Ultra-level highlight powder coating formula and preparation method thereof

A technology of powder coatings and formulations, applied in the direction of powder coatings, polyester coatings, epoxy resin coatings, etc., can solve the problems of difficult market promotion, dissimilarity, and high cost of additives, and achieve suitable promotion and application, good decorative performance, and good Effect of leveling properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

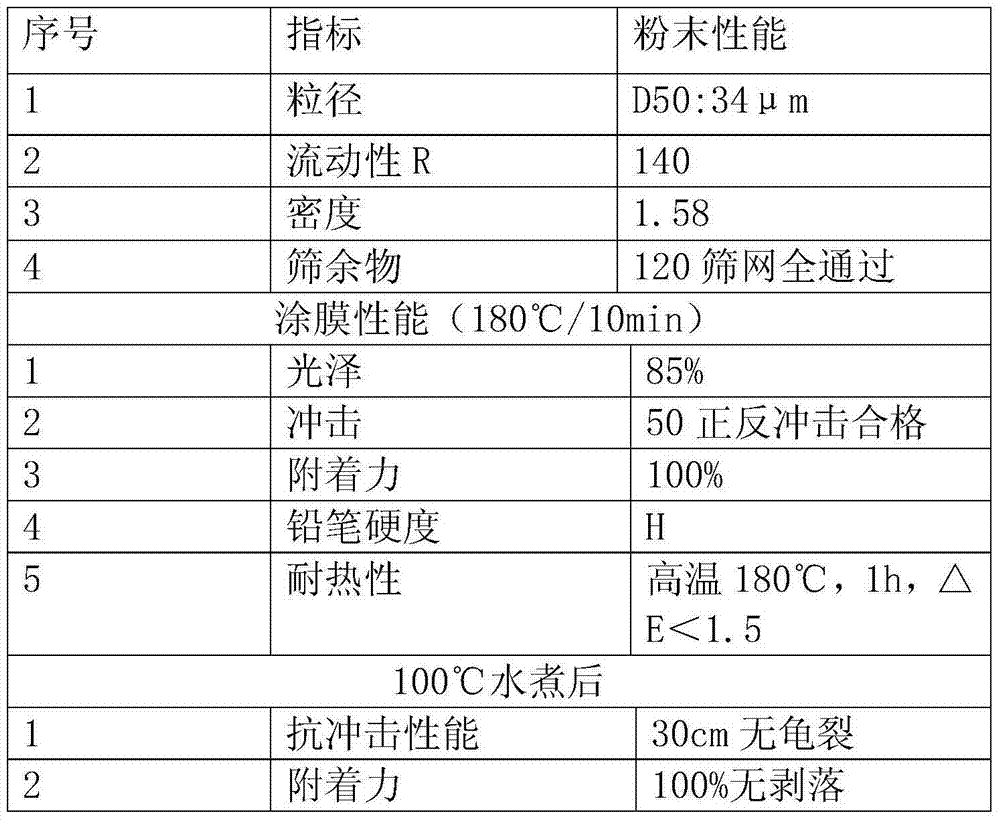

Examples

Embodiment 1

[0023] A preparation process for super-leveling high-gloss powder coatings, the preparation process has the following steps:

[0024] (1) Prepare the following components in parts by mass: 30 parts of epoxy resin, 31 parts of polyester resin, 2.5 parts of leveling agent, 24 parts of titanium dioxide, 3.2 parts of barium sulfate, 0.45 parts of benzoin, and 0.45 parts of antioxidant , 0.18 parts of ultramarine, 0.003 parts of carbon black, and 0.25 parts of silicon dioxide.

[0025] (2) Add the above-mentioned materials into the homogenizing device in sequence and homogenize for 15-25min at a speed of 250-350rpm / min;

[0026] (3) The mixed material obtained in step (2) is sequentially melted and extruded by an extruder, crushed by a tablet press, finely pulverized by a pulverizer, and screened and packaged by a rotary sieve to obtain a leveling property Better powder coating product.

[0027] Among them, the parameters of the melt extrusion section of the extruder are as follo...

Embodiment 2

[0029] A preparation process for super-leveling high-gloss powder coatings, the preparation process has the following steps:

[0030] (1) Prepare the following components in parts by mass: 34 parts of epoxy resin, 33 parts of polyester resin, 3 parts of leveling agent, 24 parts of titanium dioxide, 4 parts of barium sulfate, 0.5 part of benzoin, and 0.45 part of antioxidant , 0.15 parts of ultramarine, 0.003 parts of carbon black, and 0.25 parts of silicon dioxide. All the other steps are the same as in Embodiment 1.

Embodiment 3

[0032] A preparation process for super-leveling high-gloss powder coatings, the preparation process has the following steps:

[0033] (1) Prepare the following components in parts by mass: 29 parts of epoxy resin, 30 parts of polyester resin, 1.8 parts of leveling agent, 23 parts of titanium dioxide, 2.5 parts of barium sulfate, 0.2 parts of benzoin, and 0.22 parts of antioxidant , 0.10 parts of ultramarine blue, 0.003 parts of carbon black, and 0.20 parts of silicon dioxide. All the other steps are the same as in Embodiment 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| softening point | aaaaa | aaaaa |

| epoxy equivalent | aaaaa | aaaaa |

| acid value | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com