Numerical control steel plate double-side four-surface synchronous groove forming machine production line

A production line and molding machine technology, applied in the details of milling machine equipment, metal processing, metal processing equipment, etc., can solve the problems of low degree of automation, poor processing accuracy, and high production cost, and achieve high degree of automation, high processing accuracy, and low cost. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0059] Below the present invention will be further described in conjunction with the embodiment in the accompanying drawing:

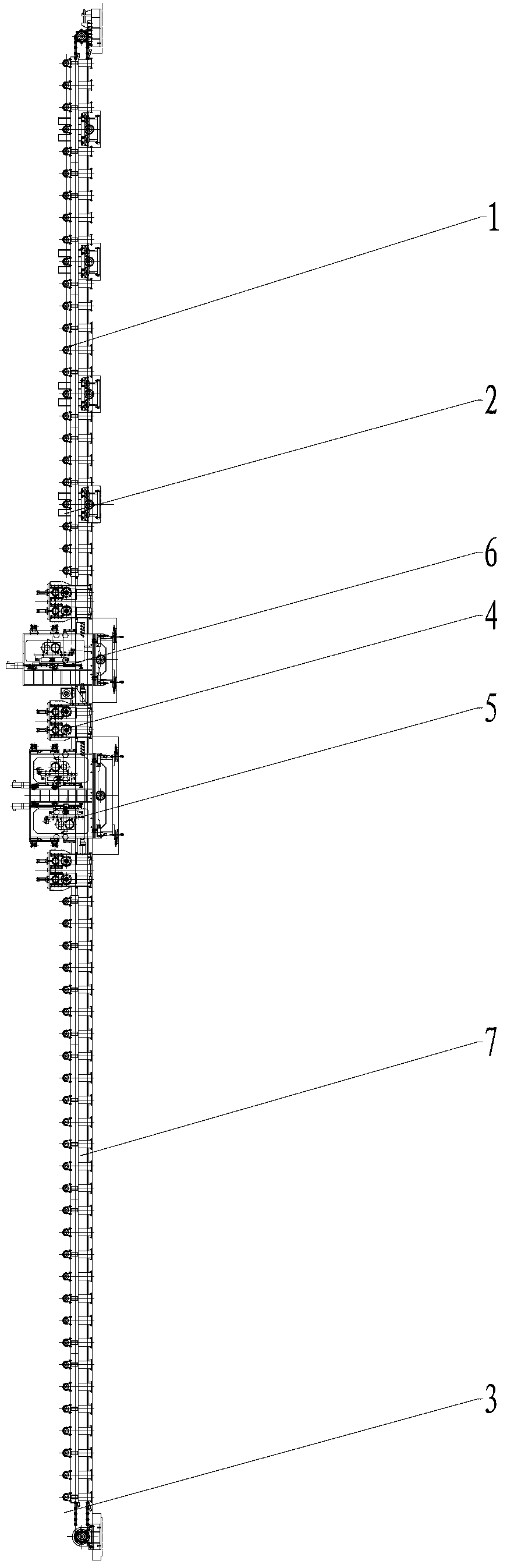

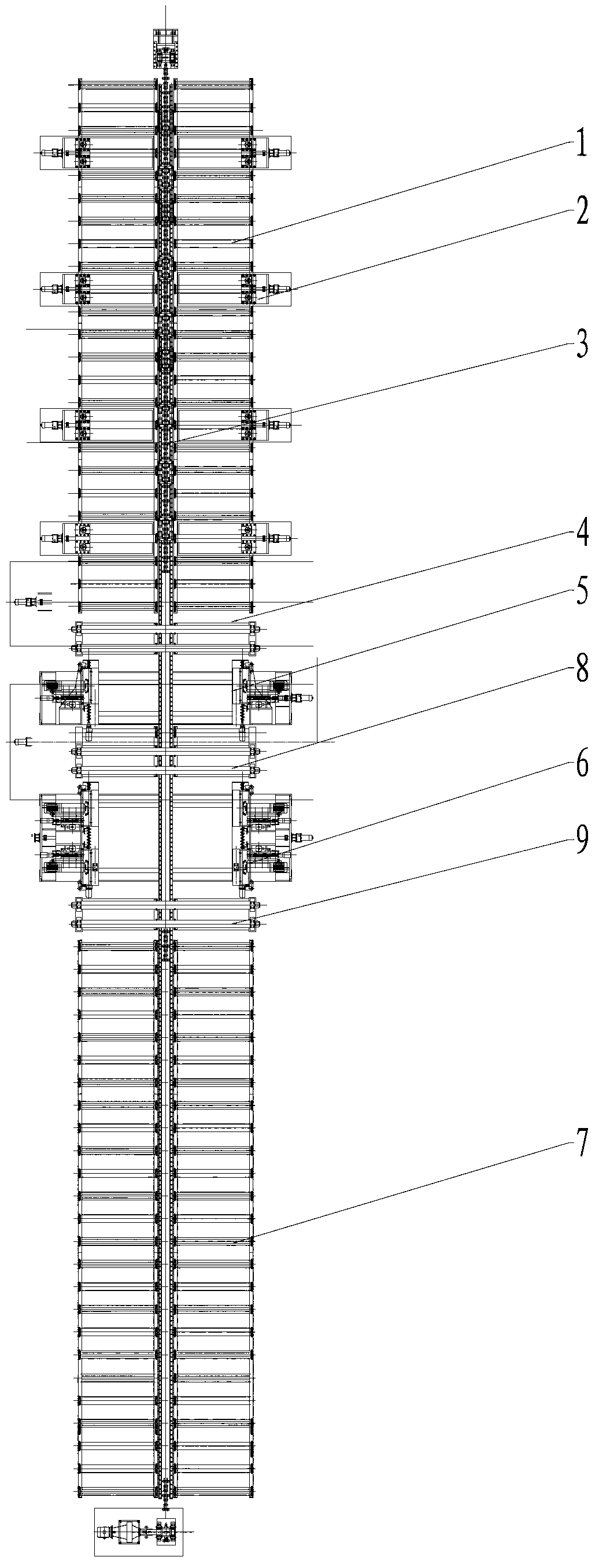

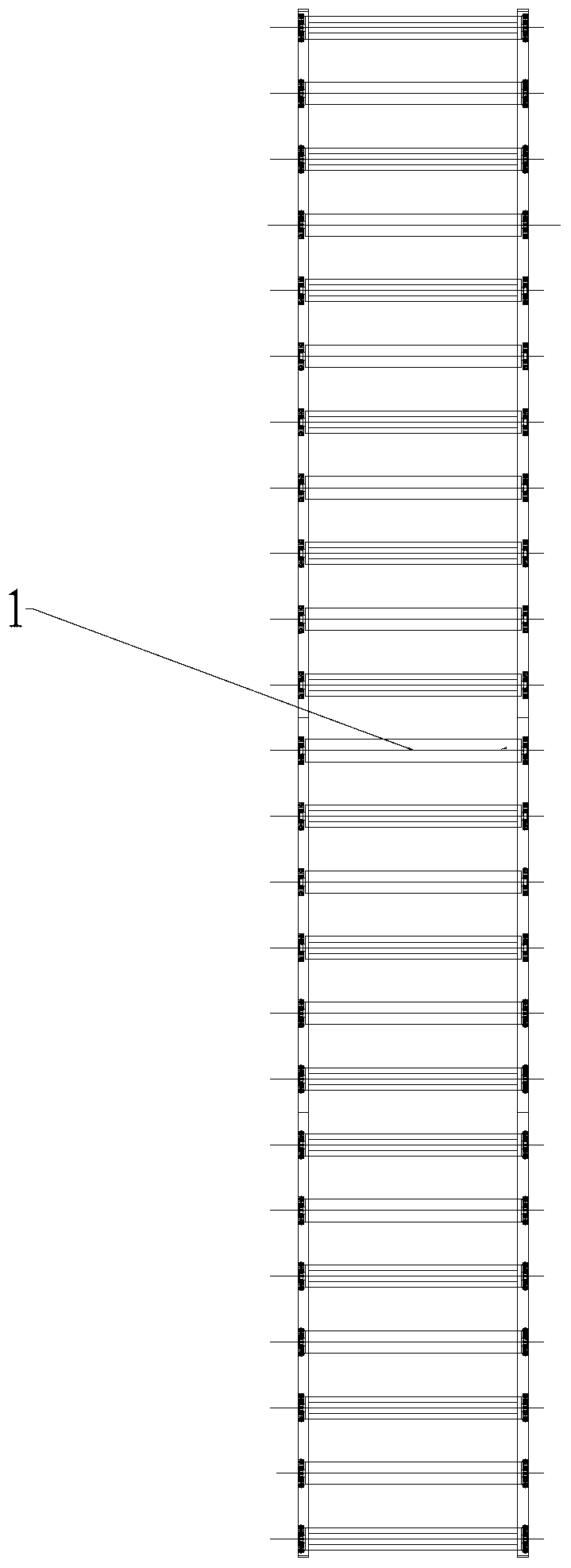

[0060] like Figure 1~2 As shown, the present invention mainly includes a front conveying roller table 1, a centering device 2, a conveying power device 3, a first pinch roller device 4, a bilateral straight edge milling machine host 5, a bilateral up and down bevel edge milling machine host 6 and The rear conveying roller table 7, the second pinch roller device 8 and the third pinch roller device 9, the middle part of the conveying power device 3 is equipped with the first pinch roller device 4, the main body of the double-sided straight edge milling machine 5, and the double-sided upper and lower grooves The main machine 6 of the edge milling machine, the second pinch roller device 8 and the third pinch roller device 9 are two each, and the two bilateral straight edge milling machine main machines 5 and the two bilateral up and down groove edge milli...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com