Cement-base sound-absorbing material for tunnel wall surfaces and preparation method thereof

A technology for sound absorption of tunnel walls and bases, applied in the field of cement-based sound-absorbing materials and their preparation, can solve the problems of obvious sound-absorbing effect, unsuitable for tunnel applications, and no mention of sound-absorbing effect, etc. Simple, sound-absorbing performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

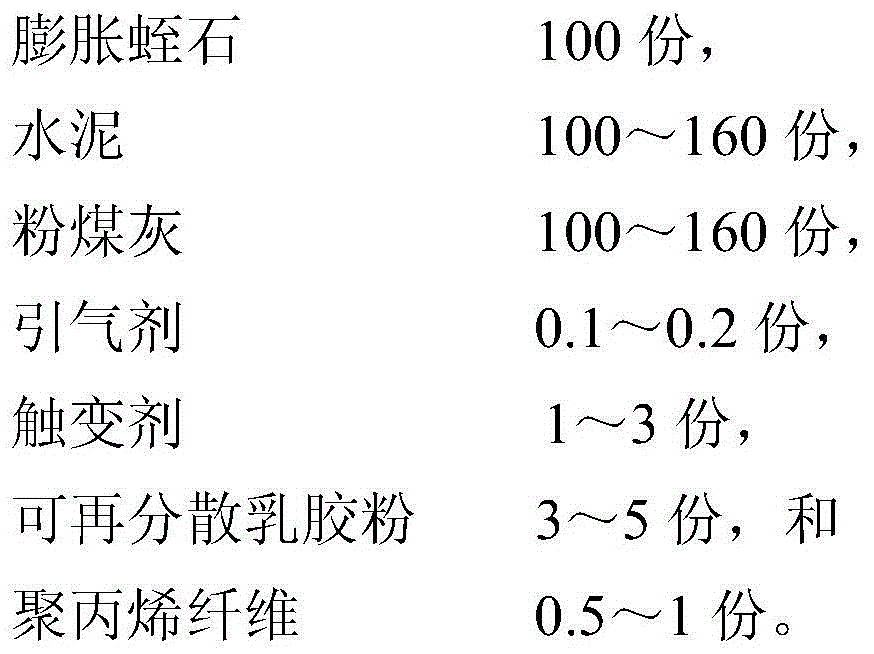

[0025] The cement-based sound-absorbing material for the tunnel wall, in parts by mass, has the following raw material composition:

[0026]

[0027] Put expanded vermiculite, portland cement, class II fly ash, vegetable protein air-entraining agent, magnesium aluminum silicate thixotropic agent, ethylene vinyl acetate copolymer rubber powder and polypropylene fiber into the mixer according to their respective mass parts, Mix well to obtain a dry mix. When applying, add water with 85% of the total mass of the dry mixture to the dry mixture, stir evenly in the mortar machine integrating stirring, pumping and spraying, and then spray in layers on the total area of 10.08m 2 On the cement board, each layer is sprayed with a thickness of 8-9mm. After the material of the previous spraying is hardened, the next spraying is carried out. The total spraying thickness reaches 25mm. The conventional natural maintenance is 28 days, and the test noise reduction coefficient NRC is 0.65....

Embodiment 2

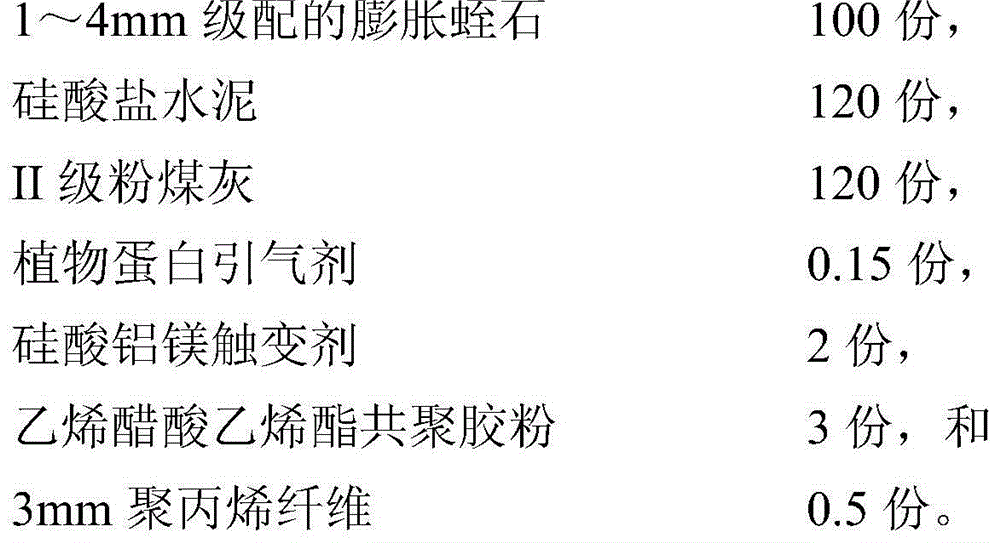

[0029] The cement-based sound-absorbing material for the tunnel wall, in parts by mass, has the following raw material composition:

[0030]

[0031]

[0032] Put expanded vermiculite, portland cement, class II fly ash, vegetable protein air-entraining agent, magnesium aluminum silicate thixotropic agent, ethylene vinyl acetate copolymer rubber powder and polypropylene fiber into the mixer according to their respective mass parts, Mix well to obtain a dry mix. When applying, add water with 90% of the total mass of the dry mixture into the dry mixture, stir evenly in the mortar machine integrating stirring, pumping and spraying, and then spray in layers on the total area of 10.08m 2 On the cement board, each layer is sprayed with a thickness of 8-9mm. After the material of the previous spraying is hardened, the next spraying is carried out. The total spraying thickness reaches 25mm. The conventional natural curing is 28 days, and the noise reduction coefficient NRC is 0...

Embodiment 3

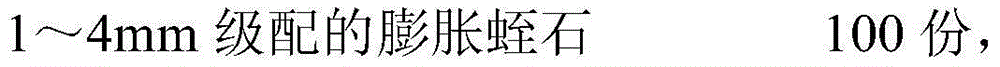

[0034] The cement-based sound-absorbing material for the tunnel wall, in parts by mass, has the following raw material composition:

[0035]

[0036] Put expanded vermiculite, portland cement, class II fly ash, vegetable protein air-entraining agent, magnesium aluminum silicate thixotropic agent, styrene acrylate copolymer rubber powder and polypropylene fiber into the mixer according to their respective mass parts, Mix well to obtain a dry mix. When applying, add water with 85% of the total mass of the dry mixture to the dry mixture, stir evenly in the mortar machine integrating stirring, pumping and spraying, and then spray in layers on the total area of 10.08m 2 On the cement board, each layer is sprayed with a thickness of 8-9mm. After the material of the previous spraying is hardened, the next spraying is carried out. The total spraying thickness reaches 25mm. The conventional natural maintenance is 28 days, and the test noise reduction coefficient NRC is 0.65.

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com