Compound modified asphalt concrete

A technology of compound modified asphalt and concrete, applied in the field of road material engineering, can solve the problems of aggravating aging, shortening the service life of the road surface, increasing the contact area, etc., and achieves the effects of improving low temperature performance, improving performance and good road performance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

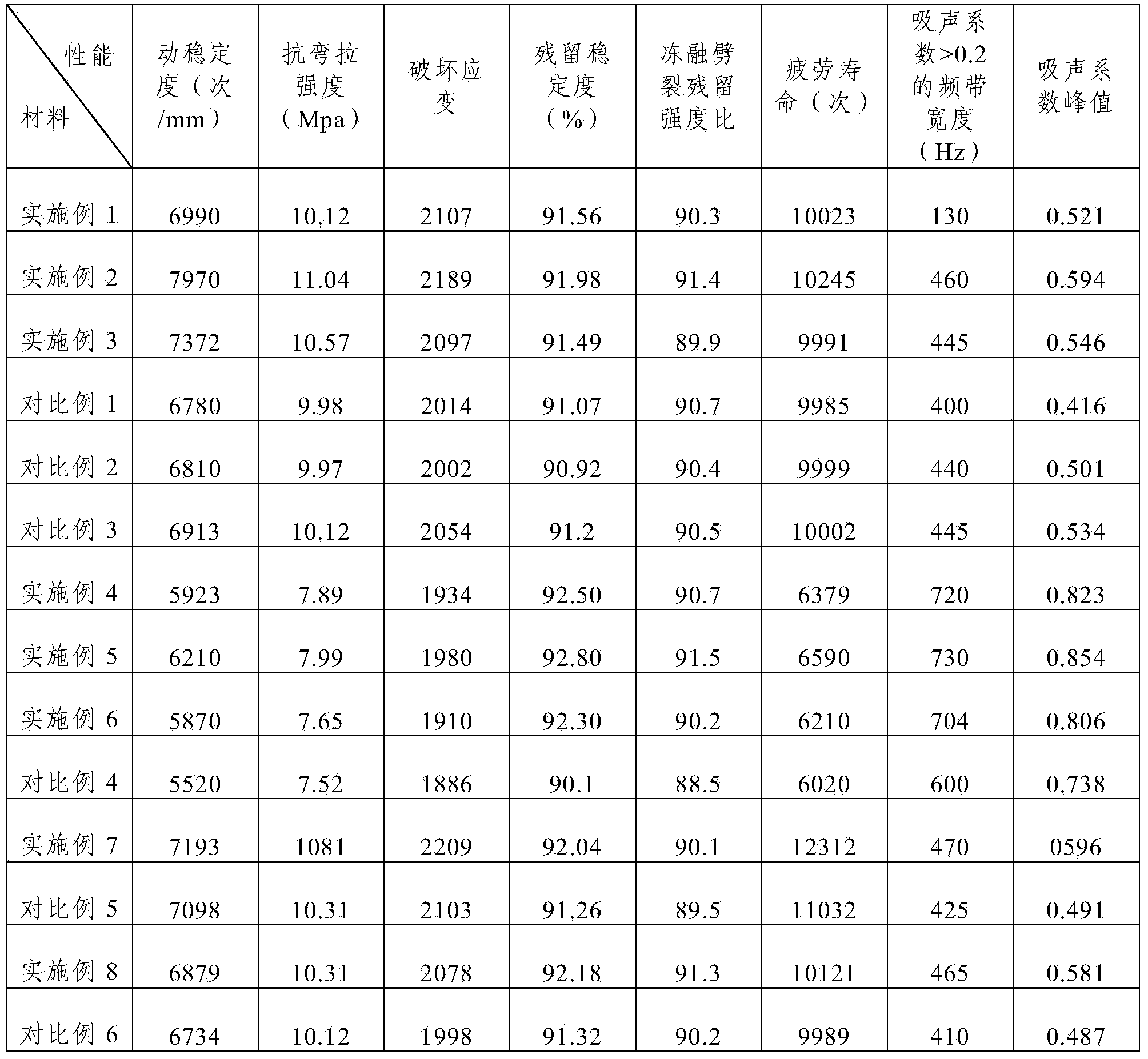

Examples

Embodiment 1

[0024] The composite modified asphalt concrete in this embodiment is made of the following raw materials in parts by weight: 100 parts of mineral aggregate, 3 parts of asphalt, 0.05 part of chlorinated polyethylene, 0.2 part of aliphatic polyurethane resin, 0.075 part of serpentine, halloysite 0.15 part, 0.001 part of coupling agent; The mineral material adopted in this embodiment is AC-13 type mineral material, and the coupling agent adopted is JL-G02FX type amino-terminated polyol ester coupling agent, and the asphalt adopted It is SBS modified asphalt.

[0025] The preparation method of the composite modified asphalt concrete of the present embodiment comprises the following steps:

[0026] Step 1. Preparation of composite modifier: Weigh and dry serpentine and halloysite, add the dried serpentine and halloysite into a high-speed mixer, and then add coupling agent. Mixed for 12min under the condition to obtain composite modifier;

[0027] Step 2. Prepare modified asphalt:...

Embodiment 2

[0030] The composite modified asphalt concrete in this embodiment is made of the following raw materials in parts by weight: 100 parts of mineral aggregate, 5 parts of asphalt, 0.12 part of chlorinated polyethylene, 1.0 part of aliphatic polyurethane resin, 0.3 part of serpentine, halloysite 0.6 part, 0.018 part of coupling agent; The ore material that present embodiment adopts is AC-13 type ore material, and the coupling agent that adopts is JL-G02FX type amino-terminated polyol ester coupling agent, and the bitumen that adopts It is SBS modified asphalt.

[0031] The preparation method of the composite modified asphalt concrete of the present embodiment comprises the following steps:

[0032] Step 1. Preparation of composite modifier: Weigh and dry serpentine and halloysite, add the dried serpentine and halloysite into a high-speed mixer, and then add coupling agent. Mixed for 15min under the condition to obtain composite modifier;

[0033] Step 2. Prepare modified asphalt...

Embodiment 3

[0036] The composite modified asphalt concrete in this embodiment is made of the following raw materials in parts by weight: 100 parts of mineral aggregate, 7 parts of asphalt, 0.15 part of chlorinated polyethylene, 1.5 parts of aliphatic polyurethane resin, 1 part of serpentine, halloysite 1.5 parts, 0.04 part of coupling agent; The mineral material adopted in this embodiment is AC-13 type mineral material, and the coupling agent adopted is JL-G02FX type amino-terminated polyol ester coupling agent, and the asphalt adopted It is SBS modified asphalt.

[0037] The preparation method of the composite modified asphalt concrete of the present embodiment comprises the following steps:

[0038] Step 1. Preparation of composite modifier: Weigh and dry serpentine and halloysite, add the dried serpentine and halloysite into a high-speed mixer, and then add coupling agent. Mix for 10 minutes under the condition to obtain composite modifier;

[0039] Step 2. Prepare modified asphalt: ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com