Halogen free flame retardant PVC material and preparation method thereof

A technology for PVC materials and flame-retardant dyes, which is applied in the field of halogen-free flame-retardant PVC materials and its preparation, and can solve the problems of affecting the flame-retardant properties of materials, low flame-retardant properties, and poor compatibility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0021] The specific preparation process of unsaturated chromatids is as follows:

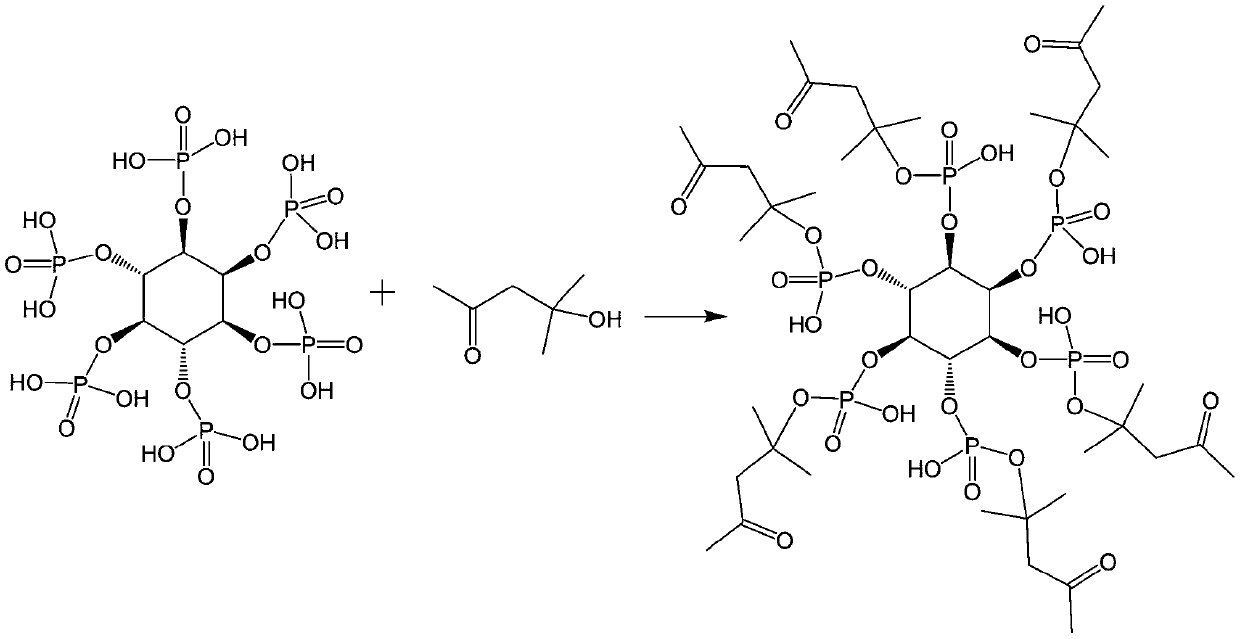

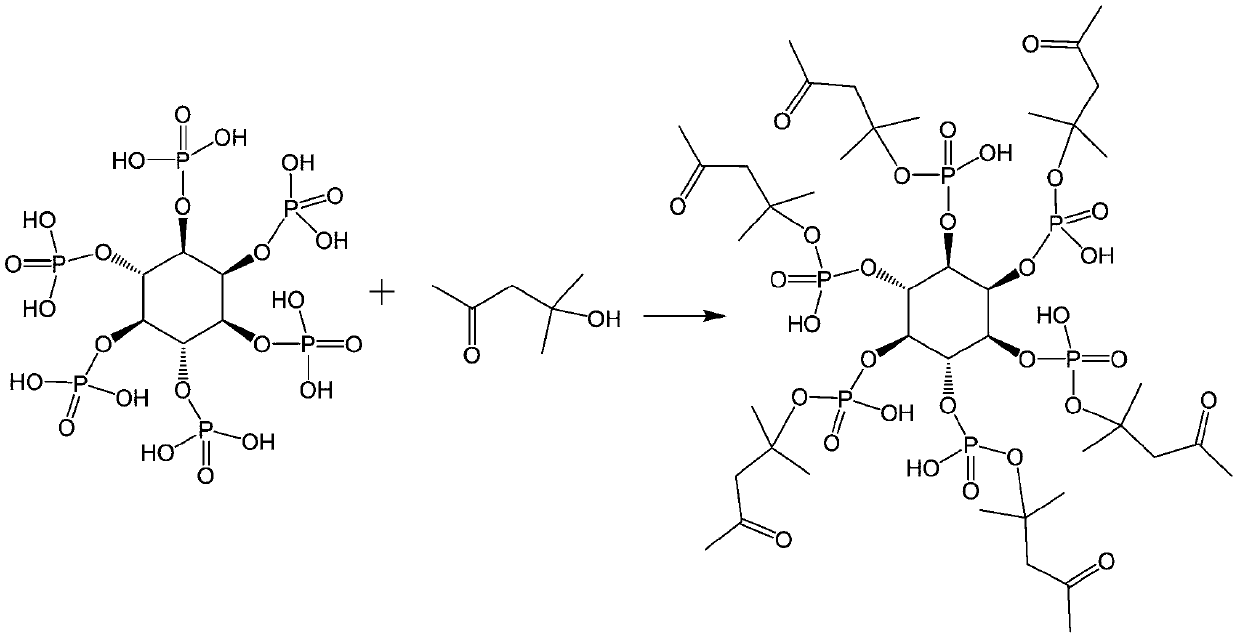

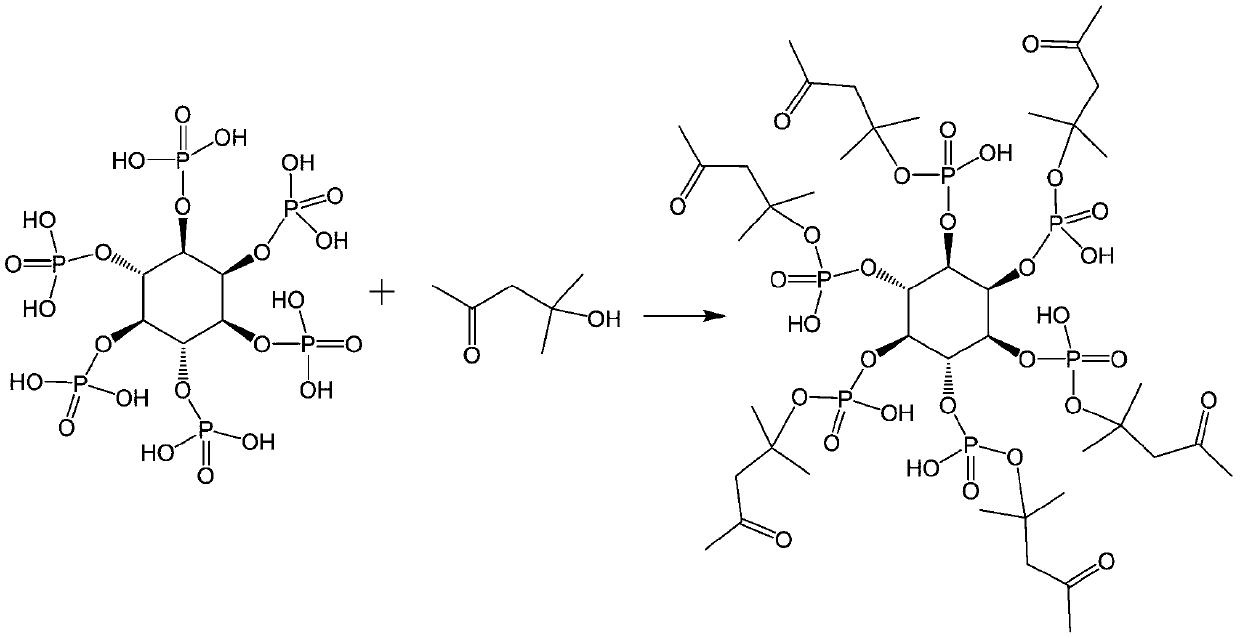

[0022] Step 1: Weigh 100g of phytic acid and dissolve it in water to form a phytic acid solution with a concentration of 60%, then add 108g of 2-methyl-4-oxo-2-pentanol and the prepared phytic acid solution to the reaction vessel at the same time, Then raise the temperature to 80-85°C and stir for 4-5h at constant temperature, then evaporate to remove the solvent to obtain product A, and the reaction structure is as follows;

[0023]

[0024] Step 2: Mix concentrated hydrochloric acid with a mass concentration of 70% and concentrated sulfuric acid with a mass concentration of 60% according to a volume ratio of 1:4 to prepare a mixed acid solution, and then add 120mL of the mixed acid solution and 23g of the direct dye to the reaction at the same time In the kettle, lower the temperature to 10-15°C, then add 3.6g of paraformaldehyde and 10g of product A to it, stir and react at constant temper...

Embodiment 2

[0027]The specific preparation process of the unsaturated chromatid is as follows: add 100g of direct dye to 200mL of water and stir to dissolve, then raise the temperature to 250°C, add 8g of p-toluenesulfonic acid to it, stir for 4-5min, then add 26g of maleic anhydride, and then react under constant temperature reflux 15-16h, then filter, wash and dry to obtain unsaturated chromatids.

Embodiment 3

[0029] The specific preparation method of unsaturated piperidine amine monomer is as follows: Add 15.6g of 2,2,6,6-tetramethylpiperidinamine into 200mL of ether, then add 7g of crotonaldehyde to it, heat up to 70-80°C for reflux reaction 8-10h, and then carry out vacuum distillation to obtain a light yellow liquid, which is the unsaturated piperidine amine monomer.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com