Method for preparing glass steel phenolic resin substrate

A technology of phenolic resin and fiberglass, which is applied in the field of phenolic resin, can solve the problems of low reactivity and slow curing speed, and achieve the effects of low smoke density, good mechanical properties and good fire resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

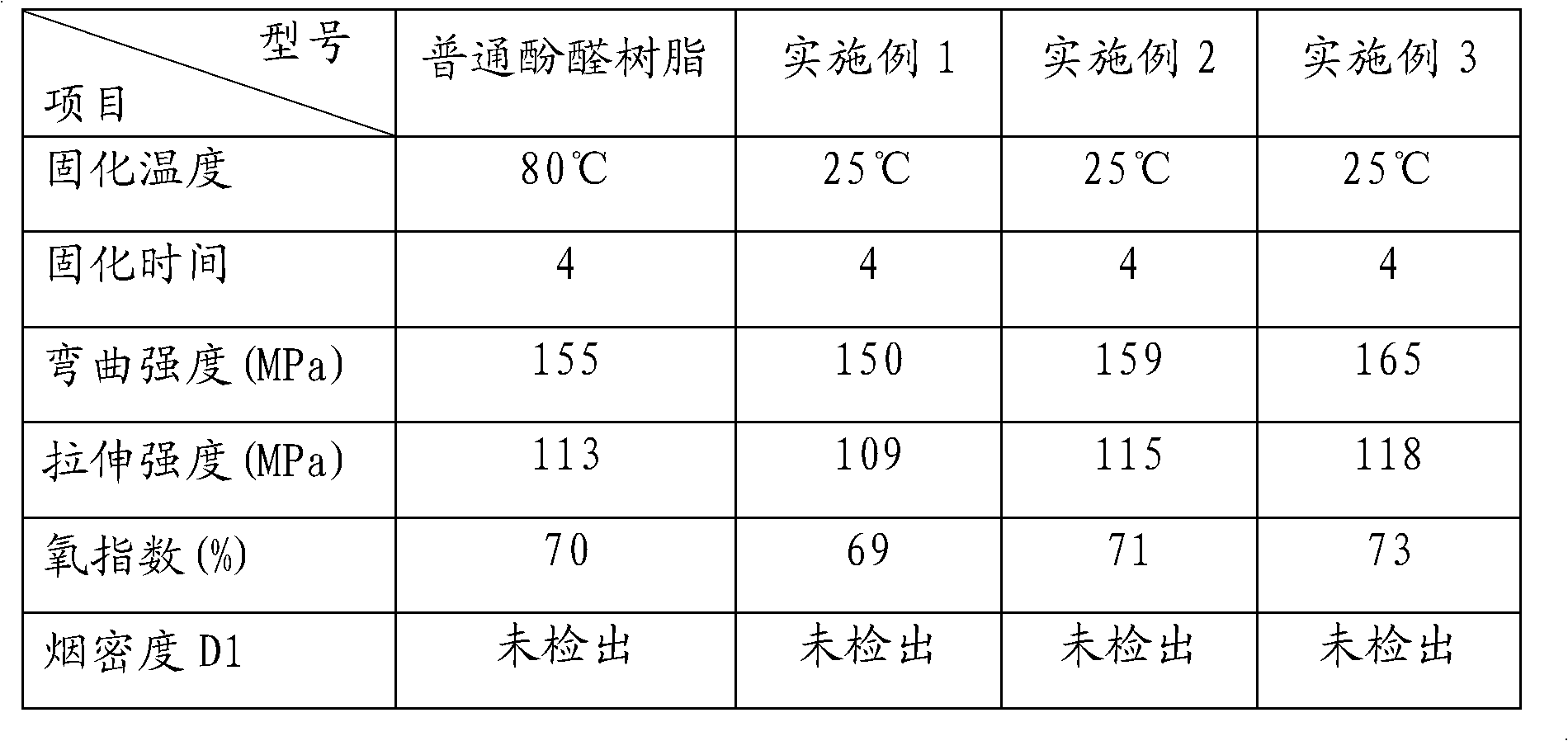

Examples

Embodiment 1

[0029] With 80kg of phenol, 20g of resorcinol, 180kg of formaldehyde (36%), 2kg of sodium hydroxide, join in the reactor successively, be warming up to 50 ℃, constant temperature reaction 6 hours, add 1.5kg phosphoric acid in the gained reaction mixture, reduce Pressure distillation, the temperature of the vacuum distillation is controlled at 38-40°C, the vacuum degree is -0.98MPa--0.94MPa, and the pressure distillation is carried out until the viscosity is 1500cp / 25°C to obtain a phenolic resin product.

[0030] The resin prepared in this embodiment has a solid content of 63% and a moisture content of 16%.

[0031] Add sulfurous acid to the phenolic resin product prepared above, and stir evenly according to the weight ratio of phenolic resin to sulfurous acid of 70:30.

Embodiment 2

[0033] 75kg of cresol, 25g of o-cresol, 200kg of paraformaldehyde (36%), and 1.5kg of alkylamine were successively added to the reaction kettle, the temperature was raised to 70°C, and the temperature was reacted for 7 hours, and 1.5kg of the resulting reaction mixture was added to mix Acid, vacuum distillation, the temperature of vacuum distillation is controlled at 40-42°C, the vacuum degree is -0.98MPa--0.94MPa, the vacuum distillation is until the viscosity is 2000cp / 25°C, and the phenolic resin product is obtained.

[0034] The resin prepared in this embodiment has a solid content of 71% and a moisture content of 14.5%.

[0035] Add oxalic acid to the phenolic resin product prepared above, and stir evenly according to the weight ratio of phenolic resin to oxalic acid 99.5:0.5.

Embodiment 3

[0037] 70kg of naphthol, 30g of pyrocatechol, 10g of cresol, propionaldehyde (36%), 180kg, and 1.6kg of sodium hydroxide were successively added to the reactor, and the temperature was raised to 80°C for constant temperature reaction for 5 hours, and the resulting reaction mixture was Add 1.5kg of mixed acid to the mixture, distill under reduced pressure, control the temperature of the reduced-pressure distillation to 41-43°C, the vacuum degree is -0.98MPa--0.94MPa, and distill under reduced pressure until the viscosity is 3000cp / 25°C to obtain the phenolic resin product.

[0038] The resin prepared in this embodiment has a solid content of 75% and a moisture content of 9%.

[0039] Add ammonium monohydrogen phosphate to the phenolic resin product prepared above, and stir evenly according to the weight ratio of phenolic resin to ammonium monohydrogen phosphate of 80:20.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com