High-voltage electrostatic plasma oil smoke purifier for continuous woven belt dyeing machine

A lampblack purifier, high-voltage electrostatic technology, applied in chemical instruments and methods, separation methods, dispersed particle separation, etc., can solve problems such as the impact of human health on the surrounding environment, and achieve the effect of reducing heat energy emissions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] In order to deepen the understanding of the present invention, the present invention will be further described in detail below in conjunction with the accompanying drawings and embodiments. The following examples are only used to illustrate the technical solution of the present invention more clearly, but not to limit the protection scope of the present invention.

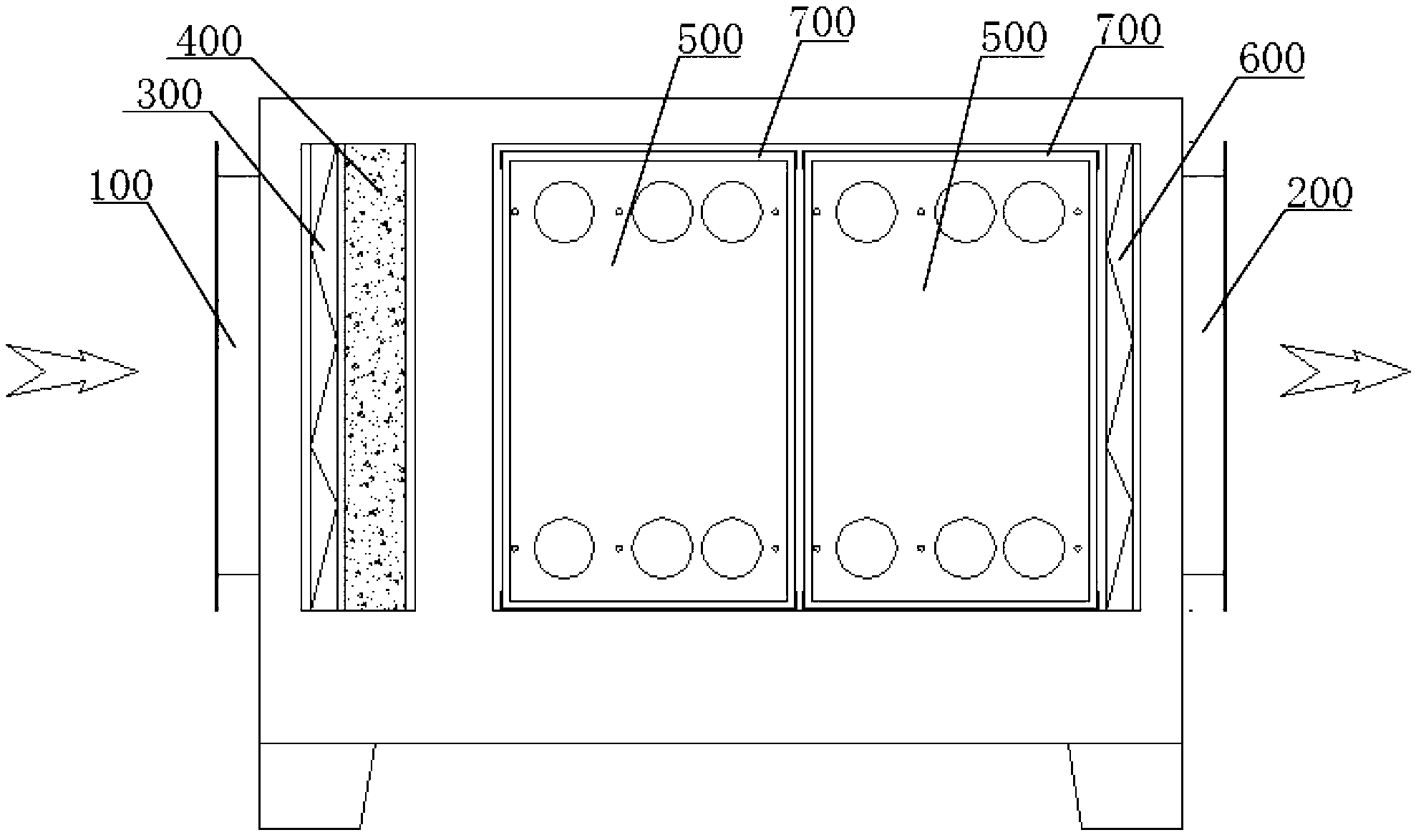

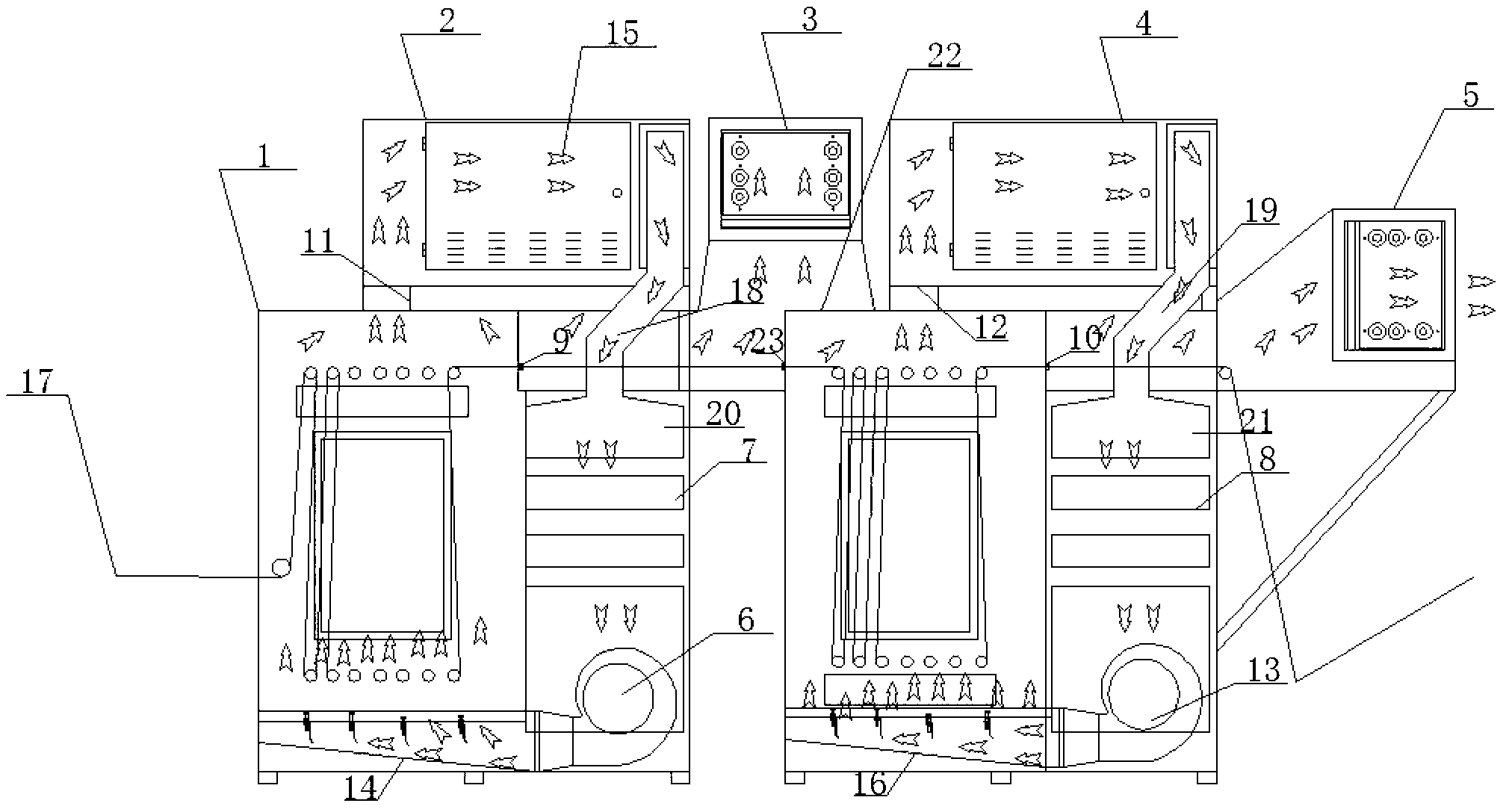

[0020] A specific embodiment of the present invention is a high-voltage electrostatic plasma oil fume purifier for a continuous dyeing machine, including a smoke inlet 100, a smoke outlet 200, a front equalizer 300, a rough filter 400, a plasma electric field 500, The rear equalizer 600, the front equalizer 300, the coarse filter 400, the plasma electric field 500, and the rear equalizer 600 are sequentially arranged between the smoke inlet 100 and the smoke outlet 200 of the oil fume purifier, The front equalizer 300 is arranged at the smoke inlet 100 of the oil fume purifier, and the front equalizer 300 is...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com