Anti-cracking and anti-ageing sealing rubber strip for glass doors and windows

A sealing strip and anti-aging technology, which is applied in the field of door and window processing, can solve the problems of poor toughness, broken sealing strip, and easy aging and deformation of materials, and achieve the effect of improving the balance of comprehensive performance, mechanical strength and weather resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

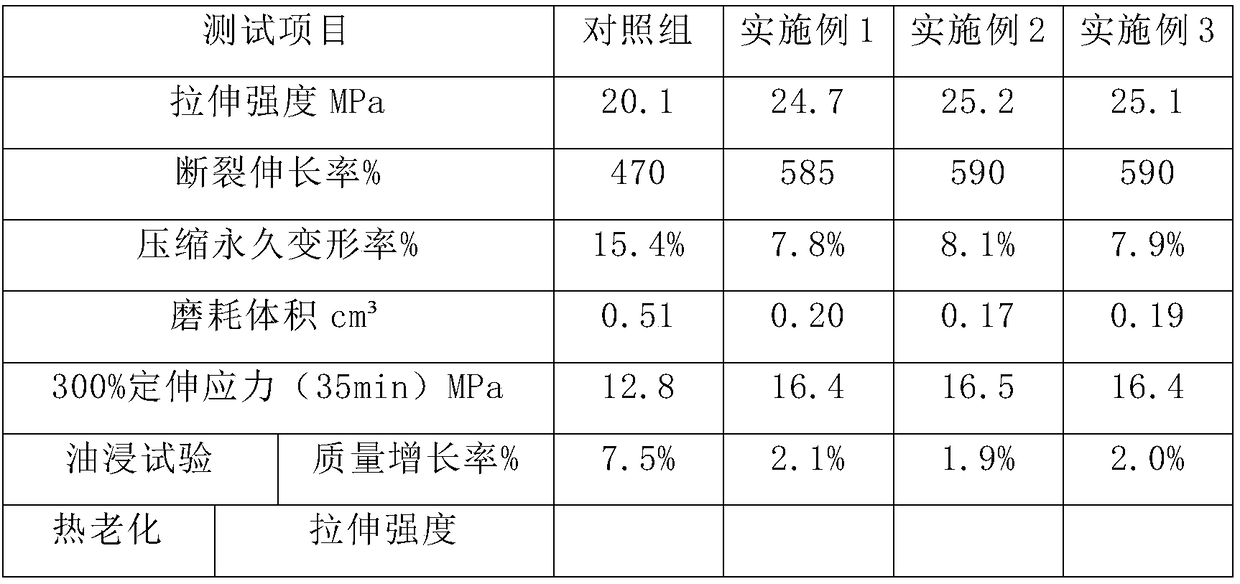

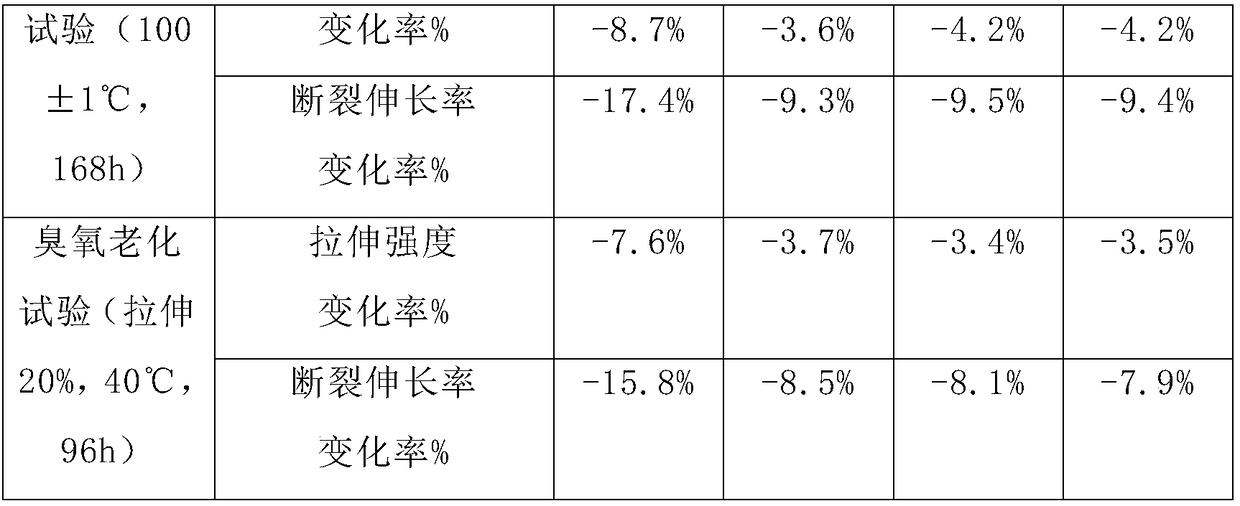

Embodiment 1

[0036]An anti-cracking and anti-aging sealing strip for glass doors and windows. The sealing strip is made of a laminated filling core composed of non-woven fabric and rubber material covered by the outer layer. The non-woven fabric and film are laminated and hot-pressed. Composite, the thickness of the film between every two layers of non-woven fabric is 2mm; according to the mass parts, the material components of the film include: 20 parts of nitrile rubber, 30 parts of natural rubber, 40 parts of EPDM rubber, light 8 parts of calcium carbonate, 4 parts of reinforcing agent, 1 part of coupling agent, 1 part of anti-aging agent, 2 parts of catalytic crosslinking agent, and 1 part of active agent.

[0037] Wherein, the reinforcing agent is MT carbon black.

[0038] Antiaging agent is antiaging agent RD.

[0039] The active agent is nanometer zinc dioxide.

[0040] The preparation method of film in the present embodiment is:

[0041] According to the parts by mass, put nitri...

Embodiment 2

