Method for preparing printer anilox roller based on thermal spraying technology

A technology for thermal spraying and printing presses, applied in printing presses, general parts of printing machinery, printing and other directions to achieve the effects of high production efficiency, high hardness and good wear resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

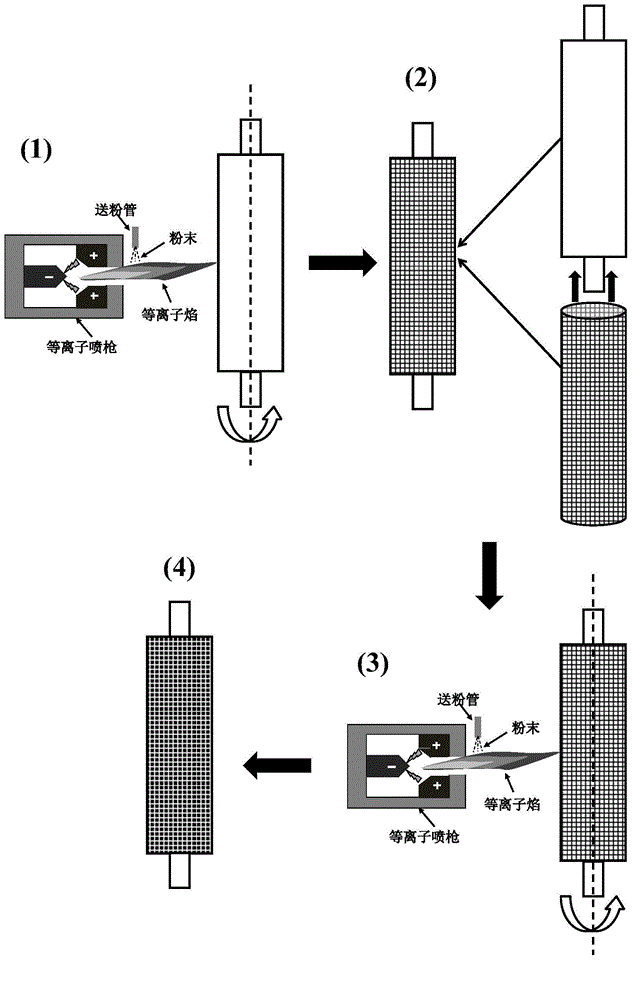

Method used

Image

Examples

Embodiment 1

[0043] In this embodiment, the anilox roller coating is composed of NiCrBSi coating and Cr 2 o 3 Coating composition, the NiCrBSi coating thickness is 90μm, Cr 2 o 3 The coating thickness was 350 μm. The NiCrBSi coating is prepared by thermal spraying of commercially available 15-45μm NiCrBSi powder, Cr 2 o 3 The coating is made of commercially available 10-40μm Cr 2 o 3 The powder is prepared by thermal spraying method, and the specific preparation method of the anilox roller is as follows:

[0044] 1. Before spraying, clean the substrate, remove oil and rust, and use 20-mesh alloy sand for surface blasting pretreatment to make the roughness meet the spraying requirements;

[0045] 2. First, spray the NiCrBSi coating, adopt the supersonic flame spraying method, and control the spraying parameters of the supersonic flame spraying gun as: supporting gas O 2 , The pressure of gas propane and compressed air are 10bar, 6bar, 7bar respectively, the flow rate is 240slpm, 70s...

Embodiment 2

[0051] In this embodiment, the anilox roller coating is sequentially composed of NiAl coating and Cr coating from the surface of the substrate. 2 o 3 Coating composition, the NiAl coating thickness is 100μm, Cr 2 o 3 The coating thickness was 380 μm. The NiAl coating is prepared from commercially available NiAl powder of 15-45 μm by thermal spraying method, Cr 2 o 3 The coating is made of commercially available 10-40μm Cr 2 o 3 The powder is prepared by thermal spraying method.

[0052] The specific preparation method of the above-mentioned anilox roller coating is the same as the preparation method in Example 1, the difference is that the powders are respectively NiAl and Cr 2 o 3 Powder, to obtain anilox roller surface coating.

