A kind of bulk halogen-free flame-retardant TPU modified material and preparation method thereof

A modified material and ontology technology, applied in the field of flame retardant, can solve the problems of reducing the strength and toughness, tensile strength and aging resistance of materials, easy dripping, poor flame retardant effect, etc., and achieve flame retardant and various performance testing. The effect of uniform data and uniform dispersion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

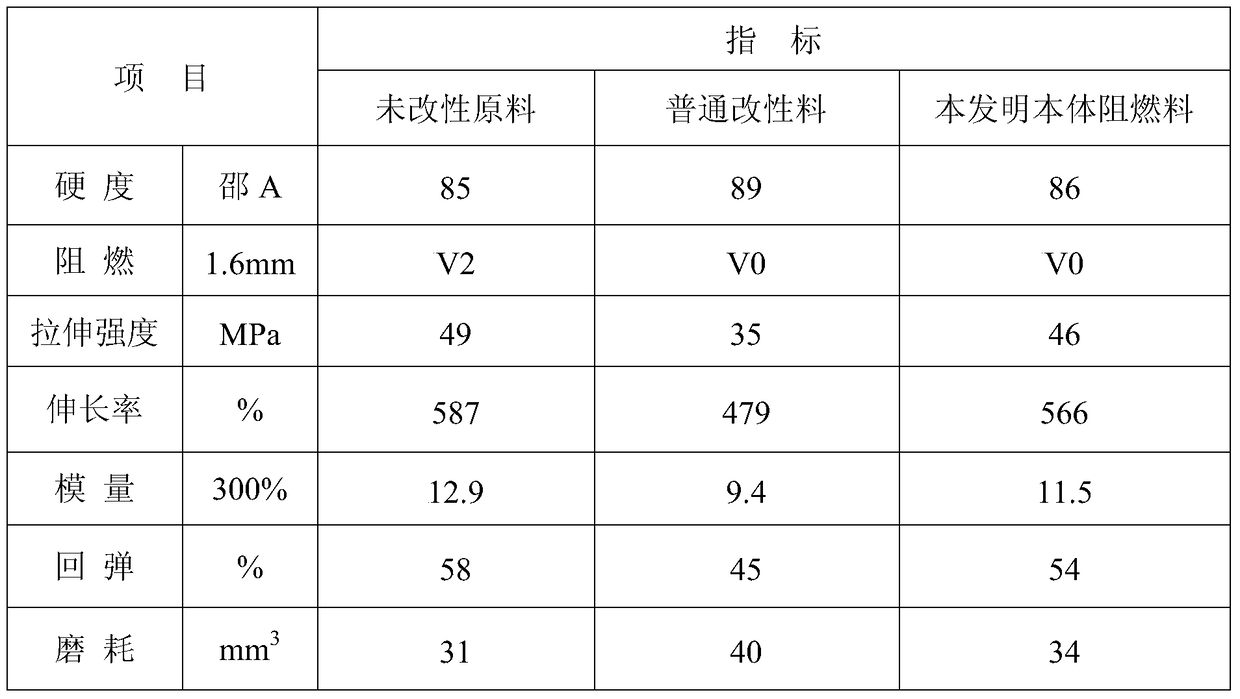

Embodiment 1

[0024] Melt polybutylene adipate at a temperature of 70°C and diphenylmethane diisocyanate at a temperature of 55°C for subsequent use, then heat the reactor body to 70°C, and heat the curing chopping board to 160°C. Then add 100 parts of polytetramethylene glycol adipate into the kettle, and then put in 17.5 parts of 1,4-butanediol and a very small amount of phosphoric acid in the environmental medium to make the amount of phosphoric acid in the system 3.5ppm, and then add 20 parts of city Sell HT-219TPU special halogen-free flame retardant (Medium particle size is less than 8μm, Jinan Taixing Fine Chemical Co., Ltd., batch number 1505012) for stirring and mixing, nitrogen protection, after stirring for 50 minutes, add 63 parts of diphenylmethane diisocyanate , emulsified polymerization reaction for 80s. After the reaction, transfer the material to the chopping board for curing. After the material block is cooled and crushed, it is extruded and granulated to obtain the final...

