Preparation method of diatom ooze coating

A diatom mud coating and coating technology, applied in the field of interior decoration coatings, can solve the problems of insignificant humidity control, poor water resistance, and resistance to scrubbing, etc., and achieve the effect of improving connection performance, improving connection performance, and increasing retention rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

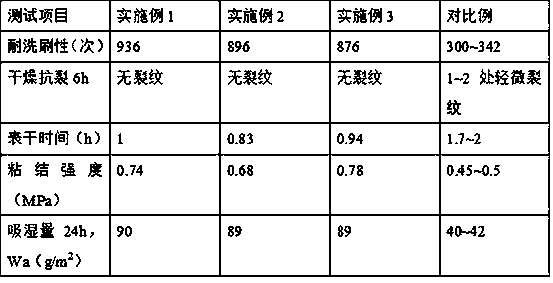

Examples

preparation example Construction

[0018] A preparation method for diatom mud coating, comprising the steps of:

[0019] (1) Take starch and add distilled water at a mass ratio of 1:8, stir and mix at 90-95°C for 1-2 hours, adjust the pH to 10-11, then add fatty acid with 10-15% starch mass and mix, keep for 30-40 minutes to get Mixture A, take diatom mud and add mixture A and distilled water according to the mass ratio of 5:2:10, stir and mix for 1~2h to obtain mixture B, take mixture B and add hydrochloric acid with a mass fraction of 20% according to the mass ratio of 1:2, keep 30 ~40min, adjust the pH to 7~7.2, get diatomite base material, set aside;

[0020] (2) Take sepiolite and crush it through a 60-mesh sieve, collect the sieved particles, add distilled water to soak for 18~24 hours according to the mass ratio of 1:10, then add sodium pyrophosphate with 2~3% of the sieved particle mass, stir and mix for 2~ 3h, let it stand still, take the supernatant and vacuum filter it, take the filter residue and d...

Embodiment 1

[0025] Iron and steel slag, ceramic polishing slag: after crushing, the fineness is 0.08mm sieve standard sieve with 3.5% remaining.

[0026] A preparation method for diatom mud coating, comprising the steps of:

[0027] (1) Take starch and add distilled water at a mass ratio of 1:8, stir and mix at 90°C for 1 hour, adjust the pH to 10, then add fatty acid with 10% starch mass and mix it for 30 minutes to obtain mixture A. Take diatom mud according to the mass ratio Add mixture A and distilled water at 5:2:10 and stir and mix for 1 hour to obtain mixture B. Take mixture B and add 20% hydrochloric acid in a mass ratio of 1:2, keep for 30 minutes, adjust the pH to 7, and obtain diatomite base material ,spare;

[0028](2) Take sepiolite and crush it through a 60-mesh sieve, collect the sieved particles, add distilled water to soak for 18 hours according to the mass ratio of 1:10, then add sodium pyrophosphate with 2% of the sieved particle mass, stir and mix for 2 hours, let sta...

Embodiment 2

[0033] Iron and steel slag, ceramic polishing slag: after crushing, the fineness is 0.08mm sieve standard sieve with 3.5% remaining.

[0034] A preparation method for diatom mud coating, comprising the steps of:

[0035] (1) Take starch and add distilled water according to the mass ratio of 1:8, stir and mix at 95°C for 2 hours, adjust the pH to 11, then add fatty acid with 15% of the mass of starch and mix for 40 minutes to obtain mixture A, take diatom mud according to the mass ratio Add mixture A and distilled water at 5:2:10 and stir for 2 hours to obtain mixture B. Take mixture B and add 20% hydrochloric acid in a mass ratio of 1:2, keep it for 40 minutes, adjust the pH to 7.2, and obtain diatomite base material ,spare;

[0036] (2) Take sepiolite and crush it through a 60-mesh sieve, collect the sieved particles, add distilled water to soak for 24 hours according to the mass ratio of 1:10, then add sodium pyrophosphate with 3% of the sieved particle mass, stir and mix f...

PUM

| Property | Measurement | Unit |

|---|---|---|

| porosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com