A high-performance flame-retardant pc/pet alloy material and its preparation method

A technology of alloy material and hindered phenol, which is applied in the field of PC/PET alloy material and its preparation, can solve the problems of appearance, processing performance and mechanical performance decline, and achieve the effect of good appearance, simple process and price advantage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

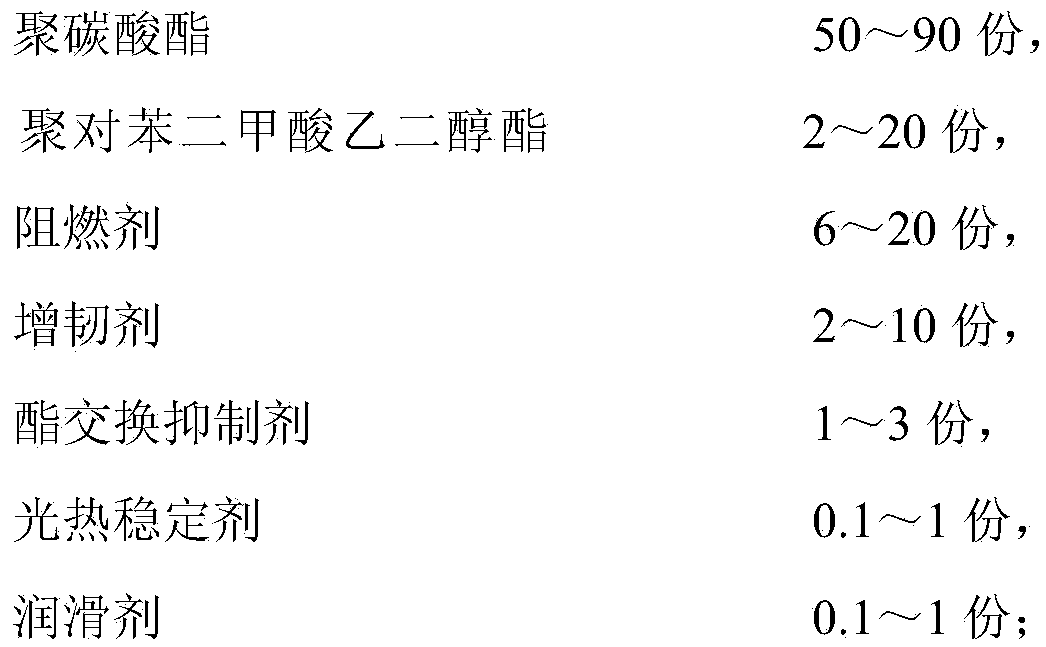

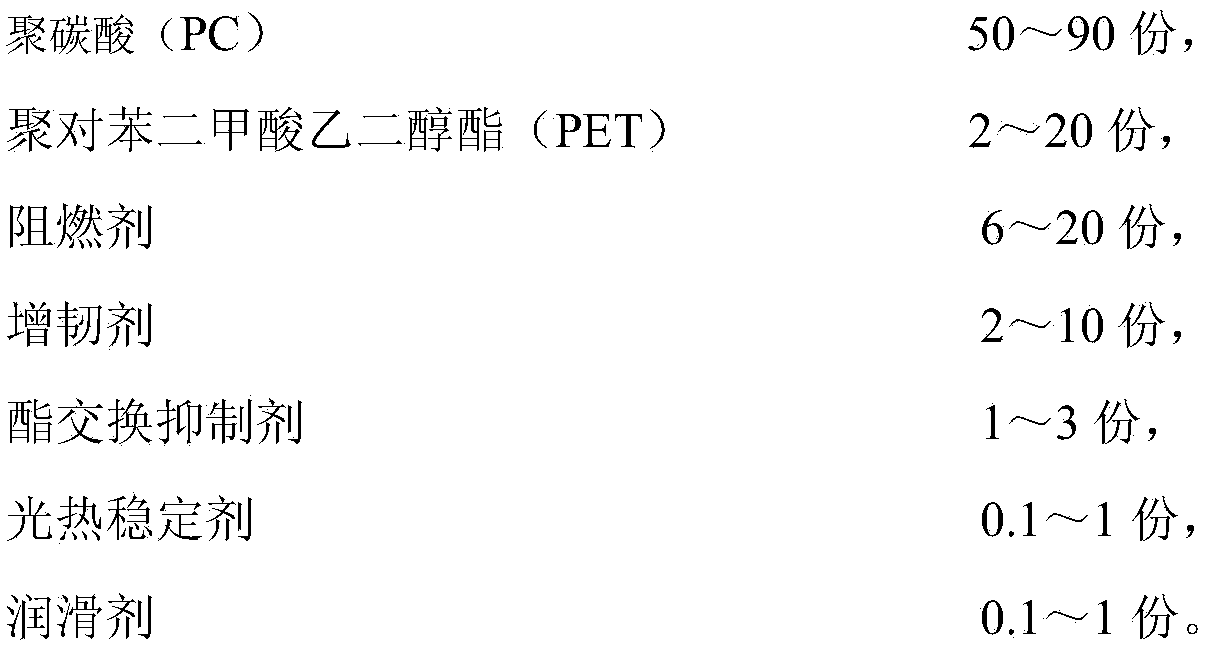

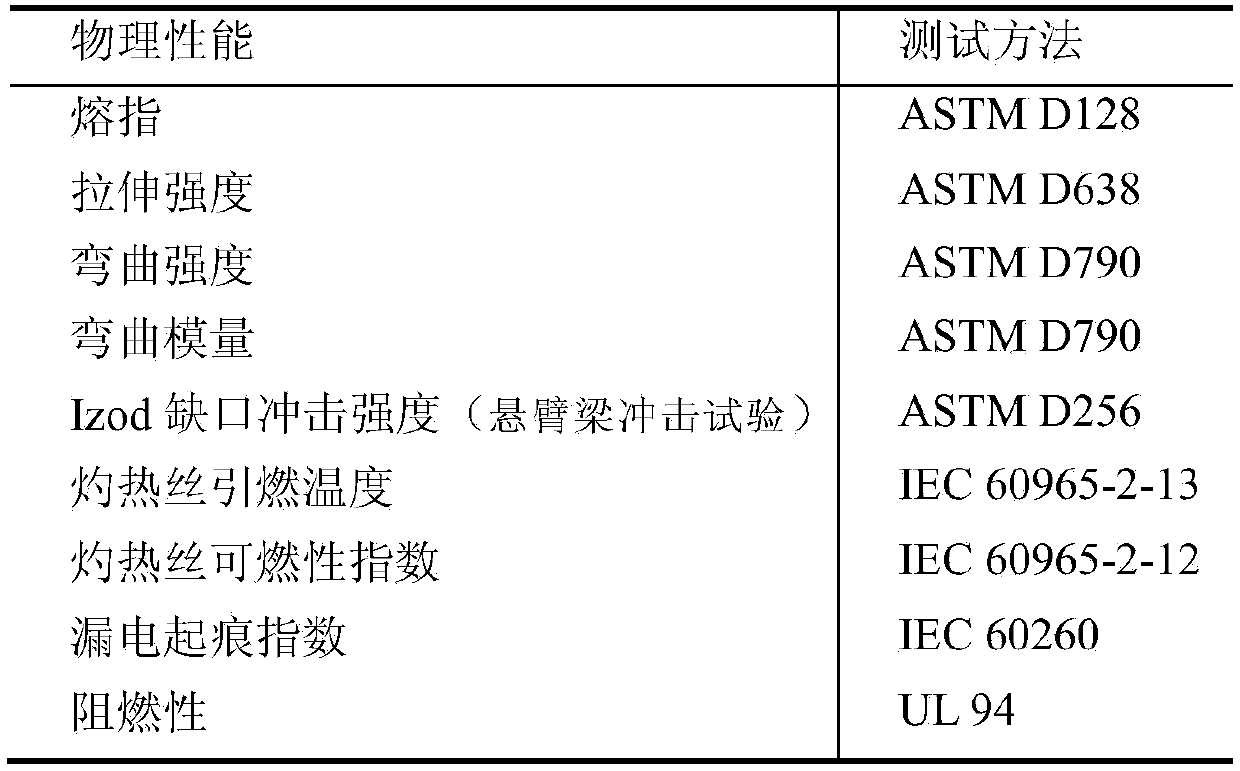

Method used

Image

Examples

Embodiment 1

[0041] (1) 90 parts of PCIR2200 resin, 2 parts of PETCB-608S resin, 2 parts of toughening agent EM500, 6 parts of flame retardant KBE-2025K, 1 part of transesterification inhibitor TPP, 0.3 part of light and heat stabilizer (antioxidant 1076: Antioxidant 168=1:2, mass ratio) and 0.1 part of lubricant PETS are mixed evenly by high-speed stirring;

[0042] (2) Send the above mixture into a twin-screw extruder, fully melt and compound under the conveying and shearing action of the screw, and then extrude through the machine head, draw, cool and pelletize.

[0043] The temperature of the first zone of the twin-screw extruder is controlled between room temperature and 80°C, and the temperature of the screws in the other sections (from the second zone to the machine head) is controlled at 220-250°C, and the screw speed is 400r / min.

[0044] The prepared compound was injection-molded into a standard sample bar for testing according to the standard size, and the performance test resul...

Embodiment 2

[0046](1) 70 parts of PCIR2200 resin, 14 parts of PETCB-608S resin, 6 parts of toughening agent EM500, 10 parts of flame retardant KBE-2025K, 2 parts of transesterification inhibitor TPP, 0.6 part of light and heat stabilizer (antioxidant 1076: Antioxidant 168=1:2, mass ratio) and 0.5 parts of lubricant PETS are mixed evenly by high-speed stirring;

