Simulation device for high temperature resistant rod bundle fuel assembly based on diffusion welding

A diffusion welding and fuel assembly technology, applied in the direction of reducing greenhouse gases, nuclear reactor monitoring, reactors, etc., can solve the problems of short life, poor performance under high temperature and high pressure conditions, etc., to improve service life, high temperature resistance, and high temperature resistance The effect of the ability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

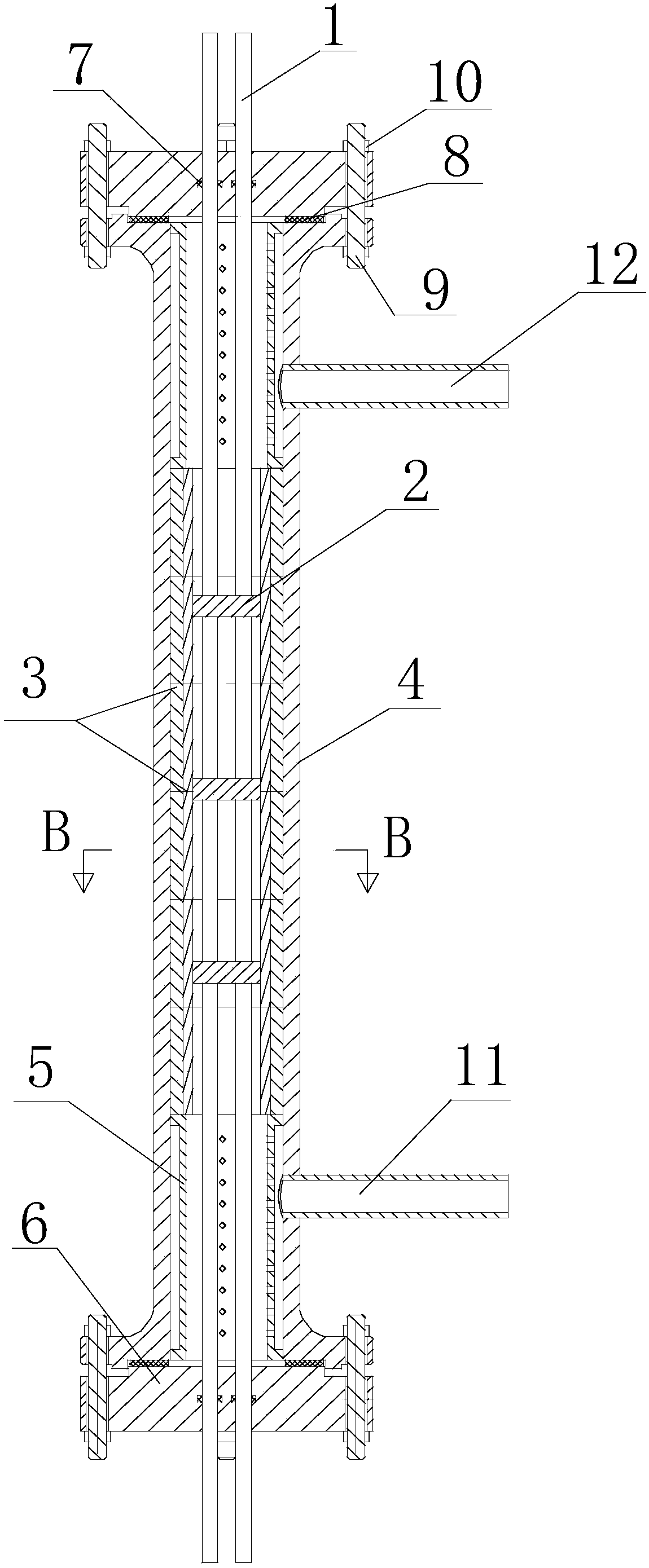

