Cylindrical radiation porous medium heater capable of achieving diffusive combustion in cavity

A diffusion combustion, porous medium technology, applied in burners, gas fuel burners, combustion methods, etc., can solve the problems of single heat transfer mode and small heat transfer coefficient, and achieve improved radiation heat transfer performance, uniform heat transfer, The effect of improving space utilization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] The present invention will be further described below in conjunction with the accompanying drawings.

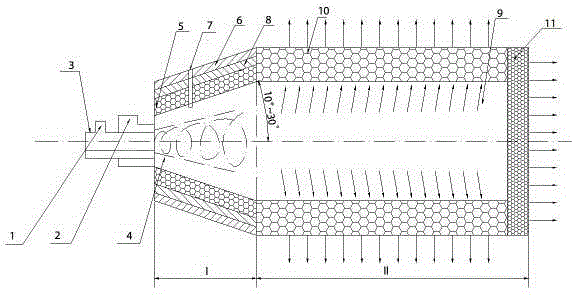

[0016] Such as figure 1 As shown, the swirl burner is designed as a whole, including three parts: swirl generator, combustion section and heat exchange section. Gas pipes and air pipes are designed on the swirl burner. Its volute structure is a whole steel plate rolled and welded, and the gas pipe, air pipe and generator are connected by welding as a whole. On the gas and air pipes, pipe threads are reserved to facilitate the connection with the corresponding pipes during on-site construction.

[0017] At the outlet of the swirl generator, a combustion section is installed, and the connection between the two is connected by welding. The specific connection method is: the whole steel plate of the combustion section is coiled and welded into a cone structure with an inclination angle of 10-30°, and the outlet of the swirl generator is welded to the steel plate on the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com