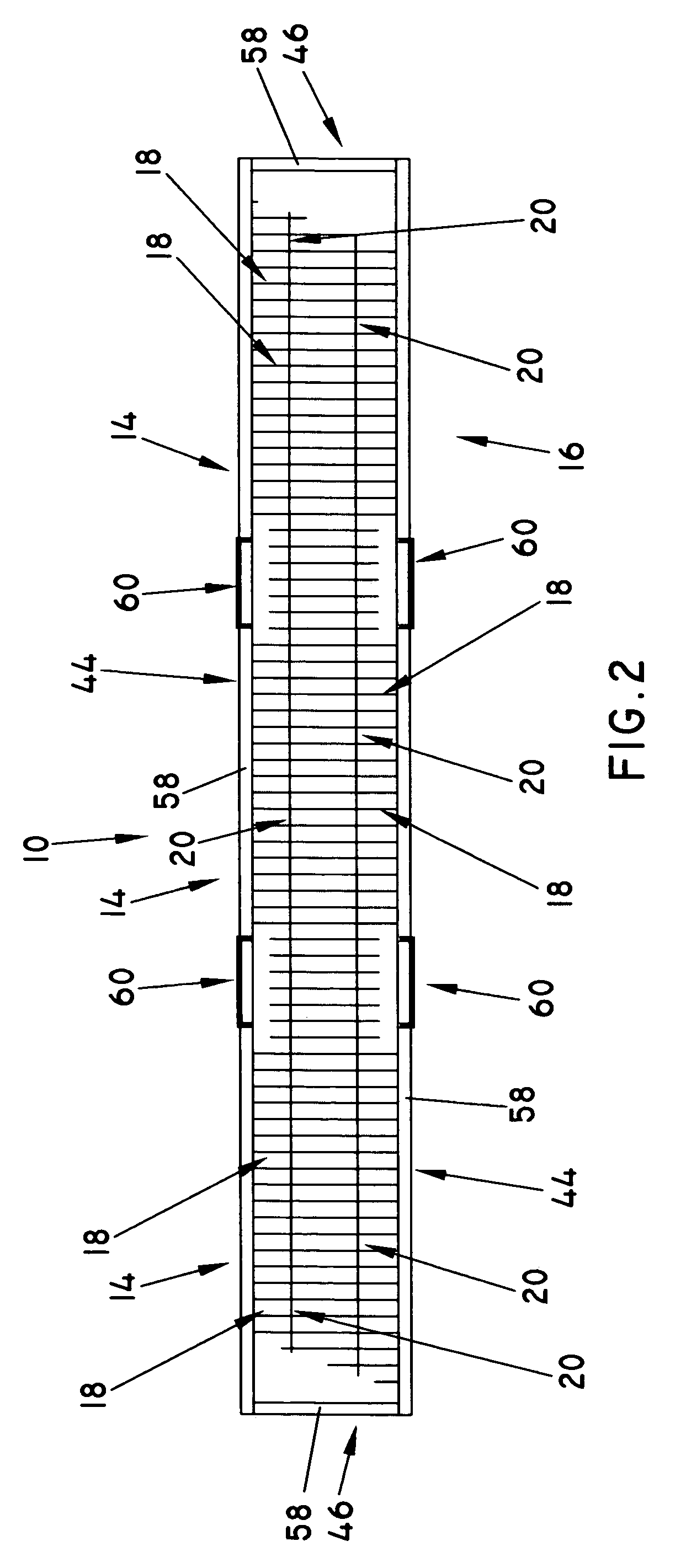

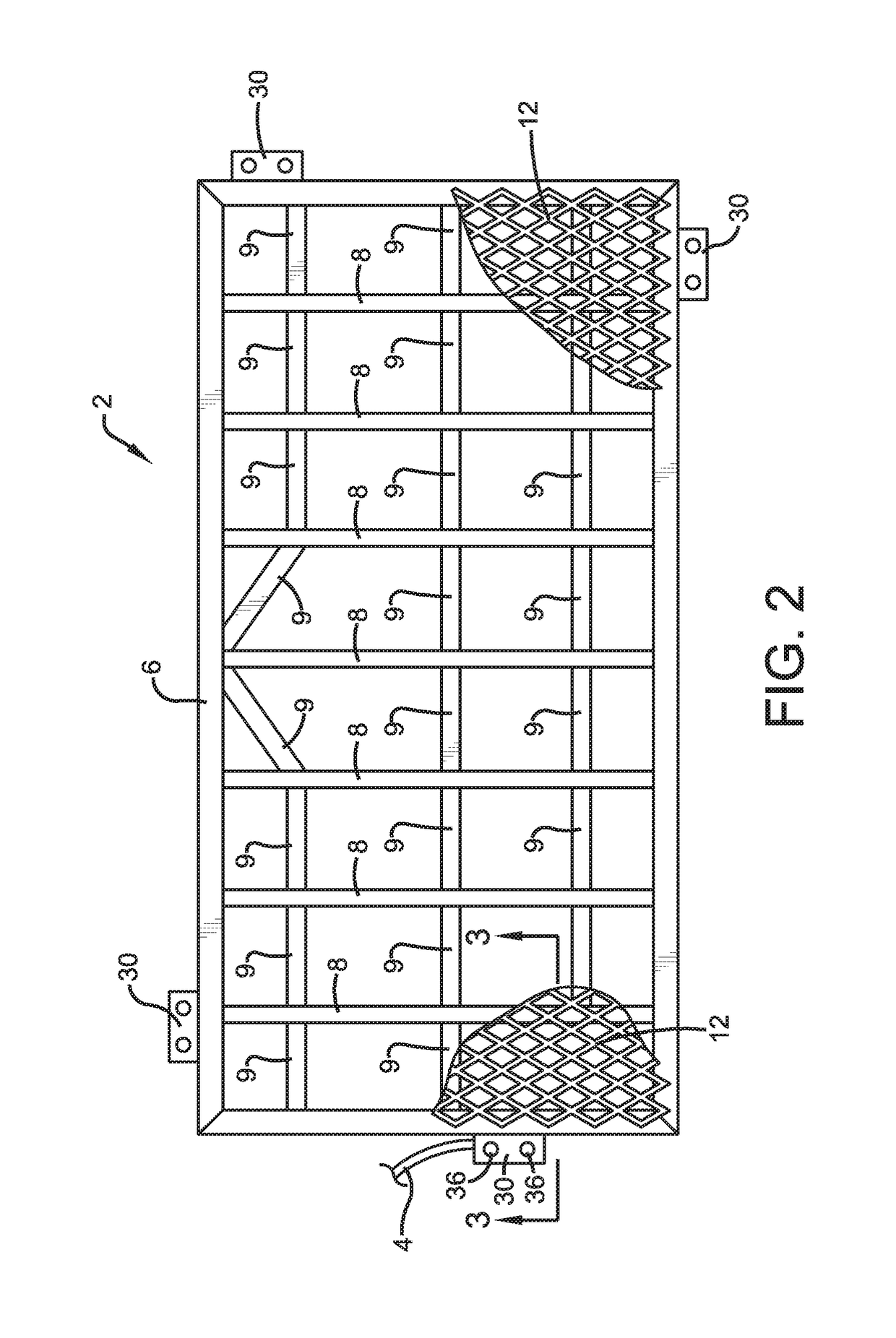

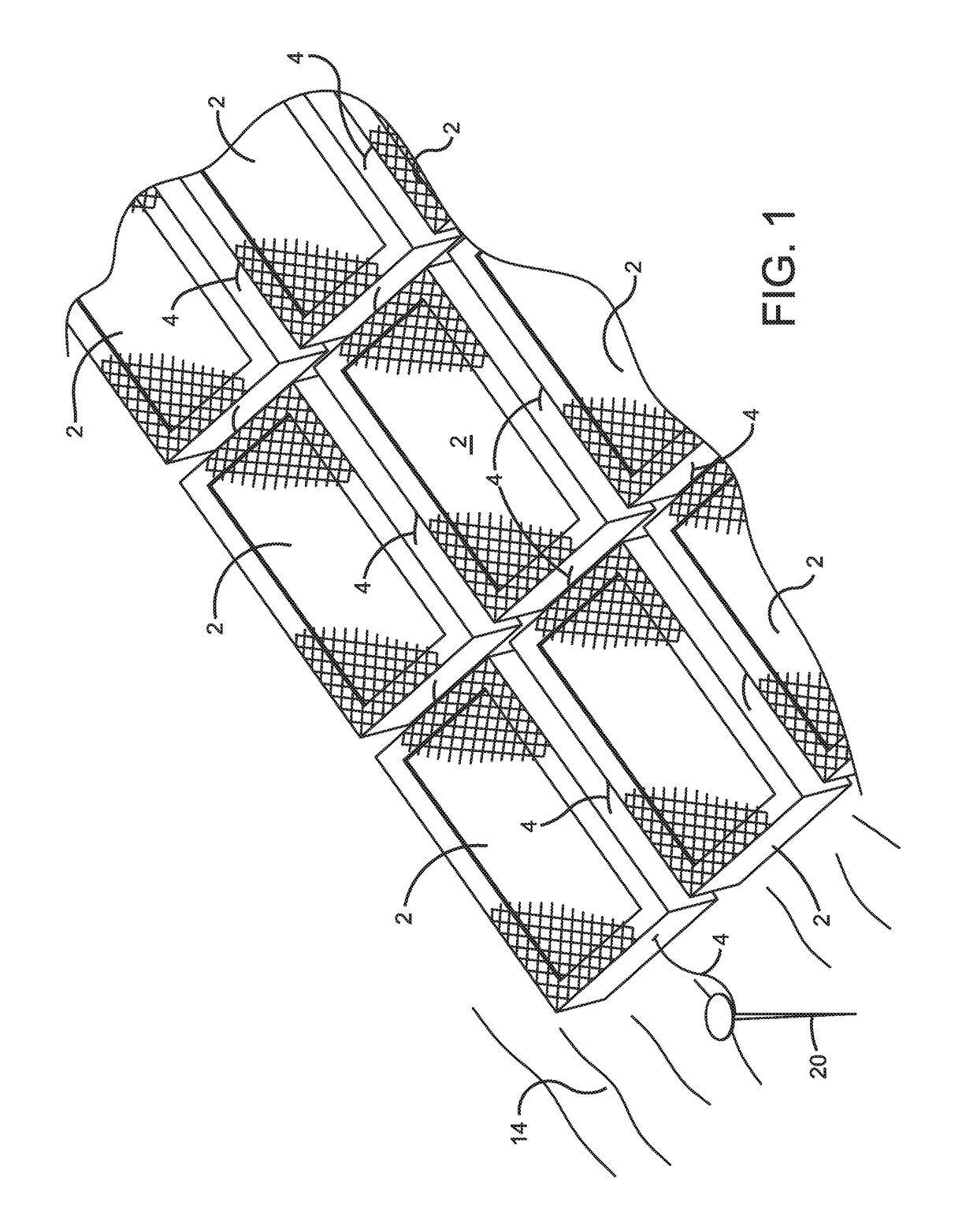

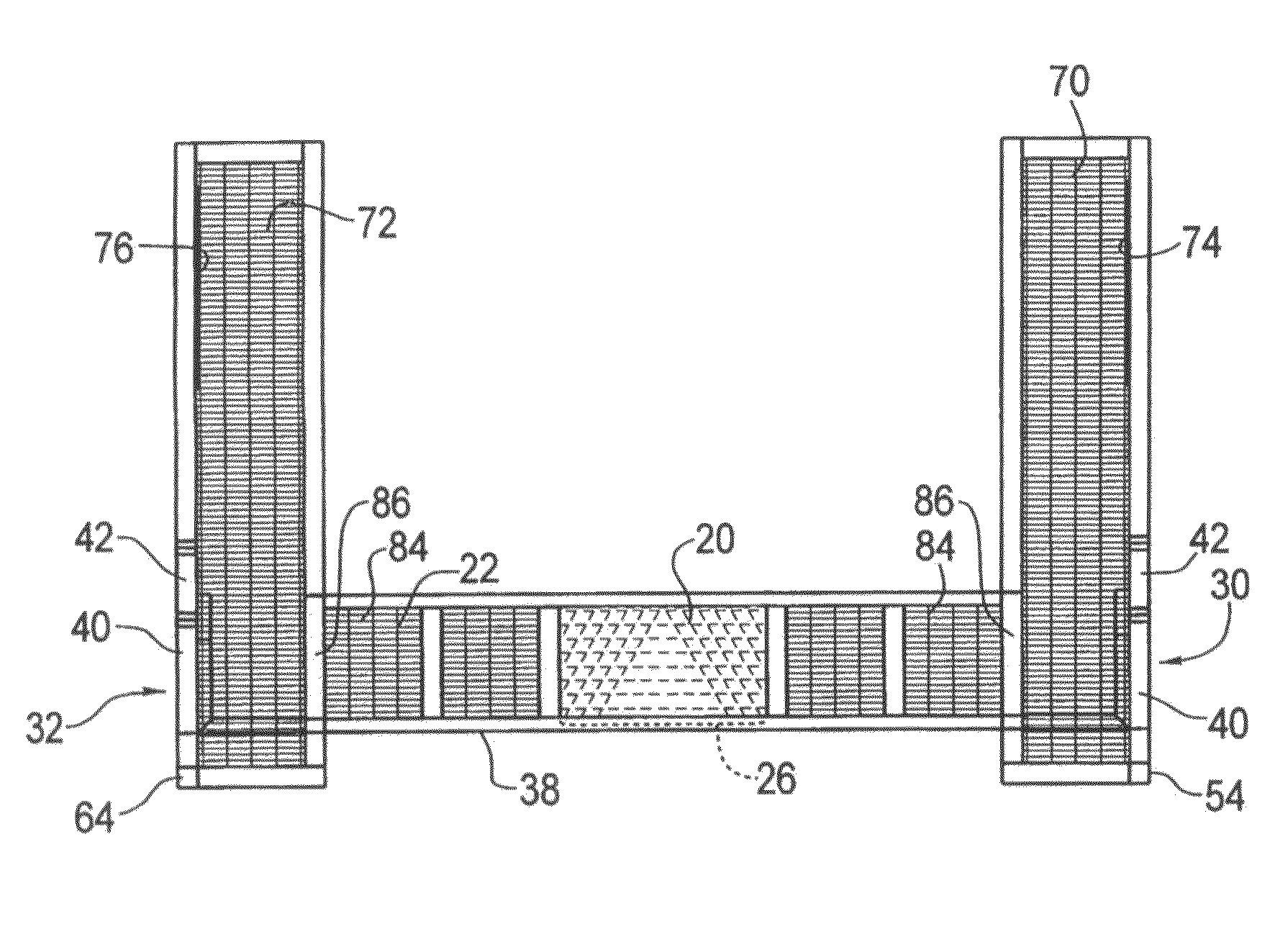

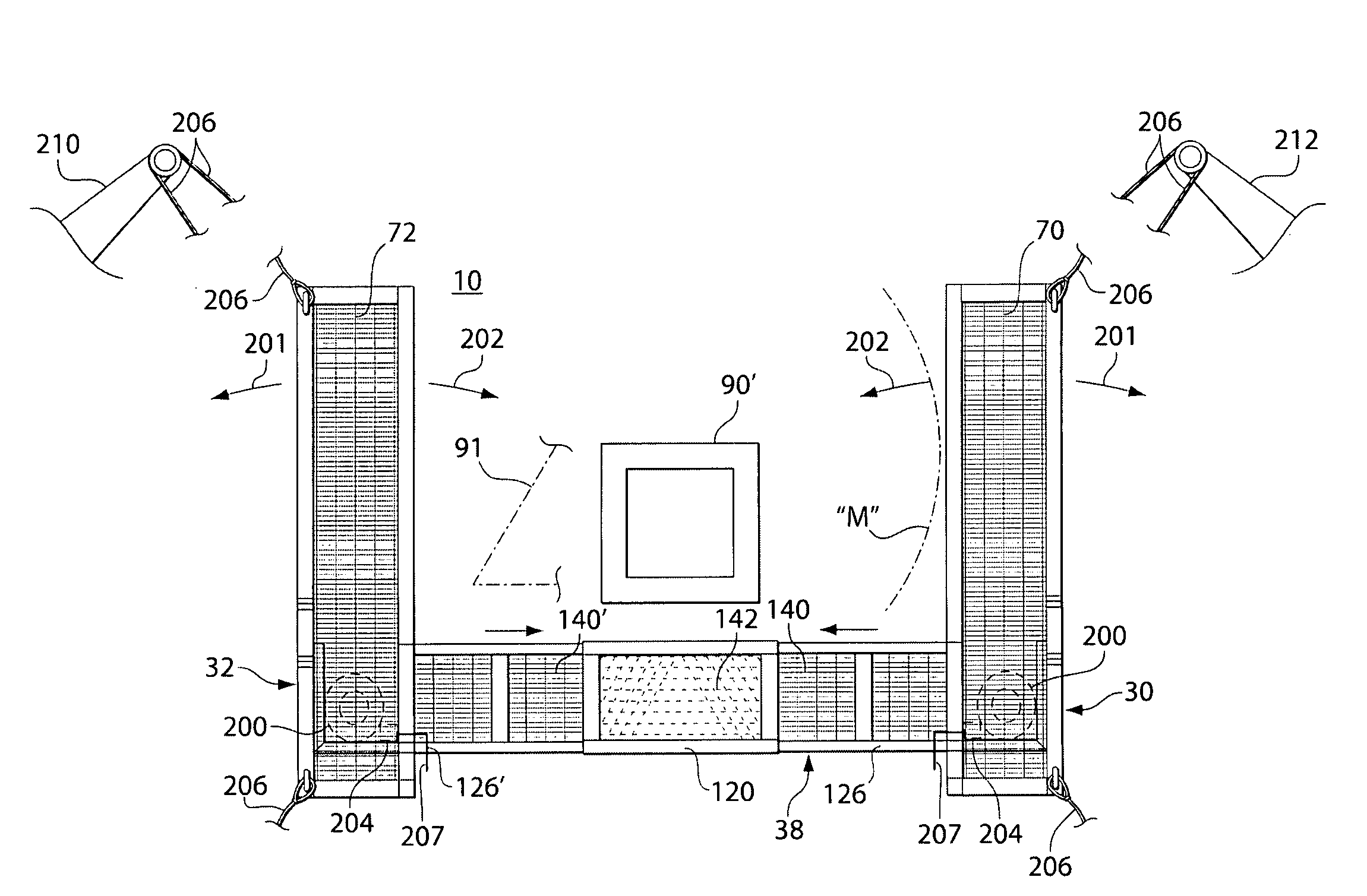

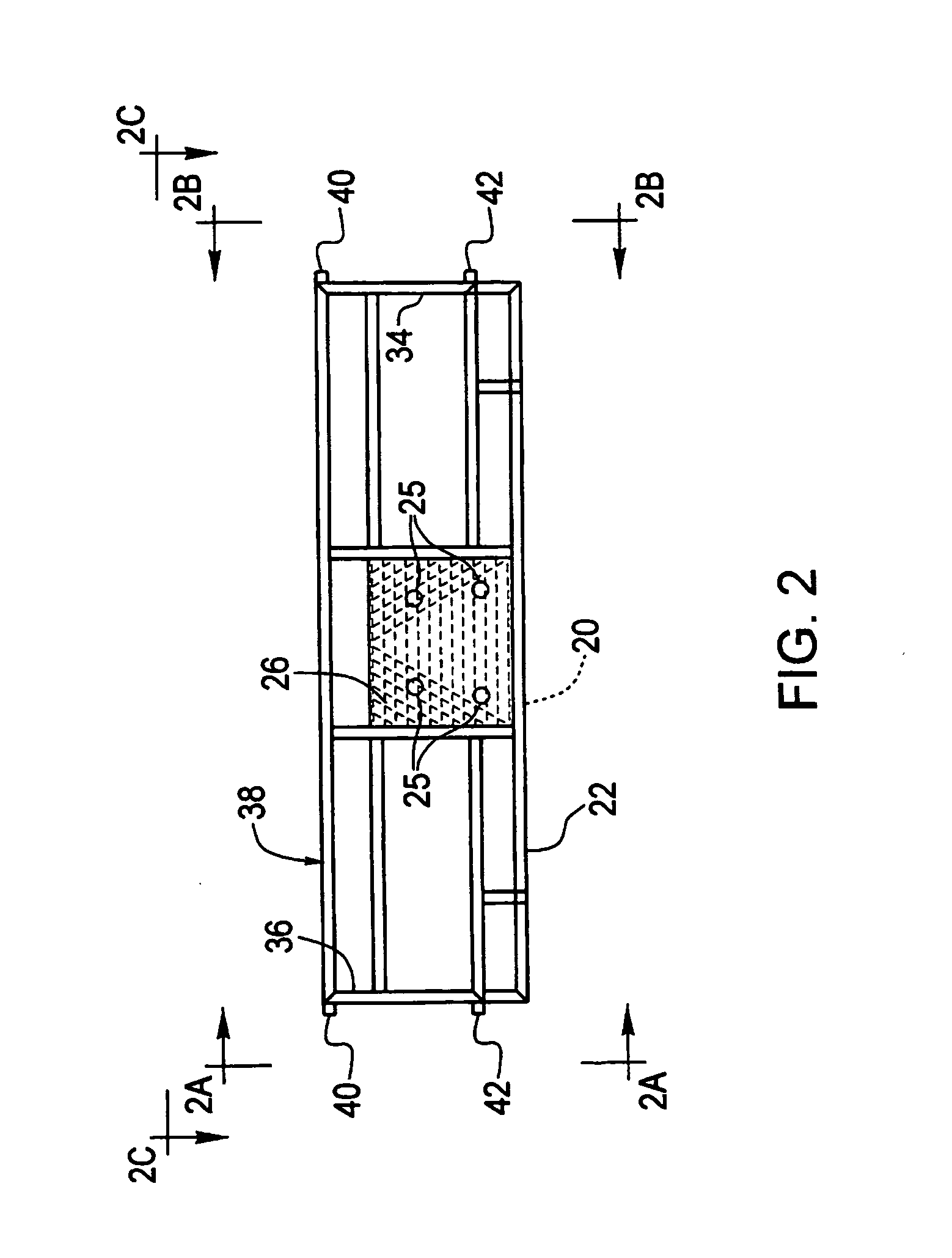

Mason's adjustable chimney-platform arrangement

InactiveUS20160069094A1Stable maintenanceLifting devicesMetal working apparatusMechanical engineeringSupport worker

An adjustable platform assembly for supporting workers and supplies about an elevated work site, the platform assembly being movably supported on an articulable support, the platform comprising a stationary curvilinear rear bridging panel arrangement having a 1st side curvilinear platform member and a 2nd side curvilinear platform member, each comprising a floor and railing assembly, wherein each elongated 1st and 2nd curvilinear side platform member floor and railing assembly is independently movable on support members outwardly and inwardly, with respect to the curvilinear bridging panel arrangement, to change the platform assembly back and forth between a generally “C” shape to a generally “O” shape, or any peripherally adjustable combination thereof, as required.

