Light flame-retardant foamed plastic and preparation method thereof

A foam plastic and light-weight technology, applied in the field of foam plastic, can solve the problems of lack of flame retardancy and other problems, and achieve the effects of light weight, enhanced stability and high mixing efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0050] The preparation method of this foamed plastics, comprises the steps:

[0051] Step S1. Accurately weigh and mix the polyether polyol, catalyst, foaming agent, and foaming aid according to the formula, then add modified expanded graphite, and stir evenly at room temperature to obtain a uniformly mixed liquid mixture;

[0052] Step S2, quickly mix the polymerized MDI weighed according to the formula with the above-mentioned liquid mixture, and place it in the foaming barrel 13 of the plastic foaming device, and turn on the first motor and the second motor at the same time,

[0053] Step S3, when the mixture starts to expand, quickly pour it from the discharge port of the foaming barrel 13 into the mold for foam molding, and take it out from the mold after the foam plastic is cooled to room temperature;

[0054] Step S4, placing the prepared foam in an oven at 80°C for 24 hours for aging treatment to obtain foamed plastics;

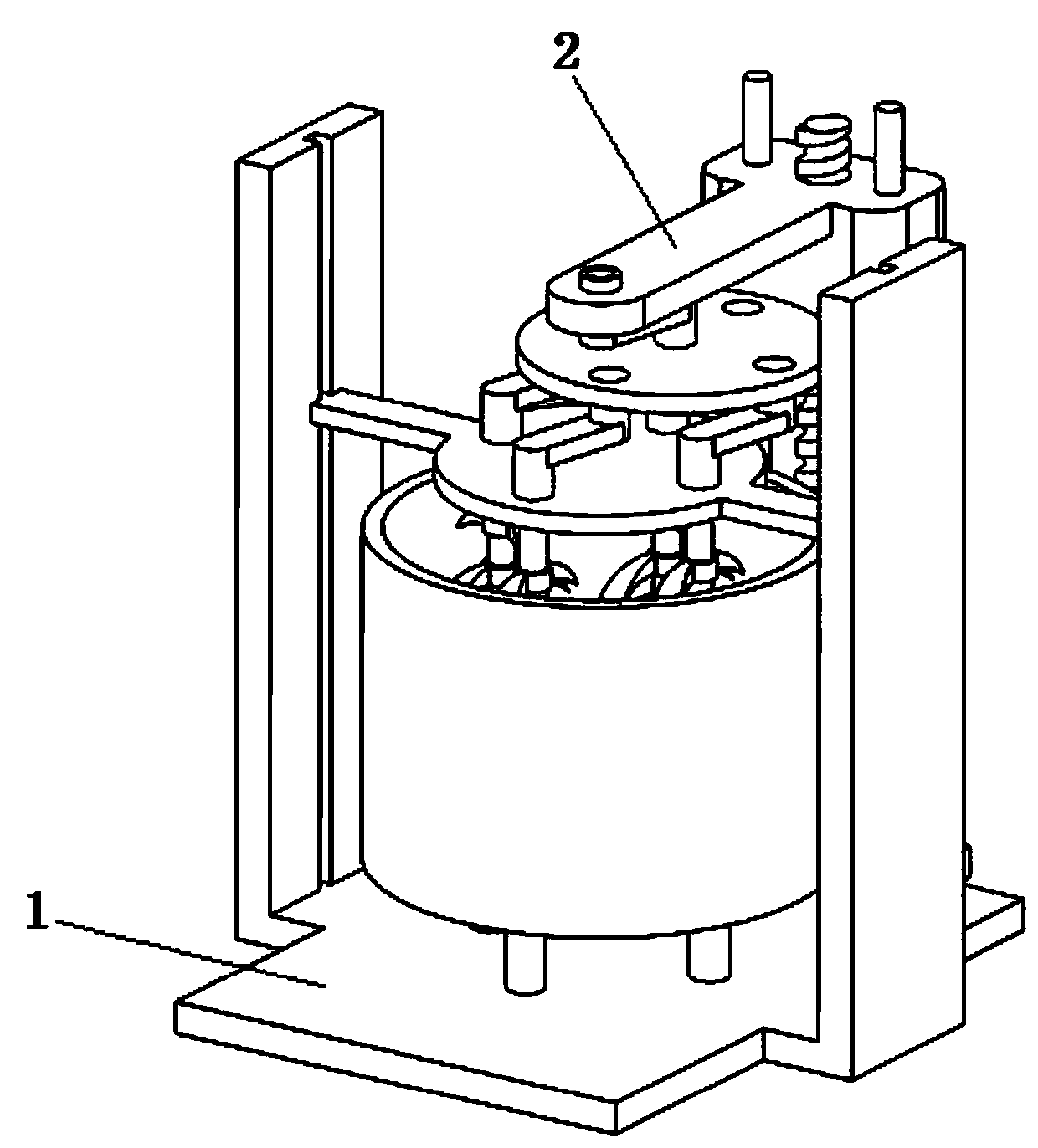

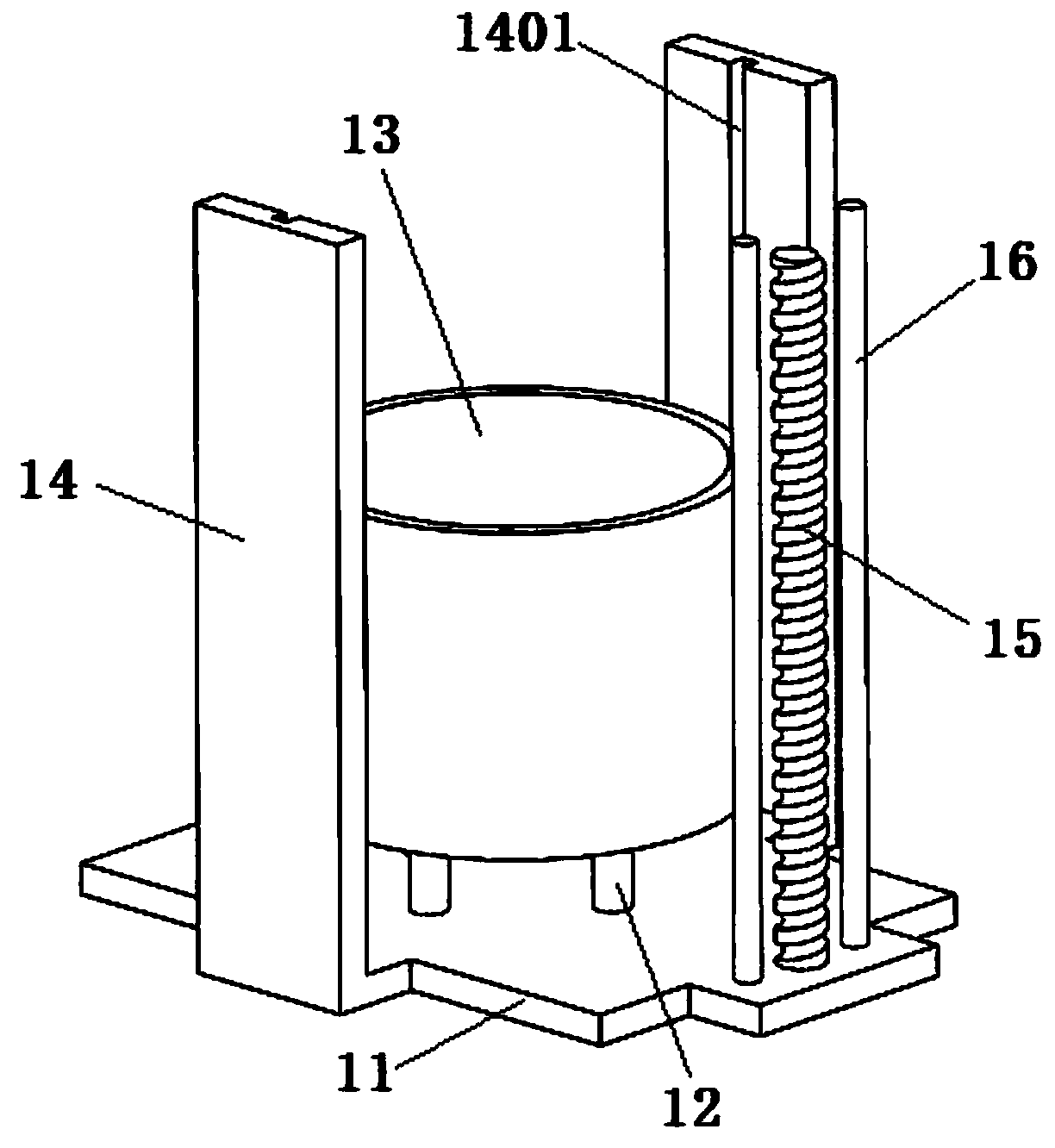

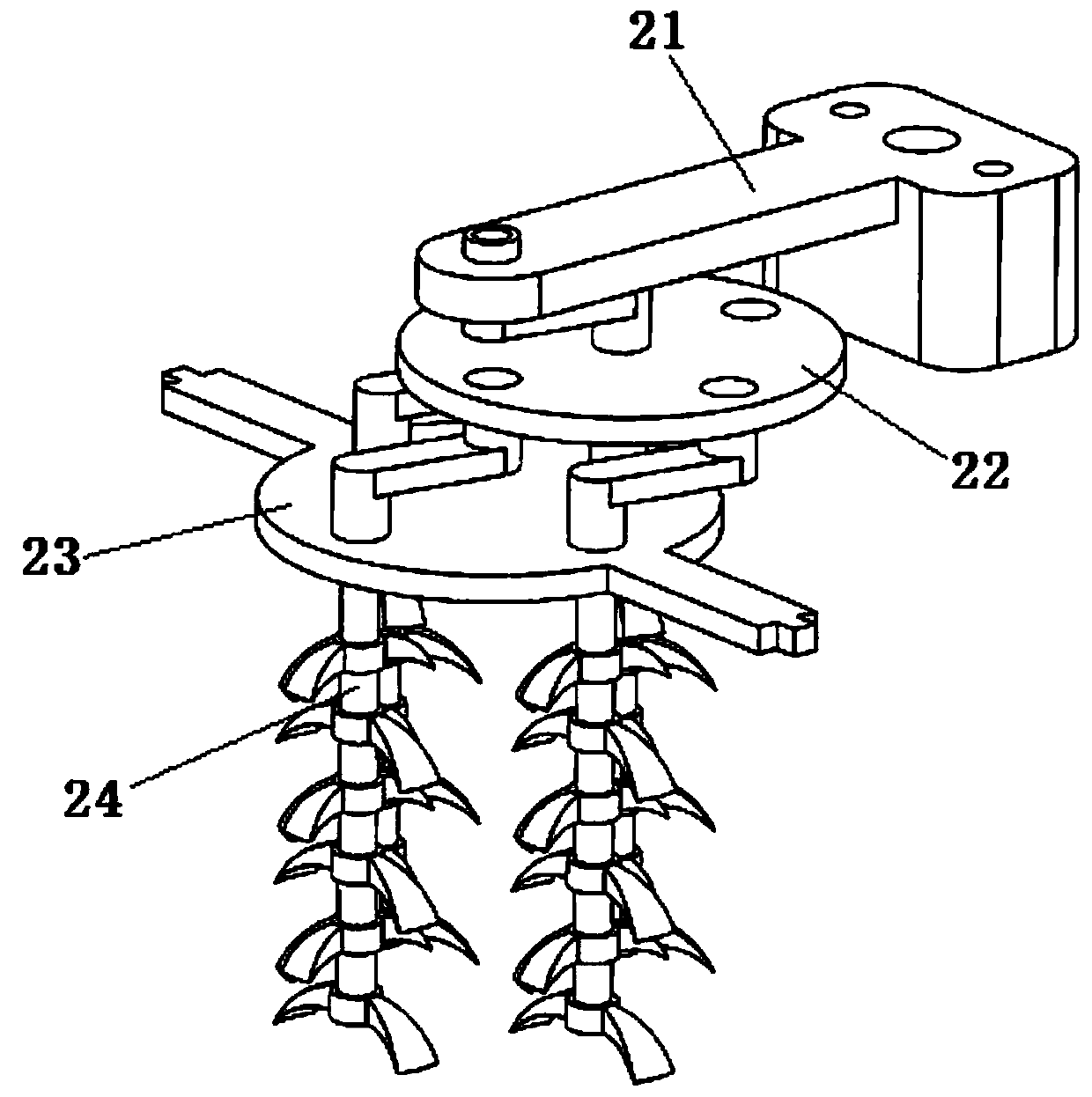

[0055] see Figure 1-7 As shown, the plastic ...

Embodiment 1

[0062] A lightweight flame-retardant foam plastic, made of the following raw materials in parts by weight: 80 parts of polyether polyol, 2 parts of foaming agent, 0.8 part of foaming aid, 0.2 part of catalyst, 6 parts of modified expanded graphite, polymerized MDI 40 copies;

[0063] This foam plastic is made by following steps:

[0064] Step S1. Accurately weigh and mix the polyether polyol, catalyst, foaming agent, and foaming aid according to the formula, then add modified expanded graphite, and stir evenly at room temperature to obtain a uniformly mixed liquid mixture;

[0065] Step S2, quickly mix the polymerized MDI weighed according to the formula with the above-mentioned liquid mixture, and place it in the foaming barrel 13 of the plastic foaming device, and turn on the first motor and the second motor at the same time,

[0066] Step S3, when the mixture starts to expand, quickly pour it from the discharge port of the foaming barrel 13 into the mold for foam molding, ...

Embodiment 2

[0069] A light flame-retardant foamed plastic, made of the following raw materials in parts by weight: 85 parts of polyether polyol, 3 parts of foaming agent, 0.9 part of foaming aid, 0.25 part of catalyst, 7.5 parts of modified expanded graphite, polymerized MDI 45 copies;

[0070] This foam plastic is made by following steps:

[0071] Step S1. Accurately weigh and mix the polyether polyol, catalyst, foaming agent, and foaming aid according to the formula, then add modified expanded graphite, and stir evenly at room temperature to obtain a uniformly mixed liquid mixture;

[0072] Step S2, quickly mix the polymerized MDI weighed according to the formula with the above-mentioned liquid mixture, and place it in the foaming barrel 13 of the plastic foaming device, and turn on the first motor and the second motor at the same time,

[0073] Step S3, when the mixture starts to expand, quickly pour it from the discharge port of the foaming barrel 13 into the mold for foam molding, a...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com