Fixing structure of gas turbine splitting ring

A fixed structure, gas turbine technology, applied in stators, mechanical equipment, engine components, etc., can solve the problems of short life, difficult disassembly, complex structure, etc., and achieve the effect of simple structure and convenient installation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

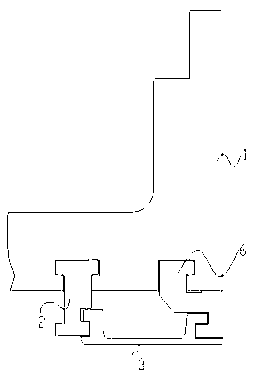

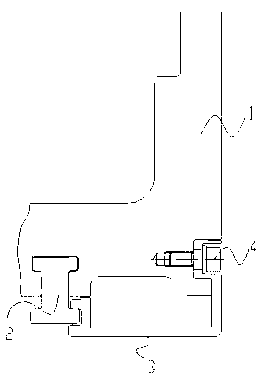

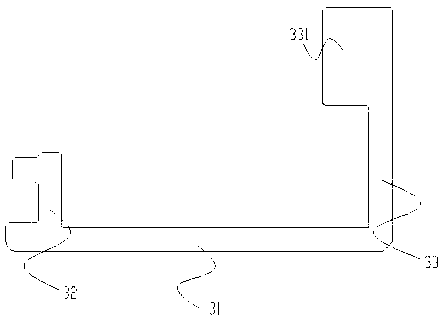

[0038] Such as Figure 1-6 As shown, a gas turbine split ring fixing structure includes a stator blade holding ring 1, a heat shield ring 2 and a split ring 3;

[0039] The vane holding ring 1 extends axially and circumferentially, and an annular groove is arranged on the end surface of the vane holding ring 1 close to the split ring 3;

[0040] The heat-shielding ring 2 extends in the circumferential direction, one end of which is embedded in the vane holding ring 1, and the other end is located in the channel of the vane holding ring 1, and has protrusions on both sides of the axial direction and extends circumferentially. A certain distance forms a circumferentially extending card slot;

[0041] The split ring 3 extends axially and circumferentially, one end of which is provided with an engaging portion 32, which is engaged and connected with the engaging groove formed by the heat shielding ring 2 and the vane holding ring 1; the other end is provided with a hook portion ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com