Gas burner

A burner, gas technology, applied in the direction of gas fuel burners, burners, combustion methods, etc., can solve problems such as poor stability, short flame, deflagration, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

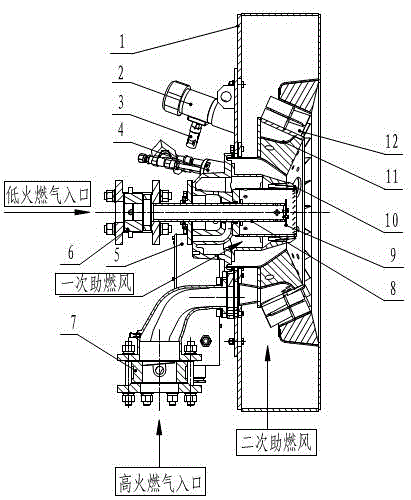

[0019] After the low-fire gas is sprayed through the low-fire gas nozzle hole, it is mixed with the high-speed and high-pressure primary combustion-supporting air for dynamic diffusion. After being ignited by the igniter, it realizes rapid and stable combustion and forms a low-fire flame. According to the requirement of load adjustment, the high-fire gas is sprayed into the secondary combustion-supporting air channel from the high-fire gas nozzle hole at an angle of 90° and at a speed of (30-70) m / s, so that the gas and air are premixed into a gas-air mixture. It is sprayed out from the annular nozzle and ignited by a low-fire flame to form a high-fire flame. The low-fire blunt body flame stabilizer fully reflows the high-temperature flue gas, ensures the reliability and stability of low-fire gas ignition, and avoids the occurrence of a fire-off state.

[0020] The burner is equipped with two sets of gas nozzles, one is a low-fire gas nozzle, and the other is a high-fi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com