Horizontal type double phase change heat exchanger

A horizontal, phase-change technology, applied in heat exchanger types, indirect heat exchangers, evaporators/condensers, etc., can solve the problems of difficult implementation, low operational reliability, difficult manufacturing and processing, and save equipment. Quantity and cost, the effect of reducing energy consumption and simplifying installation operations

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

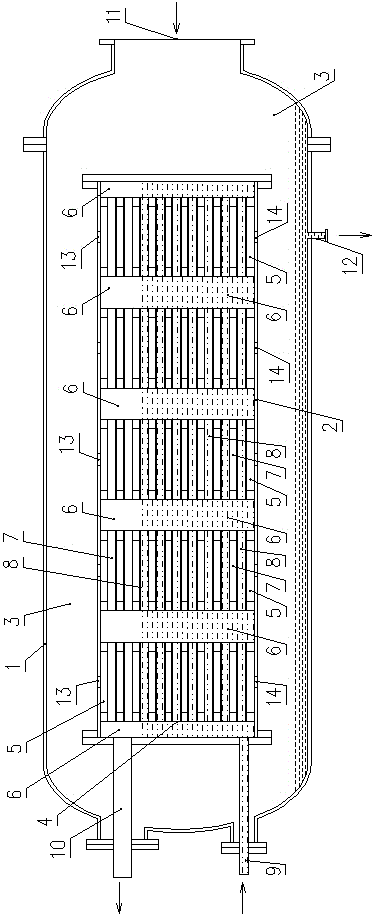

[0040] figure 1 The direction indicated by the middle arrow is the flow direction of the medium here.

[0041] Such as figure 1 As shown, a horizontal two-phase conversion heat exchanger of the present invention includes a horizontal shell 1, and a phase change cylinder 2 is horizontally arranged in the horizontal shell 1, and several phase change cylinders are evenly spaced along the horizontal direction in the phase change cylinder 2 The heat exchange unit; the phase change cylinder 2 is spaced apart from the top wall, bottom wall, left side wall and right side wall of the horizontal housing 1 . The phase change cartridge 2 can be erected on the bottom wall of the horizontal casing 1 through structures such as connecting rods or brackets, or can be connected to other side walls of the horizontal casing 1 through connecting structures. A high temperature steam chamber 3 is enclosed between the phase change cartridge 2 and the horizontal housing 1 .

[0042] The heat exchan...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com