Modified PP flame-retardant material air-conditioner plastic suction thermal-insulation plate

A flame retardant material and heat insulation board technology, applied in the field of polymer materials, can solve problems such as strength reduction, achieve good mechanical properties and improve flame retardant properties.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

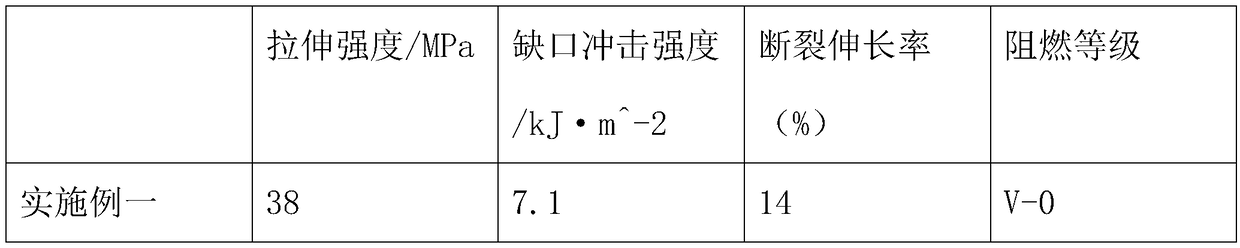

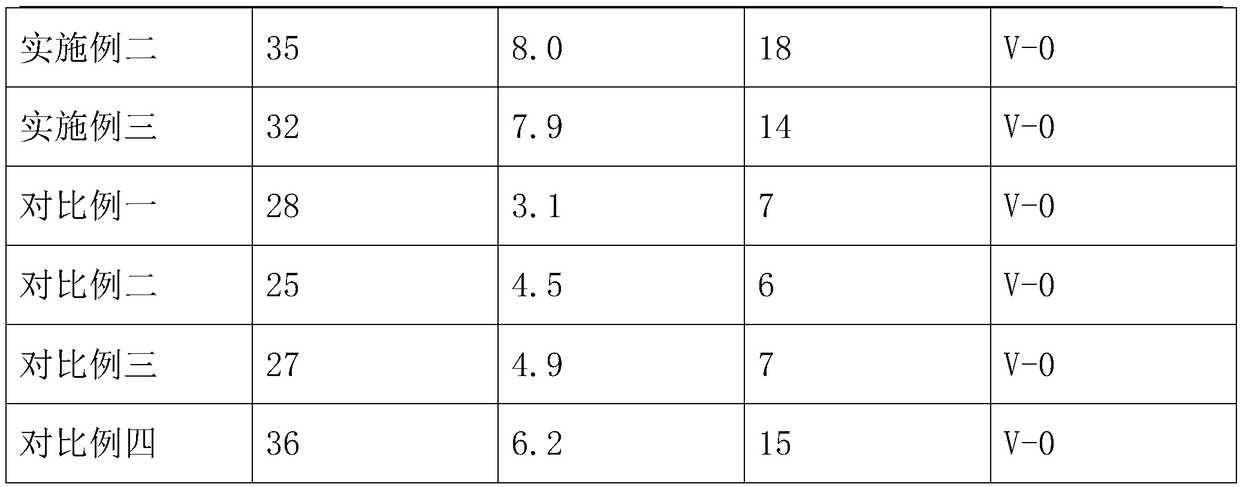

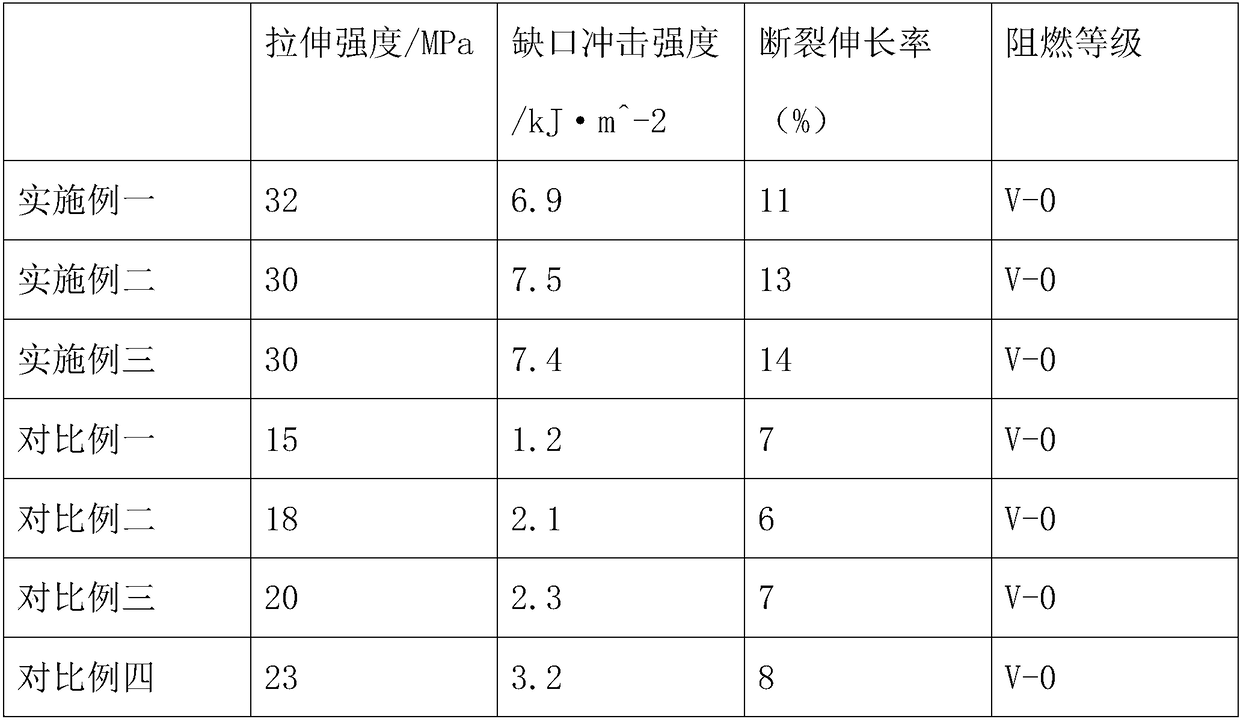

Examples

Embodiment 1

[0035] A modified PP flame-retardant material air-conditioning plastic heat insulation board, comprising the following components by weight:

[0036] Polypropylene: 50 parts

[0037] HDPE: 40 parts

[0038] Flame retardant: 20 parts

[0039] Anti-aging agent: 0.6 parts

[0040] Synergist: 3 parts

[0041] Stabilizer: 1 part

[0042] The synergist is a compound of graphite, phosphoenolpyruvate, pyridoxal 5-phosphate;

[0043] The stabilizer is sodium octyl phosphate;

[0044] The flame retardant is potassium hexatitanate whisker.

[0045] The anti-aging agent is anti-aging agent MBP.

[0046] The mass ratio of graphite, phosphoenolpyruvate and pyridoxal 5-phosphate in the synergist is 20:1:1.

[0047] The preparation method of described synergist is as follows:

[0048] Step 1: oxidizing graphene to obtain graphite oxide;

[0049] Step 2: Prepare a dispersion liquid, add 1 part of phosphoenolpyruvate and 1 part of pyridoxal 5-phosphate to an aqueous solution of 100 pa...

Embodiment 2

[0057] A modified PP flame-retardant material air-conditioning plastic heat insulation board, comprising the following components by weight:

[0058] Polypropylene: 60 parts

[0059] HDPE: 50 parts

[0060] Flame retardant: 15 parts

[0061] Anti-aging agent: 0.3 parts

