Coke oven three-way bridge pipeline heat exchanger device

A heat exchanger and bridge tube technology, which is applied in the field of coke oven three-way bridge tube heat exchanger devices, can solve the problems of internal deposition of tar and unsatisfactory use of coke treatment, so as to improve the heat transfer effect and enhance the heat transfer. effect, the effect of reducing the outside temperature

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] The present invention will be further described below in conjunction with the accompanying drawings.

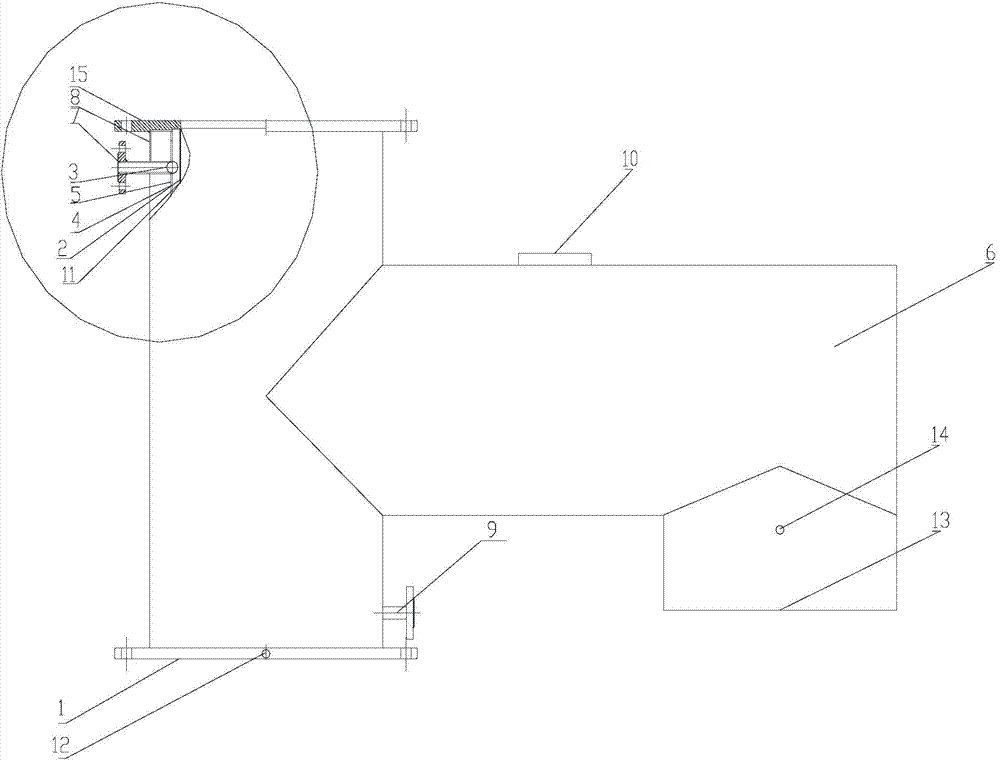

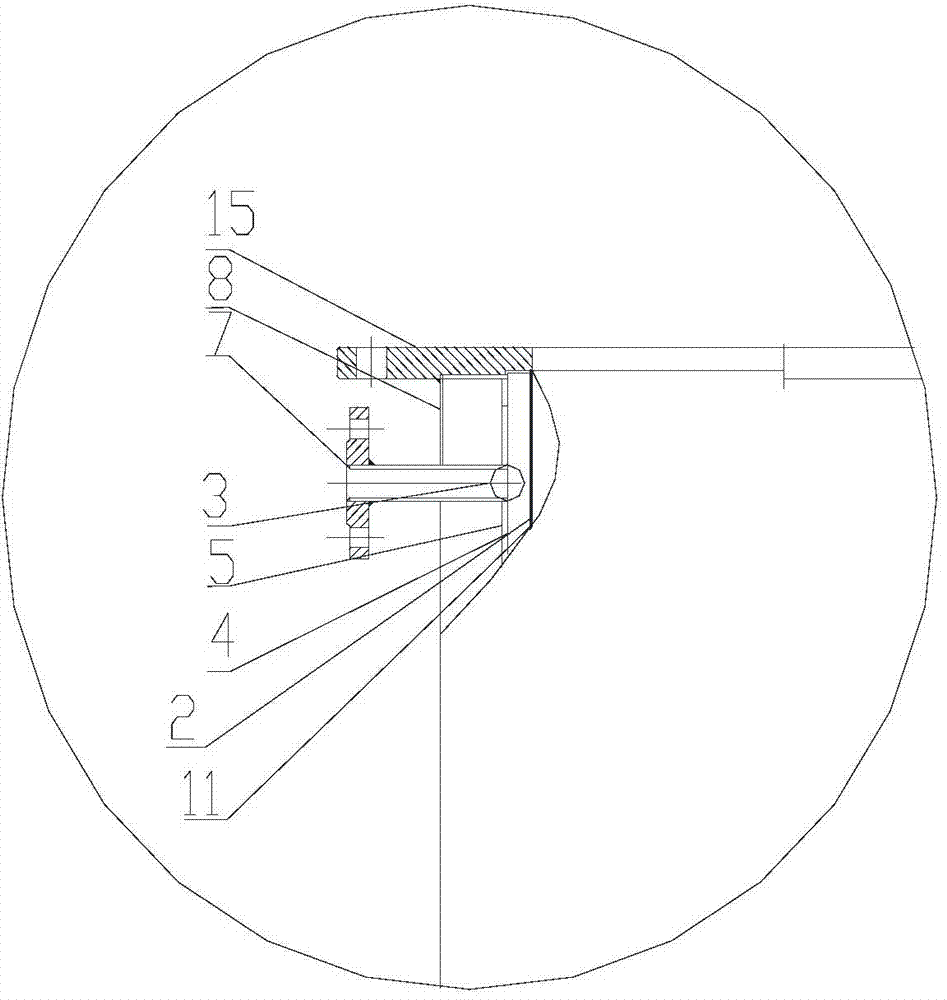

[0020] Such as figure 1 and figure 2 The shown coke oven tee bridge tube heat exchanger device includes a vertical pipe section 8 and a horizontal pipe section 6 connected to the vertical pipe section 8, the horizontal pipe section is connected in the middle of the vertical pipe section, and the lower end of the vertical pipe section 8 is the flue gas inlet 12. The upper end is a coke cleaning hole 15, which is convenient for users to clean the heat exchanger device, improves the efficiency of heat exchange, and is conducive to the reuse of waste heat. The end of the horizontal pipe section 6 is provided with a flue gas outlet 13, The top of the horizontal pipe section 6 is provided with an ammonia water spray hole 10, and the inside of the vertical pipe section 8 is provided with a heat exchange sleeve, which includes a heat exchange inner sleeve 2 and a heat exchan...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com