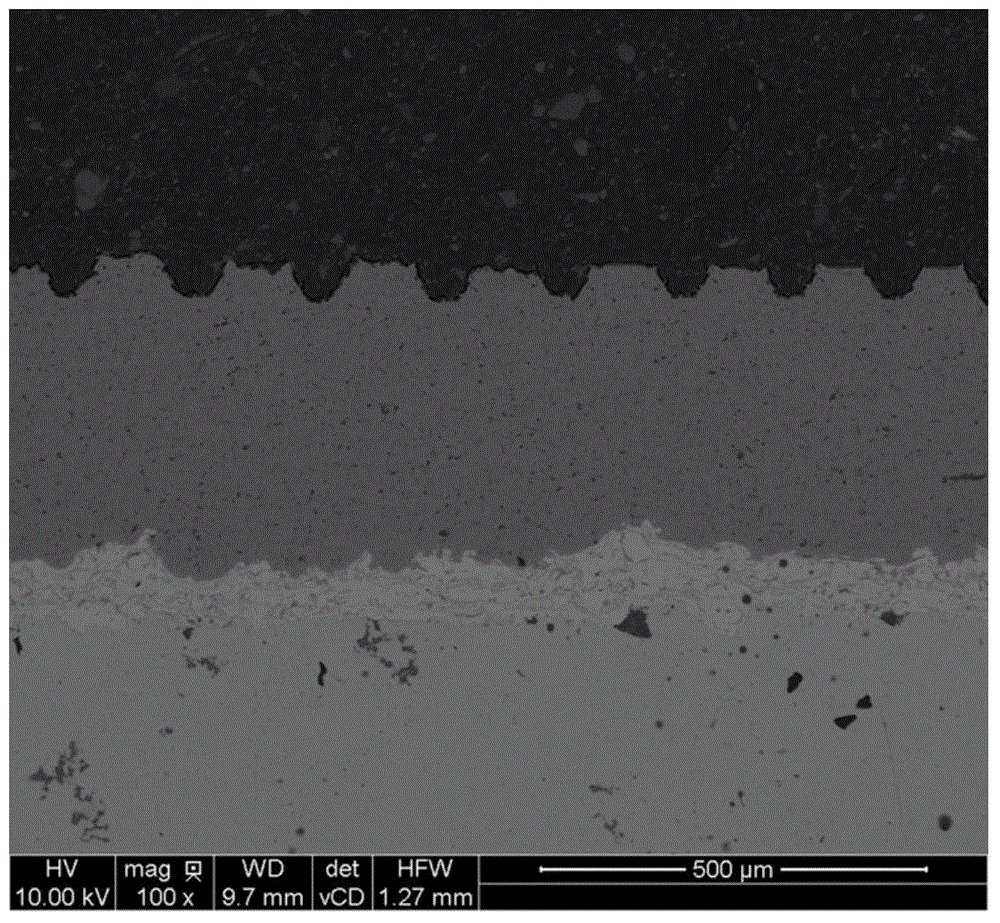

[0053] Carry out following performance test to the anilox roller coating that above-mentioned preparation obtains:

[0054] 1. Microhardness of coating: Cr is measured by coating microhardness test method 2 o 3 The average hardness of th...

Embodiment 3

[0057] In this embodiment, the anilox roller coating is sequentially composed of NiCrBSi coating and Al 2 o 3 Coating composition, the NiCrBSi coating thickness is 75μm, Al 2 o 3 The coating thickness is 300 μm. The NiCrBSi coating is prepared by thermal spraying of commercially available 15-45 μm NiCrBSi powder, Al 2 o 3 The coating is made of commercially available 10-40μm Al 2 o 3 The powder is prepared by thermal spraying method.

[0058] The specific preparation method of the above-mentioned anilox roller coating is the same as the preparation method in Example 1, the difference is that the powders are respectively NiCrBSi and Al 2 o 3 Powder, to obtain anilox roller surface coating.

[0059] Carry out following performance test to the anilox roller coating that above-mentioned preparation obtains:

[0060] 1. Coating microhardness: measured by the coating microhardness test method 2 o 3 The average hardness of the coating was 1175.4HV (73.7HRC).

[0061] 2. ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com