Low-nitrogen combustion device for coal powder gasification combustion and combustion method

A low-nitrogen combustion, pulverized coal technology, which can be applied in combustion methods, combustion using multiple fuels, combustion using lump fuels and gaseous fuels, etc., can solve problems such as reduction of NOx emission concentration

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0079] The following is an embodiment of the present invention, which shows a low-nitrogen combustion device and combustion method for pulverized coal gasification combustion, which is only used as an explanation of the present invention and not a limitation.

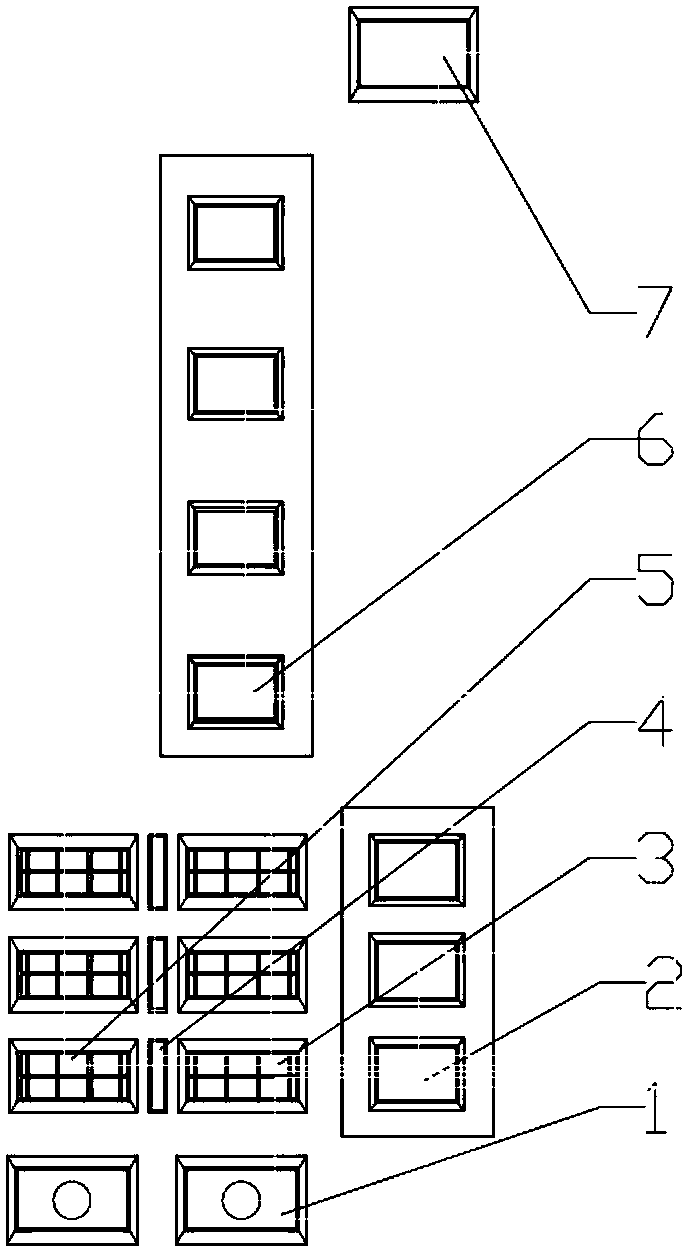

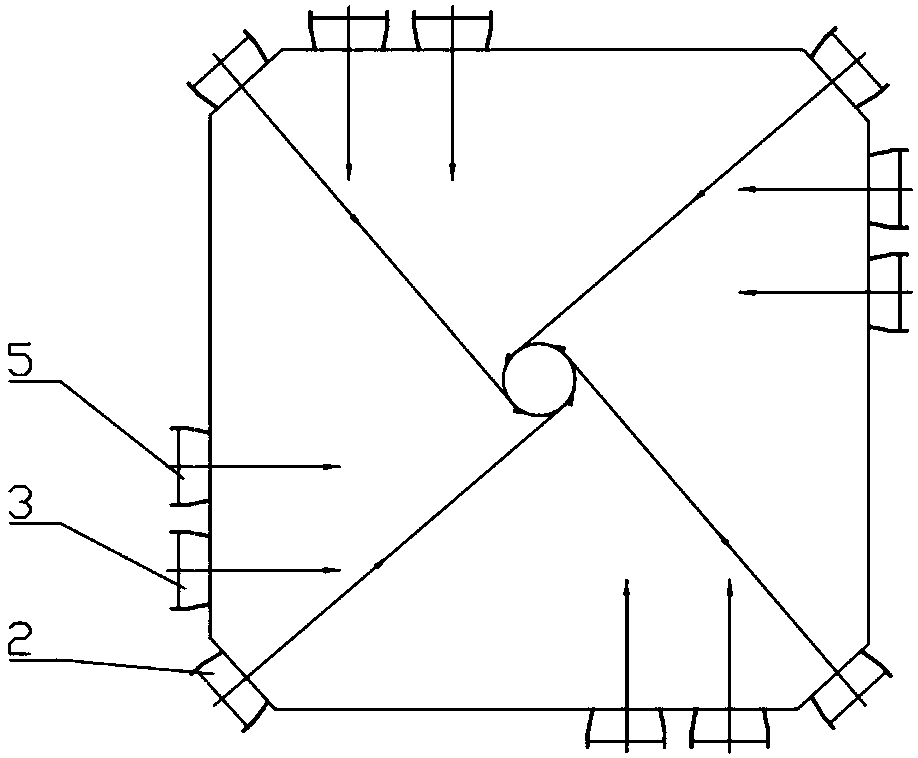

[0080] The low-nitrogen combustion device for pulverized coal gasification combustion provided by the present invention includes a multi-tangential combustion furnace, and the multi-tangential combustion furnace includes furnace corner walls and furnace side walls, and multiple tangential combustion furnace walls. A row of nozzle groups arranged along the height direction, the nozzle group includes the powder downwind nozzle 1, the gasification nozzle group composed of the gasification air nozzle 2, the second primary air nozzle 3 and the first primary air nozzle 5, and the combustion air The spout 6 and the top wind spout 7;

[0081] Among them, the first primary air nozzle, the second primary air nozzle and the gasifi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com