Owner:LOMBARDI DONALD F +1

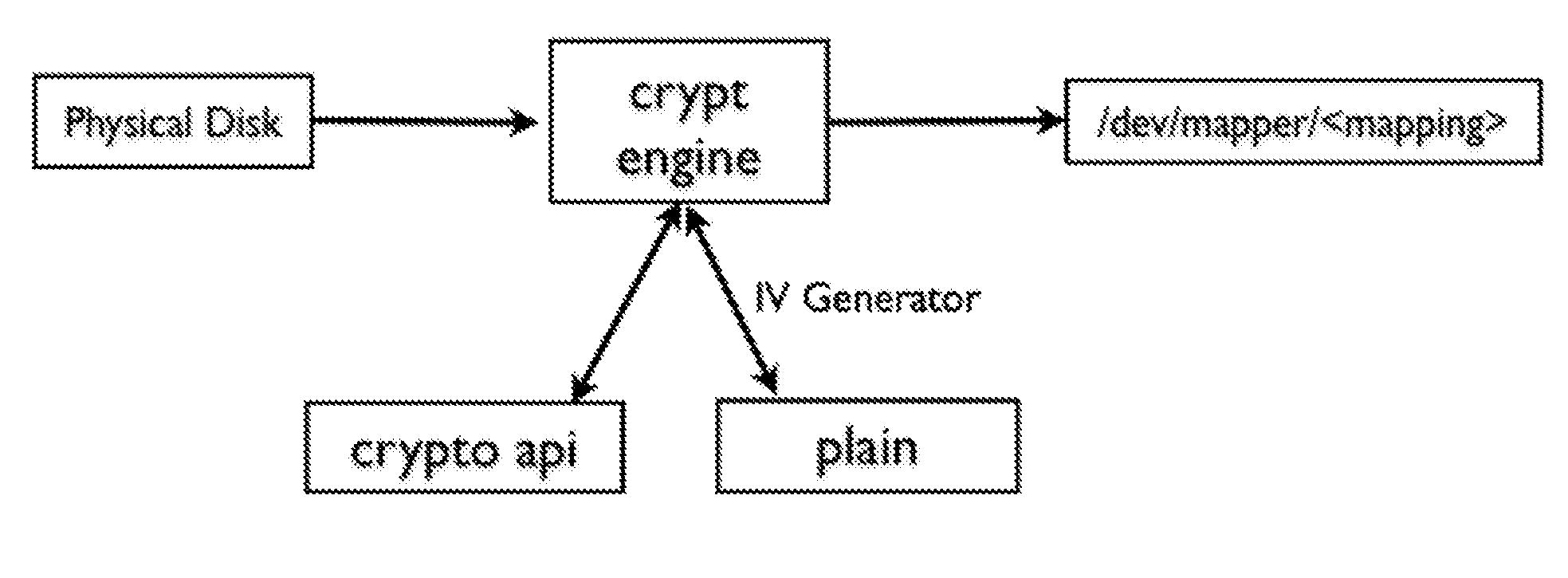

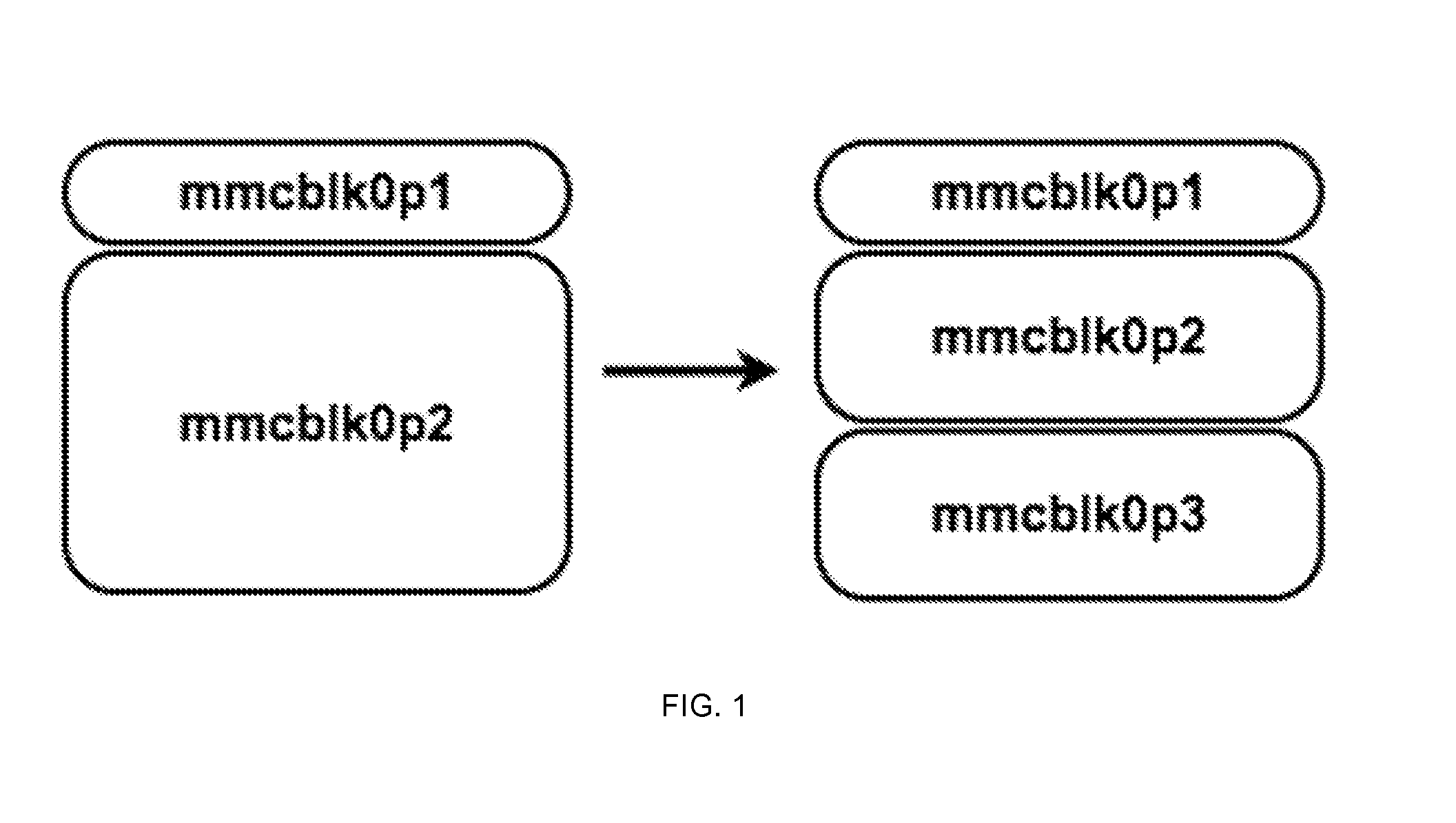

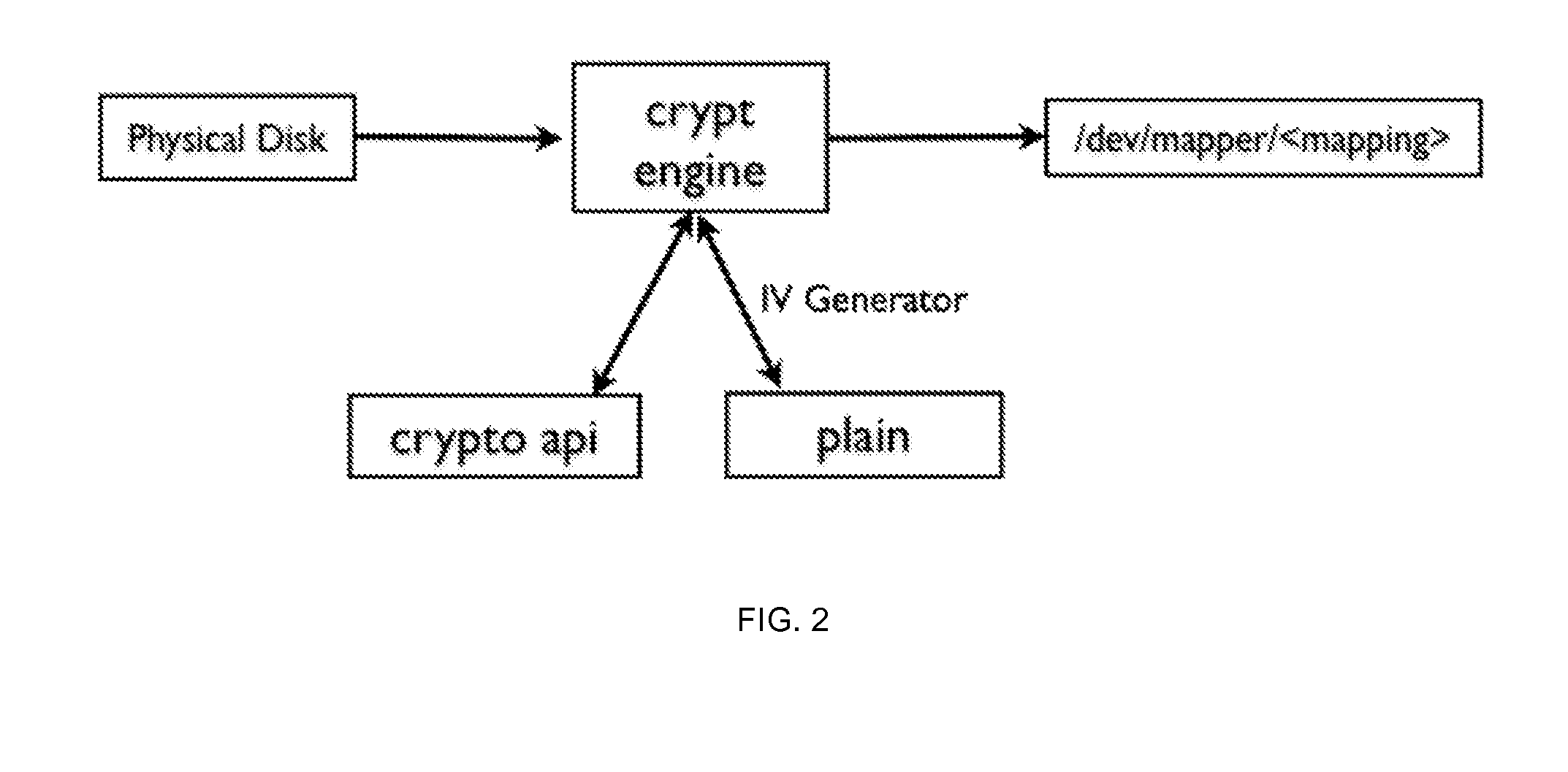

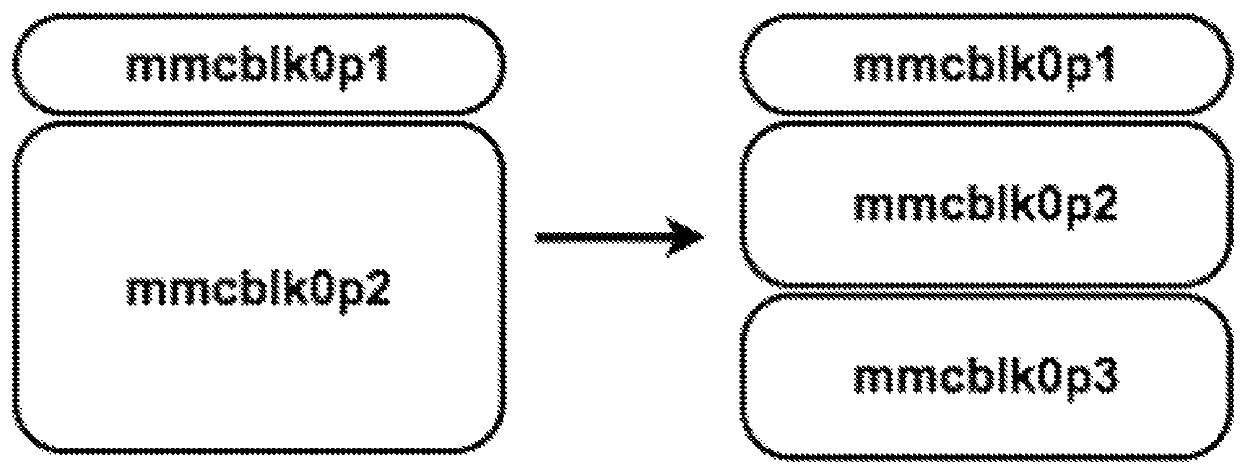

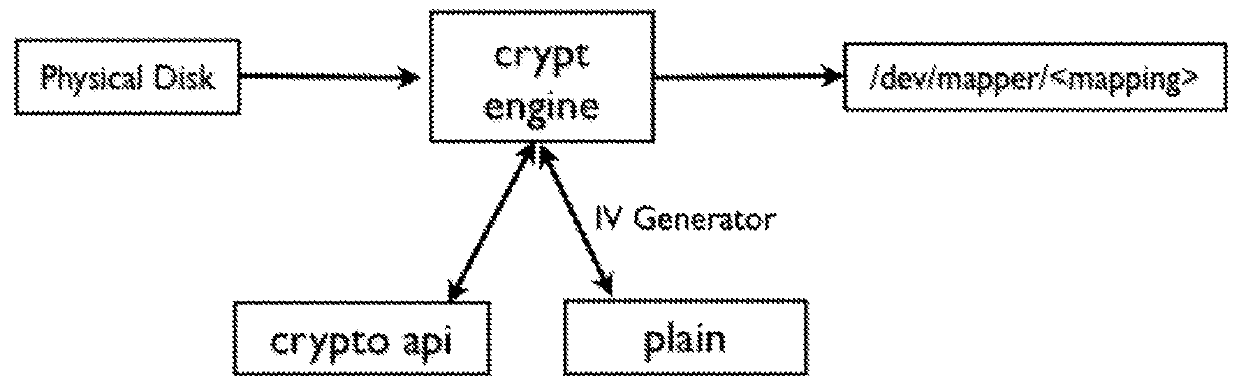

Systems and Methods for Data Gathering Without Internet

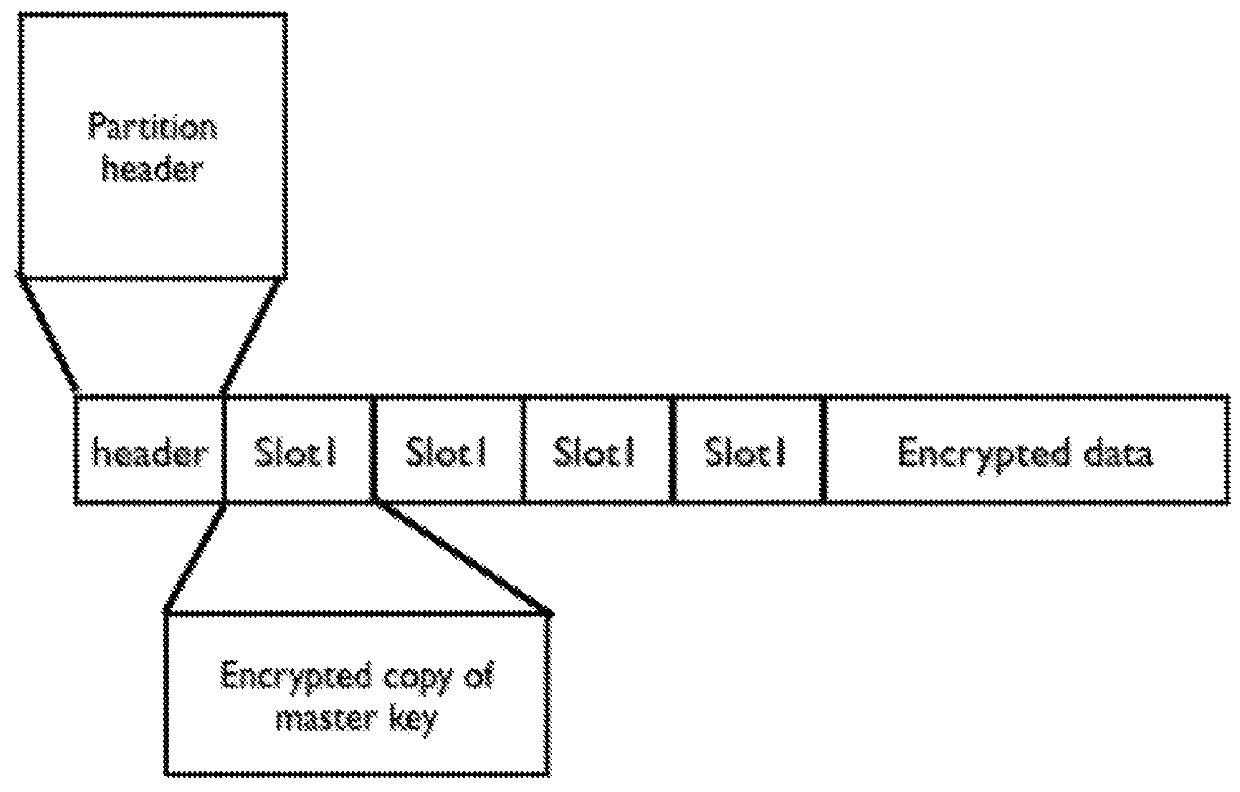

ActiveUS20160087947A1Improve variationMemory architecture accessing/allocationKey distribution for secure communicationThe InternetRemovable media

Systems and methods are provided in which external key devices are used for sealing and unsealing data-gathering devices without Internet, wherein the data-gathering devices invalidate the external key devices upon completing data collection in order to seal removable storage. Further, a sealed removable storage is transported to same location of a key server, where the key server uses a multi-factor sealing routine to unlock the sealed removable storage. The routine seals and unseals uses multiple factors including a location of the key server, hardware attributes of the removable storage, hardware attributes of the external key devices, and a private key of the key server. The data-gathering device may be used to support workers collecting data in disconnected parts in the world that are without Internet. The workers may collect data by using mobile devices to transfer data to a shared data-gathering device.

Owner:WONG SZE YUEN +1

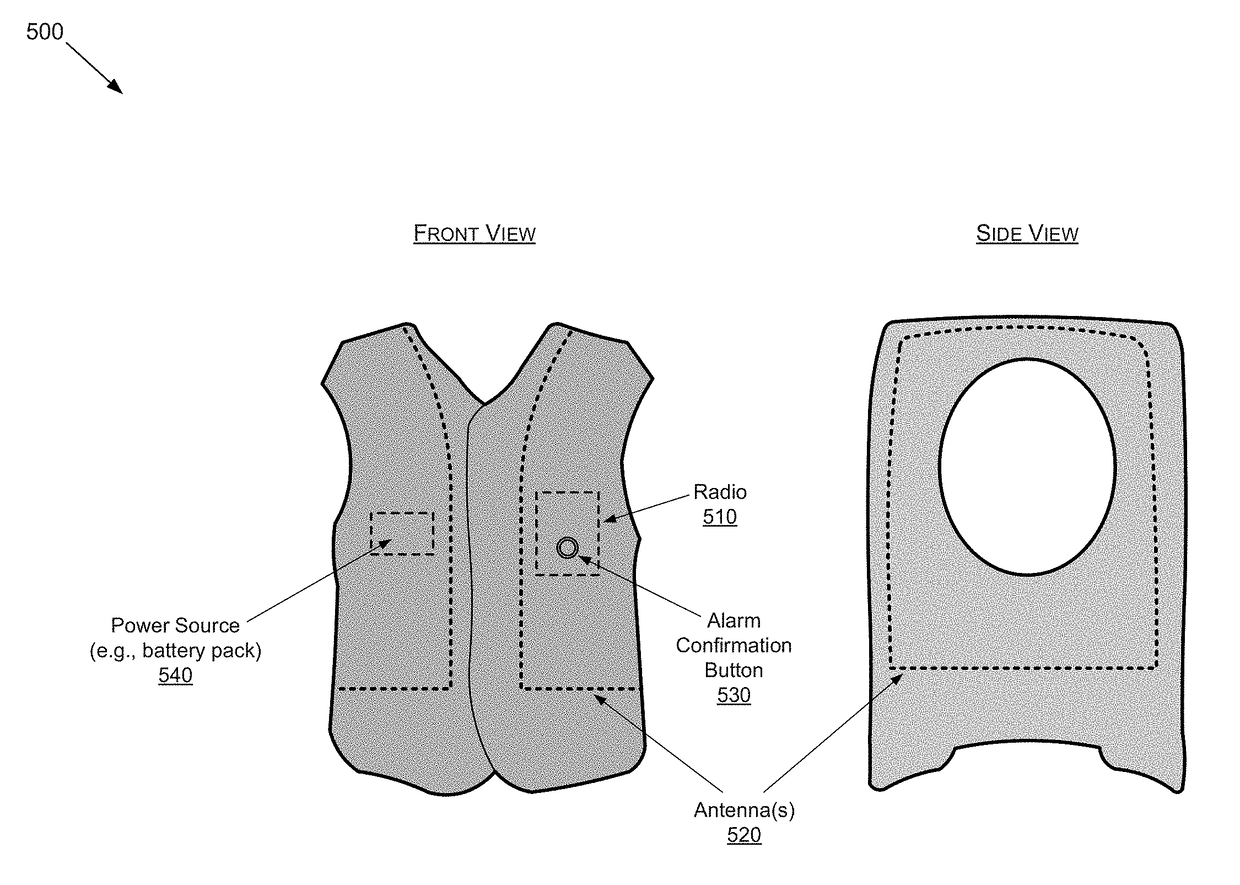

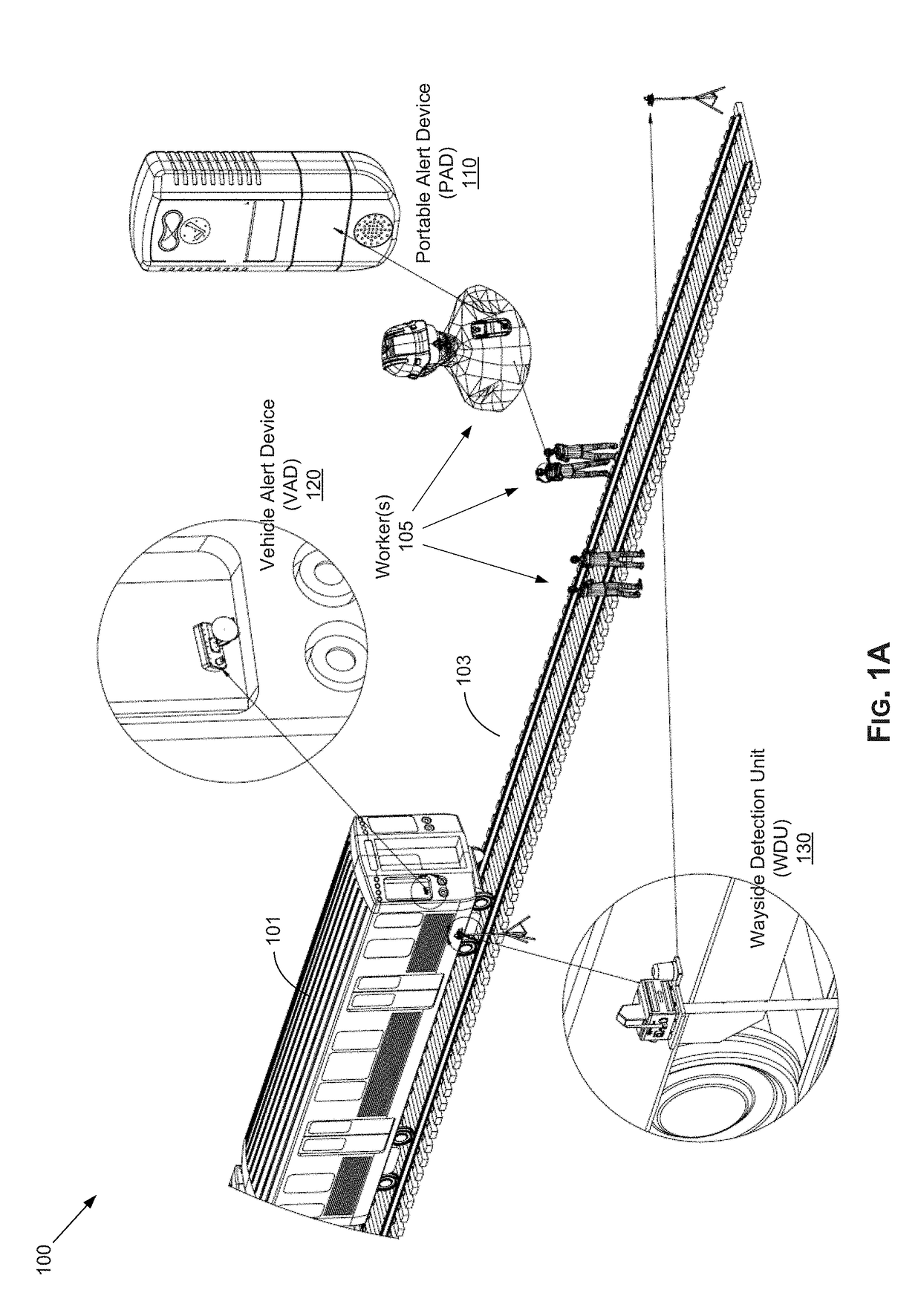

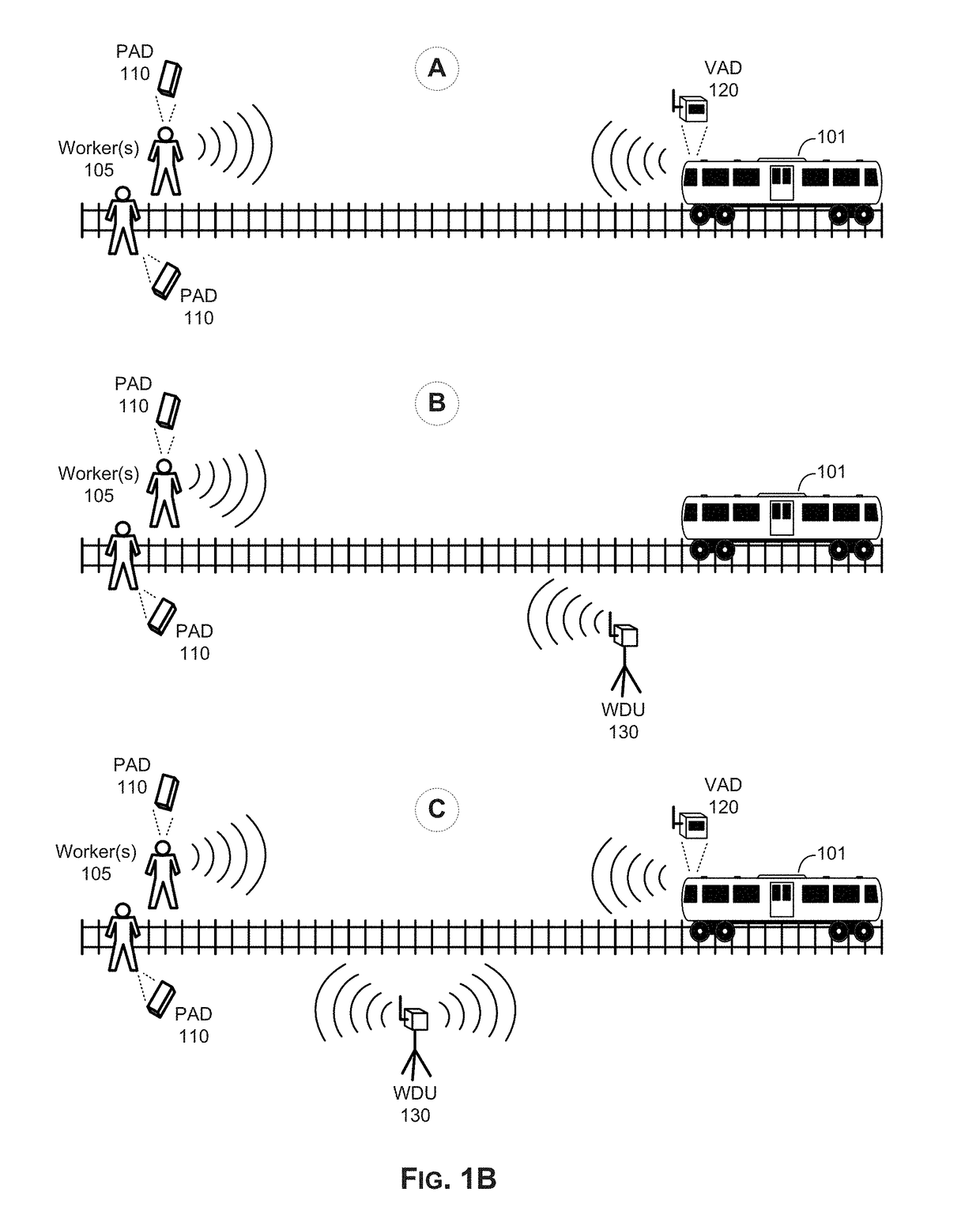

Safety vest for use in worker protection systems

Systems and methods are provided for worker protection. A safety vest may be configured to support worker protection receiver function in worker protection systems. Components used in conjunction with the receiver functions may be integrated into the safety vest. The components may include one or more antennas, radio receiver (or transceiver) circuitry, integrated power supply source, indication components, and acknowledgement components. The safety vest may generate safety alerts in response to receiving signals from peer transmitter devices in the worker protection systems.

