Efficient cooling LED backlight device

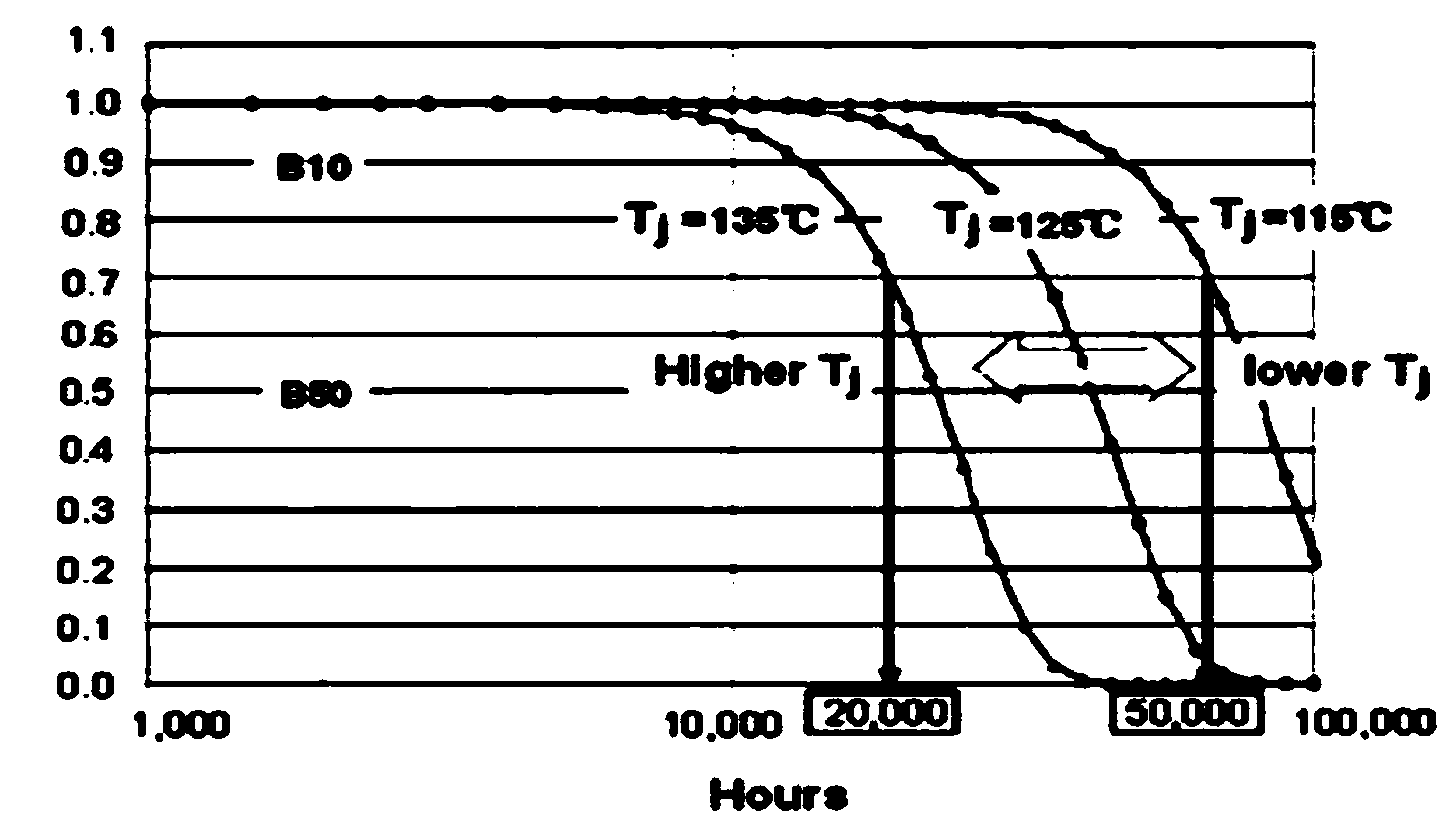

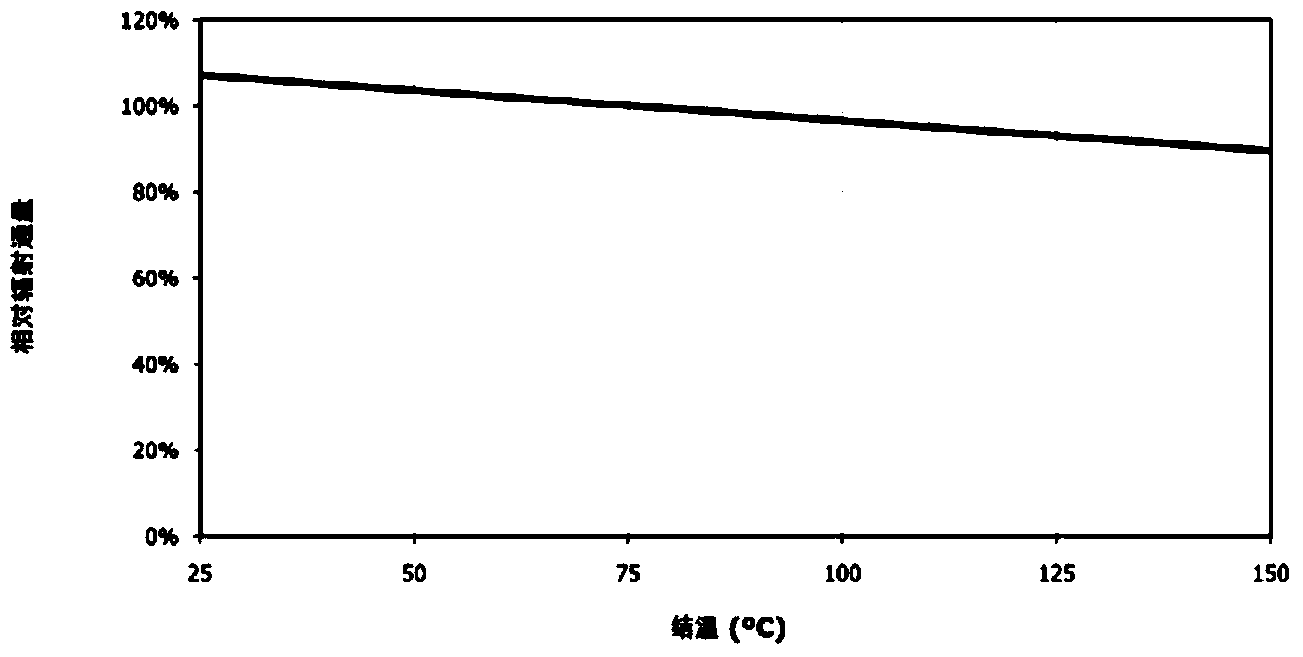

An LED backlight and LED lamp technology, which is applied to light sources, lighting devices, point light sources, etc., can solve the problems of poor thermal conductivity of the insulating resin layer 133, cannot meet the heat dissipation requirements of the backlight unit, and reduce the LED lamp 11, etc., so as to achieve enhanced Effects of radiation heat transfer capability, extended life, and improved reliability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

