Preparation method of functional resin for synthetic leather production

A functional and synthetic leather technology, applied in the field of resin, can solve the problems of solvent-free polyurethane with less functionality and is not suitable for synthetic leather, and achieve good strength and solvent resistance, enhanced water resistance, and long-lasting flame retardancy.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

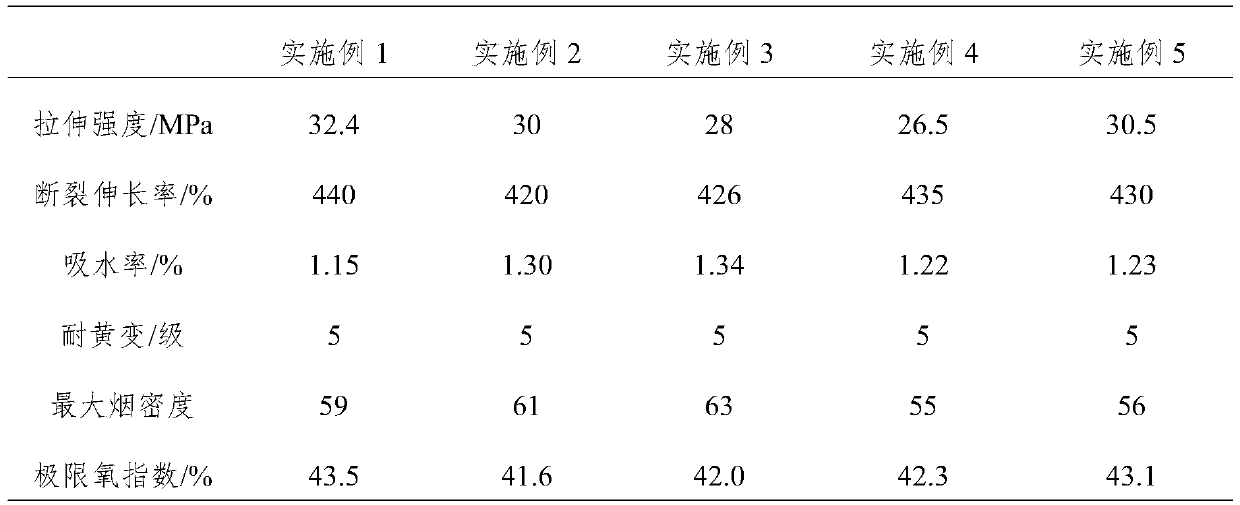

Examples

Embodiment 1

[0030] A method for preparing a functional resin suitable for synthetic leather production, comprising the following steps:

[0031] S1, raise the temperature of the reactor and keep it at 240°C, put 1,2-cyclohexanediol, terephthalic acid and dibutyltin into the reactor, the molar ratio of 1,2-cyclohexanediol to terephthalic acid 1:1, pass into N 2 Protect, react for 4 hours, detect the hydroxyl value and moisture content of the product in the reactor, wait until the hydroxyl value reaches 50mgKOH / g, and the moisture content is lower than 800ppm, reduce the temperature of the reactor to normal temperature, and obtain the hydrolysis-resistant polyester polyol;

[0032] S2, put polyester polyol, diethanolamine and 1,4-butanediol into the reaction kettle, stir and raise the temperature to 125°C, dehydrate under the vacuum condition of -0.01MPa for 6h, cool down to 50°C, add N,N -Dimethyl di(2-hydroxyethyl)aminomethylphosphonate, acrylate emulsion, foam stabilizer, dibutyltin, li...

Embodiment 2

[0036] A method for preparing a functional resin suitable for synthetic leather production, comprising the following steps:

[0037] S1, raise the temperature of the reactor and keep it at 240°C, put 1,2-cyclohexanediol, terephthalic acid and dibutyltin into the reactor, the molar ratio of 1,2-cyclohexanediol to terephthalic acid 1:1, pass into N 2 Protect, react for 4 hours, detect the hydroxyl value and moisture content of the product in the reactor, wait until the hydroxyl value reaches 50mgKOH / g, and the moisture content is lower than 800ppm, reduce the temperature of the reactor to normal temperature, and obtain the hydrolysis-resistant polyester polyol;

[0038]S2, put polyester polyol, diethanolamine and 1,4-butanediol into the reaction kettle, stir and raise the temperature to 125°C, dehydrate under the vacuum condition of -0.01MPa for 6h, cool down to 50°C, add N,N -Dimethyl di(2-hydroxyethyl)aminomethylphosphonate, acrylate emulsion, foam stabilizer, dibutyltin, lig...

Embodiment 3

[0042] A method for preparing a functional resin suitable for synthetic leather production, comprising the following steps:

[0043] S1, raise the temperature of the reactor and keep it at 250°C, put 1,2-cyclohexanediol, terephthalic acid and dibutyltin into the reactor, the molar ratio of 1,2-cyclohexanediol to terephthalic acid 1:2, pass into N 2 Protect, react for 5 hours, detect the hydroxyl value and moisture content of the product in the reactor, wait until the hydroxyl value reaches 300mgKOH / g, and the moisture content is lower than 800ppm, reduce the temperature of the reactor to normal temperature, and obtain a hydrolysis-resistant polyester polyol;

[0044] S2, put polyester polyol, diethanolamine and 1,4-butanediol into the reaction kettle, stir and raise the temperature to 110°C, dehydrate for 5h under the vacuum condition of -0.06MPa, cool down to 30°C, add N,N -Dimethyl bis(2-hydroxyethyl)aminomethylphosphonate, acrylate emulsion, foam stabilizer, dibutyltin, li...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com