Temperature distribution calculation method in H-shaped steel billet heating process

A technology of temperature distribution and calculation method, applied in the direction of heat treatment process control, heat treatment furnace, furnace type, etc., can solve problems such as temperature rise curve deviation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] The present invention will now be further described with reference to the accompanying drawings to make it clearer and easier to understand.

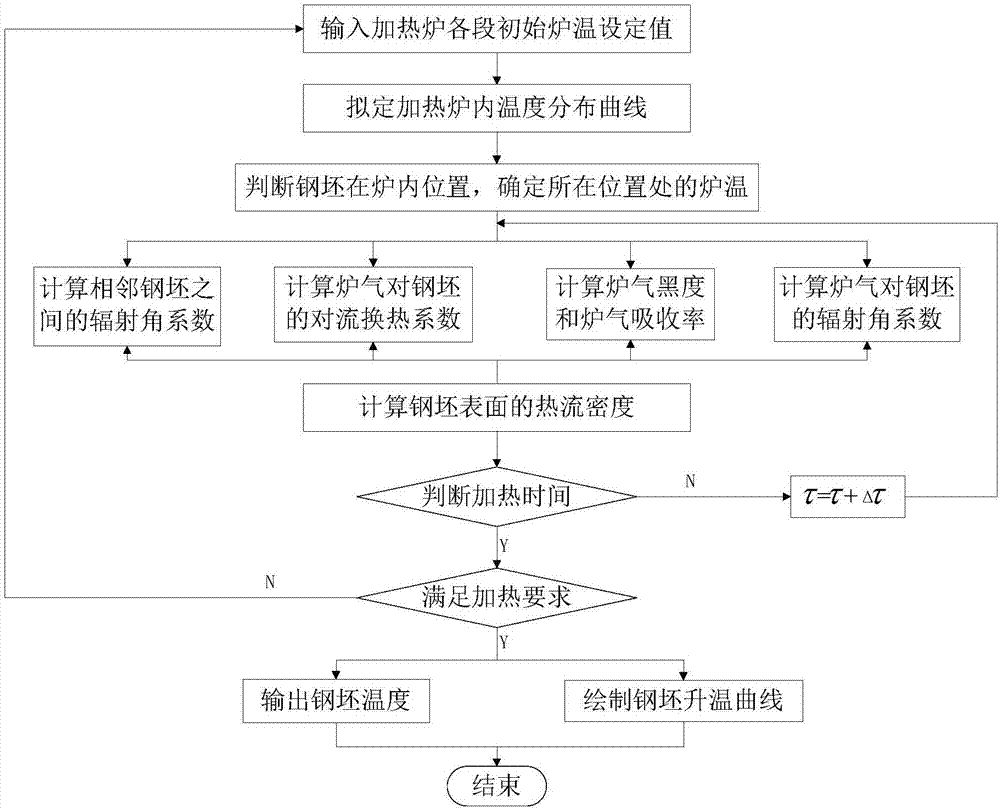

[0030] figure 1 It is a flowchart of the calculation method of the present invention. Such as figure 1 As shown, movable beams are distributed in the heating furnace, and water beams are arranged in the movable beams. When calculating the temperature distribution of the H-shaped billet heating process, the following steps are included:

[0031] 1) Input the initial furnace temperature settings of each section of the heating furnace, draw up the temperature distribution curve of the furnace temperature from the furnace inlet to the furnace outlet, determine the position of the billet in the furnace, and determine the furnace temperature at the location;

[0032] Among them, regarding the calculation of the heating furnace temperature, the heating furnace temperature is set as a function of the distribution along the length of the furnace...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com