Embodiment 2

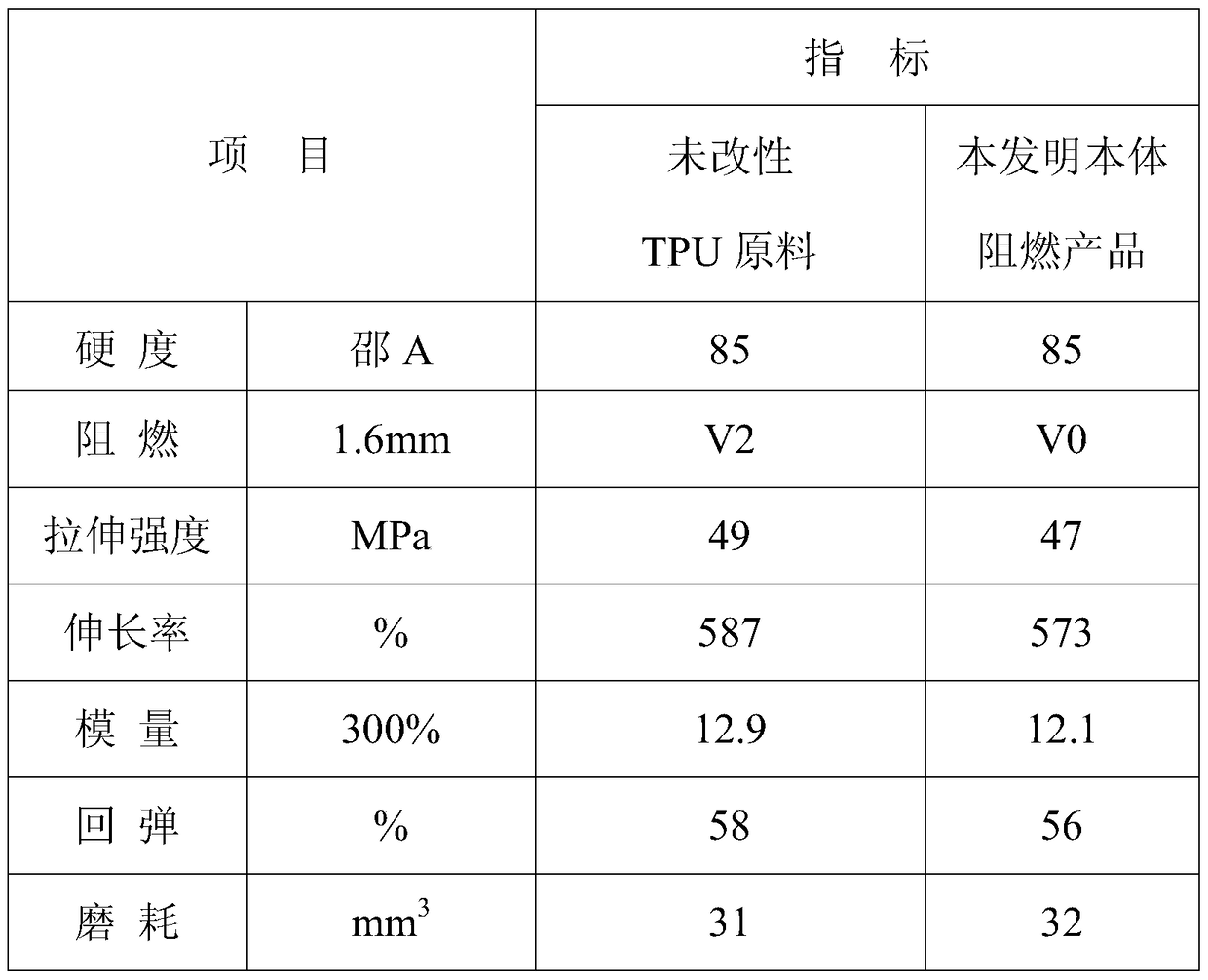

[0028] Melt polyethylene glycol adipate (molecular weight: 2000) at a temperature of 75°C and 2,6-toluene diisocyanate at a temperature of 65°C for subsequent use, then heat the reaction vessel to 80°C, chopping board Heat to 150°C for later use, then add 100 parts of polyethylene glycol adipate into the kettle, put in 15 parts of 1,6-hexanediol and a very small amount of phosphoric acid in the environmental medium to make the amount of phosphoric acid in the system within 3ppm , then add 15 parts of ammonium polyphosphate (n ≥ 1000) for stirring and mixing, pass through nitrogen for protection, stir for 30 minutes and then add 75 parts of 2,6-toluene diisocyanate, emulsification polymerization reaction 60s, after the reaction, transfer the material to The chopping board is matured, and the block is cooled, crushed, extruded and granulated to obtain the final bulk halogen-free flame-retardant modified material. The performance indicators of this embodiment are shown in Table 3...

Embodiment 3

[0032] Melt poly(ethylene glycol phthalate) at 85°C and 2,4-toluene diisocyanate at 70°C respectively for later use, then heat the reactor body to 90°C and the chopping board to 170°C for later use, and then Add 100 parts of polyhexamethylene glycol phthalate into the kettle, put in 17 parts of neopentyl glycol and a very small amount of phosphoric acid in the environmental medium according to the calculated ratio, so that the amount of phosphoric acid in the system is within 4ppm, and then synthesize TPU raw materials according to the theory Add 10 parts of aluminum tert-butylphosphinate for stirring and mixing, pass in nitrogen for protection, stir for 50 minutes and then add 50 parts of 2,4-toluene diisocyanate to carry out emulsification polymerization reaction for 70s. After the reaction, transfer the material to Put it into the chopping board for curing, wait for the block to cool down, crush it, extrude and granulate to obtain the final bulk halogen-free flame-retardant ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| hardness | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com