Owner:METROM RAIL

Mason's adjustable chimney-platform arrangement

An adjustable platform assembly for supporting workers and supplies about an elevated work site, the platform assembly being movably supported on an articulable support, the platform comprising a stationary rear bridging panel arrangement having an elongated side platform member comprising a floor and railing assembly at each end thereof, wherein each elongated side platform member floor and railing assembly is independently movable on support members forwardly, rearwardly, transversely and angularly with respect to the bridging panel arrangement, to change the platform assembly back and forth between a generally “H” shape to a generally “U” shape, or any skewed combination thereof, as required.

Owner:LOMBARDI DONALD F

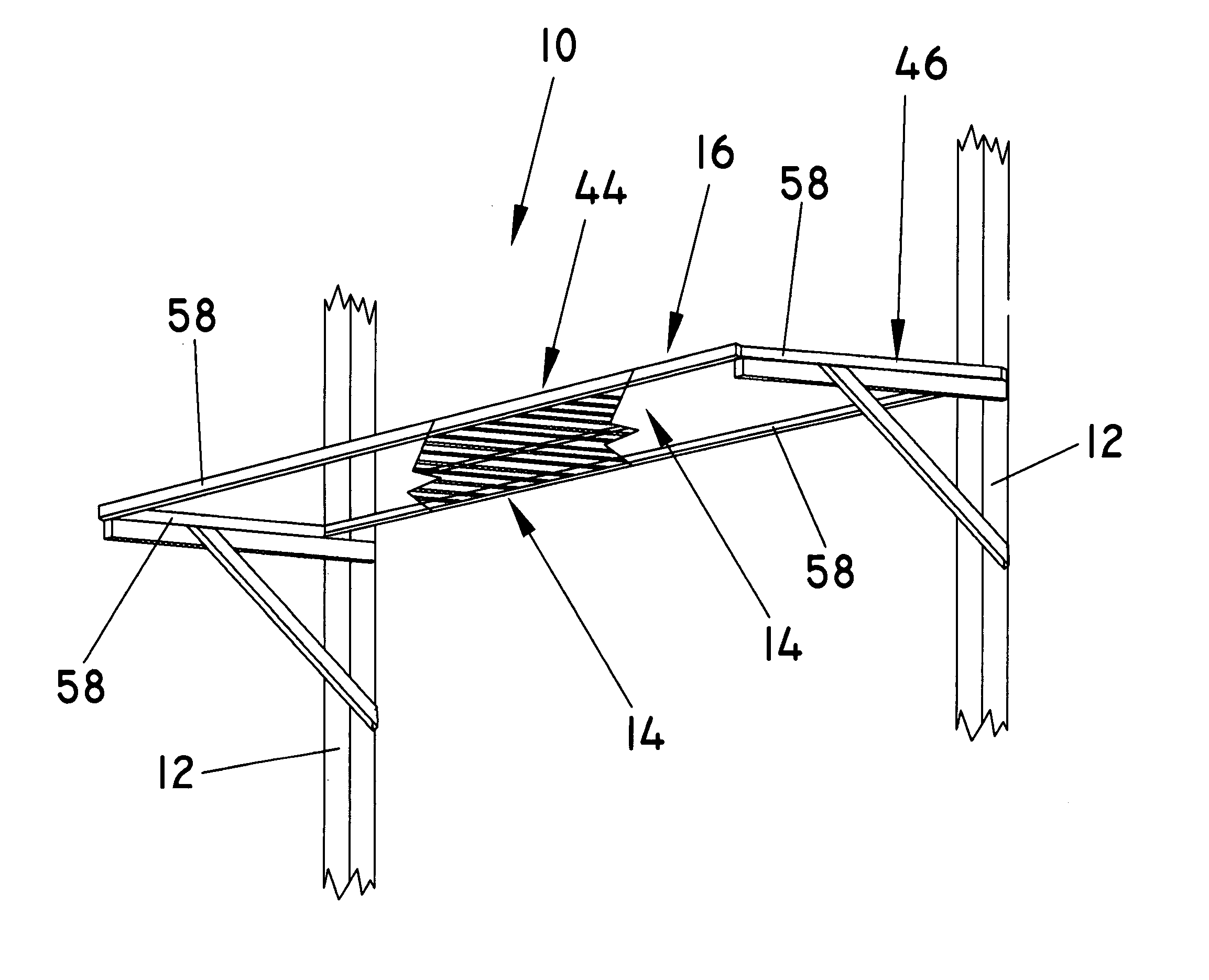