[0062] Synergist: 5 parts

[0063] Stabilizer: 0.7 parts

[0064] The synergist is a compound of graphite, phosphoenolpyruvate, pyridoxal 5-phosphate;

[0065] The stabilizer is sodium octyl phosphate;

[0066] The flame retardant is potassium hexatitanate whisker.

[0067] The mass ratio of graphite, phosphoenolpyruvate and pyridoxal 5-phosphate in the synergist is 20:1:1.

[0068] The preparation method of described synergist is as follows:

[0069]Step 1: oxidizing graphene to obtain graphite oxide;

[0070] Step 2: Prepare a dispersion liquid, add 1 part of phosphoenolpyruvate and 1 part of pyridoxal 5-phosphate to an aqueous solution of 100 parts by mass, then add graphite oxide, disperse in the ...

Embodiment 3

[0078] A modified PP flame-retardant material air-conditioning plastic heat insulation board, comprising the following components by weight:

[0079] Polypropylene: 70 parts

[0080] HDPE: 30 parts

[0081] Flame retardant: 10 parts

[0082] Anti-aging agent: 1 part

[0083] Synergist: 2 parts

[0084] Stabilizer: 0.5 parts

[0085] The synergist is a compound of graphite, phosphoenolpyruvate, pyridoxal 5-phosphate;

[0086] The stabilizer is sodium octyl phosphate;

[0087] The flame retardant is potassium hexatitanate whisker.

[0088] The mass ratio of graphite, phosphoenolpyruvate and pyridoxal 5-phosphate in the synergist is 20:1:1.

[0089] The preparation method of described synergist is as follows:

[0090] Step 1: oxidizing graphene to obtain graphite oxide;

[0091] Step 2: Prepare a dispersion liquid, add 1 part of phosphoenolpyruvate and 1 part of pyridoxal 5-phosphate to an aqueous solution of 100 parts by mass, then add graphite oxide, disperse in the aq...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com