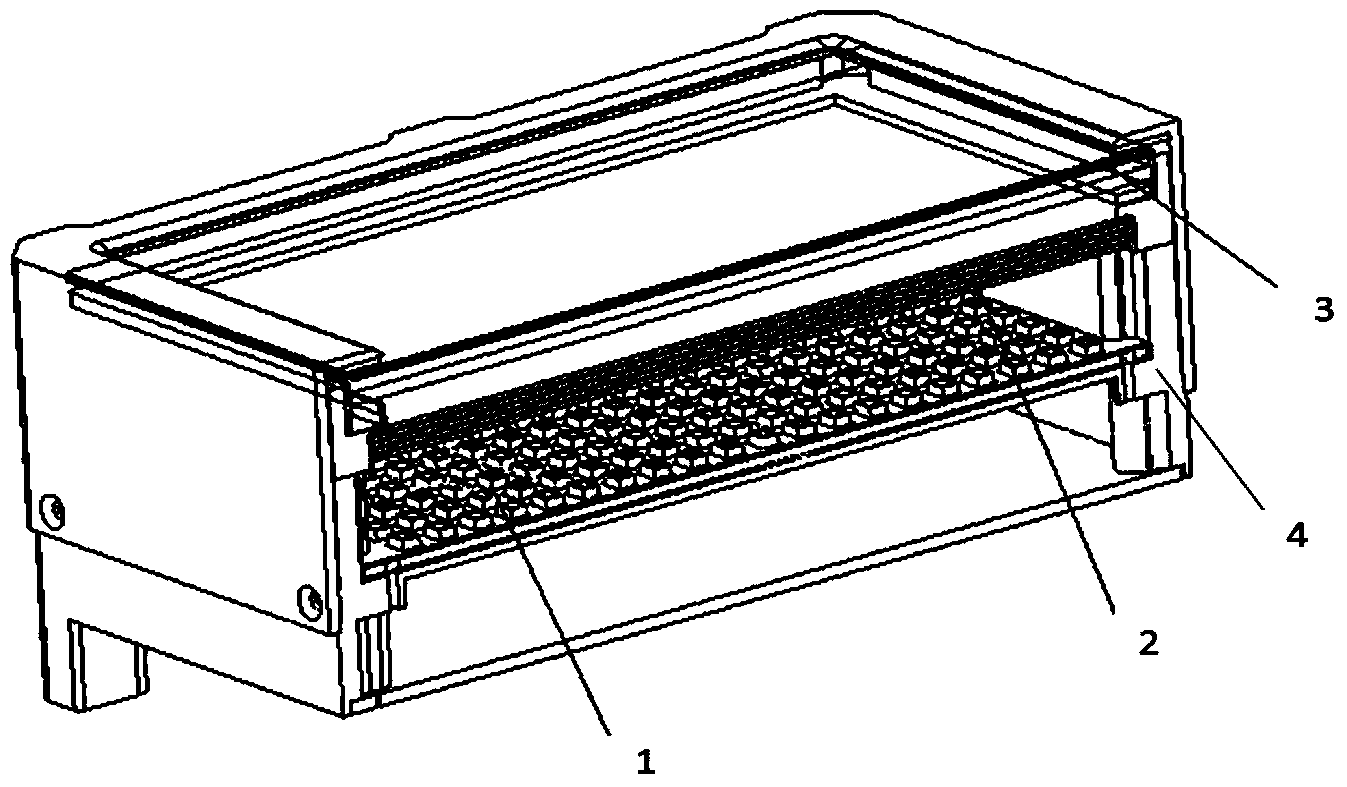

[0027] Such as Figure 6 As shown, a high-efficiency heat dissipation LED backlight device includes an LED lamp 11, a PCB lamp board 13, a heat-conducting material 14, a white reflector 12, and a backlight cavity structure 43. The LED lamp 11 is welded on the PCB lamp board 13, and the white The reflective sheet 12 is pasted on the inner wall of the backlight cavity structure 43 to effectively reduce the absorption of light by the backlight cavity and improve the light utilization rate of the backlight cavity. The heat-conducting material 14 is filled between the PCB lamp board 13 and the backlight cavity structure 43, The thermally conductive material 14 is thermally conductive silicone grease or a thermally conductive gasket, which can better conduct the heat on the upper surface of the PCB lamp board 1313 to the backlight cavity structure 43. On the lamp board 13, there are holes corresponding to the position of the LED lamp 11, so that the PCB lamp board 13 can be easily l...

Embodiment 2

[0029] Such as Figure 7As shown, a high-efficiency heat dissipation LED backlight device includes an LED lamp 11, a PCB lamp board 13, a heat-conducting material 14, a white reflector 12, and a backlight cavity structure 43. The LED lamp 11 is welded on the PCB lamp board 13, and the white The reflective sheet 12 is pasted on the inner wall of the backlight cavity structure 43 to effectively reduce the absorption of light by the backlight cavity and improve the light utilization rate of the backlight cavity. The heat-conducting material 14 is filled between the PCB lamp board 13 and the backlight cavity structure 43, The thermally conductive material 14 is thermally conductive silicone grease or a thermally conductive gasket, which can better conduct the heat on the upper surface of the PCB lamp board 13 to the backlight cavity structure 43 and the structural backplane 44, and the backlight cavity structure 43 and the white reflector 12 There are a plurality of openings corre...

PUM

| Property | Measurement | Unit |

|---|---|---|

| luminance | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com