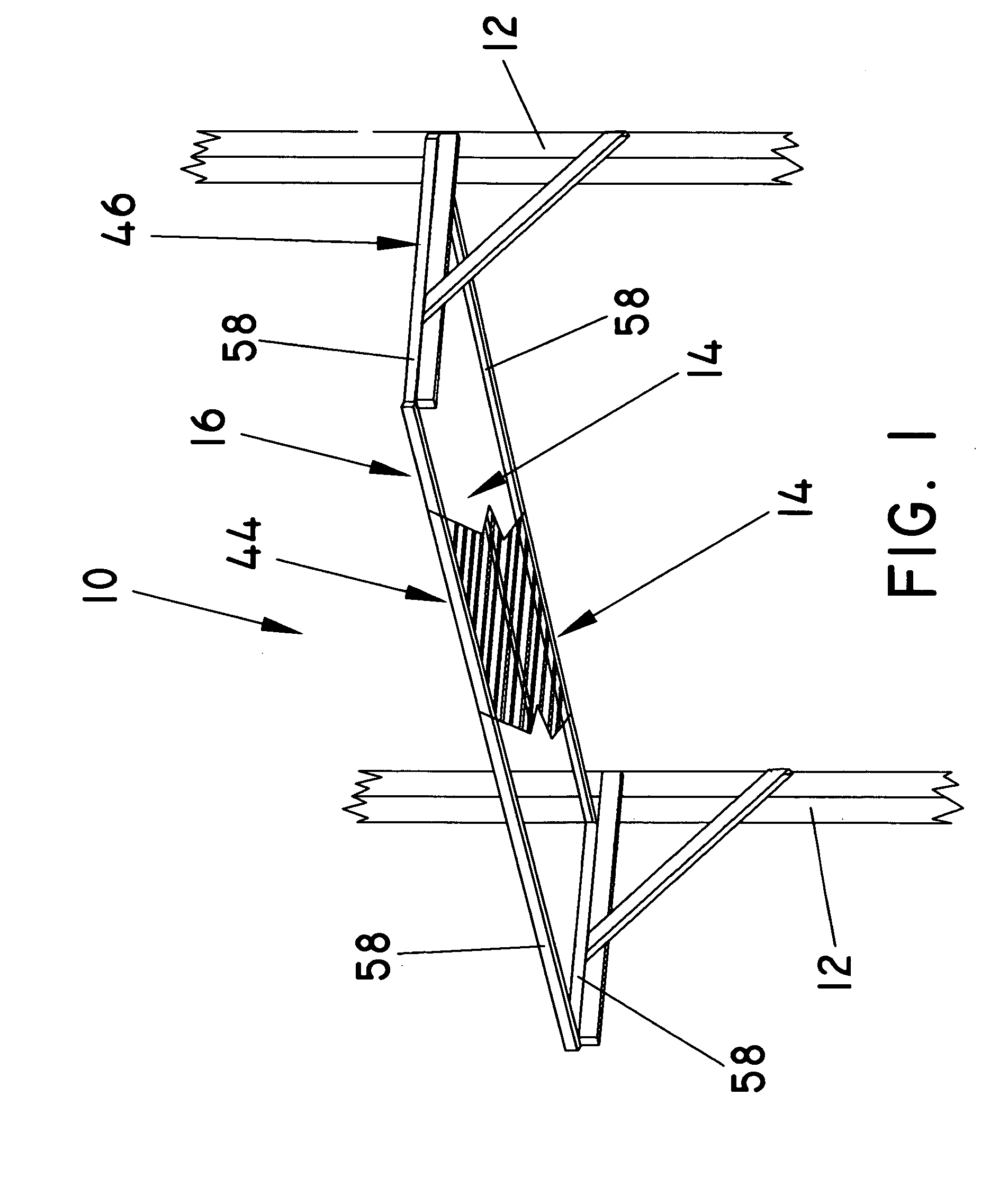

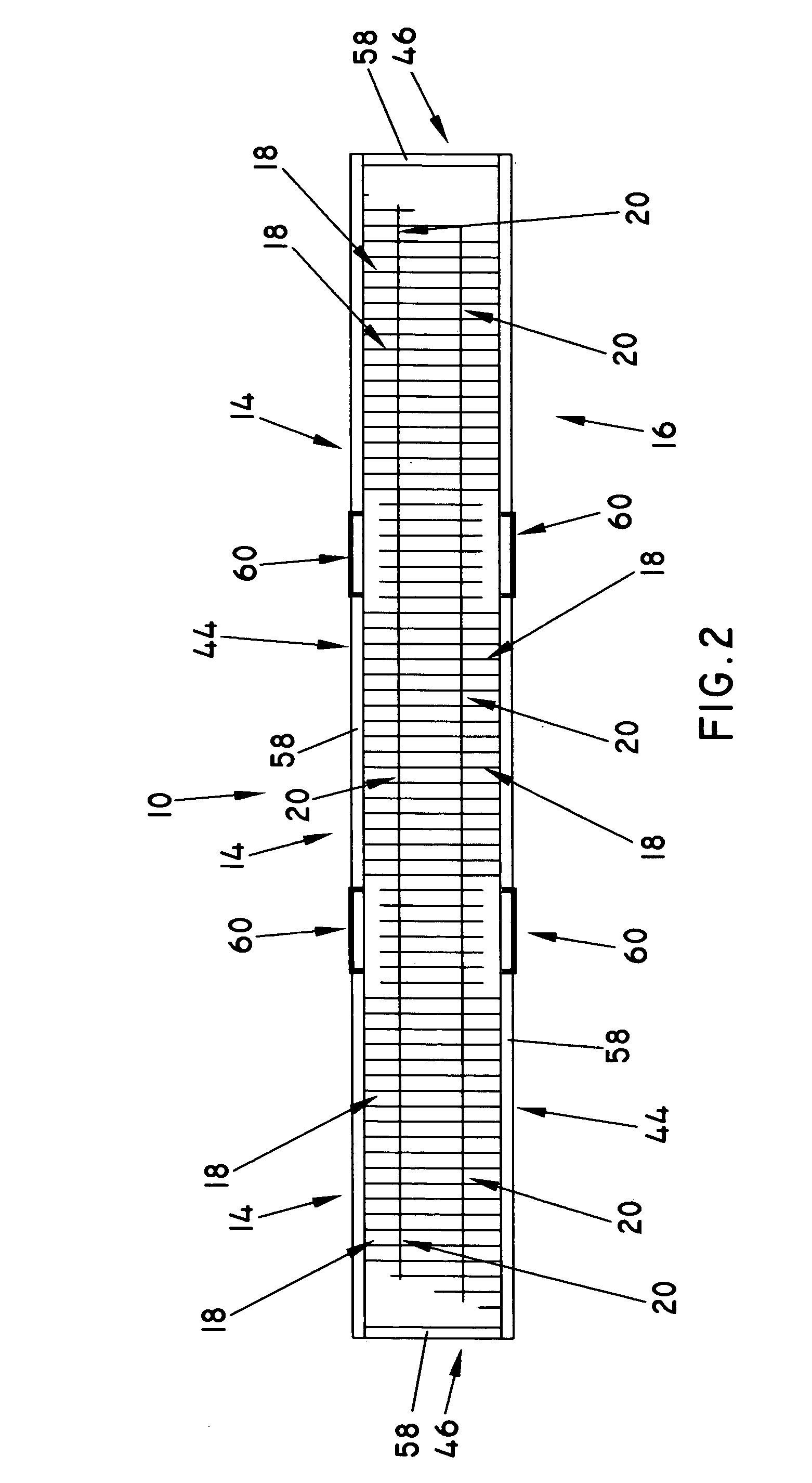

Elevated work platform

Owner:IRVIN GRADY J

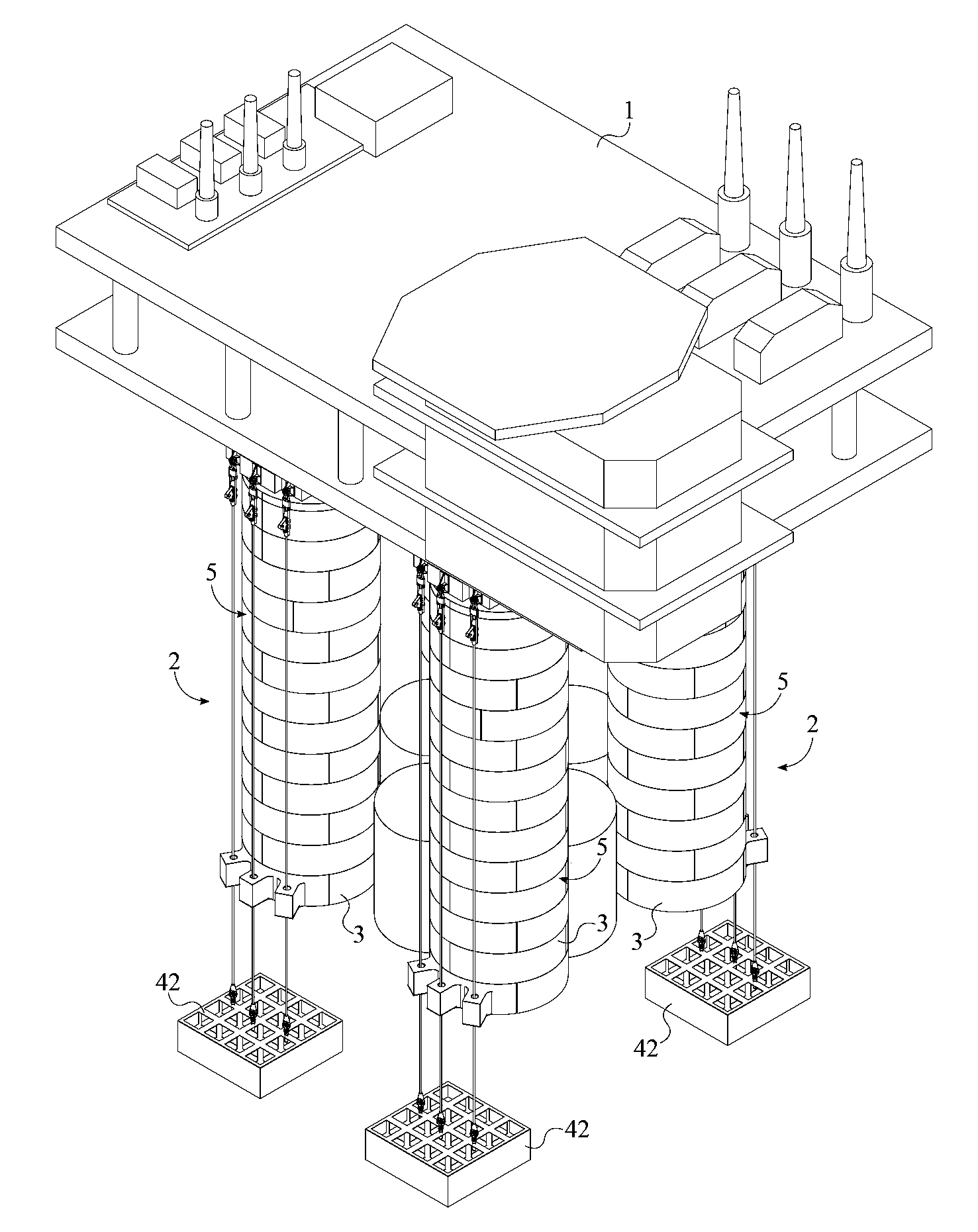

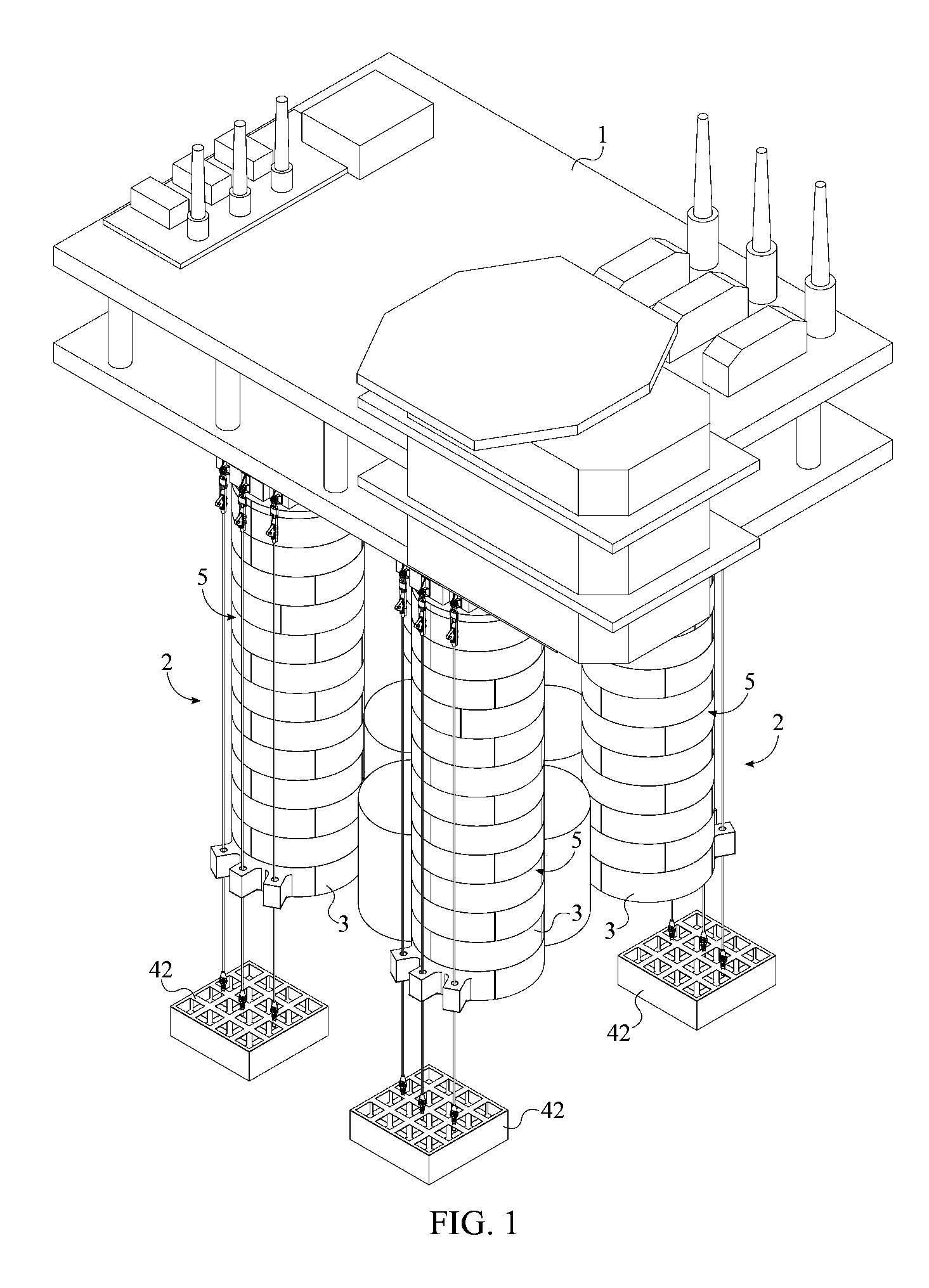

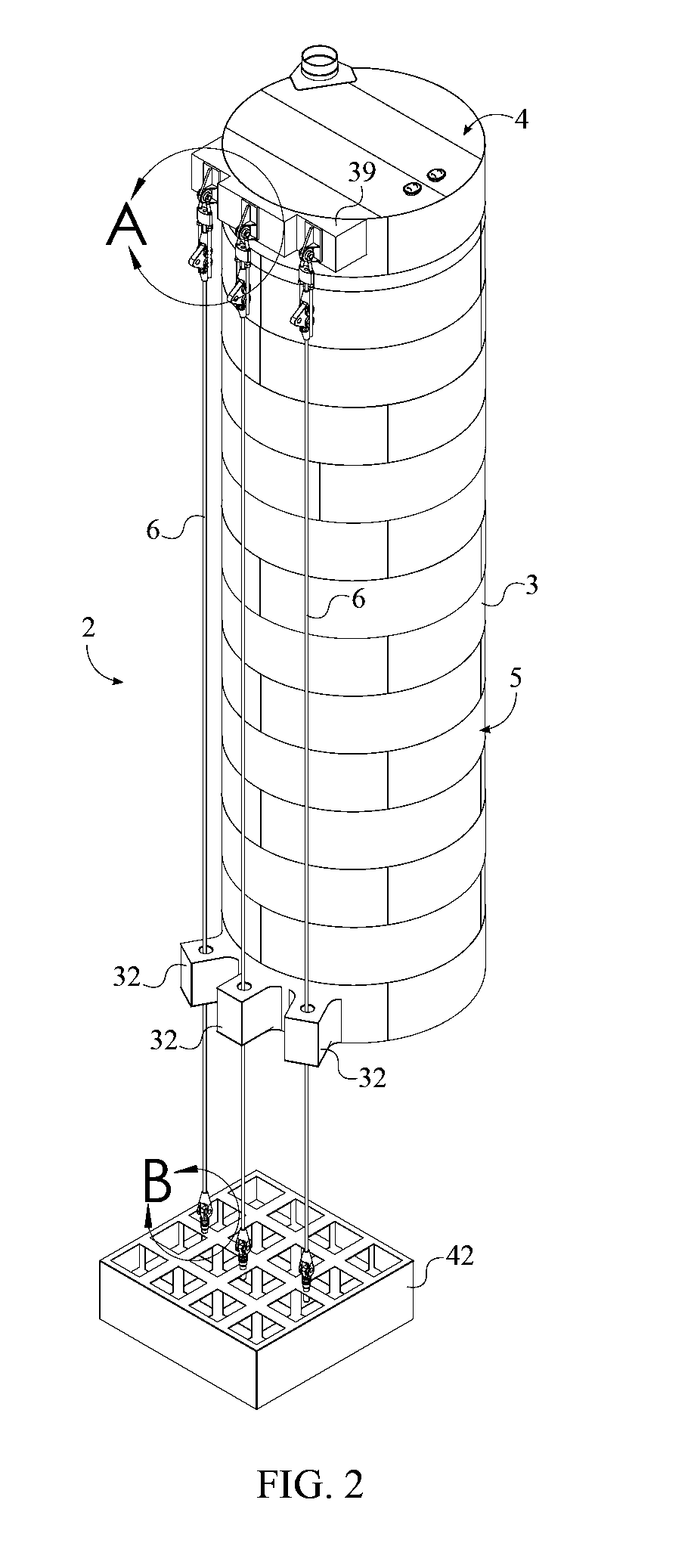

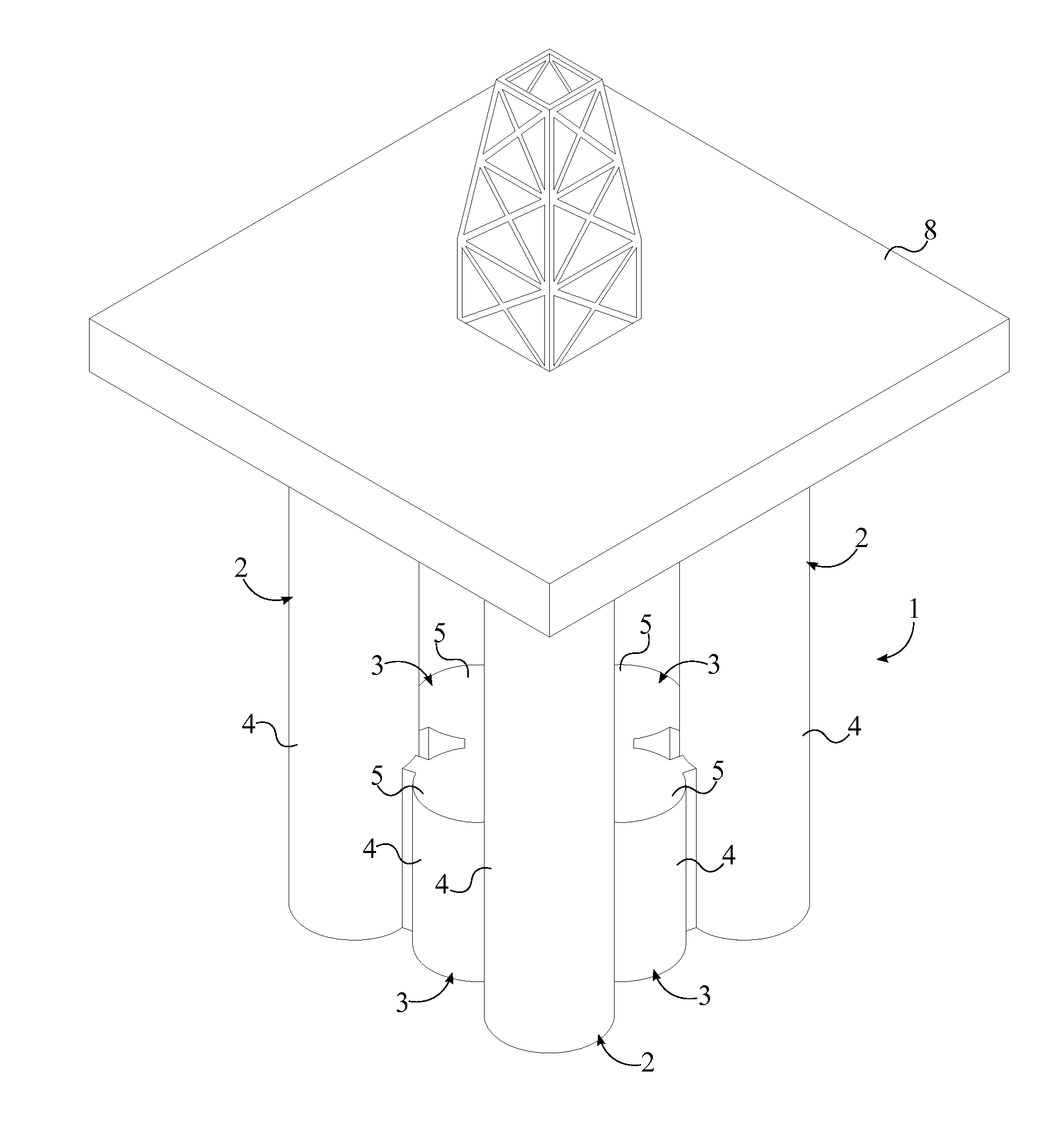

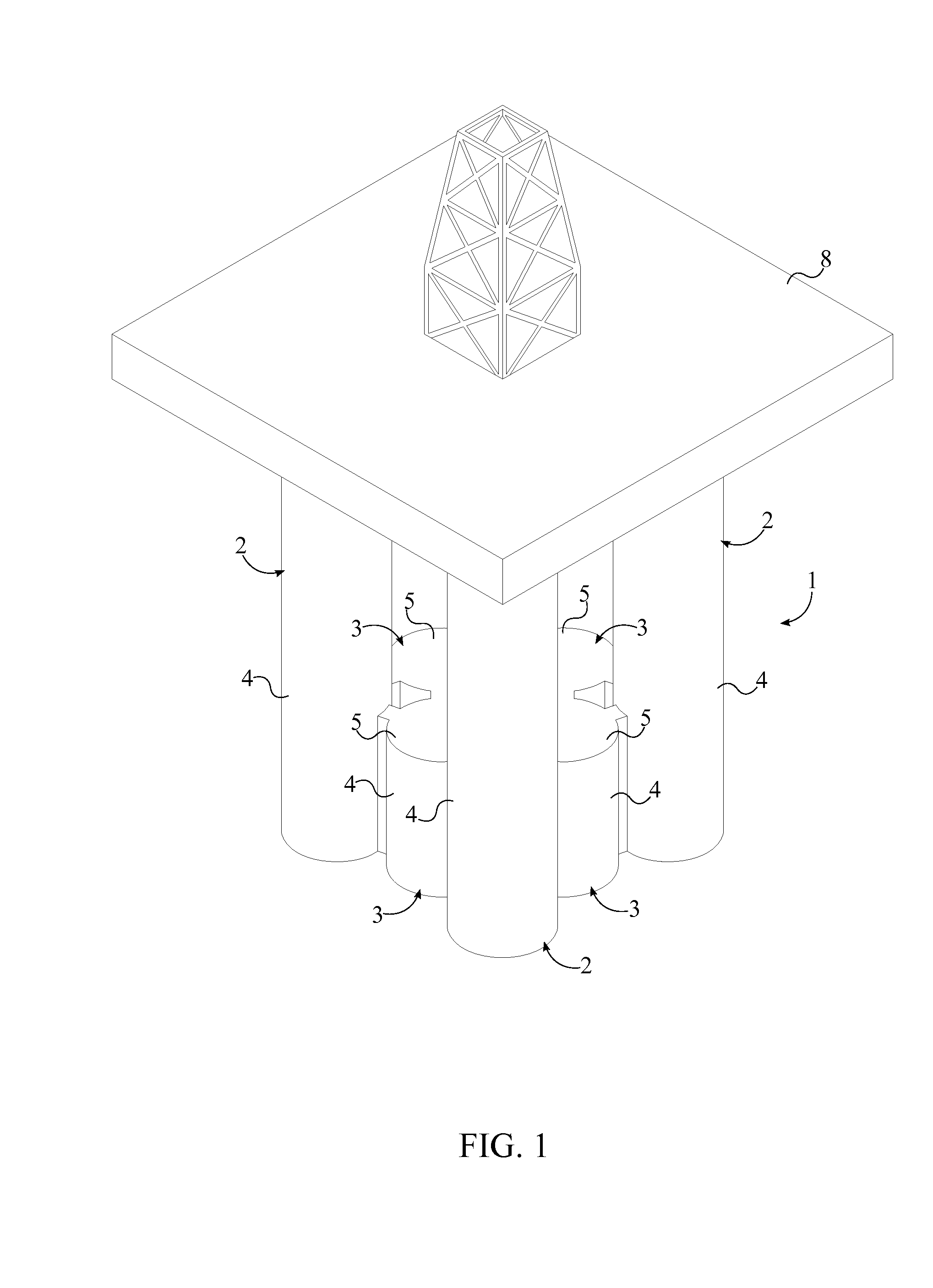

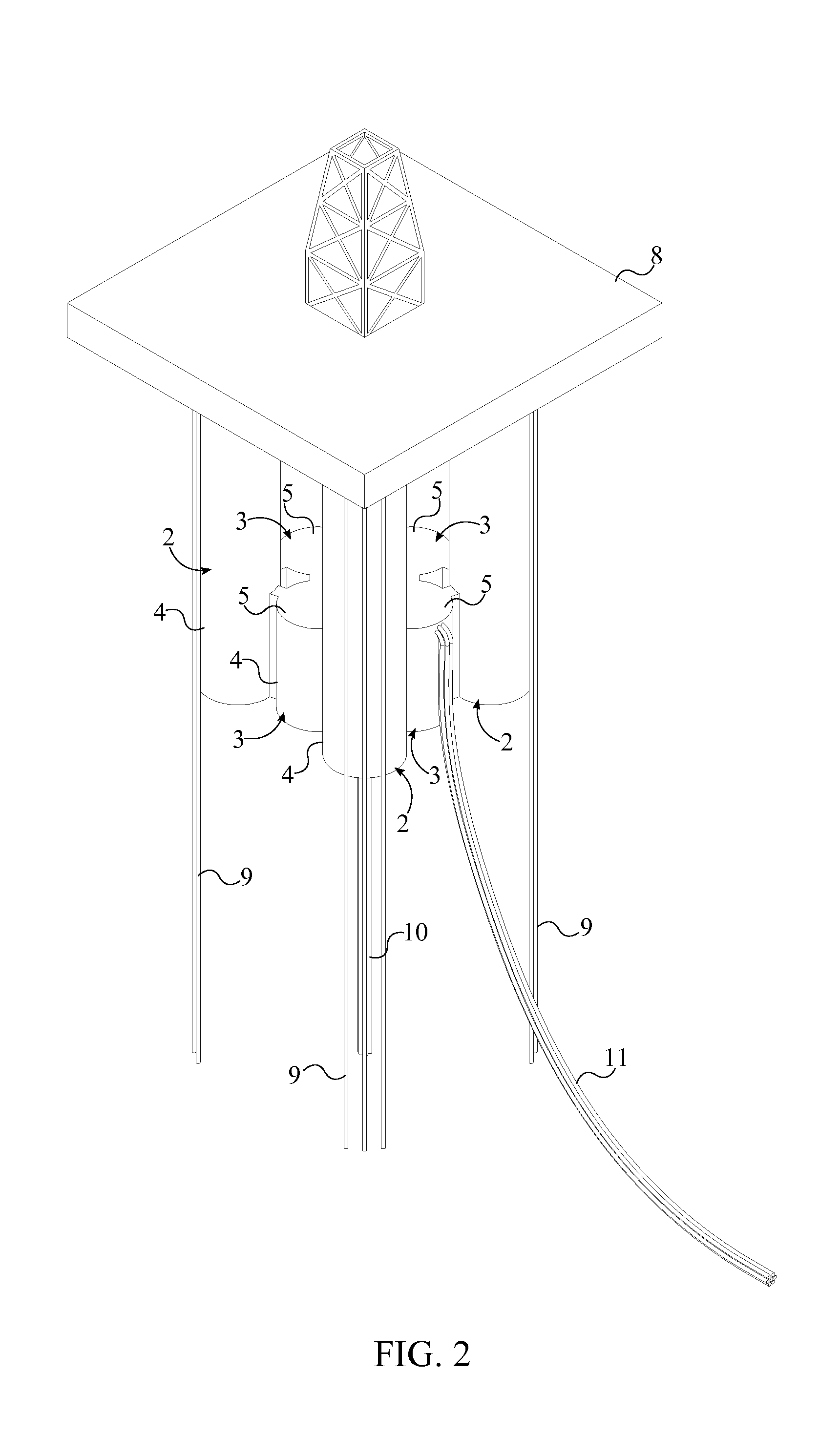

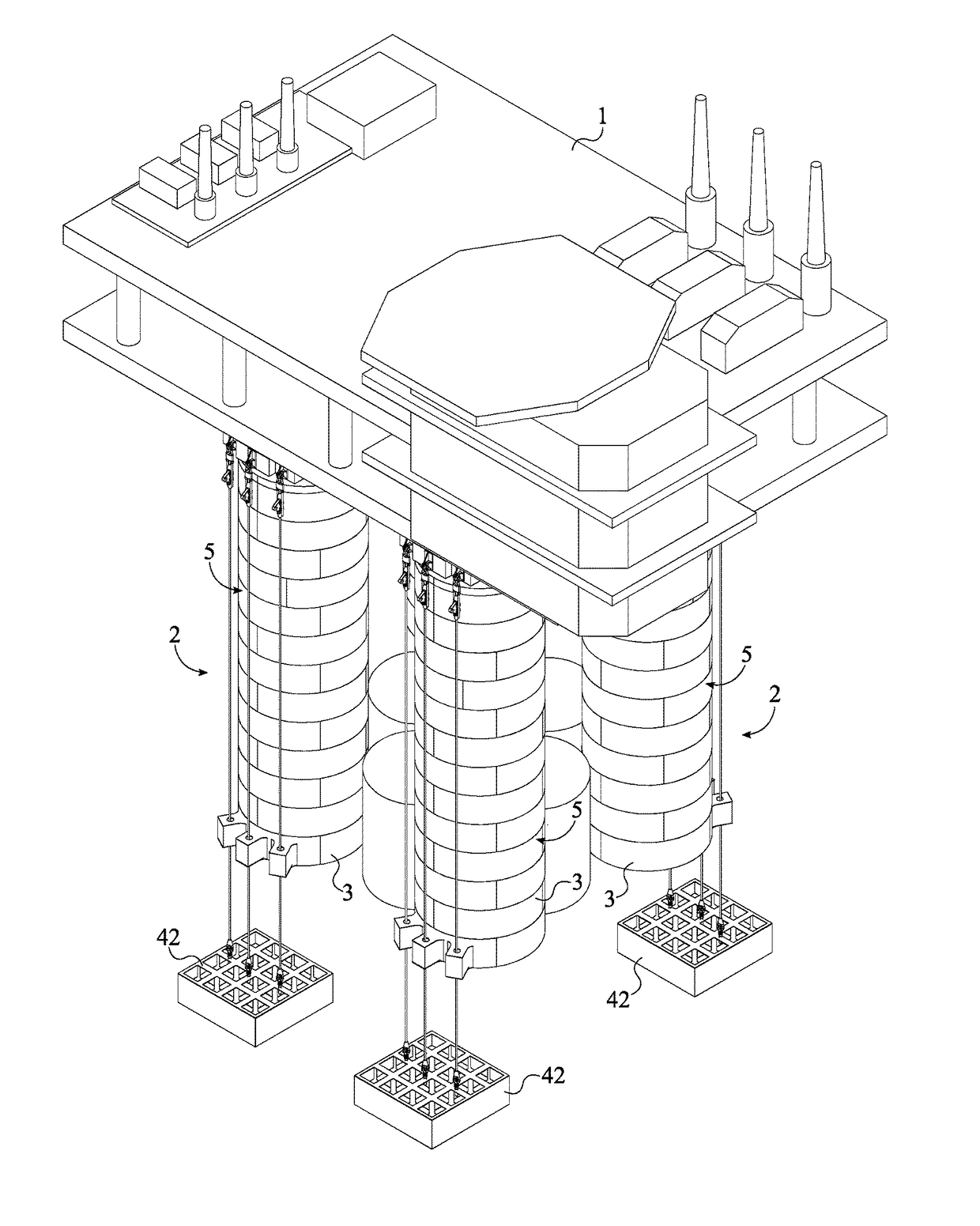

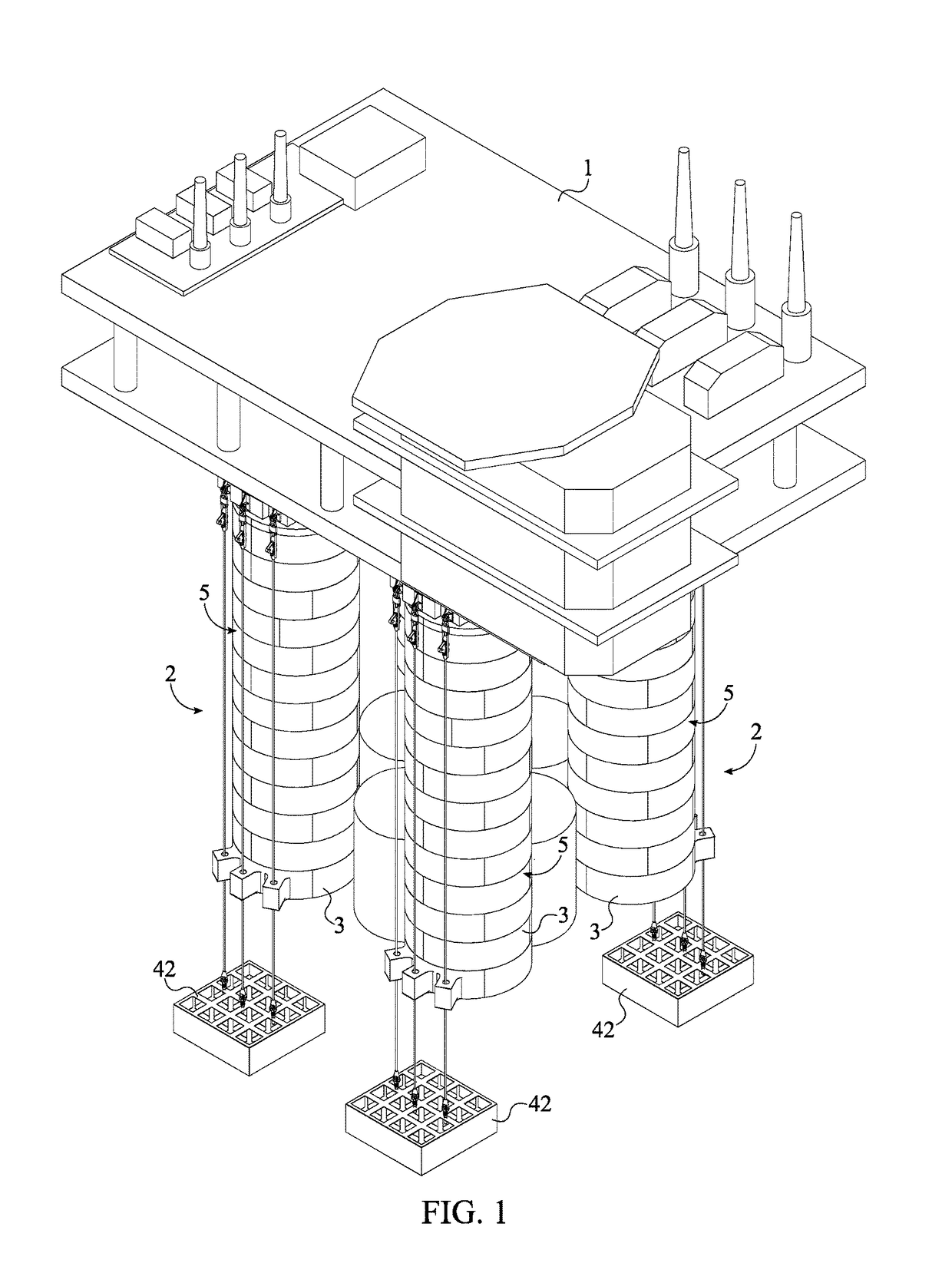

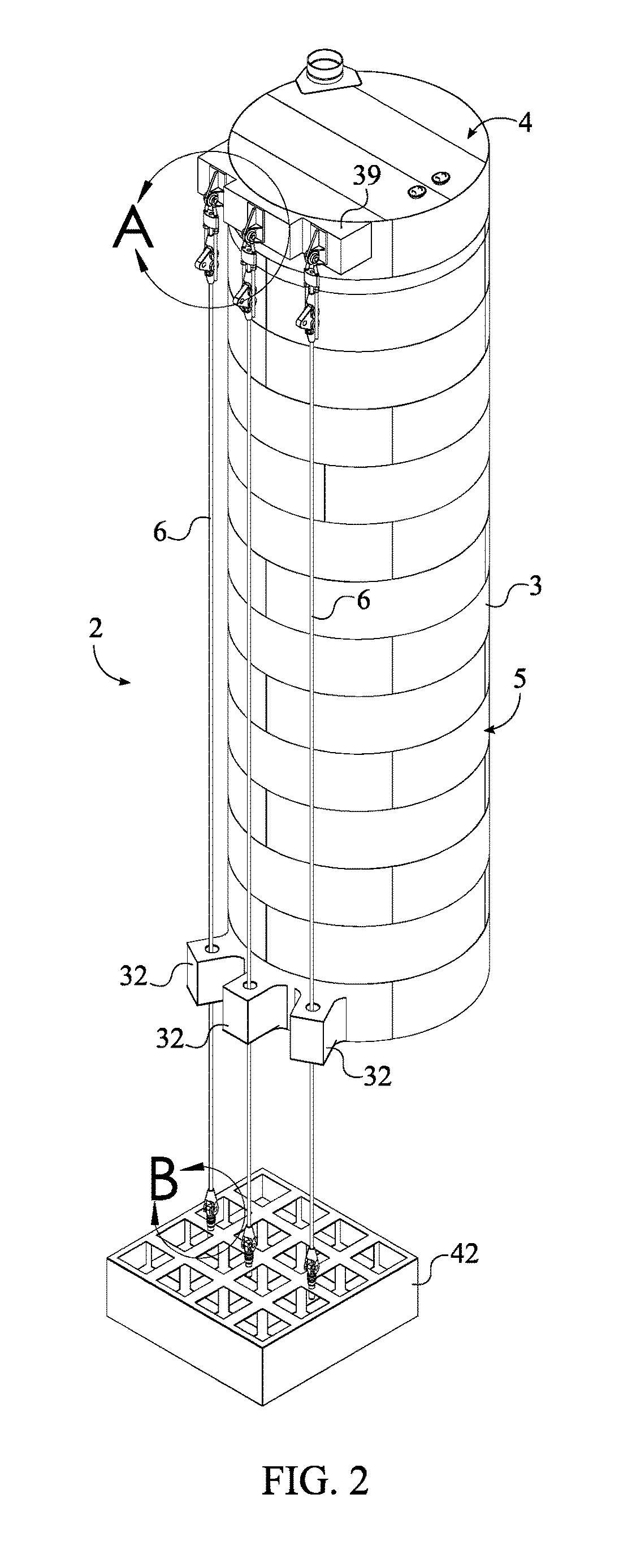

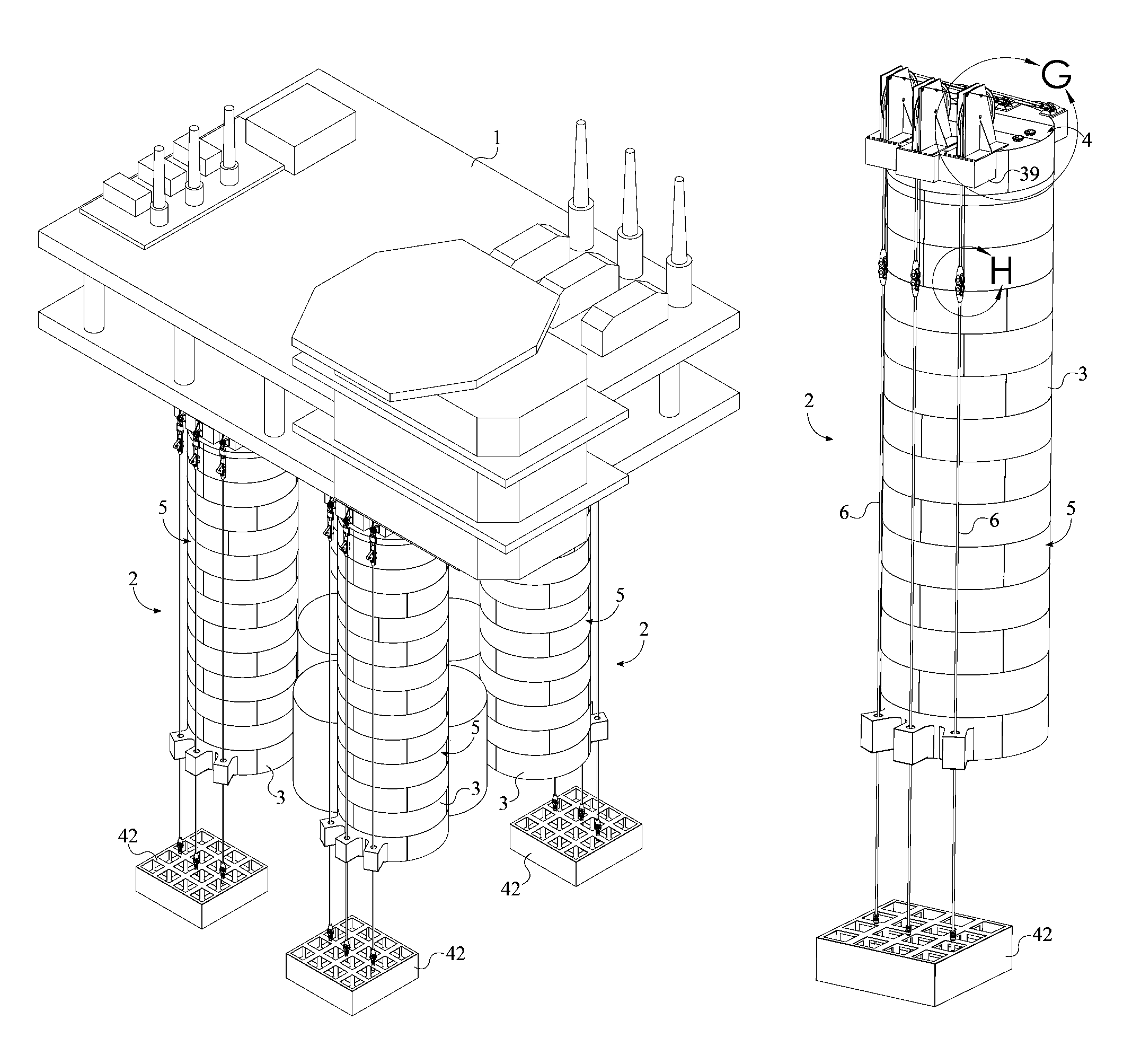

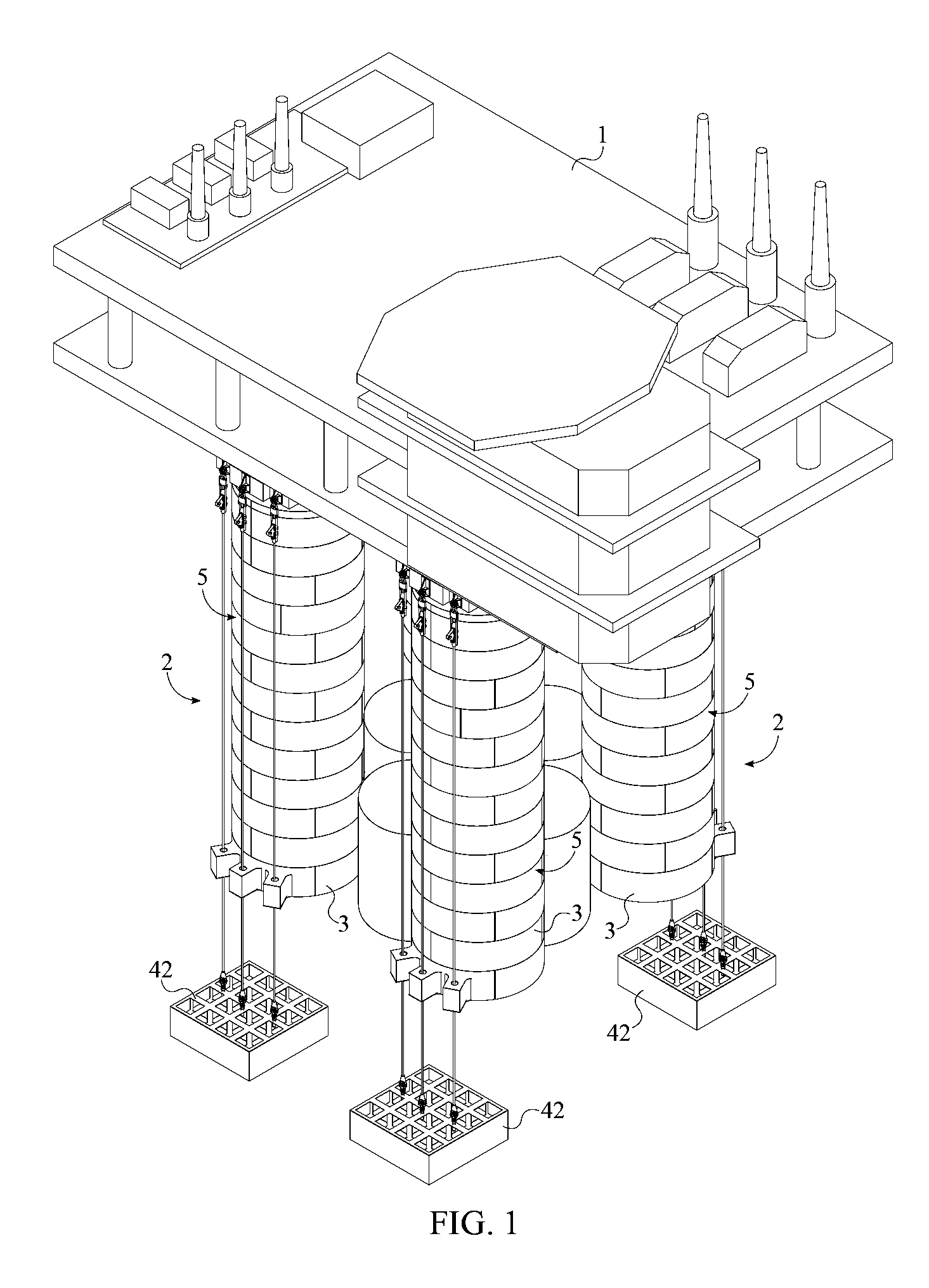

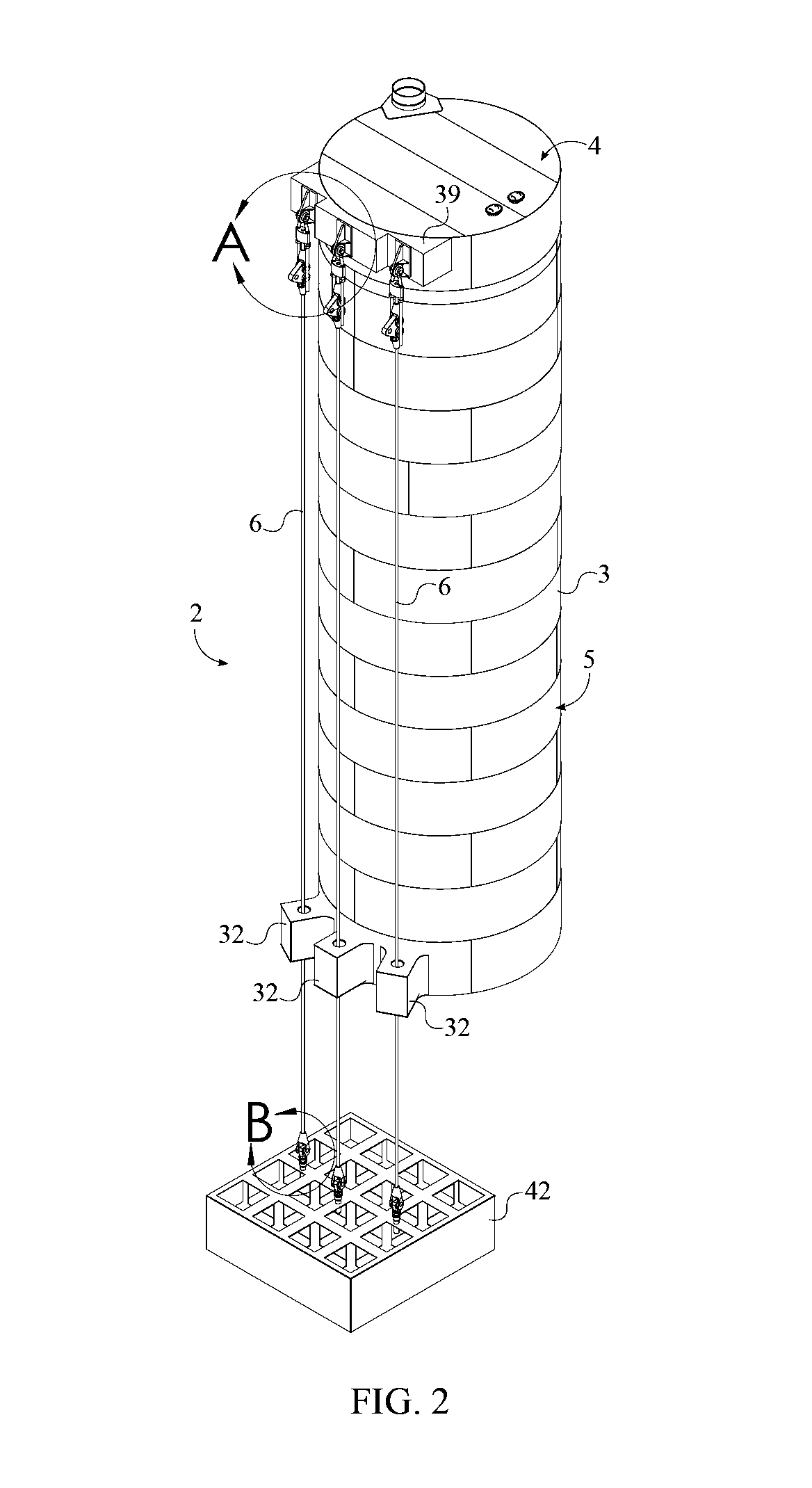

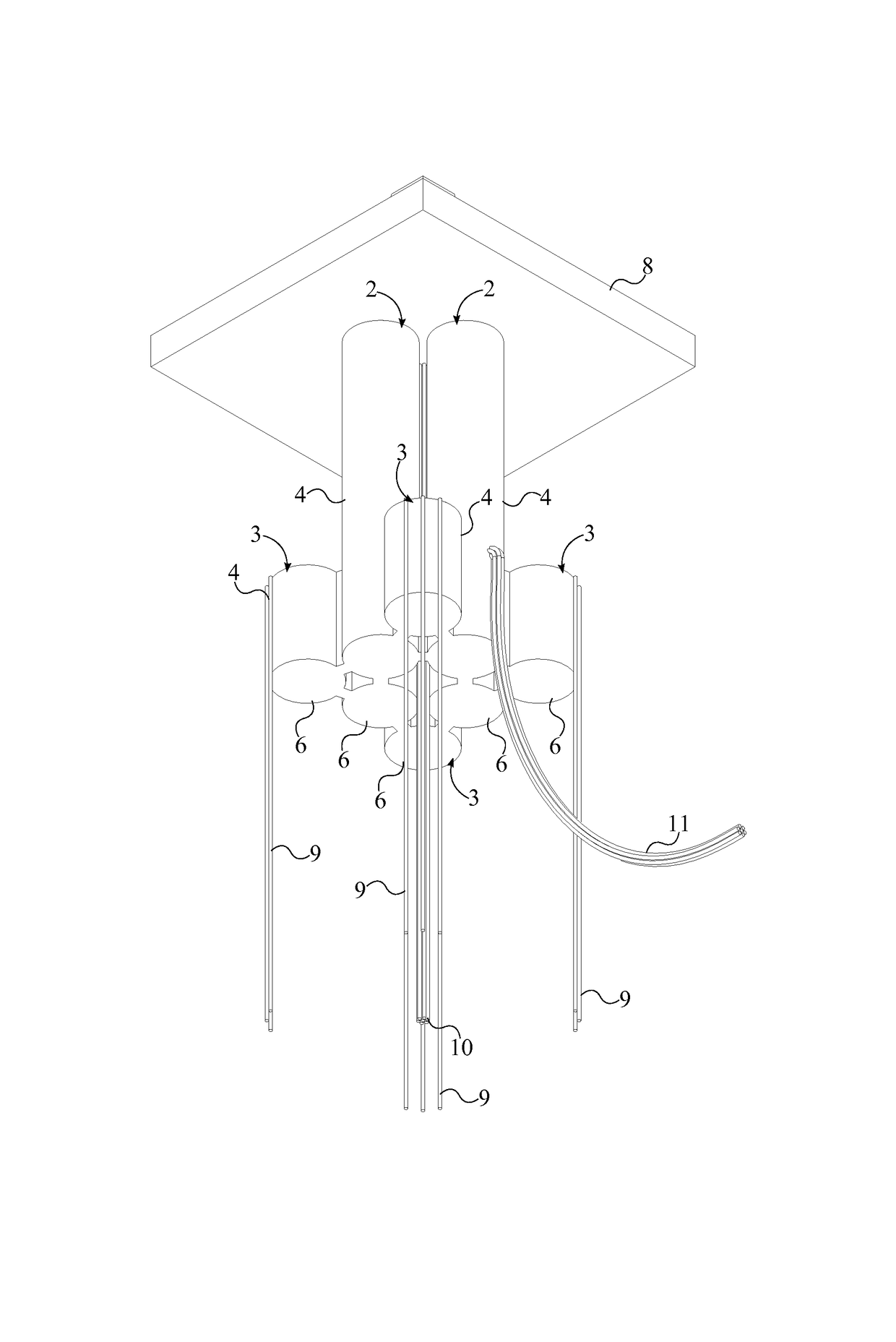

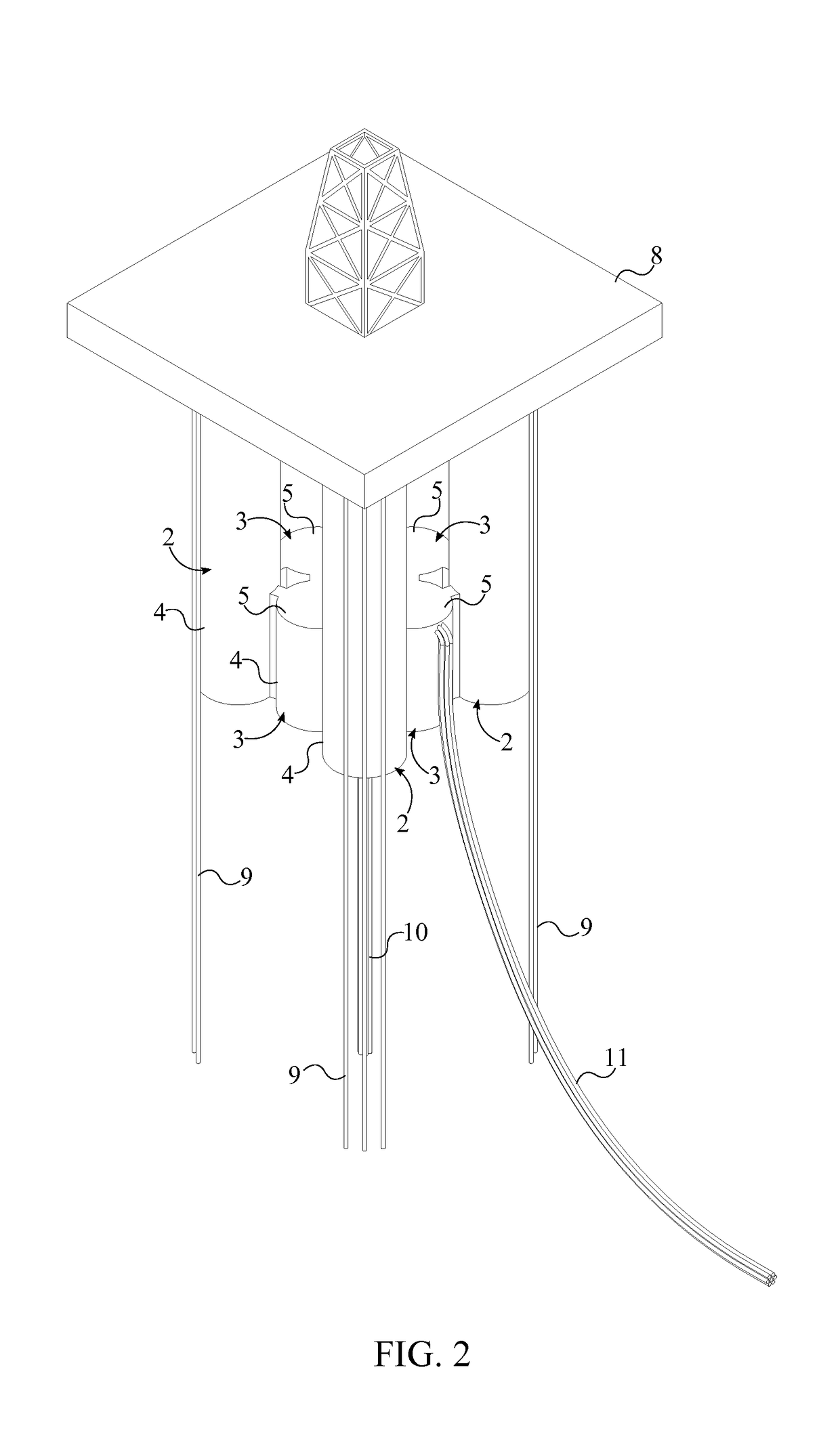

Tension-Leg Platform Anchoring System

A tension-leg platform anchoring system is used to tether the columns of a floating platform to the seabed and restrict movement of the entire platform. The tension-leg platform anchoring system includes a topside and a plurality of anchored floating supports. The topside provides a deck for supporting workers and equipment. The anchored floating supports are used to keep the topside afloat and limit movement. The anchored floating support includes a column, at least one mooring assembly, and an anchor. The column is connected to the topside and is used to keep the tension-leg platform afloat. The mooring assembly includes a column coupler, a first tendon, and an anchor coupler, which are used together to tether the column to the anchor. The column coupler is tethered to the anchor coupler through the first tendon, which is connected to the column by the column coupler.

