Industrial high-temperature kiln

A high-temperature furnace and industrial technology, applied in the field of furnaces and industrial furnaces, can solve problems such as the influence of radiation heat transfer

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

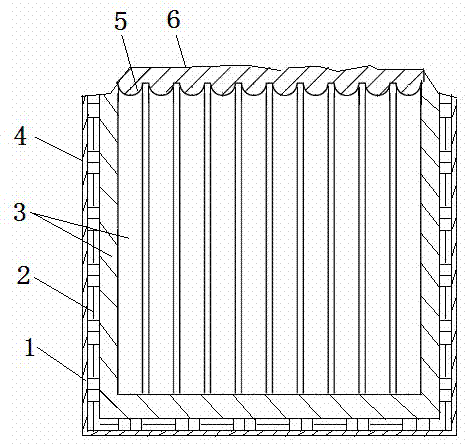

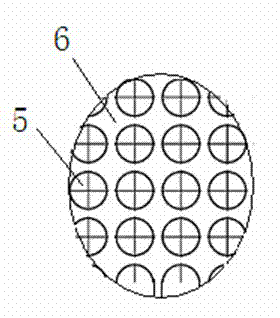

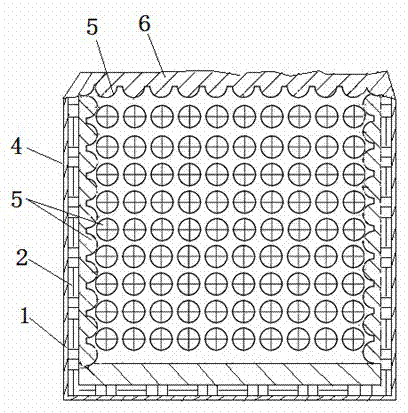

[0013] The present invention will be further described below in conjunction with the accompanying drawings.

[0014] The industrial high-temperature furnace kiln provided by the present invention comprises a hearth in it, and a body of furnace 4 whose periphery is a hearth wall, body of furnace 4 includes an outer metal shell 1, and a refractory brick layer 2 built on the inside of the metal shell 1, The refractory pouring layer arranged on the inner side of the refractory brick layer 2 is sprayed with a black coating on the inner side of the refractory casting layer. The refractory casting layer of the furnace top wall 6 is set as a hemispherical protrusion 5, and the hemispherical protrusion 5 is : per 1m 2 There are eighty hemispherical projections 5 in the area, the radius R of each hemispherical projection 5 is 30mm, and the distance between two hemispherical projections 5 is 90mm; It is a semicircular convex column 3, and the semicircular convex column 3 is: every 1m 2...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com