Flexible transparent barrier film and preparation method thereof

A technology of barrier film and transparent film, used in semiconductor/solid-state device manufacturing, semiconductor devices, electrical components, etc., can solve the problems of low light transmittance and reduced barrier performance, achieve high light transmittance, improve barrier properties, and improve Effect of curl resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

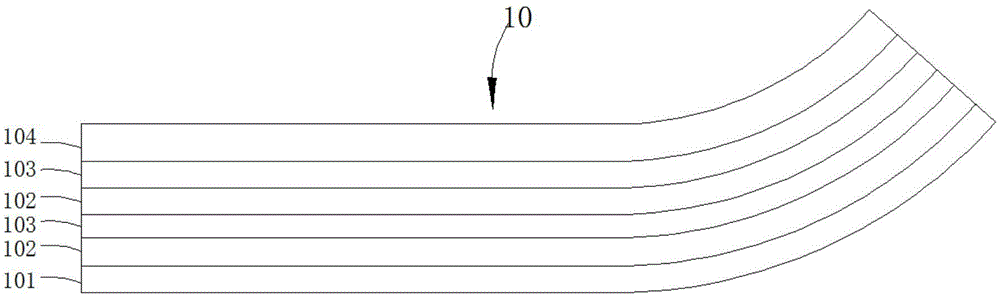

[0061] The invention provides a flexible transparent barrier film, the barrier film comprises a flexible substrate, a barrier layer is arranged on the flexible substrate, and a protective layer is arranged on the barrier layer; the flexible substrate is a transparent film; the barrier layer comprises two layers An organic layer and two inorganic layers are arranged alternately; the flexible substrate is connected with the organic layer in the barrier layer.

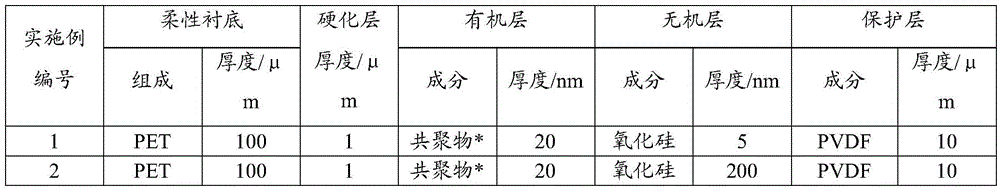

[0062] A biaxially stretched polyester film (BOPET film, thickness 100 μm, manufactured by Changyang Science and Technology Co., Ltd., trade name "OS100") was selected as the flexible substrate, and a hardening coating formed by a layer of water-based polyurethane resin was coated on the surface of the flexible substrate. layer, the thickness of the hardened coating is 1 μm; the organic layer is prepared on the hardened coating by a flash deposition process, the raw material monomer of the organic layer is deposited on the...

Embodiment 2

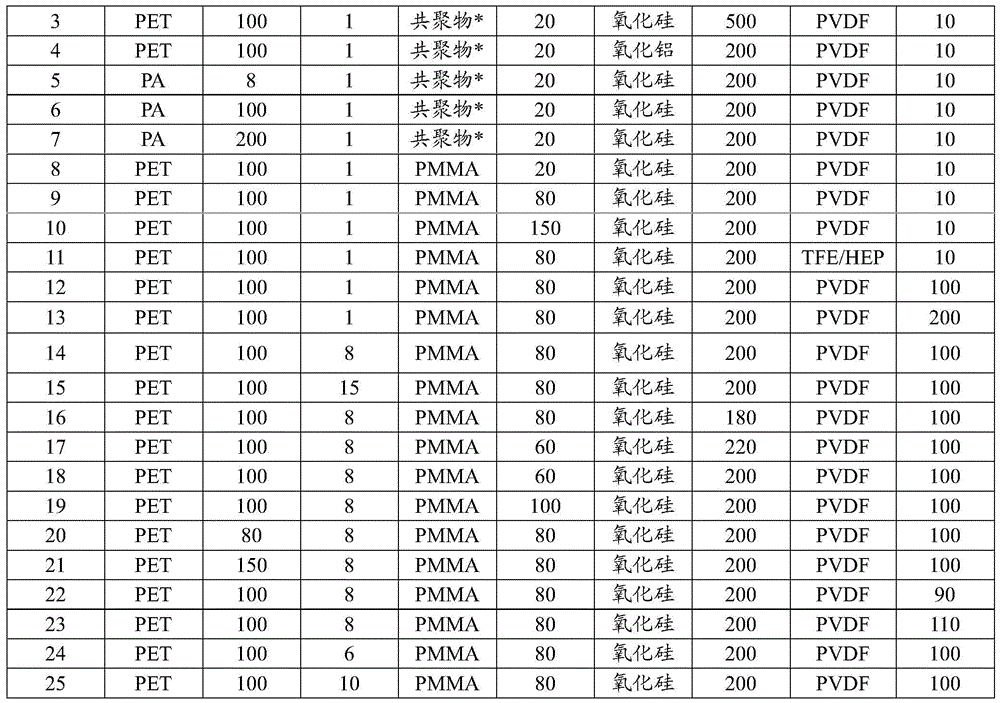

[0064] As in the flexible transparent barrier film provided in Example 1, wherein the inorganic layer is a silicon oxide SiOx inorganic layer with a thickness of 200 nm, and the properties of the barrier film are shown in Table 2.

Embodiment 3

[0066] As for the flexible transparent barrier film provided in Example 1, wherein the inorganic layer is a silicon oxide SiOx inorganic layer with a thickness of 500 nm, the properties of the barrier film are shown in Table 2.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com