Batch feeder for boiler

A feeder and boiler technology, applied in the field of feeder, can solve the problems of high density of peanut shells, straw and wood chips, lack of heat, easy to form a pile, etc., to achieve high wind pressure, high work efficiency, and enhanced flame turbulence flow effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

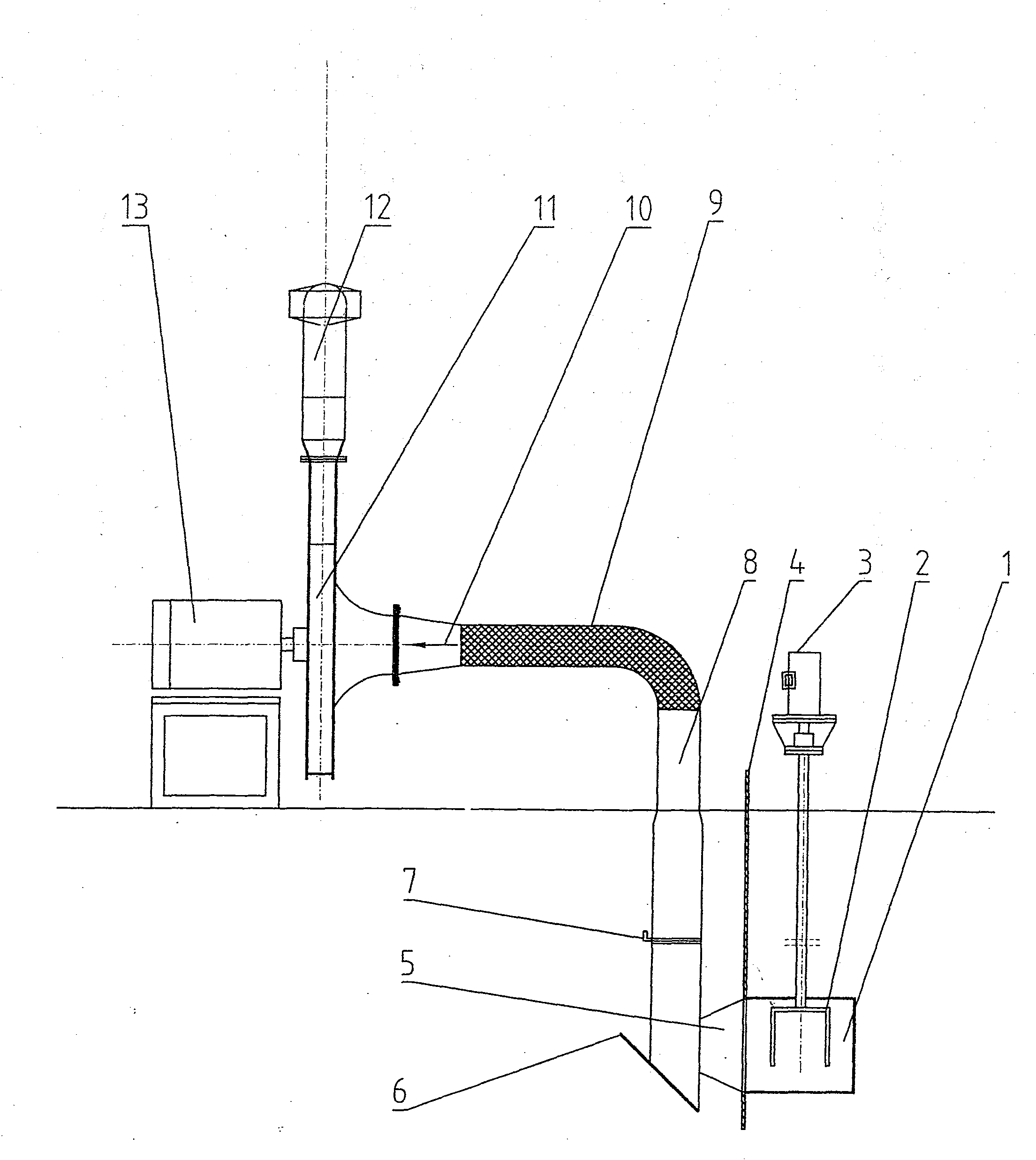

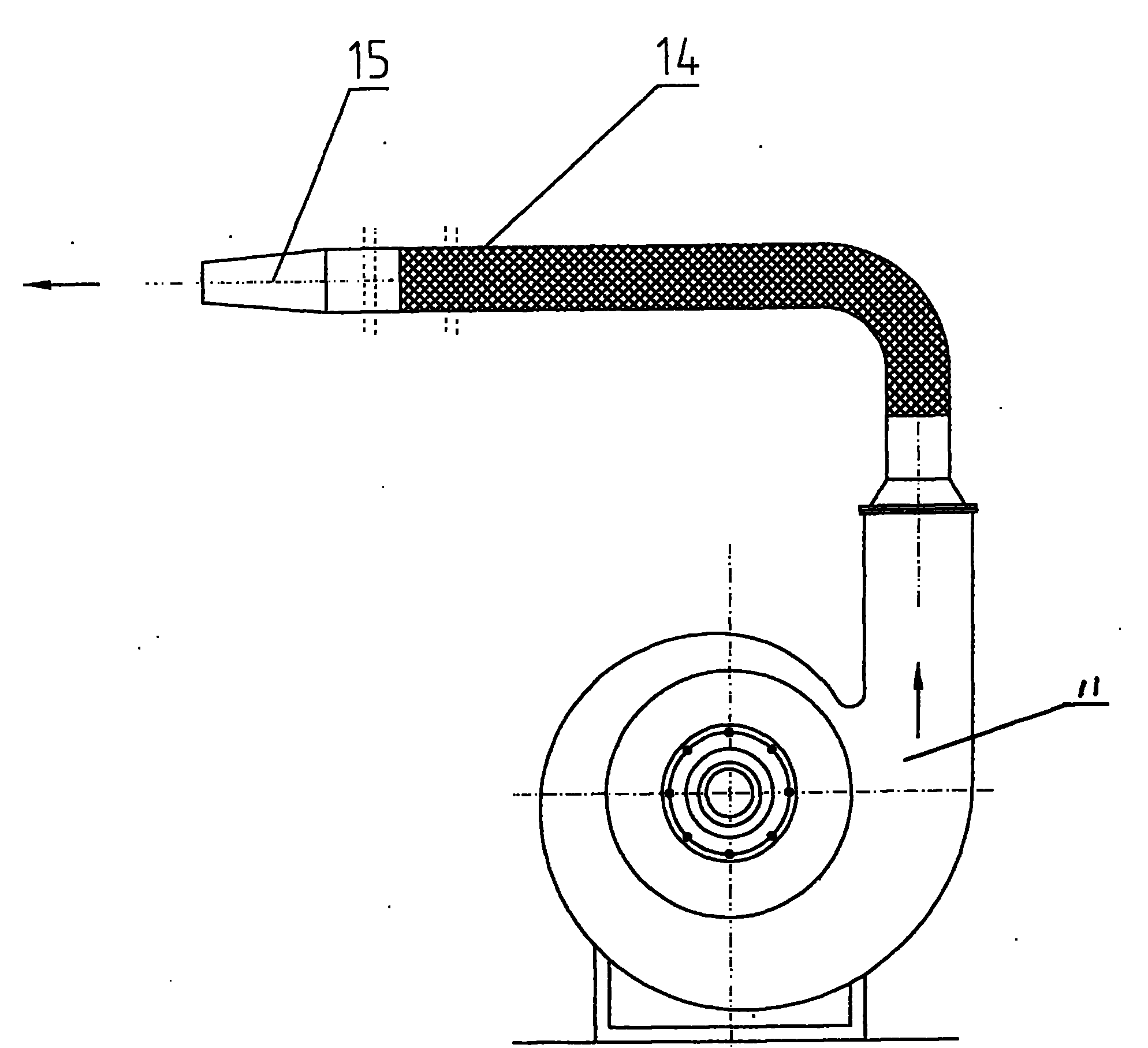

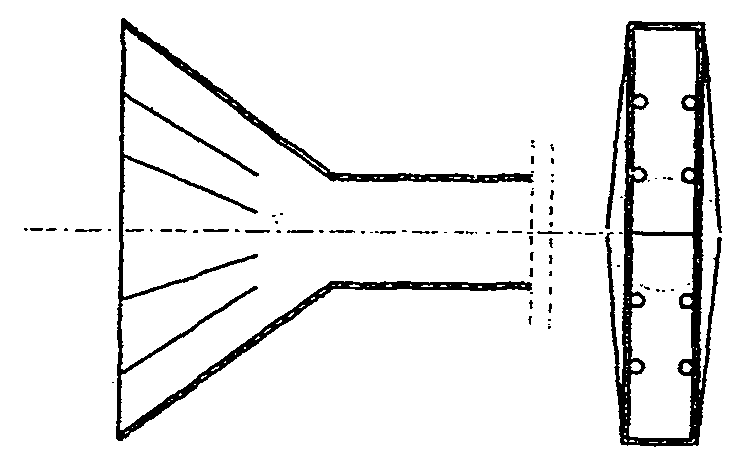

[0016] The material chamber 1 is made of iron plate and is in the shape of a cuboid. There is a square opening on one side, and there is a stirrer 2 inside. The lower end of the stirrer 2 is a "n" stirring fork, and the upper end is connected to the stirring motor 3. 3 is a 1.5KW motor, on the square mouth of the material chamber 1, one end of the feed port 5 is connected through the partition 4, the partition 4 is made of iron plate, the discharge port 5 is "eight" shaped, and the discharge port 2 The other end is connected with the feeding pipe 8, the feeding pipe 8 adopts an iron pipe, and is movably connected with the cleaning ram 6 at its lower end, and the cleaning ram 6 is made of a steel plate, which is rectangular, and the middle part of the feeding pipe 8 is movably connected with a wind turbine. The material control valve 7 and the air material control valve 7 are made of steel plates, which are "L" shaped. The upper end of the feed pipe 8 is connected to the fan inl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com