Steel rail expansion adjuster

A regulator and rail technology, which is applied to rail joints, rails, switches, etc., can solve the problems affecting the normal expansion and contraction of the basic rail of the regulator, the expansion resistance of the basic rail does not drop but rises, and the longitudinal expansion resistance is reduced. Avoiding the overrun of gauge expansion, simple and feasible processing and manufacturing, and reducing the effect of longitudinal expansion resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

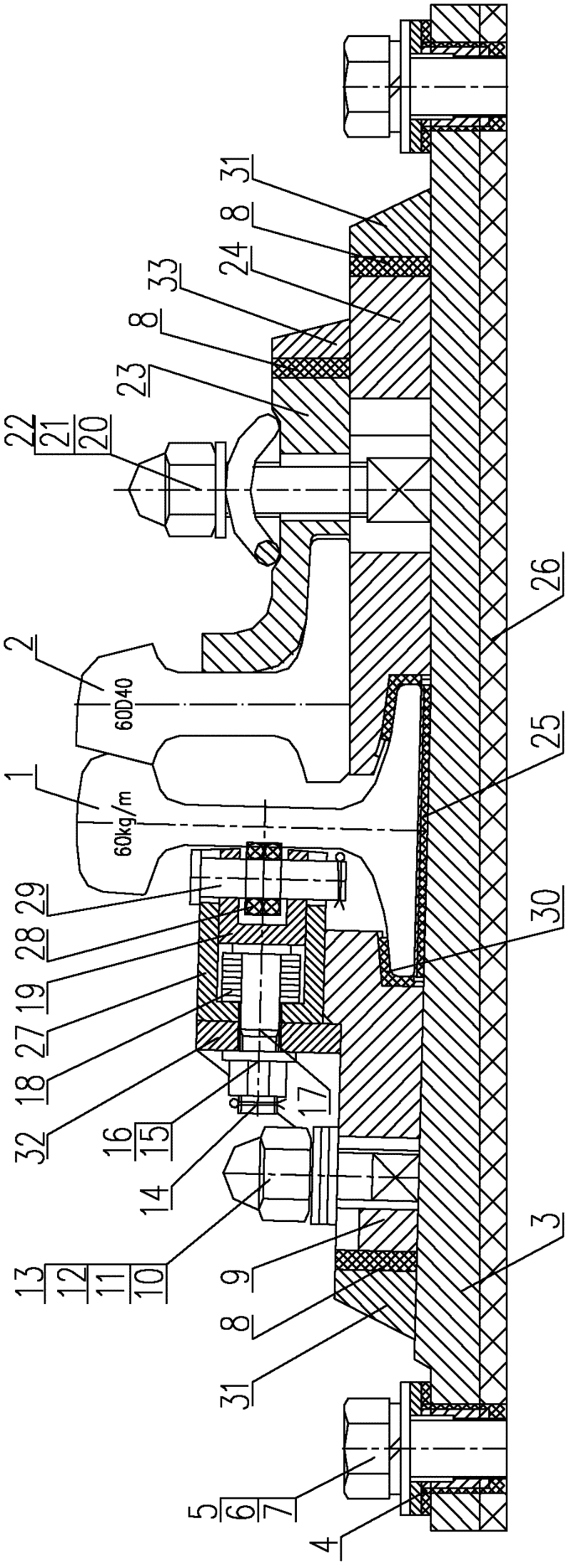

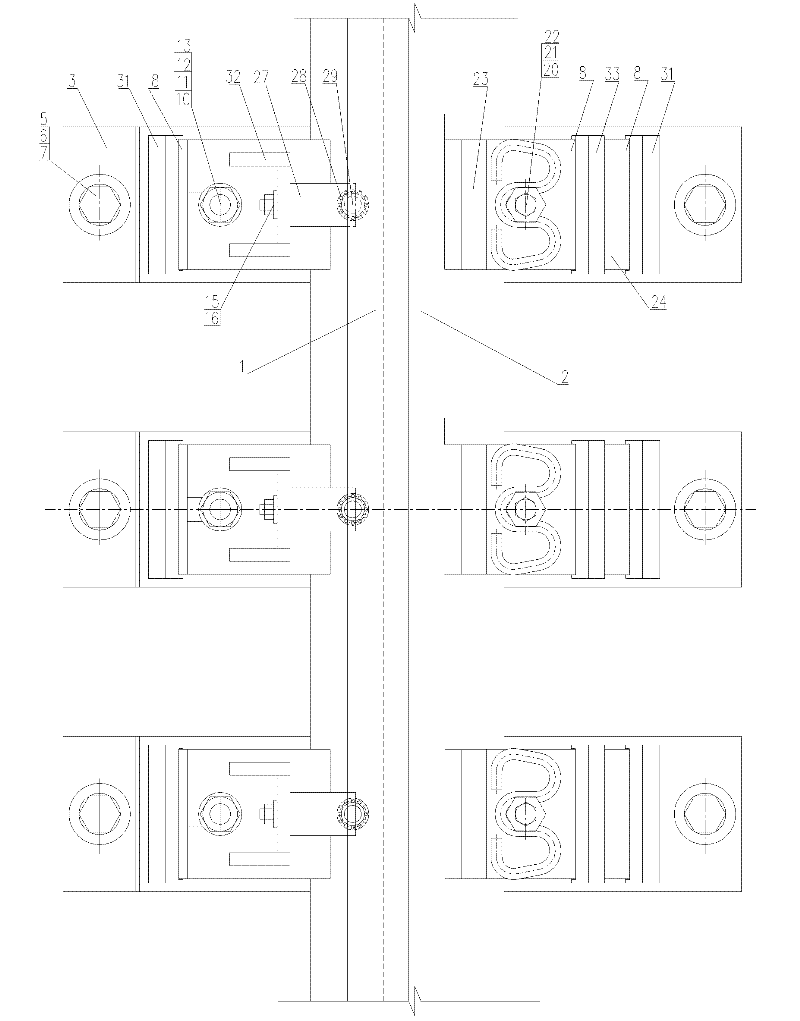

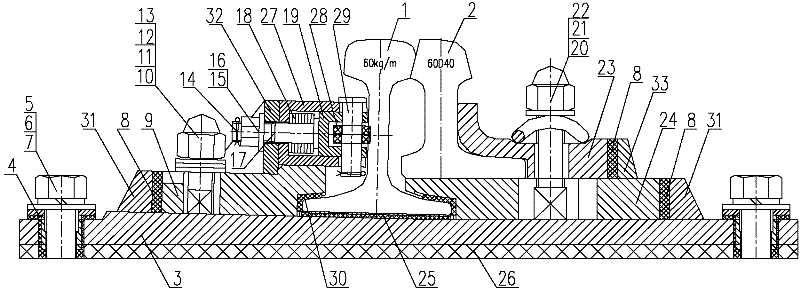

[0020] Attached below figure 1 , 2 An embodiment of the present invention is described.

[0021] A rail telescopic adjuster, which has a basic rail 1 and a point rail 2 arranged inside the basic rail 1, the basic rail 1 is located on an iron backing plate 3, and the iron backing plate 3 is passed through a switch sleeper bolt 5, a spring washer 6, a flat Washer 7 and rubber pad 26 under the board are fixed on the switch sleeper. The switch rail 2 is located on the switch rail platform assembly 24 , and the switch rail platform assembly 24 is located on the iron backing plate 3 . The basic rail 1 is fixedly buckled and pressed on the iron backing plate 3 through the basic rail buckle assembly 9 and the switch rail platform assembly 24, and the inside and bottom of the basic rail buckle assembly 9 and the switch rail platform assembly 24 are inlaid and fixed with anti-friction Fasteners 30, and the wear-reducing fasteners 30 are tightly pressed on the rail limbs on both sides...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com