Down-hole coal seam movement system for coal mine

A technology for coal mines and coal seams, which is applied in the field of coal seam transfer systems in coal mines, can solve the problems of inability to realize coal mine transfer transportation and unmanned transfer, and achieve the effects of eliminating personnel safety production accidents and saving labor management costs.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

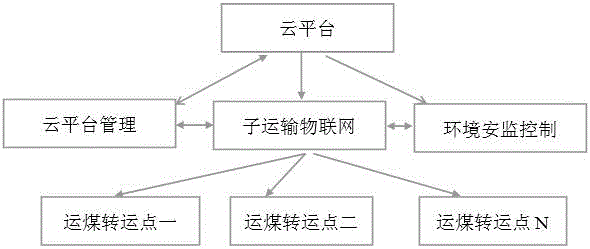

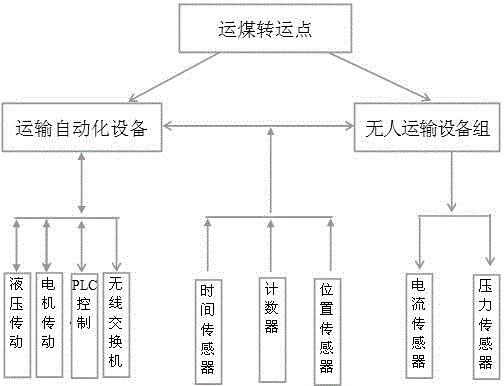

[0033] The cloud computing platform for underground unmanned transportation equipment and its safe production is mainly divided into: figure 1 The management personnel of the cloud platform shown are based on the environmental safety monitoring status and the feedback information of each sub-transportation IoT LAN. The environmental safety monitoring status is composed of methane sensor, carbon monoxide sensor, carbon dioxide sensor, oxygen concentration sensor, water level sensor, fire sensor, wind speed sensor, wind pressure Sensors, temperature sensors, humidity sensors and smoke sensors, pressure sensors, wind speed sensors and other sensors integrate feedback information. The platform management personnel regard each coal transportation transshipment point as the sub-transportation Internet of Things LAN as the main body of the implementation, and make coal transportation judgments based on the number and route of coal mines mined underground. ZIGBEE communication is used ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com