Automatic bolt feeding device

An automatic feeding and bolting technology, applied in transportation and packaging, metal processing, metal processing equipment, etc., can solve problems such as increasing equipment processing costs, manual sorting errors, and increasing labor costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

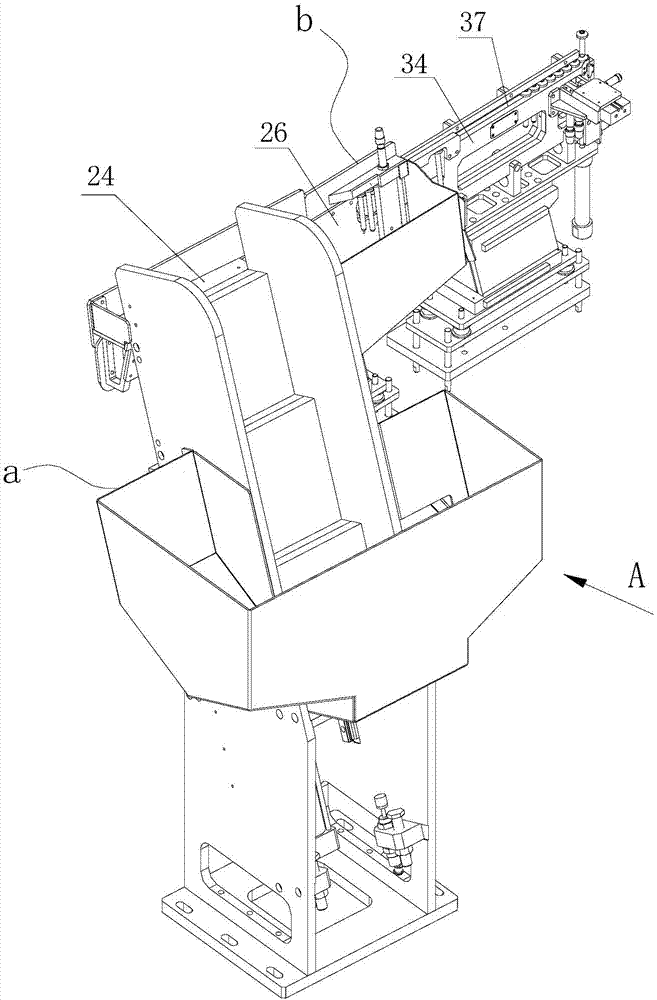

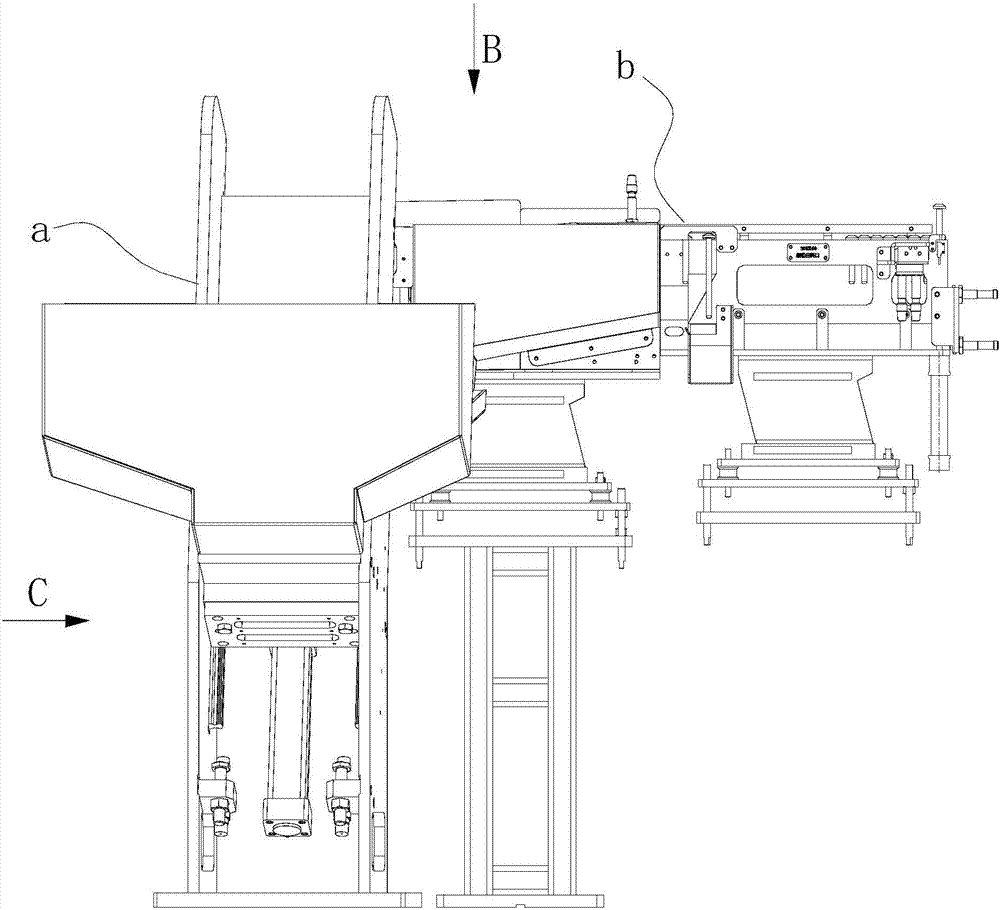

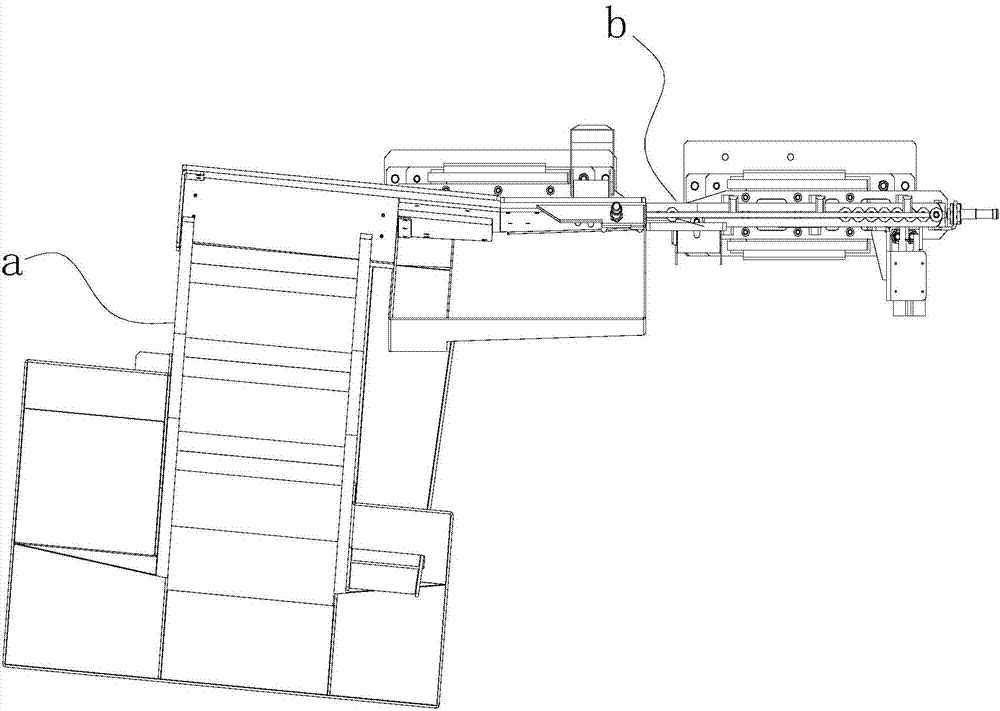

[0049] A kind of automatic feeding device for bolts in this embodiment, such as Figure 1~4 As shown, it includes the connected ladder feeding mechanism a and vibration screening mechanism b. The vibration screening mechanism includes a short bolt screening assembly and a long bolt screening assembly. According to the conveying direction of the bolts, the ladder feeding mechanism, short bolt screening assembly It is connected with the long bolt screening assembly in sequence; among them, the stepped feeding mechanism is used to automatically extract the bolts from the feeding hopper and send them to the subsequent vibration screening mechanism, and the short bolt screening assembly is used to screen and eliminate the bolts The medium-length bolts are too short, and the long-bolt screening component is used to screen and exclude bolts that are too long in the bolts, so as to obtain bolts that meet the specifications;

[0050] Such as Figure 5-8 As shown, the ladder feeding me...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com