Apparatus for breaking up and classifying cake material

A technology for collecting cake and cake material is applied in the field of devices for collecting cake material, dispersing and grading, which can solve the problems of high energy consumption, reduced ball mill efficiency, low diversion efficiency, etc., and achieves low energy consumption, improved efficiency, and large classification range. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

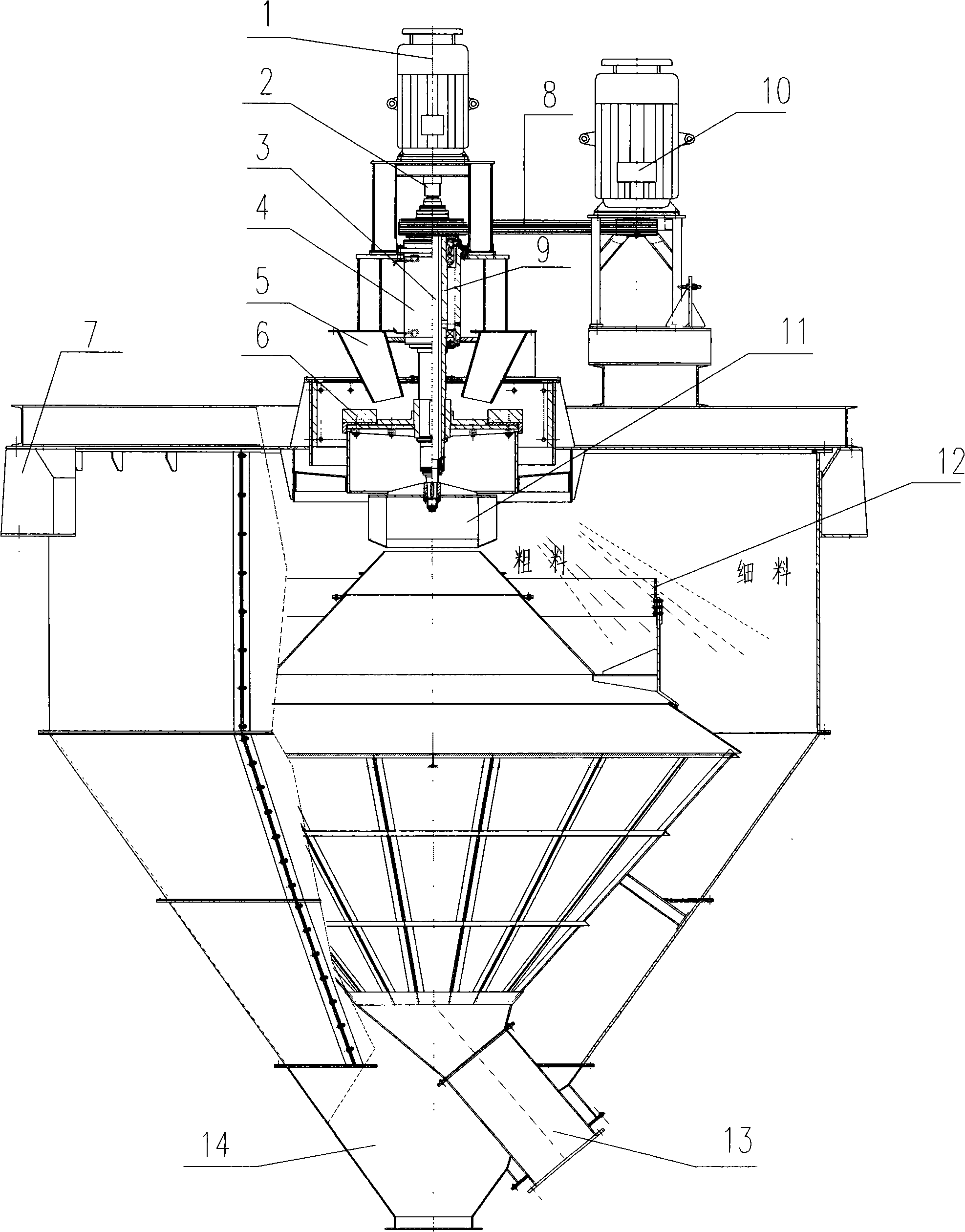

[0017] Such as figure 1 Shown: the device for breaking up and grading cake-collecting materials of the present invention consists of a wind turbine motor (1), a shaft coupling (2), a mandrel (3), a shell (4), a feed inlet (5), and a broken Disc (6), bracket (7), belt (8), hollow shaft (9), dispersing disc motor (10), wind wheel (11), adjusting plate (12), coarse material collecting cylinder (13), The fine material collection barrel (14) is composed of a tower-shaped feed inlet (5) fixed at the center of the cylindrical support (7), and a wind turbine motor (1) is installed on it, and the shaft coupling (2 ) is connected to the mandrel (3), and the mandrel (3) extends to 1 / 3 of the cavity of the bracket (7) to connect the wind wheel (11); a dispersing disc is fixed next to the wind wheel motor (1) above the bracket (7) The motor (10) is connected to the hollow shaft (9) through the belt (8), the hollow shaft (9) extends to the top of the wind wheel (11) and the dispersing disc...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com