Owner:TAHAR ARCANDRA

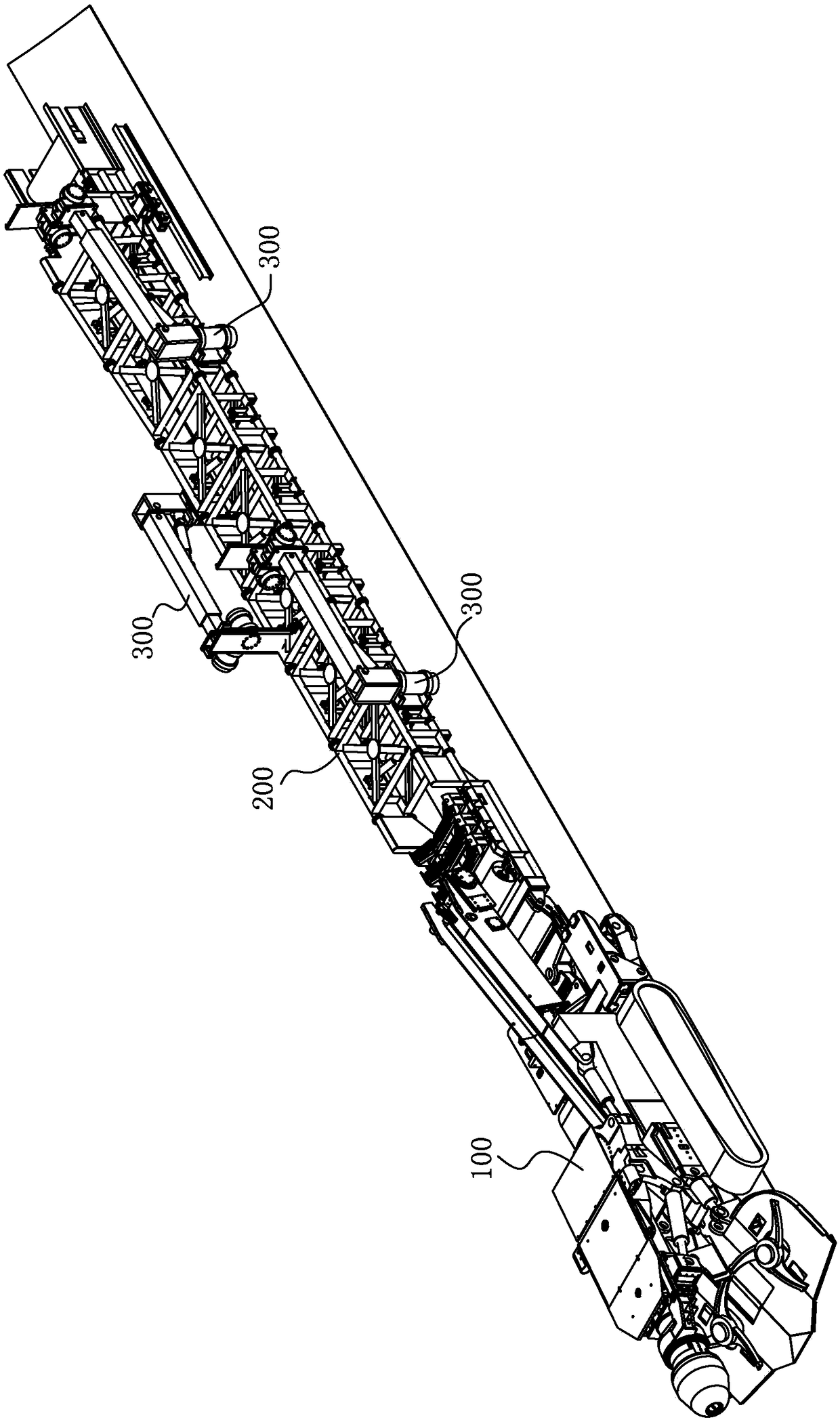

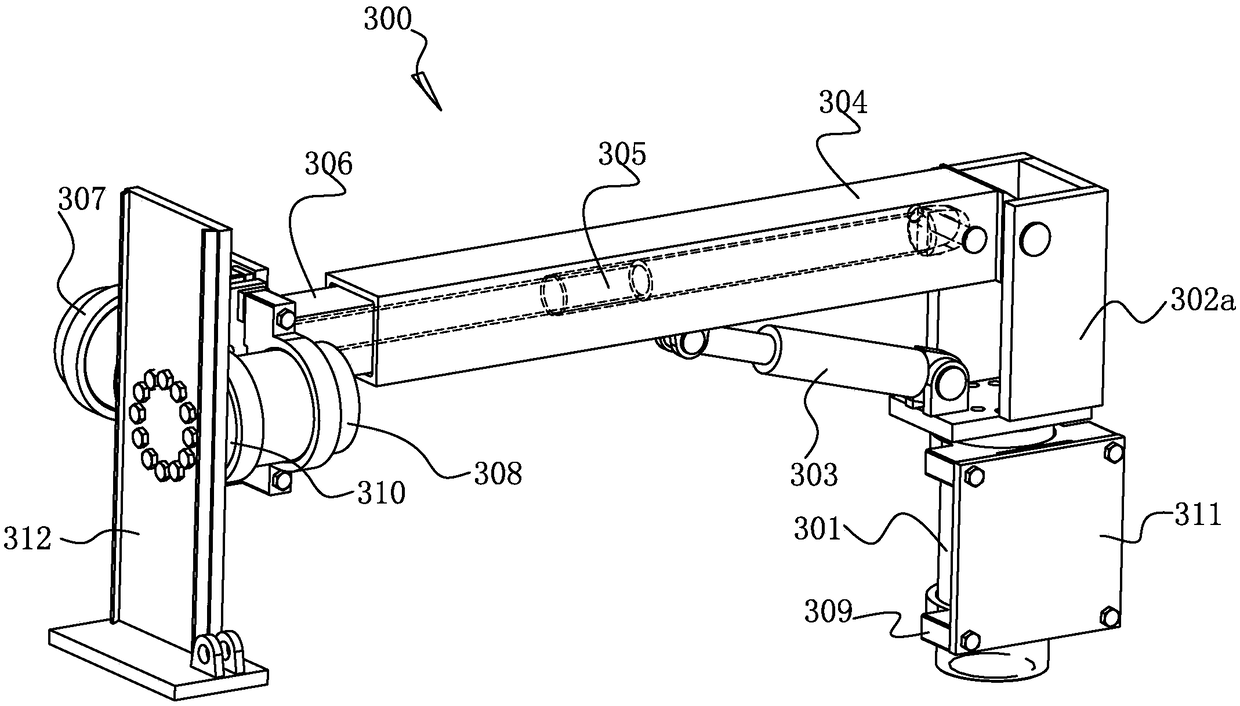

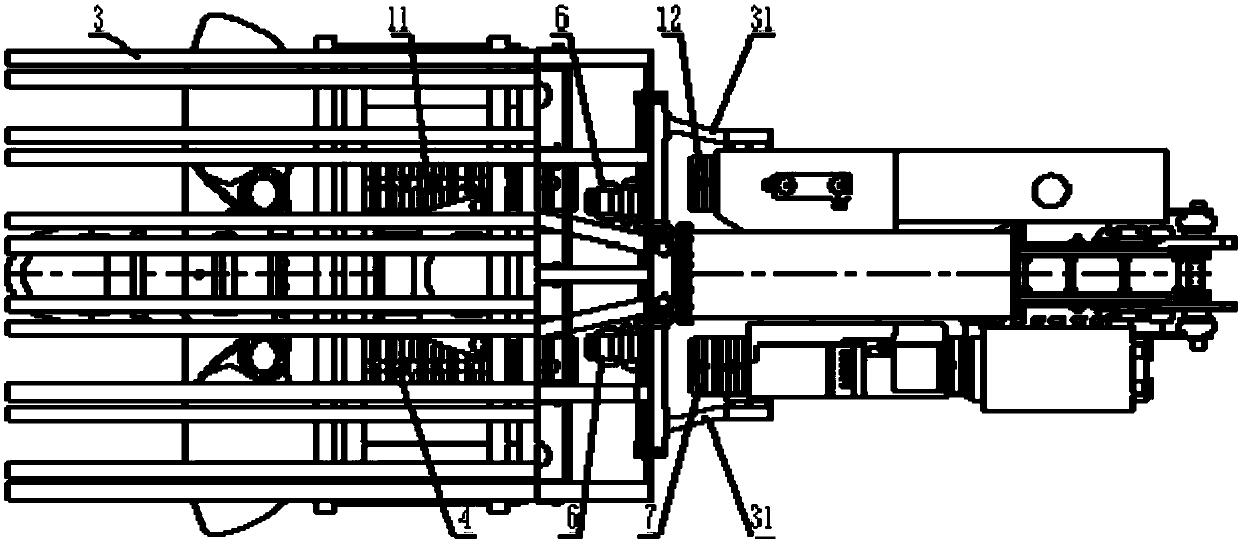

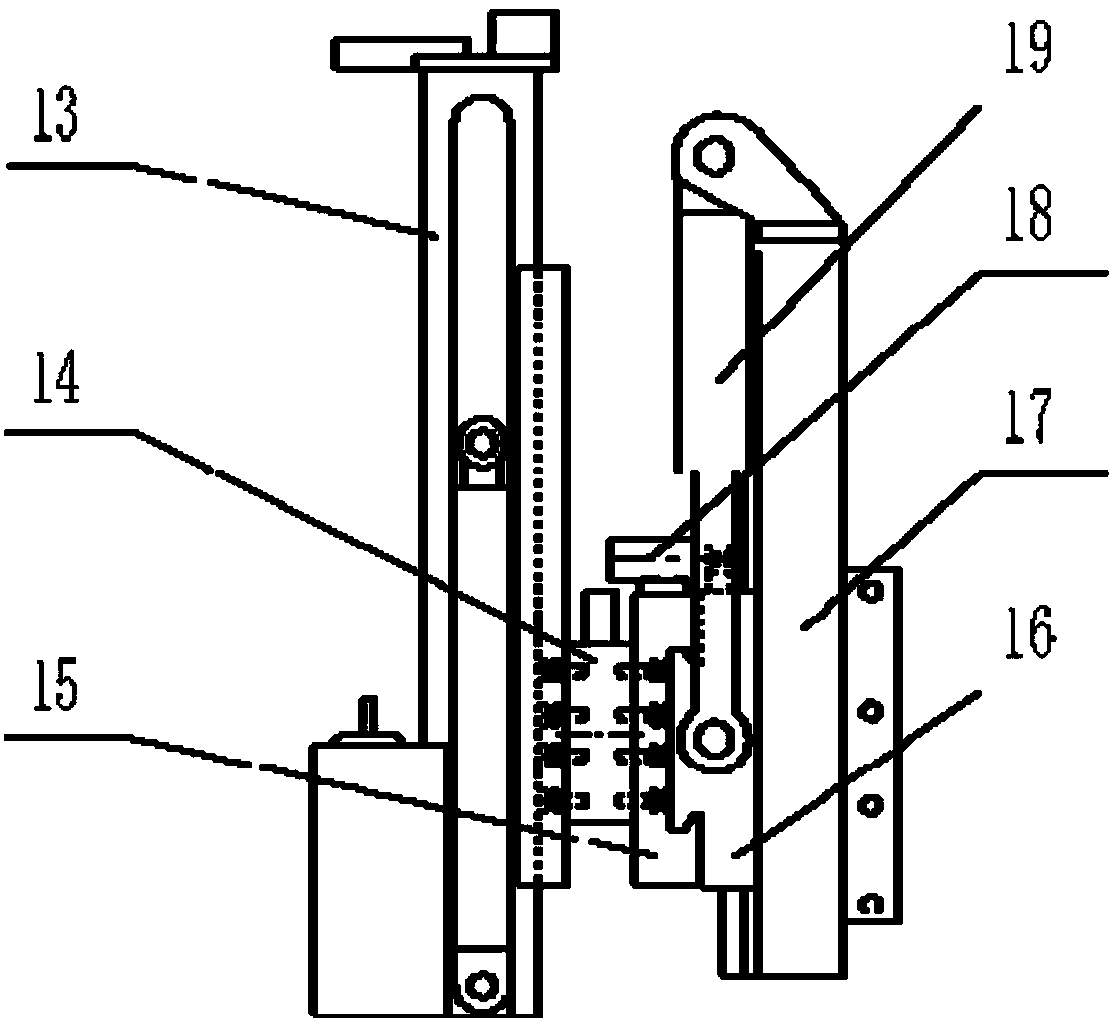

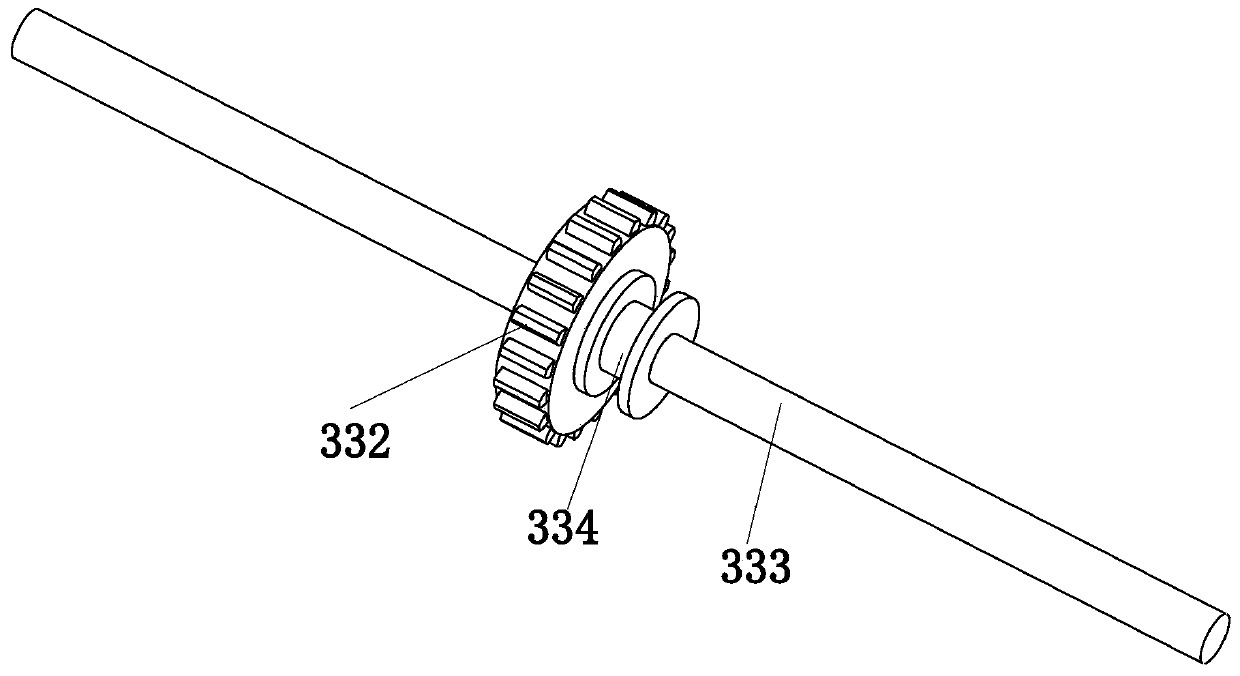

Tunneling and bolt supporting device

PendingCN108999617APrevent sinkingPrevent collapseTunnelsAnchoring boltsHorizontal axisMaterial transfer

The invention discloses a tunneling and bolt supporting device. A bolt supporting device comprises a first turning device, a vertical swing drill arm and a first hydraulic telescopic cylinder, whereinthe first turning device is disposed on a material transfer conveyor through a mounting base, a first end of the vertical swing drill arm is hinged with a hinge support seat disposed on the first turning device, a second end of the vertical swing drill arm is connected with a drilling frame through a second turning device and a third turning device that are rotationally connected with each other.The tunneling and bolt supporting device is advantaged in that the bolt supporting device and the horizontal turning center of a cantilever type longitudinal axis cutting portion can be matched witha tunneling machine which slides laterally with respect to a chassis, or can be matched with a cantilever type horizontal axis tunneling machine, the advantage of no movement in the cutting process ofthe tunneling machine is fully utilized, parallel operation between rear supporting of the tunneling machine and cutting of the tunneling machine is achieved, an idling phenomenon of waiting of supporting workers in the cutting process of the tunneling machine is eliminated, and construction efficiency can be greatly improved.

Owner:日照市上普重型装备股份有限公司

Elevated work platform

InactiveUS20060016637A1Scaffold accessoriesBuilding support scaffoldsEngineeringMechanical engineering

An elevated work platform to support workers thereon comprising a plurality of support sections held in operative relationship relative to each other by a peripheral frame wherein each support section comprises a plurality of transverse support members held in spaced relationship relative to each other by a plurality of longitudinal members and the peripheral frame comprises a pair of side frame members each including a channel to receive opposite end portions of the transverse support members of each support section to hold the support sections in operative position relative to the other support sections.

Owner:IRVIN GRADY J

Excavation and supporting anchor machine

PendingCN110344863AAvoid problems such as broken or even collapsedQuality improvementTunnelsProps/chocksEngineeringUltimate tensile strength

The invention provides an excavation and supporting anchor machine which solves the problems of low excavating efficiency, low anchor pole supporting efficiency, low safety protection coefficient of anchor pole supporting workers, high labor intensity of personnel and the like of the prior art. The anchor machine is reasonable in structure and simple in installation and maintenance. Drilling anchor devices are arranged between left front and left rear walking parts and between right front and right rear walking parts. Each drilling anchor device has the functions of drilling a top plate and sides and mounting anchor poles on the top plate and the sides. The drilling anchor devices can cover all positions where the top plate and the sides need to be drilled and provided with the anchor poles. A gantry-type temporary supporting device can temporarily support the top plate just exposed after the excavation. The excavation and supporting anchor machine fully meets the requirements of coalmine roadway excavation and support, realizes the mechanized continuous operation of coal (rock) cutting, loading and transportation and anchor pole supporting of the top plate and the two sides in aroadway, and significantly improves the roadway excavation and supporting efficiency and the personnel safety protection coefficient.

Owner:欧玉金

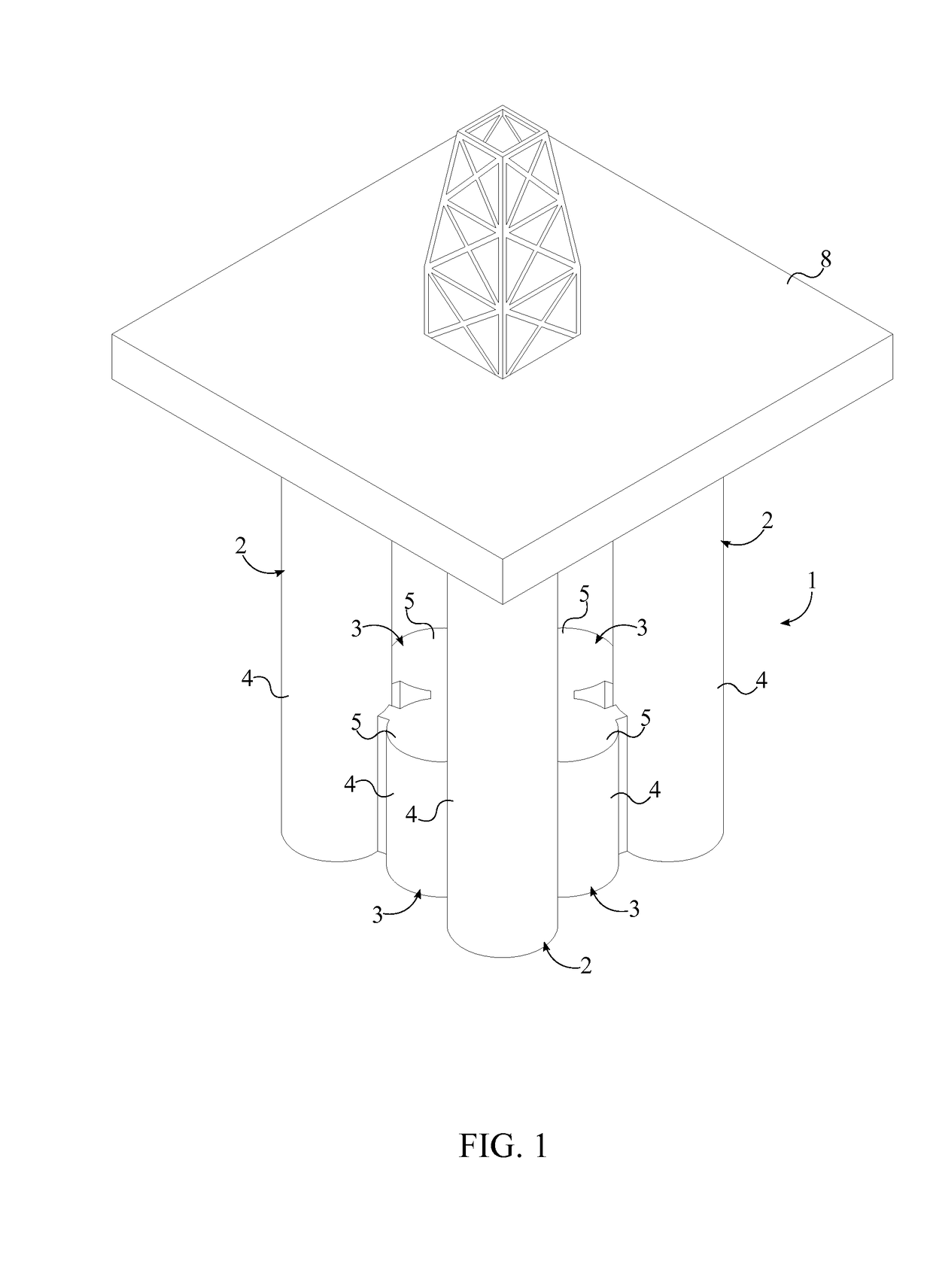

Multi-Column Tension Leg Platform

A multi-column tension leg platform is an offshore floating structure that is used to facilitate production of natural resources contained below the seabed. The multi-column tension leg platform includes a hull which is used to keep the entire structure afloat. The structure also includes a topside which is mounted to the top of the hull. The topside is used as a surface for supporting workers and equipment. The hull is made up of a plurality of flotation columns and a plurality of pontoons. Both the plurality of flotation columns and the plurality of pontoons are positioned about a vertical central axis of the topside. The plurality of flotation columns and the plurality of pontoons are buoyant structures that are aligned vertically and are used to keep the topside above water. The plurality of pontoons is mounted amongst the plurality of flotation columns.

Owner:TAHAR ARCANDRA

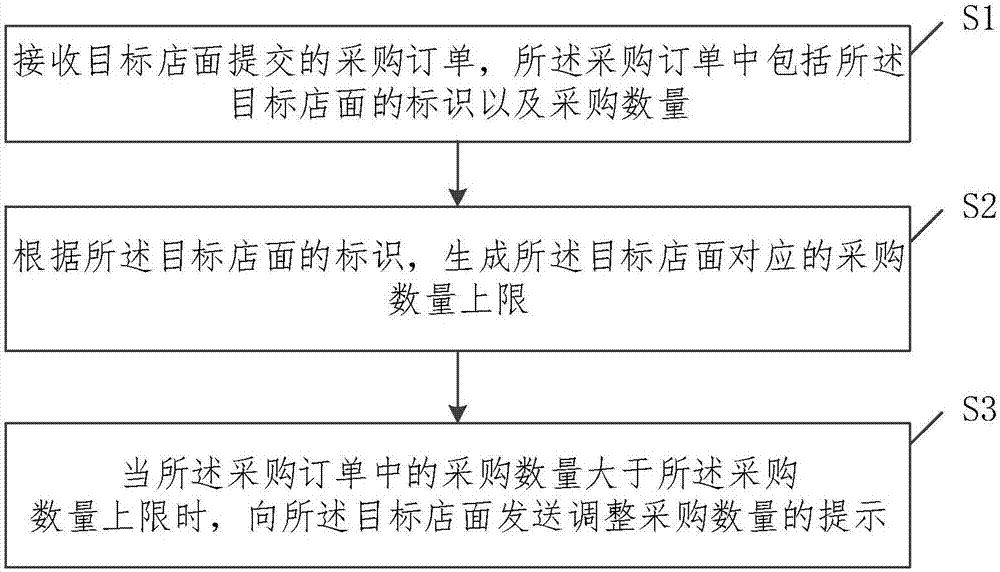

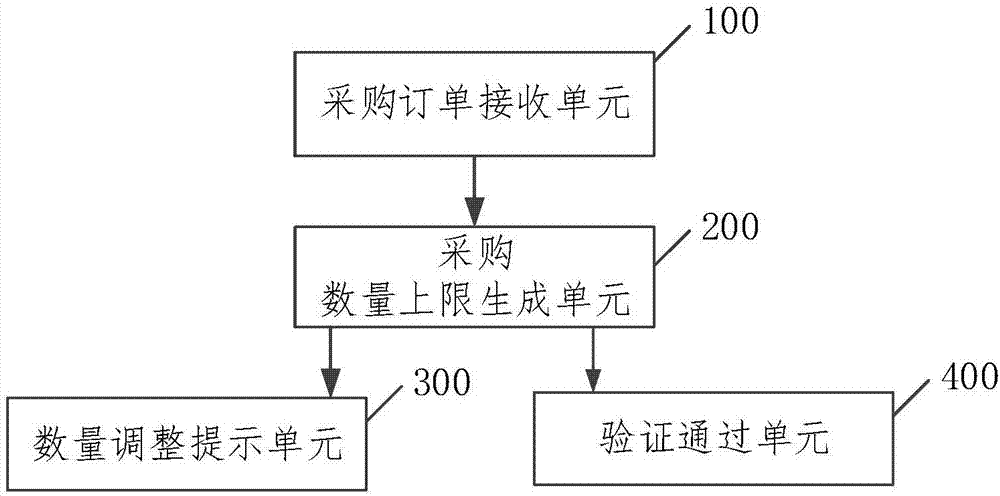

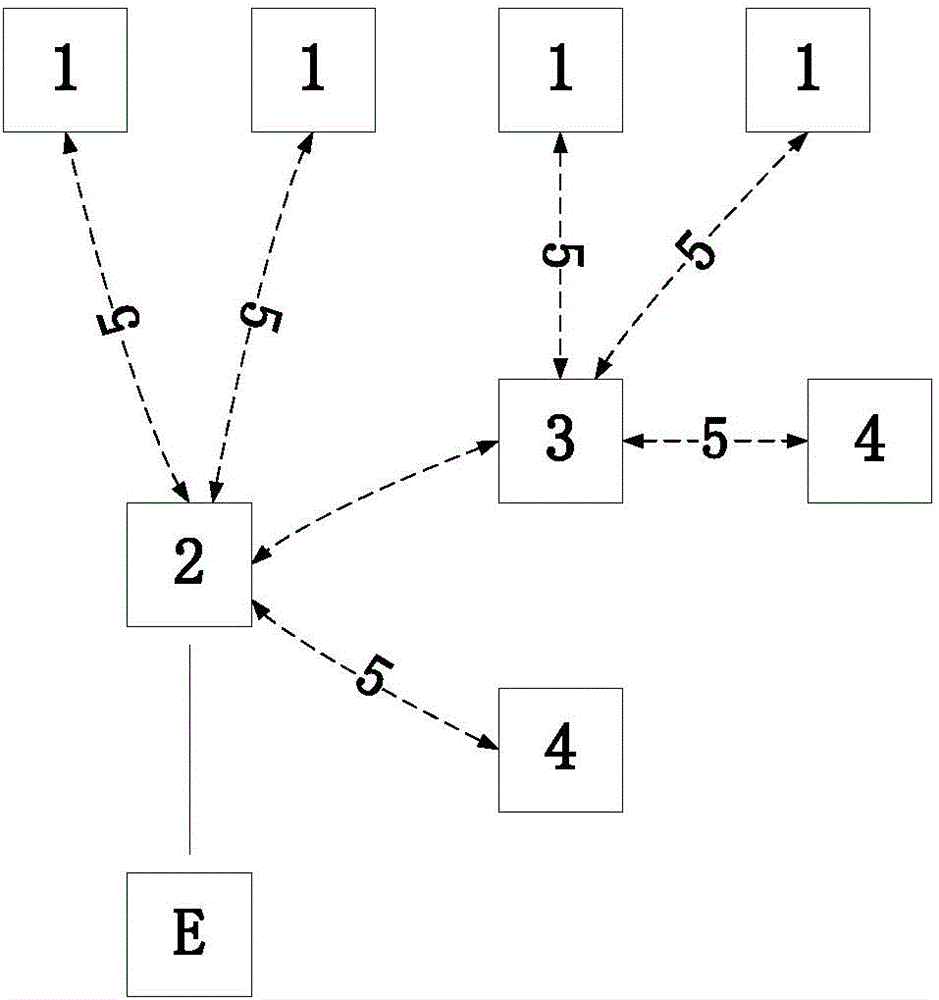

Purchase order control method and control system

InactiveCN106920148AImprove review efficiencyReduce workloadBuying/selling/leasing transactionsControl systemWorkload

The invention relates to a purchase order control method and control system. The method includes the following steps: receiving a purchase order transmitted by an object seller, wherein the purchase order includes a marker of the object seller and the number of purchase; on the basis of the marker of the object seller, generating an upper limit of the number of purchase corresponding to the object seller; and when the number of purchase in the purchase order is greater than the upper limit of the number of the purchase, transmitting an alert for adjusting the number of purchase to the object seller. According to the application, the control method and the control system can increase examination and approval efficiency of the purchase order so as to reduce the workload of support workers.

Owner:邹学峰 +2

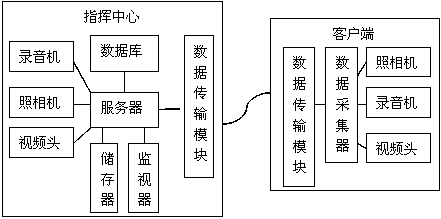

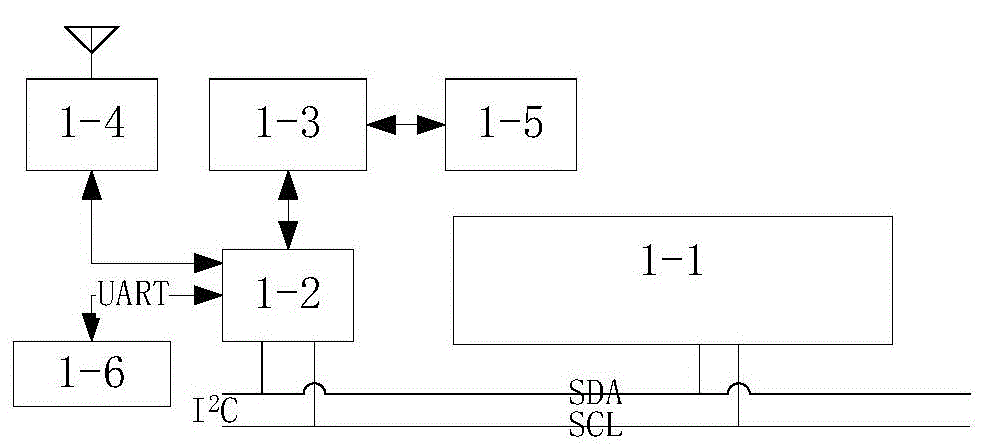

Intelligent multimedia interactive platform system for electric power fault emergency repair process

InactiveCN105512956AEffective interactionStrengthen the three-dimensional interaction of informationData processing applicationsRepair timeData acquisition

The invention relates to an intelligent multimedia interactive platform system for an electric power fault emergency repair process. The system comprises a command center and a client end. A server is arranged in the command center and connected with a database, a memory, a monitor, a recorder, a camera, a video head and a data transmission module. The client end is provided with a data collector which is connected with the camera, the video head and the data transmission module. According to the invention, timely effective interaction of information in the electric power fault emergency repair process is achieved; functions of production and emergency repair information collection, overall commanding and unified allocation are achieved; information stereo interaction between on-site emergency repair workers and center emergency repair support workers is reinforced; the emergency repair support workers of the command center are allowed to know on-site situations more conveniently, quickly and directly and provide quickest, most precise and most practical technical supports and assistance; emergency repair time of all kinds of faults is reduced; and fault emergency repair efficiency is increased.

