Environment-friendly decorative plate and preparation method thereof

A decorative sheet and environmental protection technology, applied in the field of environmental protection decorative sheet and its preparation, can solve the problems of being easily harassed by insects and ants, pollute the environment, insufficient strength, etc., and achieve the effects of improving hydrophilic surface, excellent mechanical properties and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

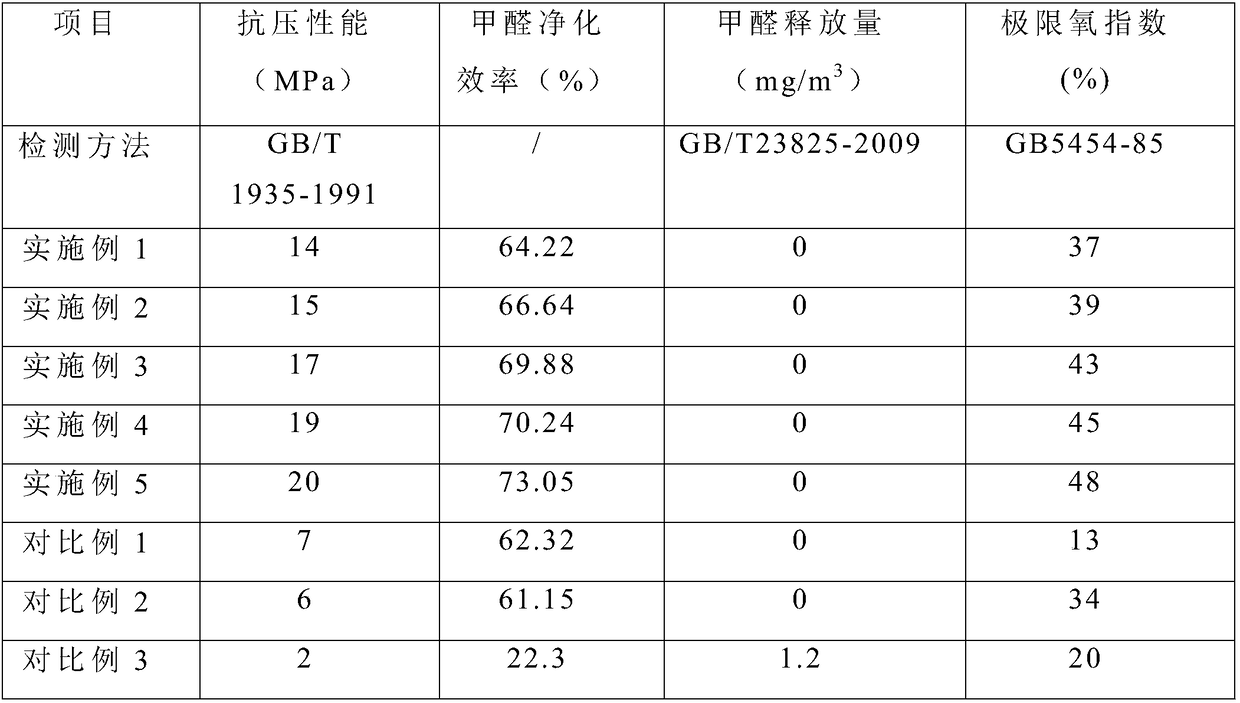

Examples

Embodiment 1

[0029] An environmentally friendly decorative board, comprising the following raw materials and their weight fractions: 15 parts of surface-modified cellulose nanocrystals, 25 parts of epoxy resin modified chitin fibers, 20 parts of waste tire rubber powder, 5 parts of kapok fiber, and 5 parts of coconut fiber 5 parts, 5 parts of asphalt, 2 parts of opal shale, 5 parts of nano silicon powder, 2 parts of silane coupling agent KH-550, 2 parts of nano fluorine coating wax.

[0030] Wherein, the preparation method of the surface-modified cellulose nanocrystals comprises the following steps: dissolving 10 g of dimethyl phthalimidomethyl phosphate in 50 g of dimethyl sulfoxide, heating and stirring at 85° C. After it was completely dissolved, 20 g of nanocellulose crystals were added, stirred and reacted for 6 hours, and the solvent was removed by a rotary evaporator to obtain a crude product, which was ground into a powder for later use.

[0031] The preparation method of the epoxy...

Embodiment 2

[0038] An environmentally friendly decorative board, including the following raw materials and their weight fractions: 17 parts of surface-modified cellulose nanocrystals, 29 parts of epoxy resin modified chitin fibers, 23 parts of waste tire rubber powder, 7 parts of kapok fiber, and 7 parts of coconut fiber 7 parts, 7 parts of asphalt, 3 parts of opal shale, 7 parts of nano silicon powder, 3 parts of silane coupling agent KH-550, 3 parts of nano fluorine coating wax.

[0039] Wherein, the preparation method of the surface-modified cellulose nanocrystals comprises the following steps: dissolving 10 g of dimethyl phthalimidomethyl phosphate in 70 g of N,N-dimethylformamide, Heat and stir at 88°C, add 23g of nanocellulose crystals after it is completely dissolved, stir and react for 6.5 hours, and then remove the solvent with a rotary evaporator to obtain a crude product, which is ground into a powder for later use.

[0040] The preparation method of the epoxy resin modified ch...

Embodiment 3

[0047] An environmentally friendly decorative board, including the following raw materials and their weight fractions: 18 parts of surface-modified cellulose nanocrystals, 31 parts of epoxy resin modified chitin fibers, 26 parts of waste tire rubber powder, 8 parts of kapok fiber, and 7 parts of coconut fiber 6 parts, 6 parts of asphalt, 4 parts of opal shale, 8 parts of nano silicon powder, 4 parts of silane coupling agent KH-550, 3 parts of nano fluorine coating wax.

[0048] Wherein, the preparation method of the surface-modified cellulose nanocrystals comprises the following steps: dissolving 10 g of dimethyl phthalimidomethyl phosphate in 77 g of N-methylpyrrolidone, and heating at 89° C. Stir, and add 26g of nanocellulose crystals after it is completely dissolved, stir and react for 7 hours, and then remove the solvent with a rotary evaporator to obtain a crude product, which is ground into a powder for later use.

[0049] The preparation method of the epoxy resin modifi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Formaldehyde emission | aaaaa | aaaaa |

| Formaldehyde emission | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com