[0047] (2) Send the above mixture into a twin-screw extruder, fully melt and compound under the conveying and shearing action of the screw, and then extrude through the machine head, draw, cool and pelletize.

[0048] The temperature of the first zone of the twin-screw extruder is controlled between room temperature and 80°C, and the temperature of the screws in the other sections (from the second zone to the head) is controlled between 220 and 250°C, and the screw speed is 400r / min.

[0049] The prepared compound was injection-molded into a standard sample bar for testing according to the standard size, and the performance test r...

Embodiment 3

[0051] (1) 50 parts of PCIR2200 resin, 20 parts of PETCB-608S resin, 10 parts of toughening agent EM500, 20 parts of flame retardant KBE-2025K, 3 parts of transesterification inhibitor TPP, 0.9 part of light and heat stabilizer (antioxidant 1076: Antioxidant 168=1:2, mass ratio) and 1 part of lubricant PETS are mixed evenly by high-speed stirring;

[0052] (2) Send the above mixture into a twin-screw extruder, fully melt and compound under the conveying and shearing action of the screw, and then extrude through the machine head, draw, cool and pelletize.

[0053] The temperature of the first zone of the twin-screw extruder is controlled between room temperature and 80°C, and the temperature of the screws in the other sections (from the second zone to the machine head) is controlled at 220-250°C, and the screw speed is 400r / min.

[0054] The prepared compound was injection-molded into a standard sample bar for testing according to the standard size, and the performance test res...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

| melting point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com