Owner:QINGDAO XINYIFA IND & TRADE

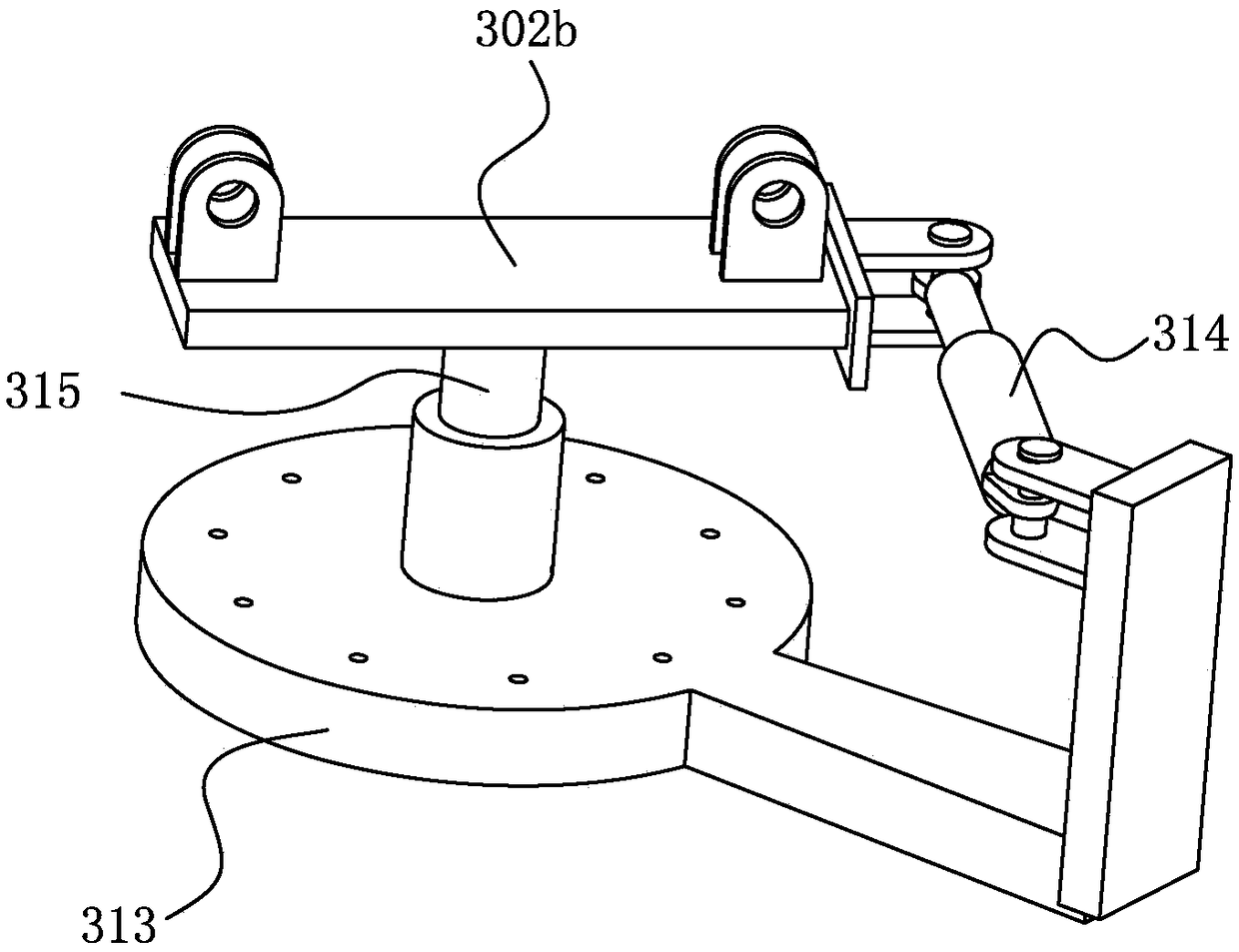

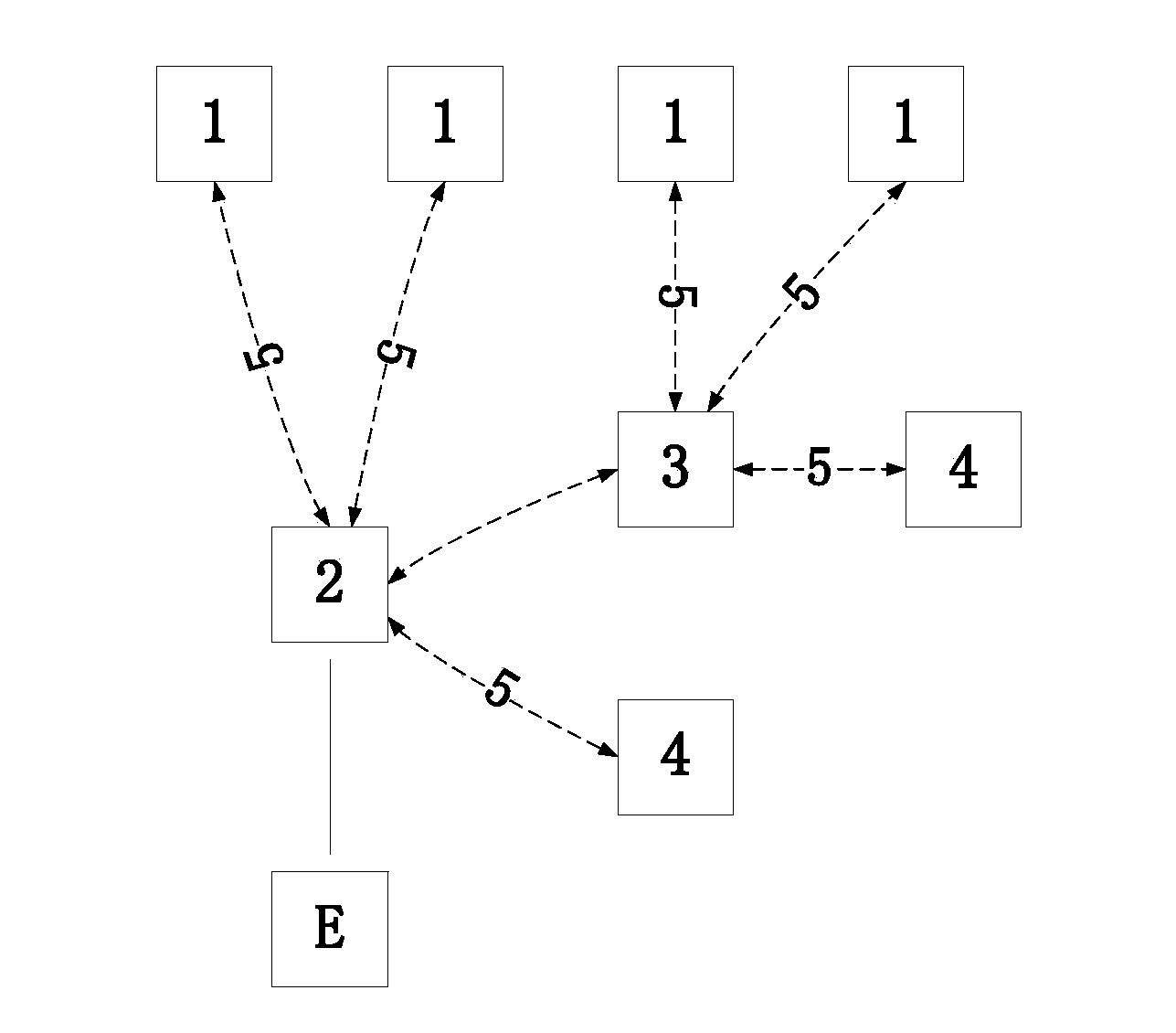

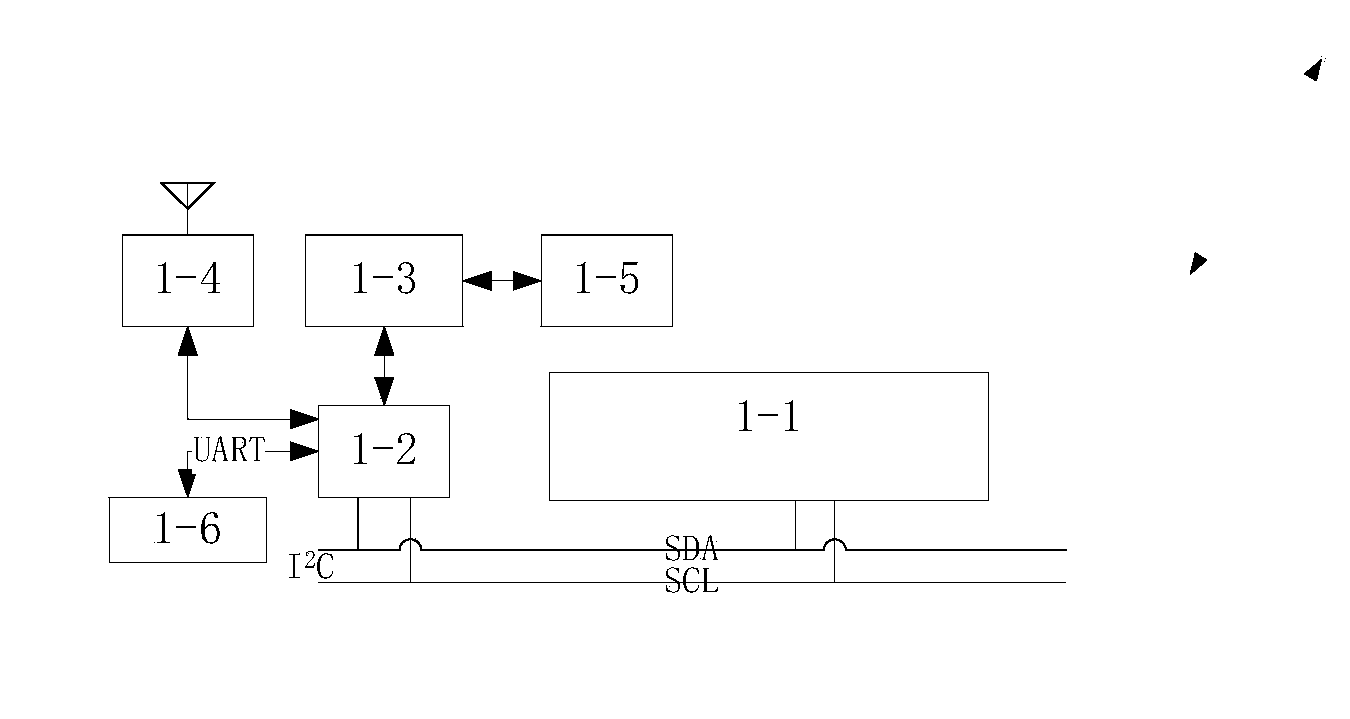

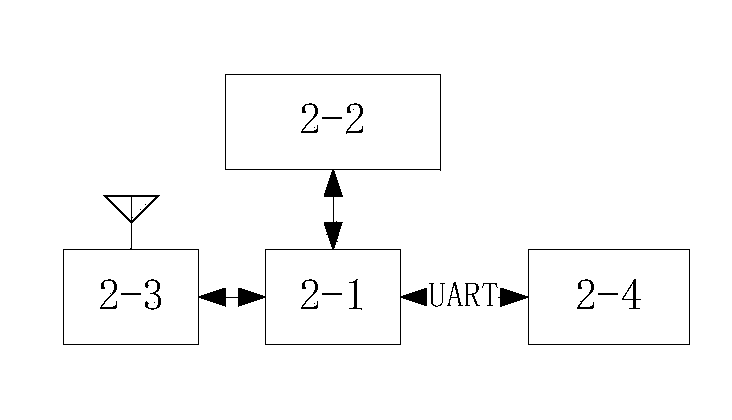

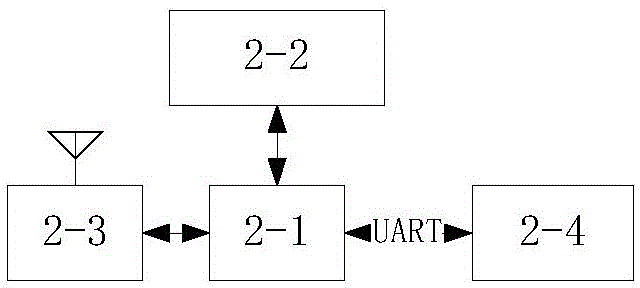

Wireless monitoring system for leveling of crane hoisting gesture

ActiveCN103723631AFast and dynamic self-access networkFast ad hoc networkLoad-engaging elementsControl systemMonitoring system

The invention discloses a wireless monitoring system for leveling of a crane hoisting gesture. The wireless monitoring system comprises a balance monitor and a master controller, wherein the balance monitor is arranged on a crane; the master controller is arranged outside a crane cab, and connected with a hoisting equipment control system through a communication bus; the balance monitor is used for collecting a balance angle value of the crane, calculating a balance angle calculating correction value according to the balance angle value of the crane, and conveying the balance angle calculating correction value to the master controller through a wireless network; the master controller is used for building a wireless network and conveying the balance angle calculating correction value to the hoisting equipment control system. An accurate, efficient and safe bran-new hoisting operation construction device is provided for multi-point balanced hoisting construction, the construction method of the device can be effectively improved, and the control on the hoisting operation difficulty and cost is achieved well; the wireless monitoring system is small in size, low in manufacturing cost, high in safety and reliability, and convenient to assemble and dismantle, and can be widely applicable to various balanced hoisting operations; the hoisting operation efficiency can be significantly improved, and the quantity of support workers and the workload are reduced.

Owner:武桥重科工程有限公司

Tension-Leg Platform Anchoring System

Owner:TAHAR ARCANDRA

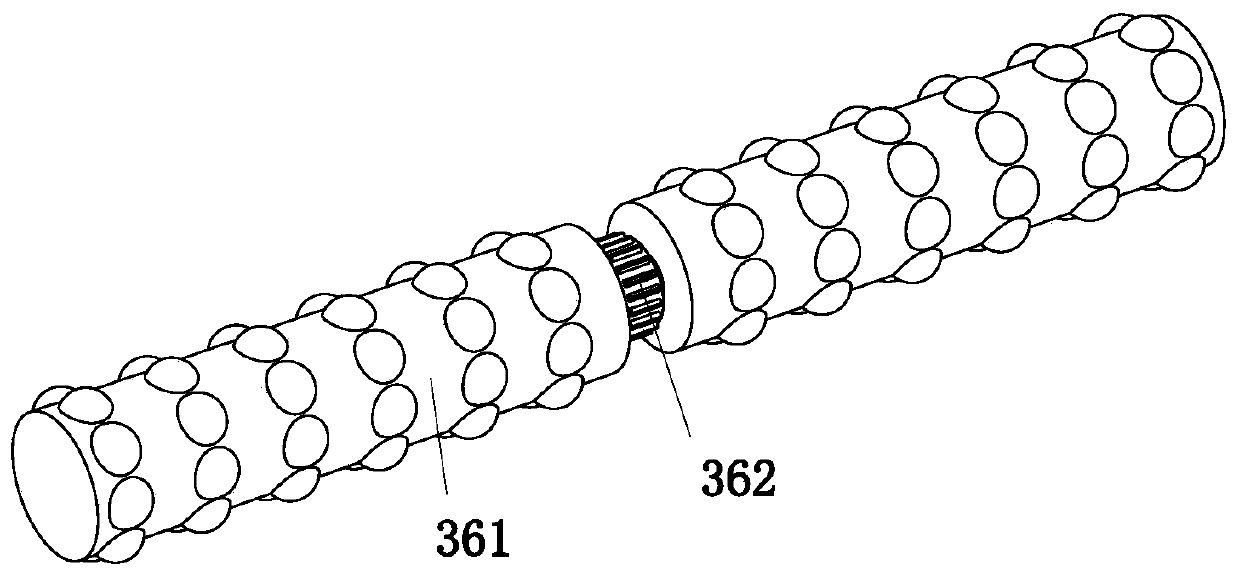

Lying type leg exercise apparatus and method

ActiveCN110772396AImprove comfortSave energyChiropractic devicesRoller massagePhysical medicine and rehabilitationLeg exercise

The invention relates to a lying type leg exercise apparatus and a method. The lying type leg exercise apparatus comprises a bed body, a footrest unit, a backrest unit and a linkage unit. The footrestunit is arranged at the left end of the bed body, the linkage unit is arranged in the middle of the bed body, and the backrest unit is arranged at the right end of the bed body. The problems that nursing staff needs to greatly spend effort when assisting people to make each group of bridge-style movement, especially after multiple sets are completed, when the people are assisted to exercise again, the standardability of people movement is difficult to ensure due to the greater energy consumption of the nursing staff, and in the whole process of assisting, physical pain of the people is proneto being caused due to the failure of the nursing staff to control the intensity are solved.

Owner:HARBIN UNIV

Systems and methods for data gathering without internet

ActiveUS9380034B2Memory architecture accessing/allocationKey distribution for secure communicationThe InternetRemovable media

Systems and methods are provided in which external key devices are used for sealing and unsealing data-gathering devices without Internet, wherein the data-gathering devices invalidate the external key devices upon completing data collection in order to seal removable storage. Further, a sealed removable storage is transported to same location of a key server, where the key server uses a multi-factor sealing routine to unlock the sealed removable storage. The routine seals and unseals uses multiple factors including a location of the key server, hardware attributes of the removable storage, hardware attributes of the external key devices, and a private key of the key server. The data-gathering device may be used to support workers collecting data in disconnected parts in the world that are without Internet. The workers may collect data by using mobile devices to transfer data to a shared data-gathering device.

