Tunneling and bolt supporting device

A technology of equipment and roadheader, which is applied in mining equipment, bolt installation, earthwork drilling and mining, etc. It can solve the problems of not being able to install roof bolts, restricting the installation position of bolting machines, limiting the number of bolting machines and operating range, etc. Achieve the effects of improving construction speed and labor production efficiency, preventing roof separation and sinking, and eliminating the phenomenon of waiting for idle work

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] The technical solution of the present invention will be described in detail below in conjunction with the accompanying drawings and specific embodiments to further understand the purpose, solution and effect of the present invention, but it is not intended to limit the scope of protection of the appended claims of the present invention.

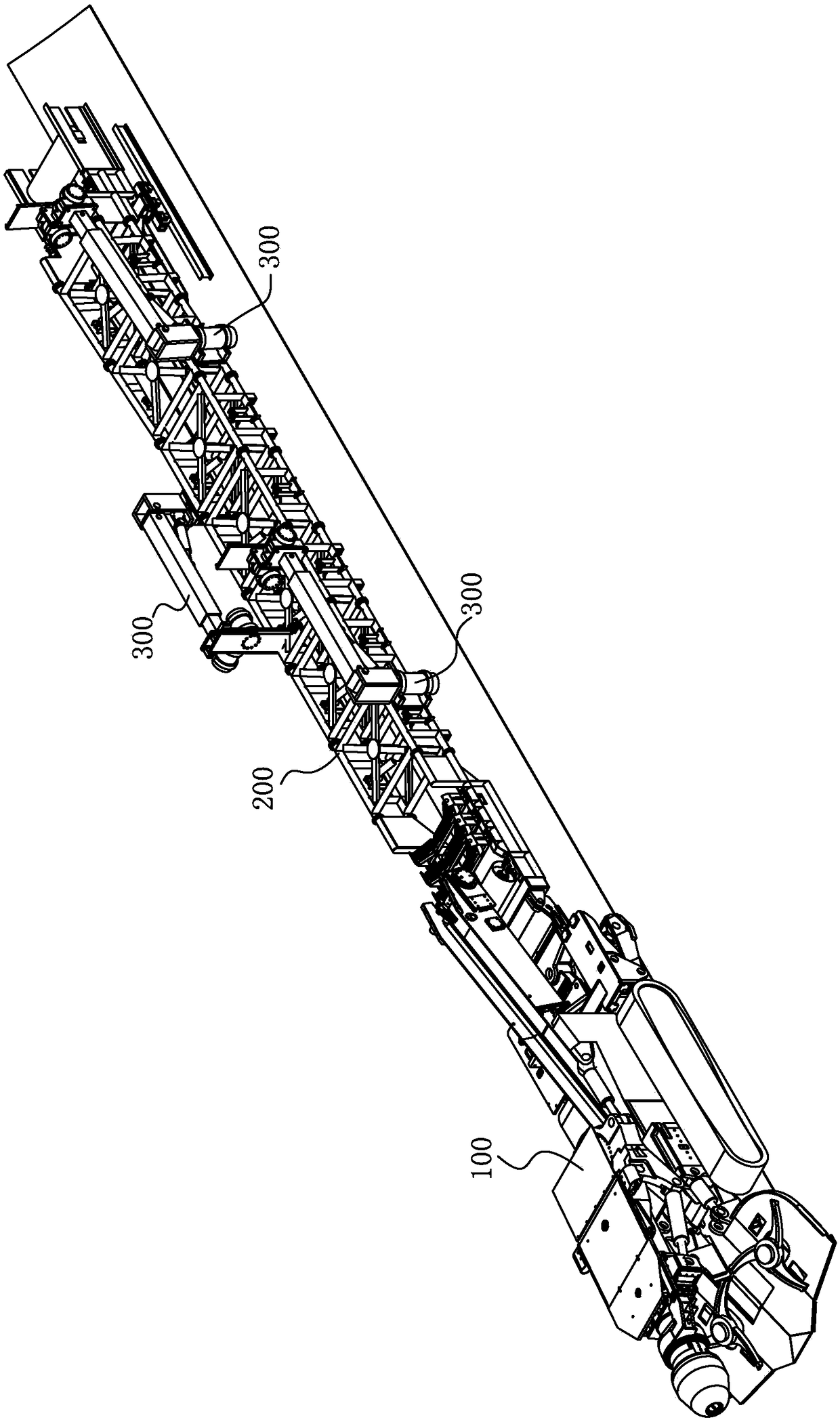

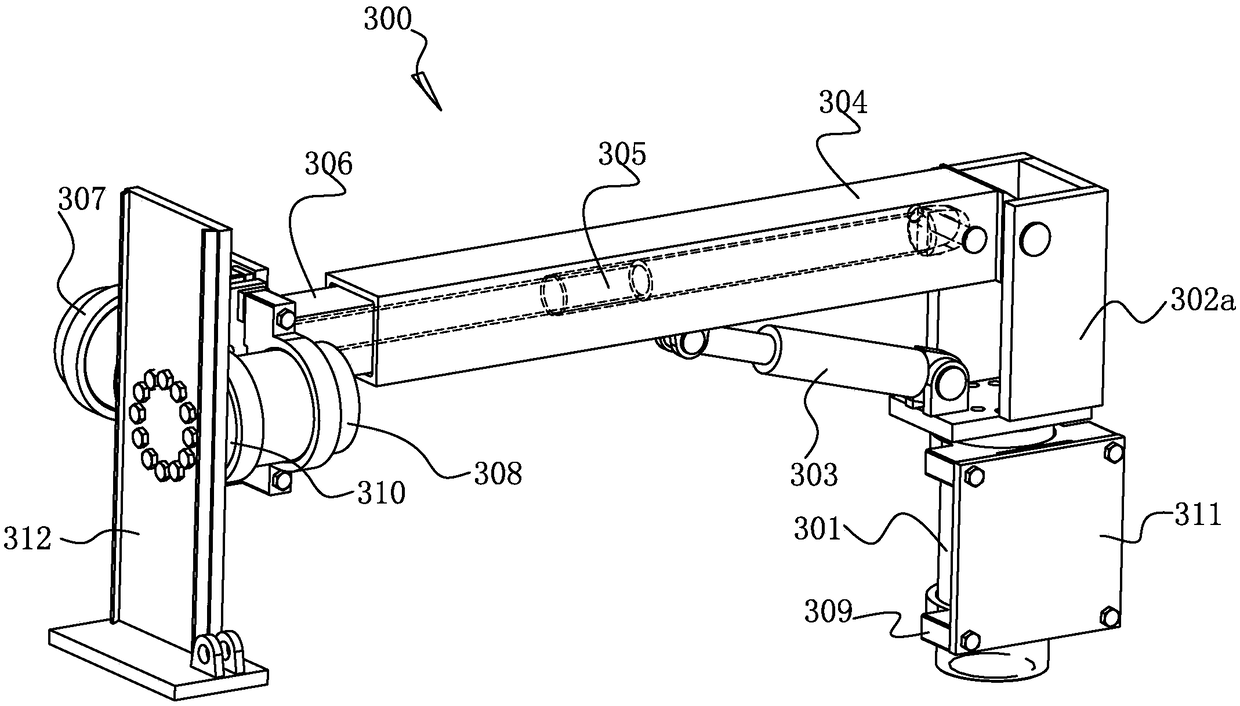

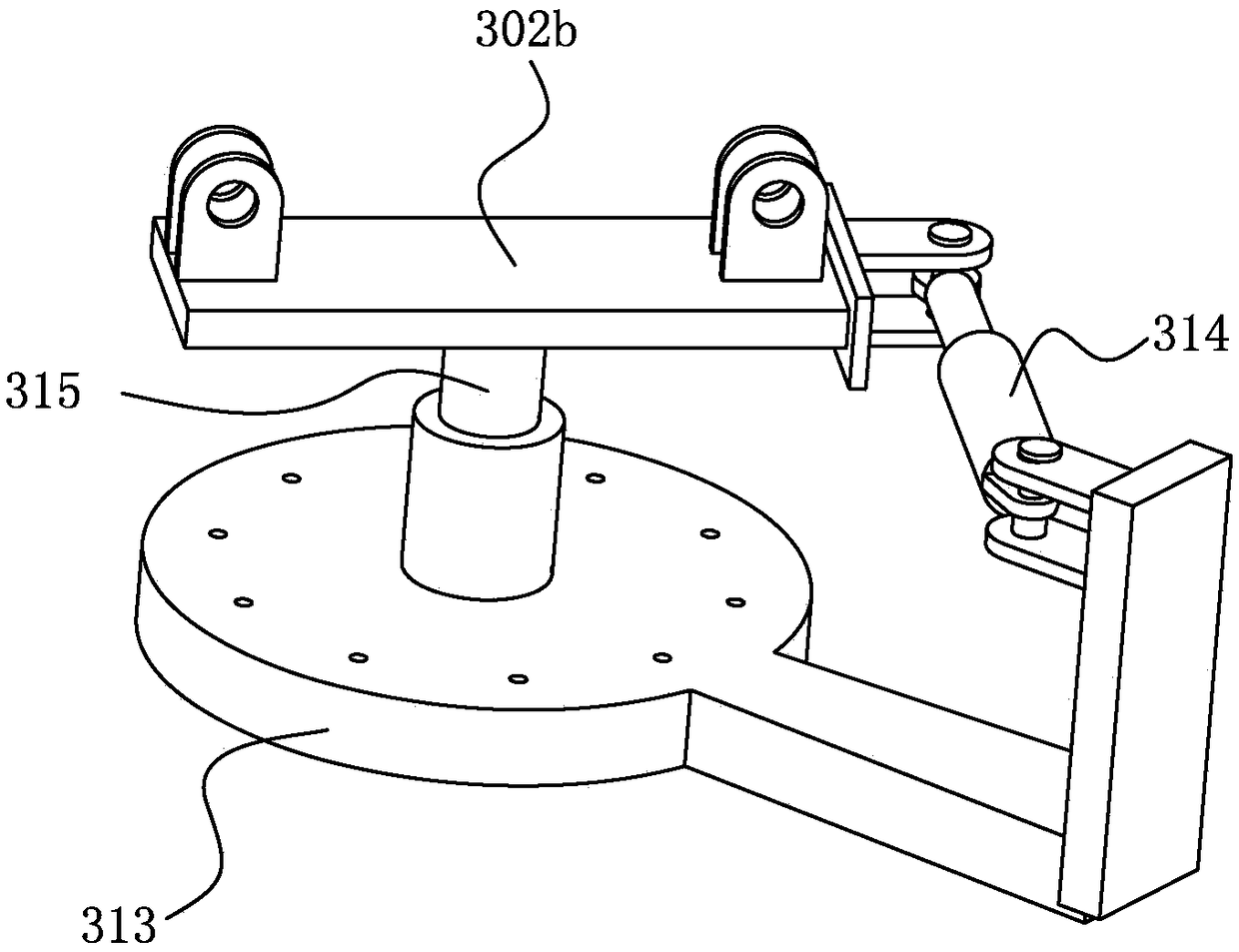

[0023] Such as figure 1 As shown, a kind of bolt digging equipment includes a roadheader 100, a material transfer conveyor 200 and a bolt support device 300. The roadheader 100 is provided with a chassis and a cantilever cutting part, and the chassis includes a frame body and double crawlers The frame body is connected to the double-crawler walking part; the material transfer conveyor 200 is arranged behind the roadheader 100 and is movably connected with the roadheader 100, and the material transfer conveyor 200 is commonly called the second conveyor. As we all know, the cantilever cutting part refers to the cutting part of the roadhe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com