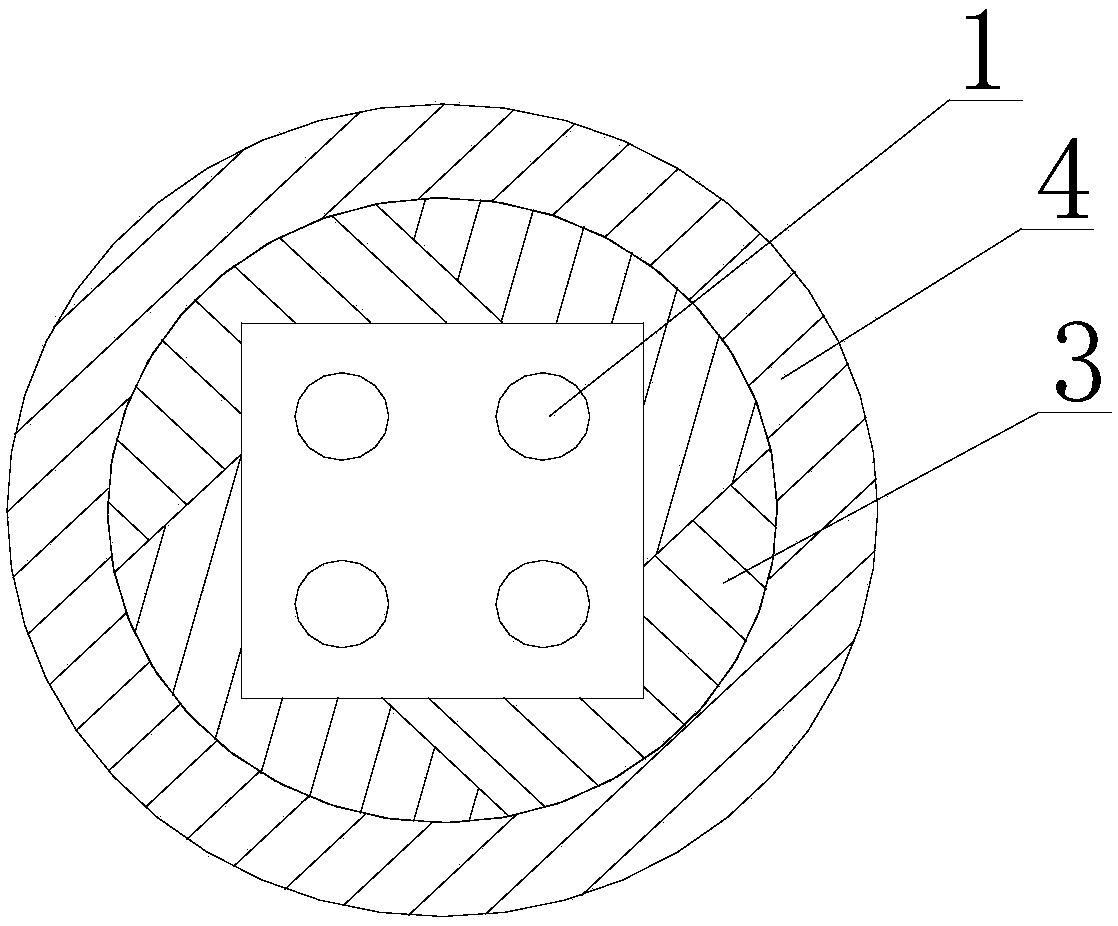

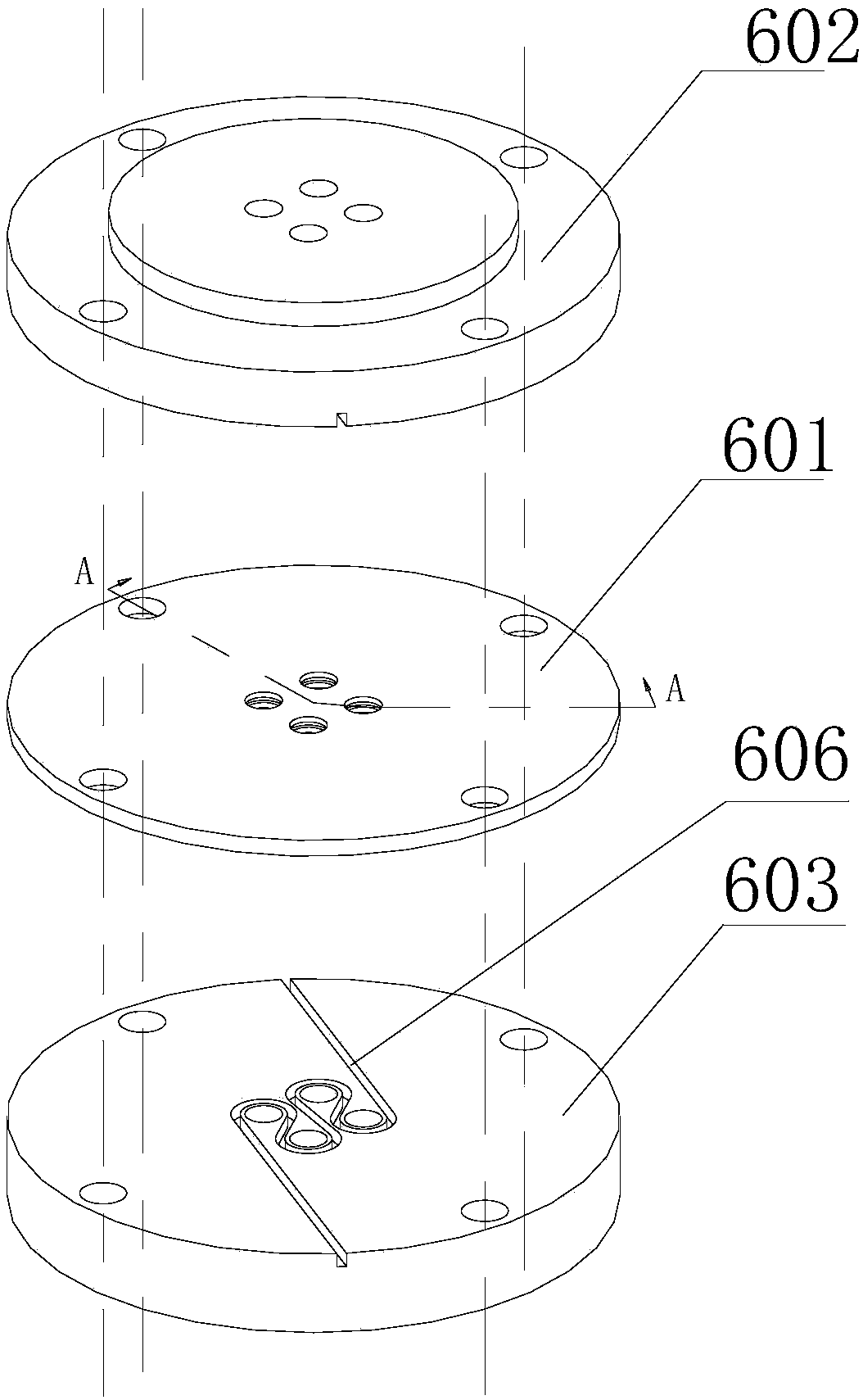

[0027] Such as Figures 1 to 4 As shown, the high temperature resistant rod bundle fuel assembly simulation device based on diffusion welding in the present invention includes a pressure-bearing sleeve 4, which is a pressure-bearing thick-walled cylinder, and its wall thickness is calculated by the material strength and deformation under high pressure To determine, an inlet connecting pipe 11 and an outlet connecting pipe 12 are provided near the two ends. A ceramic runner chamber 3 is arranged in the pressure sleeve 4, the outer diameter of the ceramic runner chamber 3 is consistent with the inner diameter of the pressure sleeve 4, and the inside is the flow channel of the rod bundle fuel assembly, which is used for heating rod bundles Simulation 1 is insulated from pressure sleeve 4 . At the same time, the internal pressure of the flow channel is transmitted to the pressure sleeve 4. Along the axial direction of the flow channel, the ceramic flow channel chamber 3 is formed...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com