Excavation and supporting anchor machine

A windlass and main body technology, which is applied in the installation of bolts, mining equipment, earthwork drilling and mining, etc., can solve the problems of low safety factor in the work site of support personnel, increase the load of the cutting part, and high labor intensity of personnel, etc., to achieve The effect of improving quality and construction efficiency, improving construction quality and efficiency, and reducing labor intensity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

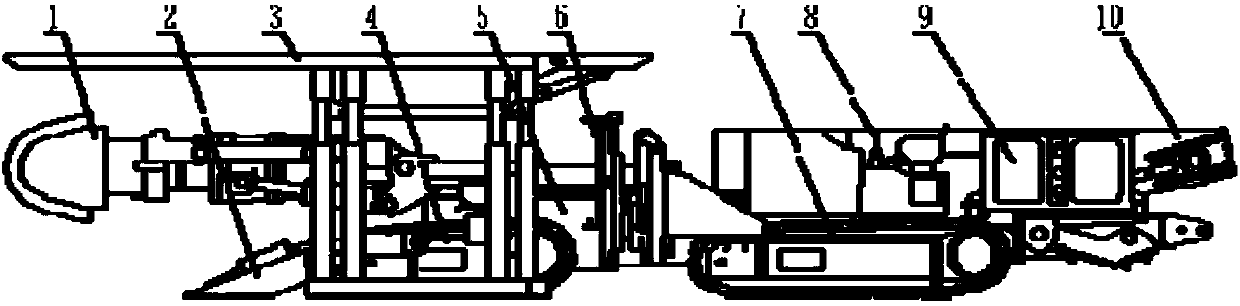

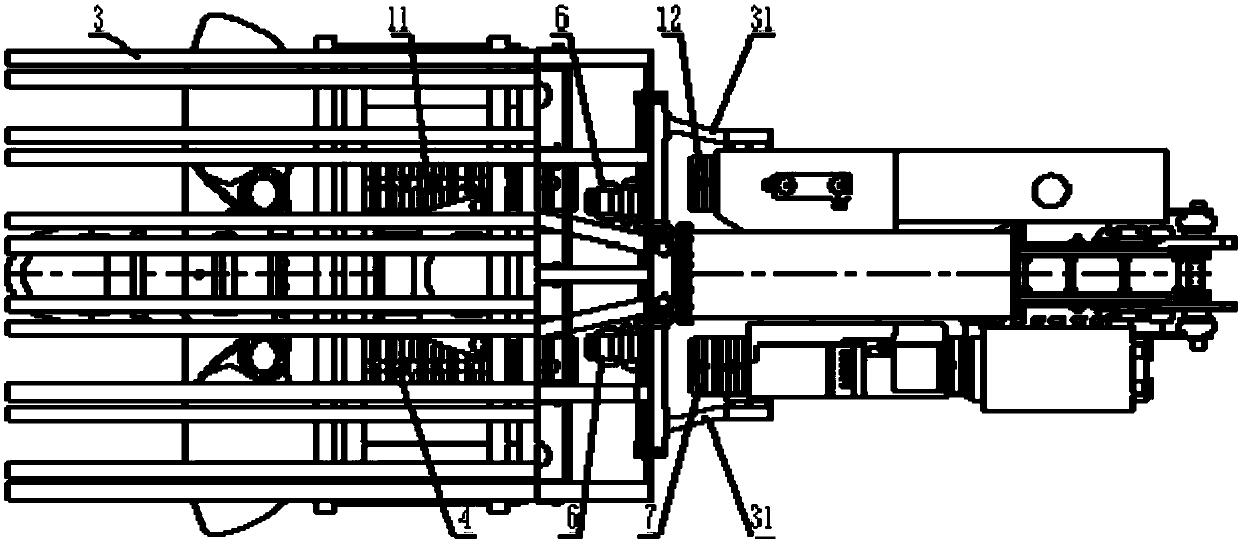

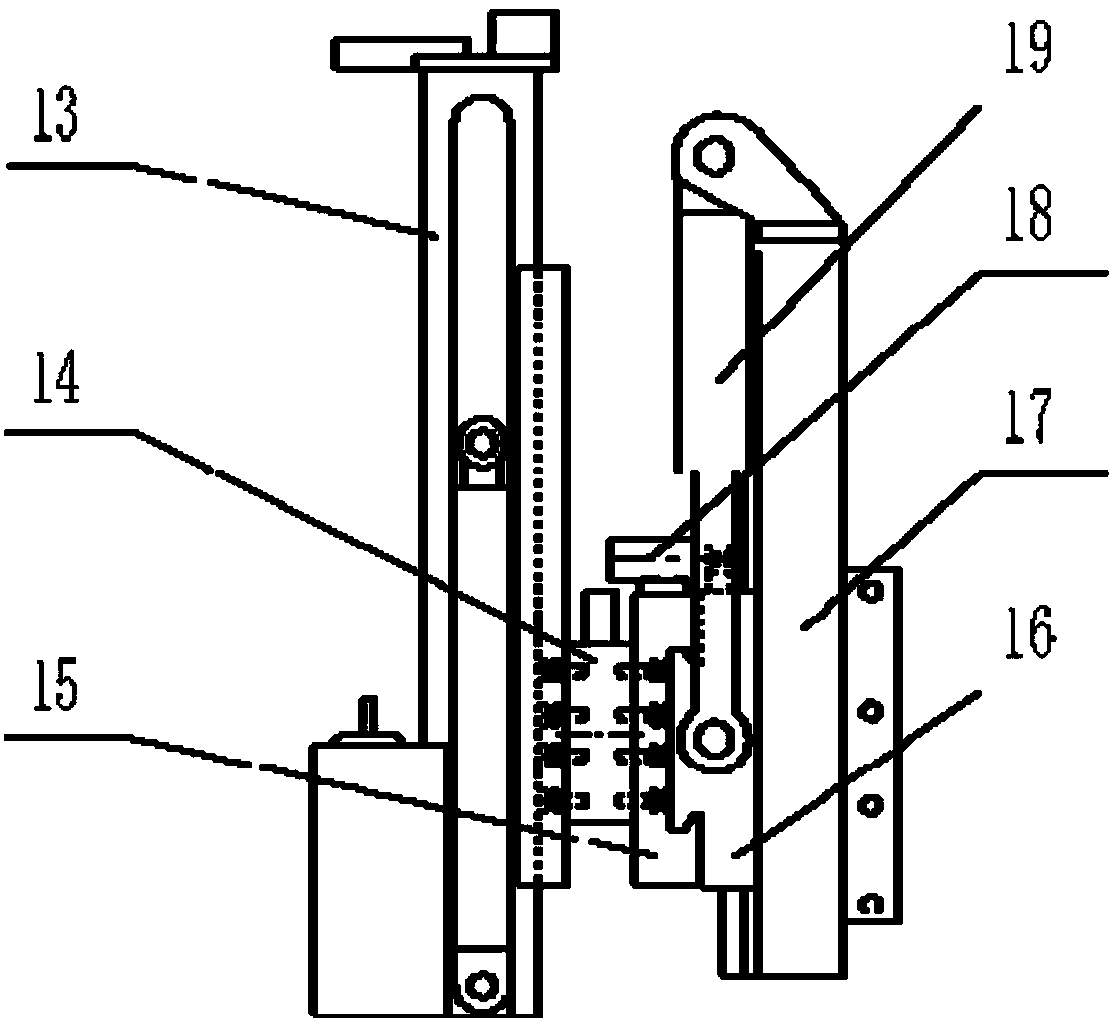

[0019] Attached below Figure 1-7 The present invention is further described.

[0020] Such as Figure 1~2 As shown, the present invention provides a bolter digger comprising a cutting part 1 hinged at the front end of the body part 5, a left front running part 4, a left rear running part 7, a right front running part 11, and a right rear running part 12 mounted on the body part 5 on both sides, the shovel part 2 is hinged with the front end of the body part 5 under the cutting part 1, and the drill and anchor device 6 is respectively installed between the left front running part 4 and the left rear running part 7 and between the right front running part 11 and the right rear running part 12 and connected with the body part 5, the support frame 31 is connected with the slide rail frame 17 and connected with the left rear and right rear walking parts respectively, the transportation part 10 is installed on the body part 5, and the gantry type temporary support device 3 base is...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com