Tension-Leg Platform Anchoring System

a platform and anchoring technology, applied in the direction of anchoring arrangements, anchoring structures, vessel construction, etc., can solve the problems of increasing the number of other utilities that are often susceptible to wind, wave, current forces,

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

second embodiment

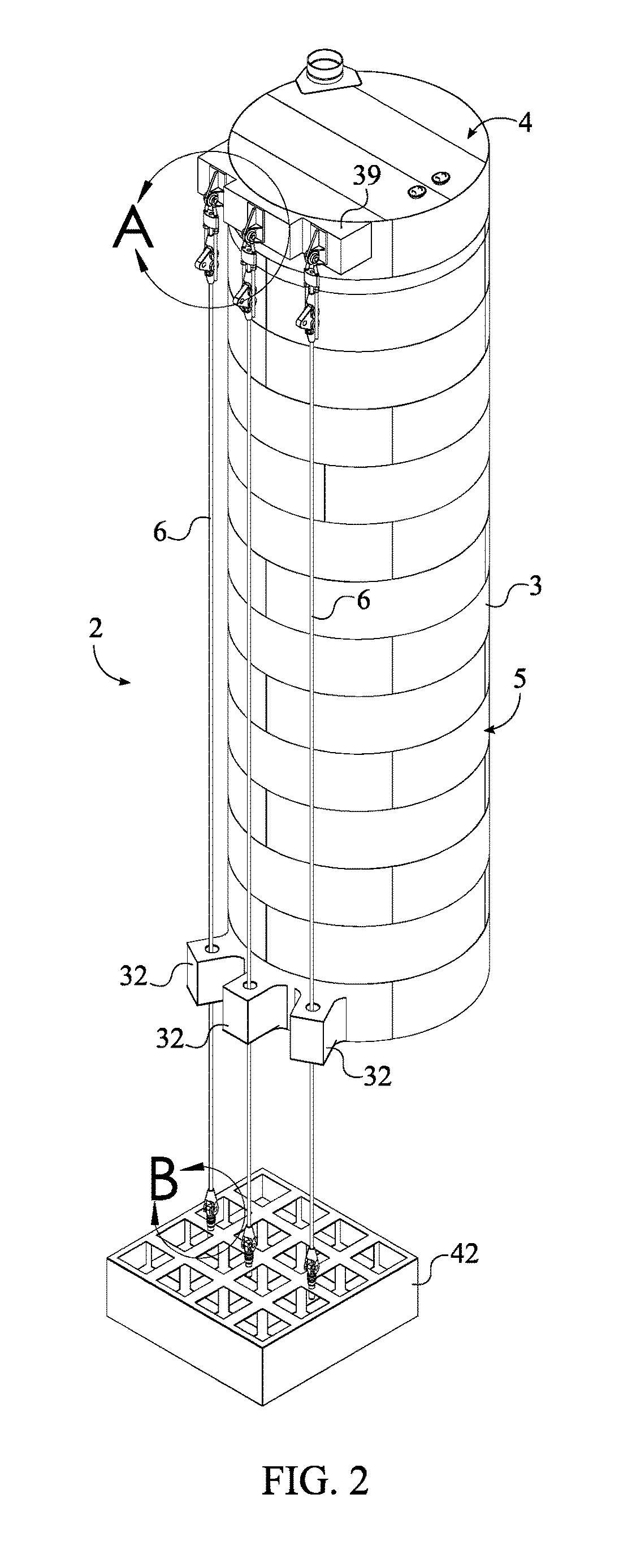

[0030]In the column coupler 7, the column coupler 7 comprises a mounting bracket 8, a first pivot link 9, a second pivot link 10, a first rocker bracket 11, and a second rocker bracket 12. The mooring assembly 6 further comprises a protruding mount 39. In reference to FIGS. 5-6, the protruding mount 39 is connected adjacent to the lateral portion 5, adjacent to the first base 4. The protruding mount 39 is used to provide clearance between the first tendon 27 and the lateral portion 5 of the column 3. The mounting bracket 8 is suspended from the protruding mount 39, adjacent to the lateral portion 5. The mounting bracket 8 acts as a base for the rest of the column coupler 7 to extend from. The first pivot link 9 and the second pivot link 10 are each hingedly connected to the mounting bracket 8. The first pivot link 9 and the second pivot link 10 are positioned opposite to each other along the mounting bracket 8. The first pivot link 9 and the second pivot link 10 are able to rotate a...

third embodiment

[0033]In the column coupler 7, the column coupler 7 comprises a first pivot link 9, a second pivot link 10, a first stabilizing bracket 17, a second stabilizing bracket 18, a first swinging bracket 19, and a second swinging bracket 20. In reference to FIGS. 7A, 7B, 8A, and 8B, the first pivot link 9 is hingedly mounted to the protruding mount 39 and the second pivot link 10 is hingedly mounted to the protruding mount 39, adjacent to the first pivot link 9. The first pivot link 9 and the second pivot link 10 help to stabilize the column 3 in the event that the anchor 42 settles on the seabed or if the column 3 moves. The first stabilizing bracket 17 is hingedly connected to the first pivot link 9, opposite to the protruding mount 39. The first stabilizing bracket 17 is also hingedly connected to the second pivot link 10, opposite to the protruding mount 39. The second stabilizing bracket 18 is connected perpendicular to the first stabilizing bracket 17, in between the first pivot lin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com