Diatomite modified composite environment-friendly coating and preparation method thereof

A technology of environmentally friendly coatings and diatomite, which is applied in the direction of epoxy resin coatings, fireproof coatings, polyurea/polyurethane coatings, etc., can solve the problems of affecting flame retardant performance and uneven dispersion of flame retardants, so as to improve mechanical strength, Uniform flame retardant properties and improved adsorption capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

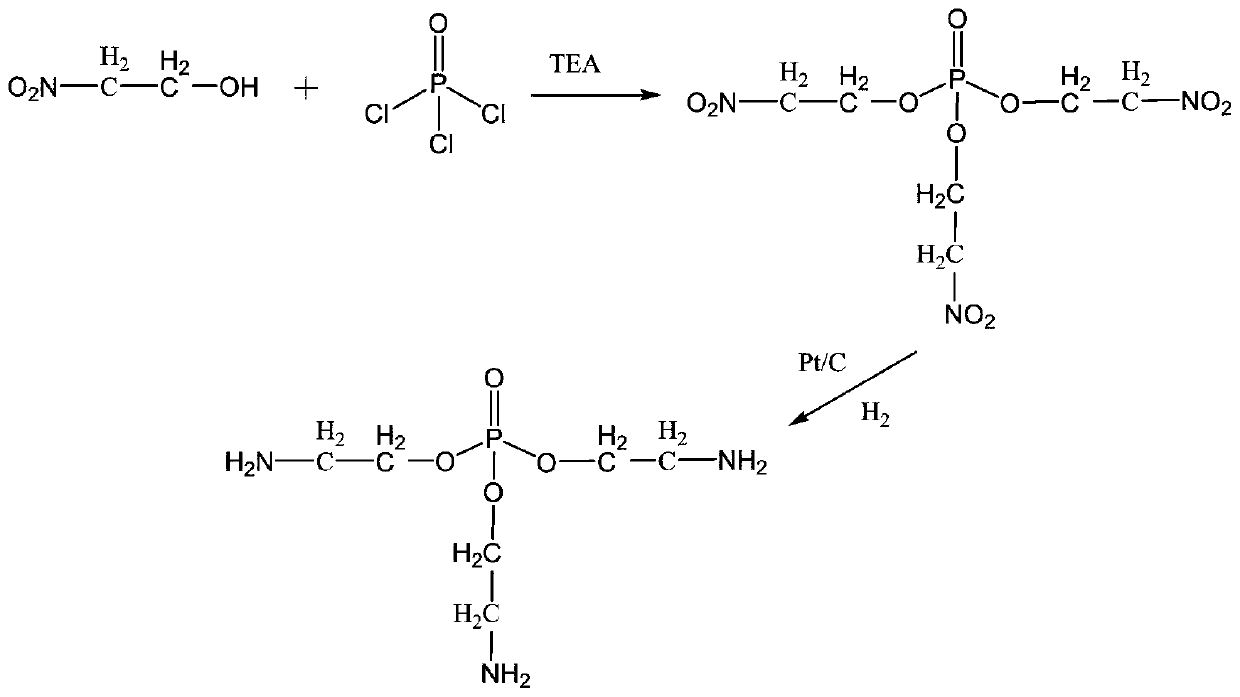

Method used

Image

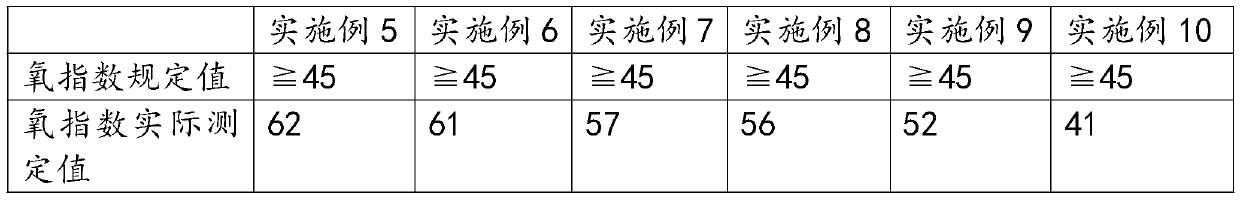

Examples

Embodiment 1

[0026] The specific preparation process of polyurethane loaded diatomite material is as follows:

[0027] Step 1: Configure 1kg of aluminum chloride aqueous solution with a concentration of 25-27%, then add 85g of activated carbon powder to it, ultrasonically disperse for 5-10min, then add 420g of diatomaceous earth to the mixed solution, and continue ultrasonically dispersing for 30-40min, Then slowly add 813g of concentrated ammonia water with a concentration of 22%-25% to the solution dropwise, ultrasonicate while adding dropwise, and ultrasonically shake for 1-1.5h after the dropwise addition is complete, then filter, wash and dry to obtain modified diatomite ;

[0028] Step 2: 5.3kg modified diatomite prepared in step 1, 3.2kg polyether polyol, 3.8kg isocyanate, 0.1kg cell opening agent, 0.3kg water, 0.1kg o-xylene dibutyl ester, 0.05kg formazan After mixing base silicone oil and 0.05kg silane coupling agent, stir quickly, stop stirring when the viscosity of the material...

Embodiment 2

[0033] The specific preparation process of polyurethane loaded diatomite material is as follows:

[0034] Step 1: Configure 1kg of aluminum chloride aqueous solution with a concentration of 25-27%, then add 420g of diatomaceous earth to it, continue ultrasonic dispersion for 30-40min, and then slowly add 813g of it with a concentration of 22%-25% to the solution The concentrated ammonia water was added dropwise and ultrasonically, and after the dropwise addition was complete, ultrasonically oscillated for 1-1.5h, and then filtered, washed and dried to obtain modified diatomite;

[0035] Step 2: 5.3kg modified diatomite prepared in step 1, 3.2kg polyether polyol, 3.8kg isocyanate, 0.1kg cell opening agent, 0.3kg water, 0.1kg o-xylene dibutyl ester, 0.05kg formazan After mixing base silicone oil and 0.05kg silane coupling agent, stir quickly, stop stirring when the viscosity of the material increases rapidly, pour it into the mold and foam at room temperature, and put the mold a...

Embodiment 3

[0040] The specific preparation process of polyurethane loaded diatomite material is as follows:

[0041] Step 1: Mix 5.3kg diatomite, 0.2kg aluminum hydroxide, 3.2kg polyether polyol, 3.8kg isocyanate, 0.1kg cell opener, 0.3kg water, 0.1kg o-xylene dibutyl ester, 0.05kg methyl Silicone oil and 0.05kg silane coupling agent are mixed and then stirred rapidly. When the viscosity of the material increases rapidly, the stirring is stopped, poured into the mold and foamed at room temperature, until the volume of the product no longer increases, the mold is placed in an 80°C Insulate in oven for 9-10h, obtain composite material;

[0042] Step 2: Pulverize the composite material obtained in step 1 with a pulverizer, place the pulverized material in cold nitrogen for 3-5 minutes, take it out quickly, and then add it to grinding, and keep the content of cold nitrogen during the grinding process, Pass the ground particles through a 300-400 mesh sieve to obtain a polyurethane-loaded dia...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com