[0043] An anti-cracking and anti-aging sealing strip for glass doors and windows. The sealing strip is made of a laminated filling core composed of non-woven fabric and rubber material covered by the outer layer. The non-woven fabric and film are laminated and hot-pressed. Composite, the thickness of the film between every two layers of non-woven fabric is 2.5mm; according to the mass parts, the material components of the film include: 30 parts of nitrile rubber, 35 parts of natural rubber, 50 parts of EPDM rubber, 13 parts of light calcium carbonate, 9 parts of reinforcing agent, 1.6 parts of coupling agent, 2 parts of anti-aging agent, 3 parts of catalytic crosslinking agent, and 2 parts of active agent.

[0044] Wherein, the reinforcing agent is MT carbon black.

[0045] Antiaging agent is antiaging agent D.

[0046] The active agent is nanometer zinc dioxide.

[0047] The preparation method of film in the present embodiment is:

[0048] According to the parts by mass, p...

Embodiment 3

[0050] An anti-cracking and anti-aging sealing strip for glass doors and windows. The sealing strip is made of a laminated filling core composed of non-woven fabric and rubber material covered by the outer layer. The non-woven fabric and film are laminated and hot-pressed. Composite, the thickness of the film between each two layers of non-woven fabric is 2mm; according to the mass parts, the material components of the film include: 25 parts of nitrile rubber, 33 parts of natural rubber, 46 parts of EPDM rubber, light 11 parts of calcium carbonate, 7 parts of reinforcing agent, 1.4 parts of coupling agent, 1.5 parts of anti-aging agent, 2.6 parts of catalytic crosslinking agent, and 1.4 parts of active agent.

[0051] Wherein, the reinforcing agent is MT carbon black.

[0052] Anti-aging agent is anti-aging agent 264.

[0053] The active agent is nanometer zinc dioxide.

[0054] The preparation method of film in the present embodiment is:

[0055] According to the mass part...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com