Water diversion channel device for coal mine and using method thereof

A water diversion tank and coal mine technology, applied in safety devices, drainage, mining equipment, etc., can solve problems such as complex structure, inconvenient operation, waste of water sources, etc., and achieve the effects of low operation error rate, high diversion efficiency, and convenient operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

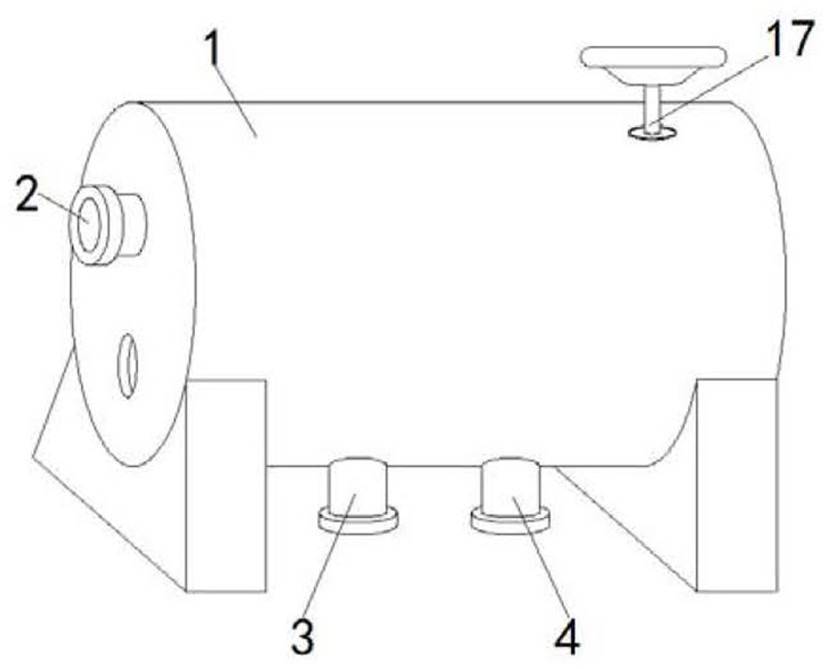

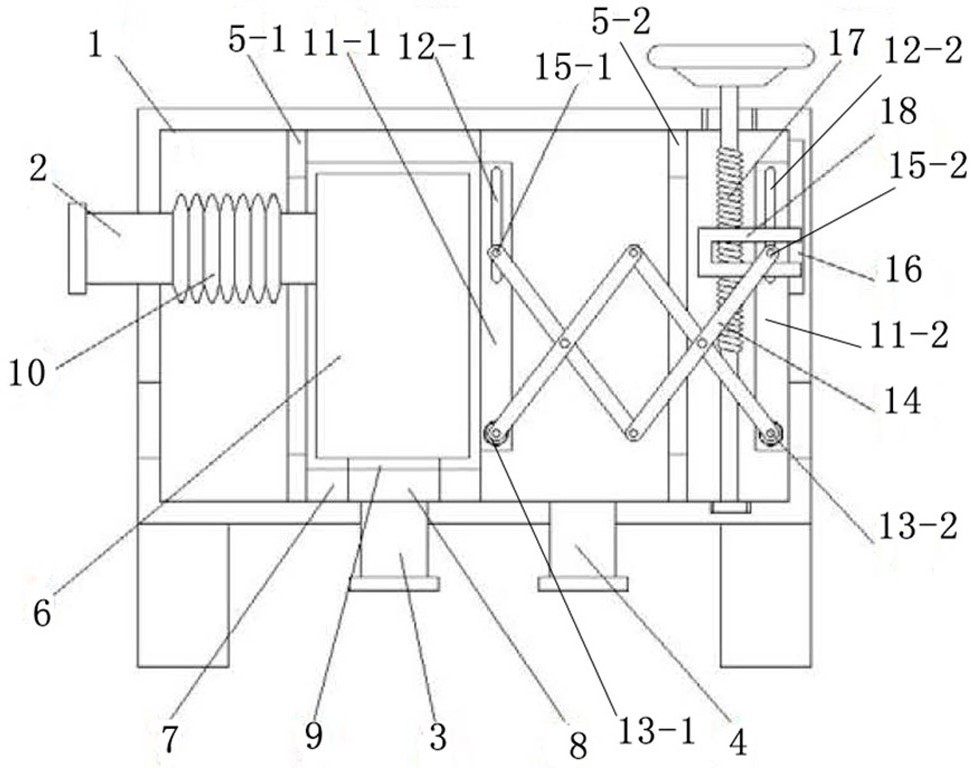

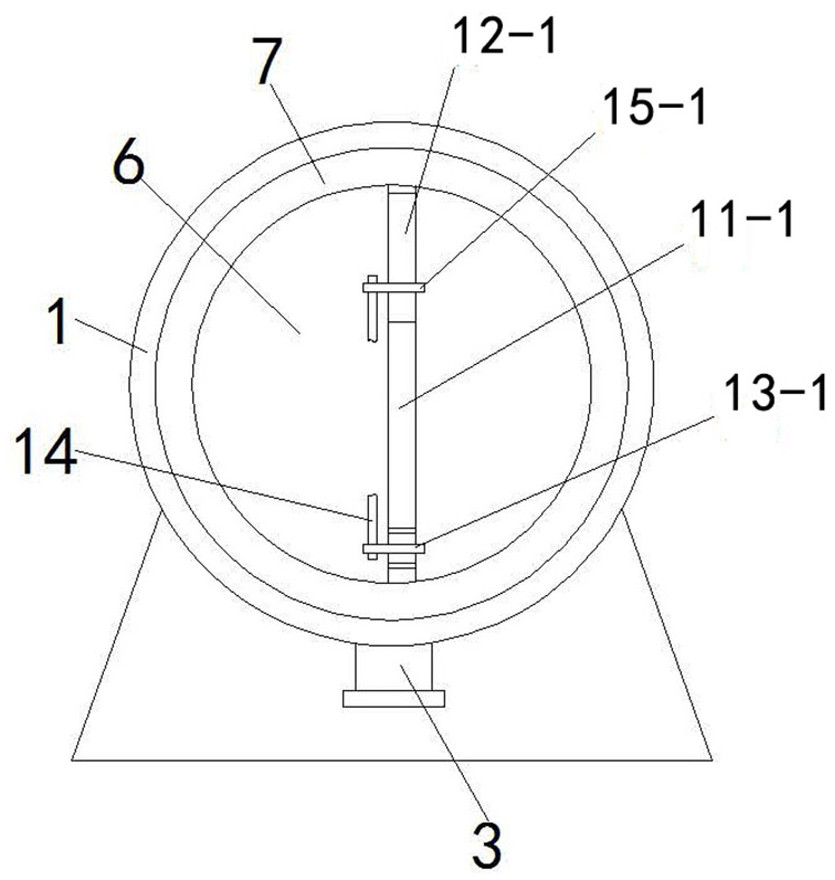

[0026] like Figure 1~3 A water diversion tank device for coal mine is shown, which includes a casing 1, the front end of the casing 1 is connected with a liquid inlet pipe 2, the bottom of the casing 1 is fixed with a support, and the front and rear sides of the casing 1 are provided with air holes. The first water outlet pipe 3 and the second water outlet pipe 4 are connected to the front and back of the lower part of the housing 1 in sequence, and a first stop ring 5-1 and a second The limit ring 5-2, the position of the first water outlet pipe 3 and the second water outlet pipe 4 are between the two limit rings, a movable water tank 6 is arranged between the two limit rings, and the lower cover of the water tank 6 There is a sealing block 7 attached to the lower wall of the housing 1, the inner wall of the housing 1 is a smooth wall (to facilitate the movement of the box and the bonding of the sealing block), the middle part of the sealing block 7 is provided with a throug...

Embodiment 2

[0037] Present embodiment is the method for adopting the device in embodiment 1 to divert clear water and sewage, and concrete operation is as follows:

[0038] 1) When the liquid to be transported is clean water, the liquid enters the inside of the water tank 6 through the liquid inlet pipe 2 and the telescopic pipe 10, and then the liquid passes through the perforation 9 and the through hole 8 in sequence and is exported from the first outlet pipe 3;

[0039] 2) When the liquid to be transported is sewage, turn the handwheel on the screw 17 to make the U-shaped piece 18 slide up along the chute 16, and the U-shaped piece 18 drives the second round rod 15-2 along the second sliding hole 12-2 Slide up so that the scissors frame 14 drives the first rotating shaft 13-1 close to the second rotating shaft 13-2, the first rotating shaft 13-1 drives the first vertical block 11-1 to move backward, and the first vertical block 11-1 drives the water tank 6 behind The water tank 6 drive...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com