Antibacterial glutinous rice glue and preparation method thereof

A technology of glutinous rice glue and glutinous rice, applied in the direction of monocarboxylic acid ester copolymer adhesive, adhesive type, adhesive additive, etc., can solve the problems such as the safety of auxiliary materials cannot be ignored and the environmental protection performance is poor.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1-2

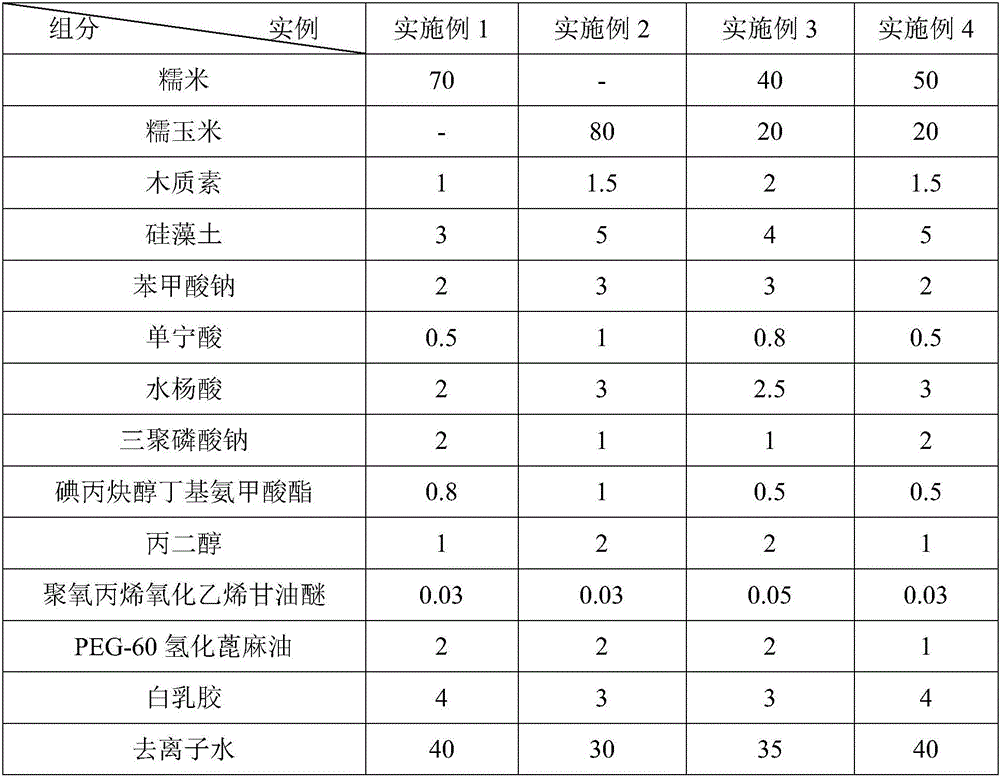

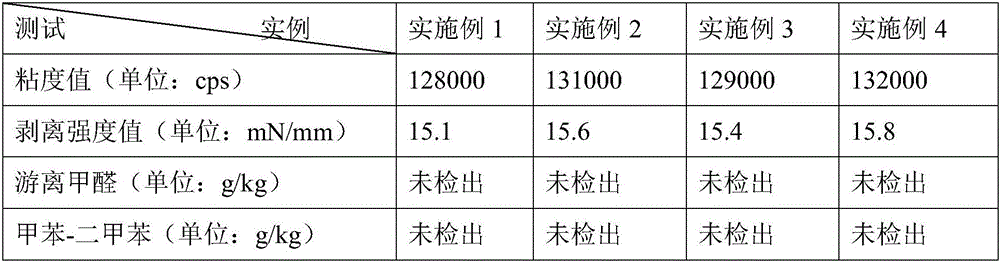

[0025] A kind of antibacterial glutinous rice glue, its raw material formula is shown in Table 1, and the preparation process of this antibacterial glutinous rice glue is:

[0026] The first step is to wash the glutinous rice and soak it in deionized water for 12 hours; cook the soaked glutinous rice at 90°C for 2 minutes;

[0027] In the second step, grind the cooked glutinous rice, filter it with a 150-mesh filter, add sodium hydroxide to adjust the pH value to 9, react at 60°C for 5h, add sodium tripolyphosphate, react at 60°C for 1h, and then react at 90°C Carry out gelatinization, gelatinize into colloidal glutinous rice starch, measure the content of glutinous rice starch after gelatinization to meet the requirements of product production;

[0028] The third step is to add lignin, diatomaceous earth, sodium benzoate, tannic acid, salicylic acid, iodopropynyl butyl carbamate, propylene glycol, polyoxypropylene successively to the gelatinized glutinous rice starch Ethylen...

Embodiment 3-4

[0030] A kind of antibacterial glutinous rice glue, its raw material formula is shown in Table 1, and the preparation process of this antibacterial glutinous rice glue is:

[0031] The first step is to wash the glutinous rice and soak it in deionized water for 12 hours; cook the soaked glutinous rice at 100°C for 2 minutes;

[0032] The second step is to grind the cooked glutinous rice, filter it with a 150-mesh filter, add sodium hydroxide to adjust the pH value to 10, react at 70°C for 6h, add sodium tripolyphosphate, react at 40°C for 2h, and react at 95°C Carry out gelatinization, gelatinize into colloidal glutinous rice starch, measure the content of glutinous rice starch after gelatinization to meet the requirements of product production;

[0033] The third step is to add lignin, diatomaceous earth, sodium benzoate, tannic acid, salicylic acid, iodopropynyl butyl carbamate, propylene glycol, polyoxypropylene successively to the gelatinized glutinous rice starch Ethylene...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com