Owner:WONG SZE YUEN +1

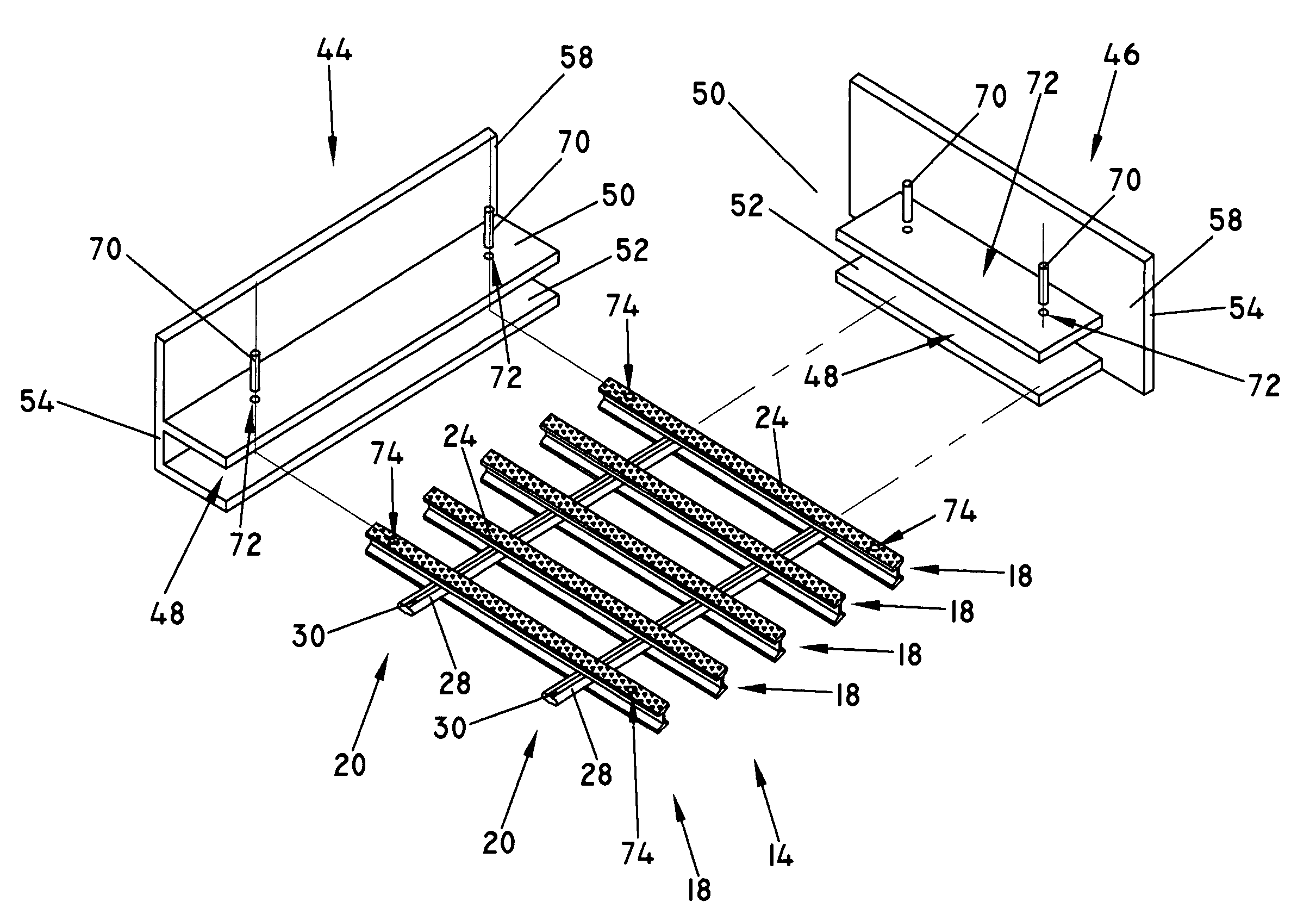

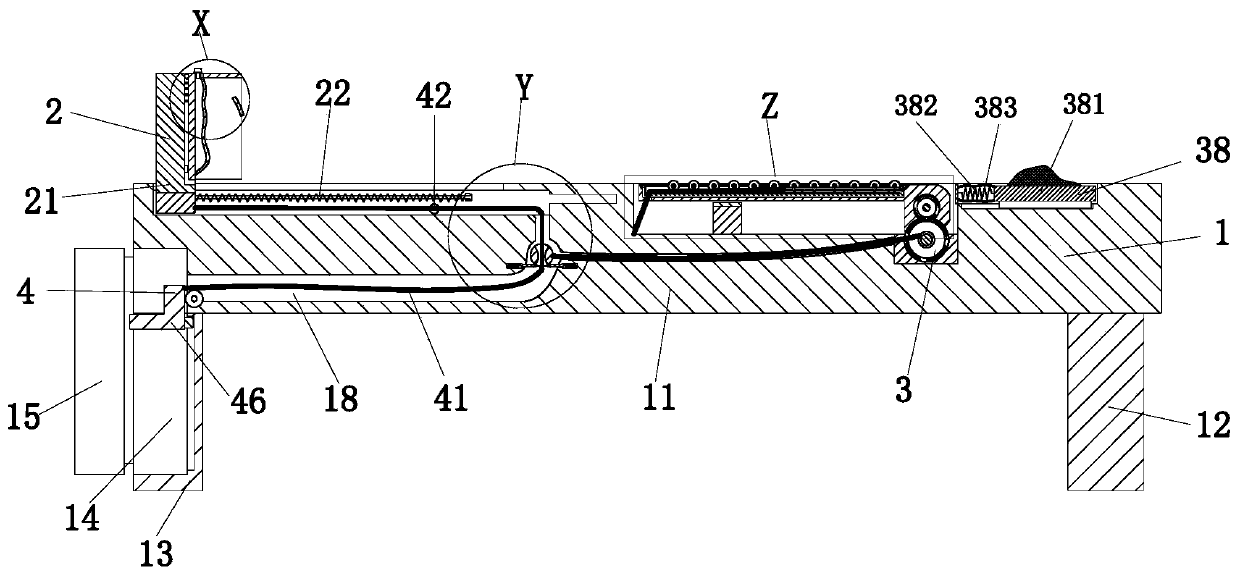

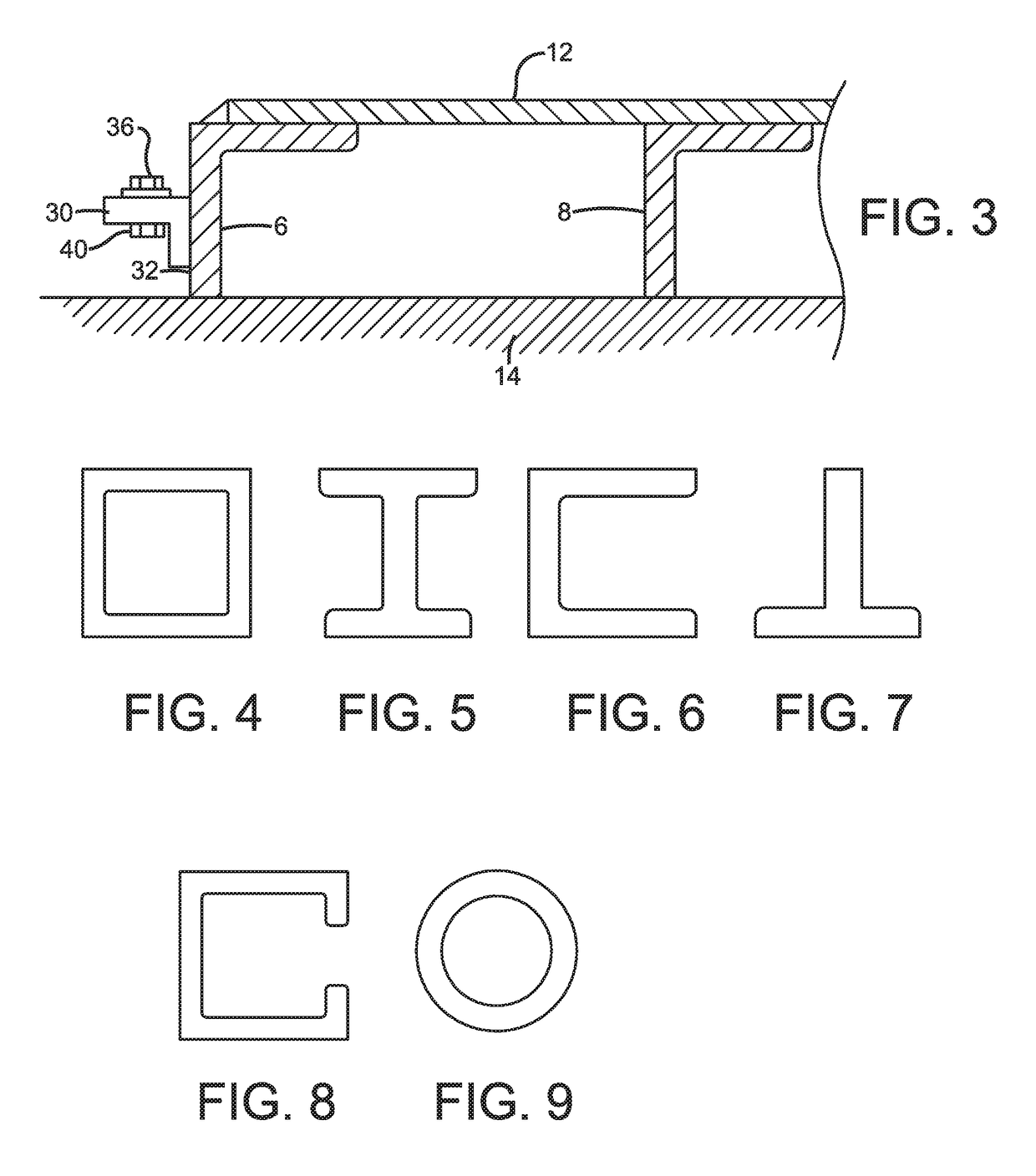

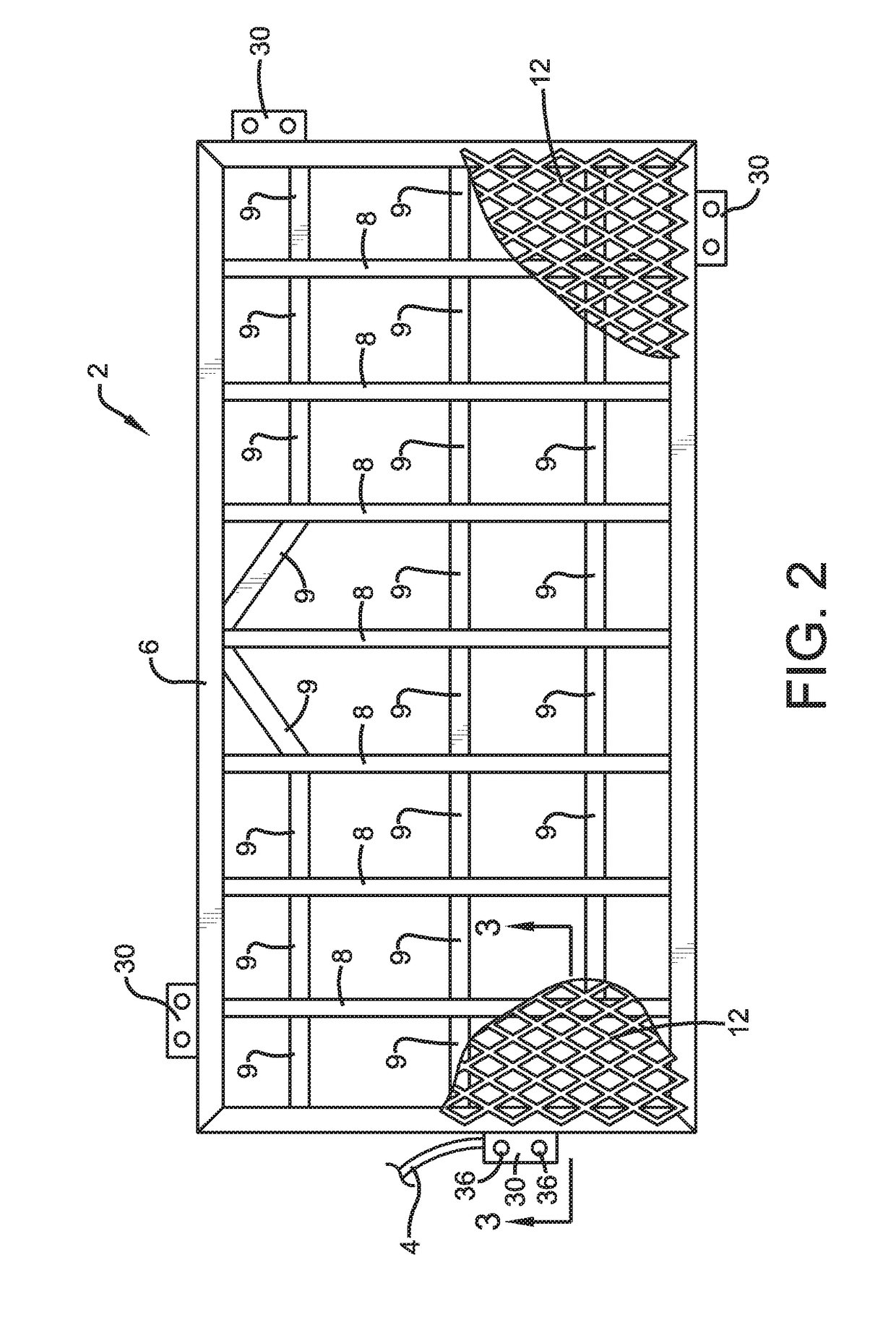

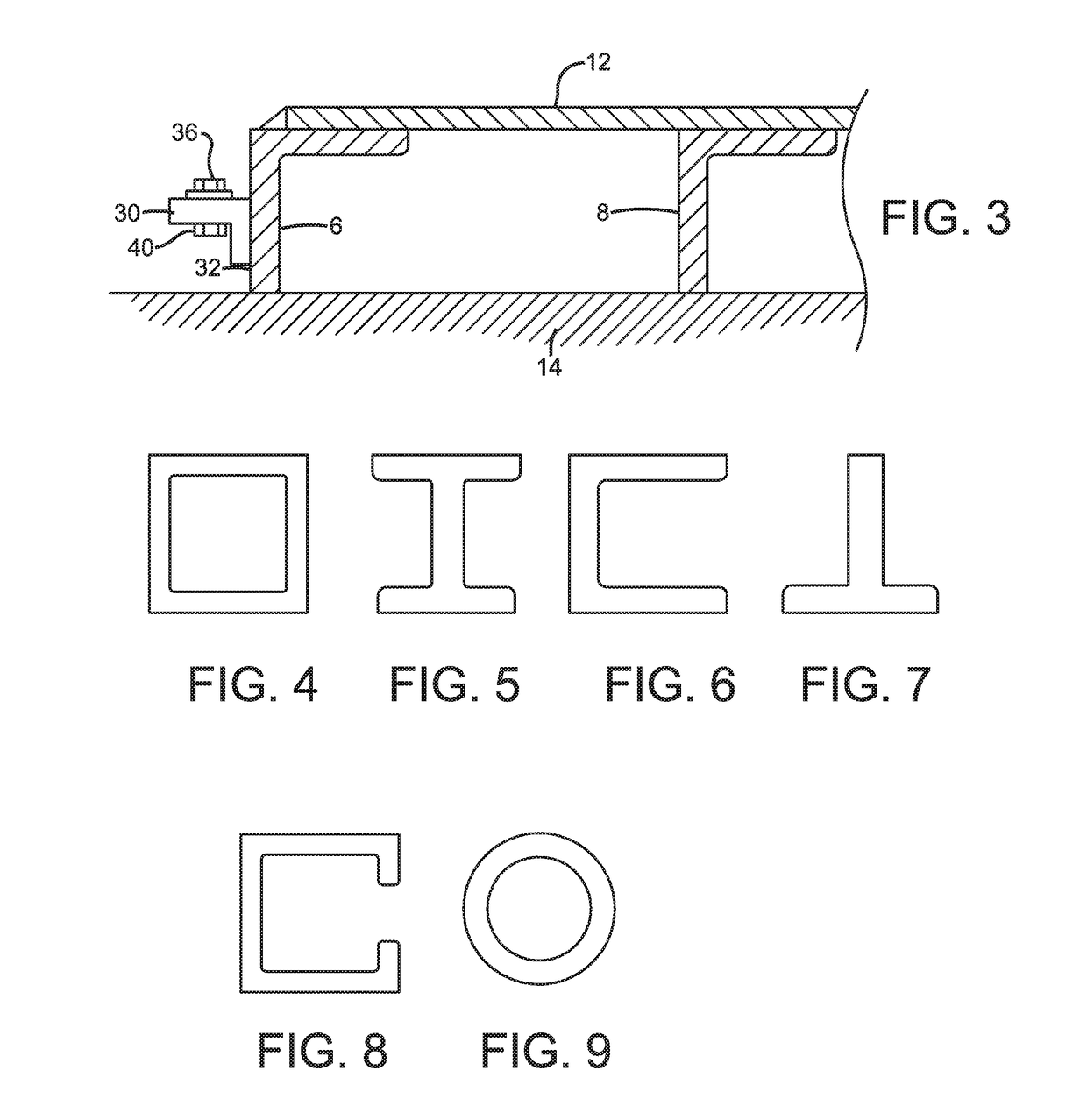

Equipotential grounding grate

ActiveUS10181681B1Great tractionLimited amountSingle unit pavingsTemporary pavingsElectricitySupport worker

Self-supporting equipotential grounding grates are used to create an equipotential zone for workers and equipment. The grates have a plurality of supports that cooperate to position the upper surface of a conductive grid above the surface on which the grates are used. The inner supports include upper and lower structural grids that allow debris to be readily removed from the grate after use. The grate supports workers and equipment. A plurality of the grates are electrically connected with cables to define a platform with the entire structure grounded with one or more grounding pins.

Owner:KLEIN PARENT LLC

Tension-leg platform anchoring system

A tension-leg platform anchoring system is used to tether the columns of a floating platform to the seabed and restrict movement of the entire platform. The tension-leg platform anchoring system includes a topside and a plurality of anchored floating supports. The topside provides a deck for supporting workers and equipment. The anchored floating supports are used to keep the topside afloat and limit movement. The anchored floating support includes a column, at least one mooring assembly, and an anchor. The column is connected to the topside and is used to keep the tension-leg platform afloat. The mooring assembly includes a column coupler, a first tendon, and an anchor coupler, which are used together to tether the column to the anchor. The column coupler is tethered to the anchor coupler through the first tendon, which is connected to the column by the column coupler.

Owner:TAHAR ARCANDRA

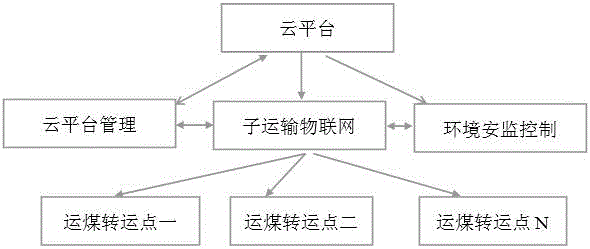

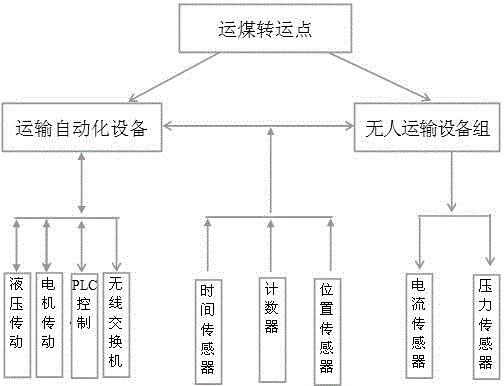

Down-hole coal seam movement system for coal mine

ActiveCN106593522ARealize the interaction of remote operation managementReduce labor management costsMining devicesUnderground transportEngineeringMovement system

The invention provides a down-hole coal seam movement system for a coal mine and relates to a coal mine conveying system. The down-hole coal seam movement system for the coal mine comprises a cloud platform, cloud platform management, subsidiary conveying internet of things, environment safety supervision control and coal conveying transshipment points. Each coal conveying transshipment point comprises a conveying automatic device and an unmanned conveying device. Unmanned conveying vehicles are remotely operated by management staff of the cloud platform, and the unmanned conveying devices march on the surfaces with certain flatness, so that marching of the unmanned conveying vehicles and driving of coal conveying are achieved. Connecting devices are tools of unmanned conveying vehicle intellectualization and being automatically connected with other devices. According to the down-hole coal seam movement system for the coal mine, through the unmanned conveying vehicles, existing down-hole operating staff such as scrapping plate reversed loader and working face scrapping plate conveyor drivers, adhesive tape conveyor drivers, hydraulic support workers and coal mine end workers do not need to be adopted, so that safe production of coal mine down-hole conveying operation is achieved, down-hole unmanned coal conveying operation is achieved, and work safety accidents of the staff are avoided.

Owner:TAISHAN MEDICAL UNIV

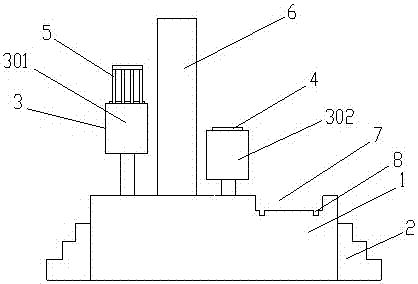

Inductive adjustable-height standing working platform

The invention discloses an inductive height-adjustable standing workbench, which includes a standworkbench body, two ends of the standworkbench body are provided with step-up platforms, and multi-level steps are arranged on the step-up platform. The standing workbench There are two standing sub-platforms on the upper end of the platform body, pressure sensor devices are arranged on the upper end of the first and second standing sub-platforms, and the bottom ends of the first standing sub-platform and the second standing sub-platform All are equipped with a hydraulic lifting mechanism, the pressure sensor device is connected with the hydraulic lifting mechanism, a tool cabinet is erected between the first standing sub-table and the second standing sub-table, and the upper end surface of the standing workbench body One end is also recessed and provided with a scaffold fixing groove. Through the above method, the present invention can be used as a work standing platform to support the staff to complete the work, and the standing workbench body has a first standing sub-platform and a second standing sub-platform to be selected according to the work requirements of different heights.

Owner:WUXI TAISHUN FLOCKING MACHINERY FACTORY

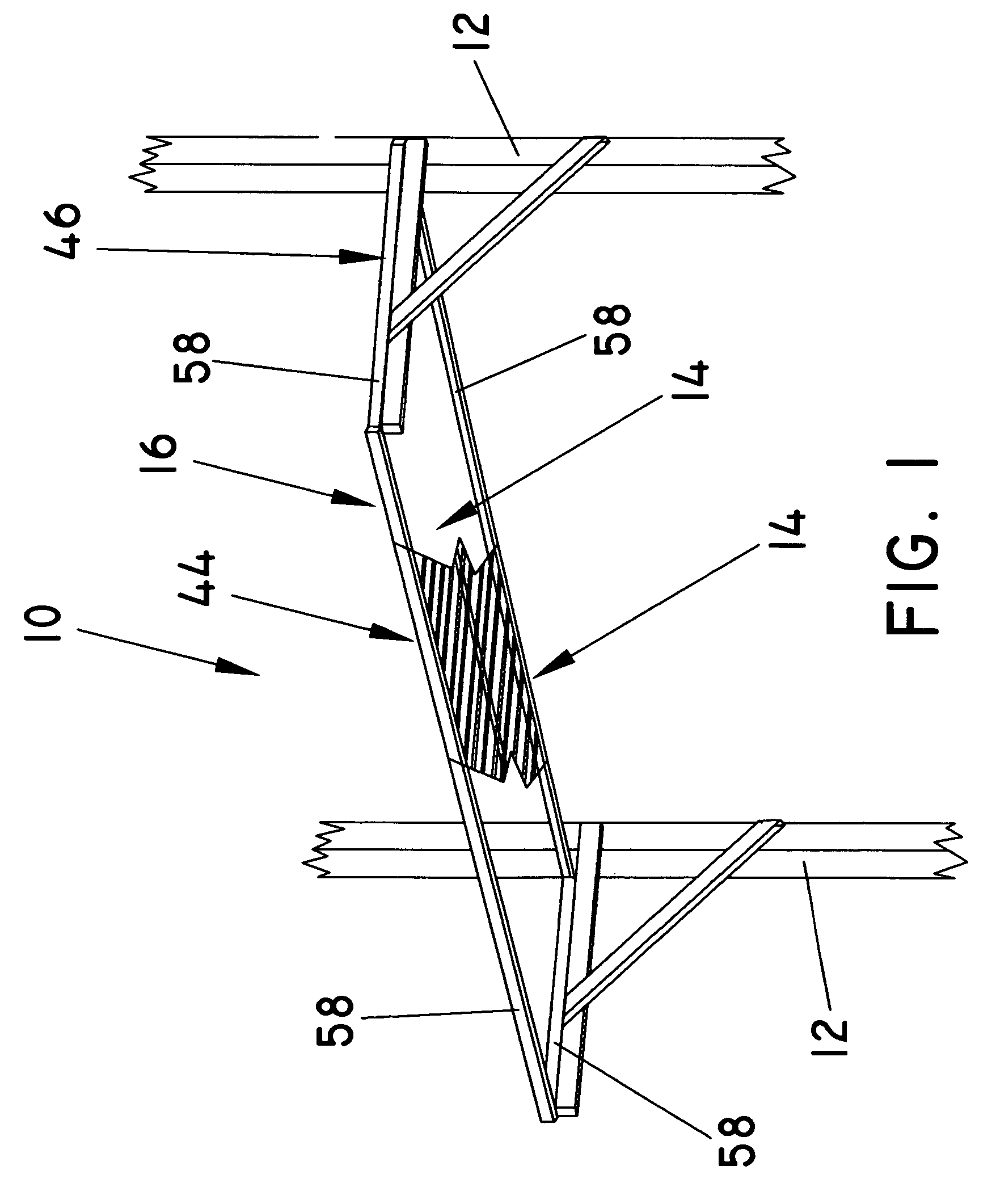

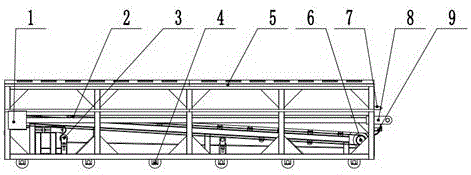

Machine especially for harvesting leaf vegetables

InactiveUS20080083208A1Easy accessSimplify the harvesting processHarvestersSolid materialGreenhouseMechanical engineering

The invention concerns a machine for harvesting and boxing leaf vegetables cultivated in greenhouses, which comprises a main frame holding a front cutting bar, means for transferring the product longitudinally from the cutting bar towards the rear in boxes to be filled, and a platform supporting workers and a number of benches of boxes. At the rear of the machine at least one transporter (23) is provided positioned transversally to the forward direction, designed to receive the product from the longitudinal transfer means and to deposit it in the boxes. One group (30) that comprises the front cutting bar (20), the means for collecting and transferring (21,22) the product towards the rear and at least one rear transverse transporter (23) moves on the main frame (11) crossways to the forward direction of the machine and which can be moved between a central position and a protruding lateral position from at least one side relative to the main frame

Owner:MOLA ENRICO

Equipotential grounding grate

ActiveUS20180375260A1Great tractionLimited amountTemporary pavingsCoupling protective earth/shielding arrangementsSupport workerMesh grid

Self-supporting equipotential grounding grates are used to create an equipotential zone for workers and equipment. The grates have a plurality of supports that cooperate to position the upper surface of a conductive grid above the surface on which the grates are used. The inner supports include upper and lower structural grids that allow debris to be readily removed from the grate after use. The grate supports workers and equipment. A plurality of the grates are electrically connected with cables to define a platform with the entire structure grounded with one or more grounding pins.

Owner:KLEIN PARENT LLC

Wireless monitoring system for hoisting, attitude and leveling of hanging parts

ActiveCN103723631BFast and dynamic self-access networkExpress routeTransmission systemsLoad-engaging elementsControl systemMonitoring system

The invention discloses a wireless monitoring system for leveling of a crane hoisting gesture. The wireless monitoring system comprises a balance monitor and a master controller, wherein the balance monitor is arranged on a crane; the master controller is arranged outside a crane cab, and connected with a hoisting equipment control system through a communication bus; the balance monitor is used for collecting a balance angle value of the crane, calculating a balance angle calculating correction value according to the balance angle value of the crane, and conveying the balance angle calculating correction value to the master controller through a wireless network; the master controller is used for building a wireless network and conveying the balance angle calculating correction value to the hoisting equipment control system. An accurate, efficient and safe bran-new hoisting operation construction device is provided for multi-point balanced hoisting construction, the construction method of the device can be effectively improved, and the control on the hoisting operation difficulty and cost is achieved well; the wireless monitoring system is small in size, low in manufacturing cost, high in safety and reliability, and convenient to assemble and dismantle, and can be widely applicable to various balanced hoisting operations; the hoisting operation efficiency can be significantly improved, and the quantity of support workers and the workload are reduced.

Owner:武桥重科工程有限公司

Mason's adjustable chimney-platform arrangement

An adjustable platform assembly for supporting workers and supplies about an elevated work site, the platform assembly being movably supported on an articulable support, the platform comprising a stationary rear bridging panel arrangement having an elongated side platform member comprising a floor and railing assembly at each end thereof, wherein each elongated side platform member floor and railing assembly is independently movable on support members forwardly, rearwardly, transversely and angularly with respect to the bridging panel arrangement, to change the platform assembly back and forth between a generally “H” shape to a generally “U” shape, or any skewed combination thereof, as required.

Owner:LOMBARDI DONALD F

Mason's adjustable chimney-platform arrangement

An adjustable platform assembly for supporting workers and supplies about an elevated work site, the platform assembly being movably supported on an articulable support, the platform comprising a stationary rear bridging panel arrangement having an elongated side platform member comprising a floor and railing assembly at each end thereof, wherein each elongated side platform member floor and railing assembly is independently movable on support members forwardly, rearwardly, transversely and angularly with respect to the bridging panel arrangement, to change the platform assembly back and forth between a generally “H” shape to a generally “U” shape, or any skewed combination thereof, as required.

Owner:LOMBARDI DONALD F

Multi-column tension leg platform

A multi-column tension leg platform is an offshore floating structure that is used to facilitate production of natural resources contained below the seabed. The multi-column tension leg platform includes a hull which is used to keep the entire structure afloat. The structure also includes a topside which is mounted to the top of the hull. The topside is used as a surface for supporting workers and equipment. The hull is made up of a plurality of flotation columns and a plurality of pontoons. Both the plurality of flotation columns and the plurality of pontoons are positioned about a vertical central axis of the topside. The plurality of flotation columns and the plurality of pontoons are buoyant structures that are aligned vertically and are used to keep the topside above water. The plurality of pontoons is mounted amongst the plurality of flotation columns.

Owner:TAHAR ARCANDRA

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com