Polyimide nanofiber yarn and preparation method thereof suitable for industrial production

A nanofiber and polyimide technology, which is applied in the field of polyimide nanofiber yarn and its preparation suitable for industrial production, can solve the problems of yarn quality influence, yarn discontinuity, short length, etc., and achieve thermal insulation. Good effect, good softness, the effect of improving softness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0052] The invention provides a kind of preparation method of polyimide nanofiber yarn suitable for industrialized production, comprising the following steps:

[0053] A) electrospinning the diluted polyimide precursor solution to obtain polyamic acid nanofibers;

[0054] B) utilize endless metal transmission belt, the polyamic acid nanofiber that above-mentioned step obtains is collected into continuous polyamic acid nanofiber belt;

[0055] C) the above-mentioned steps are obtained continuous polyamic acid nanofiber belt, carry out thermal imidization process, obtain continuous polyimide nanofiber belt;

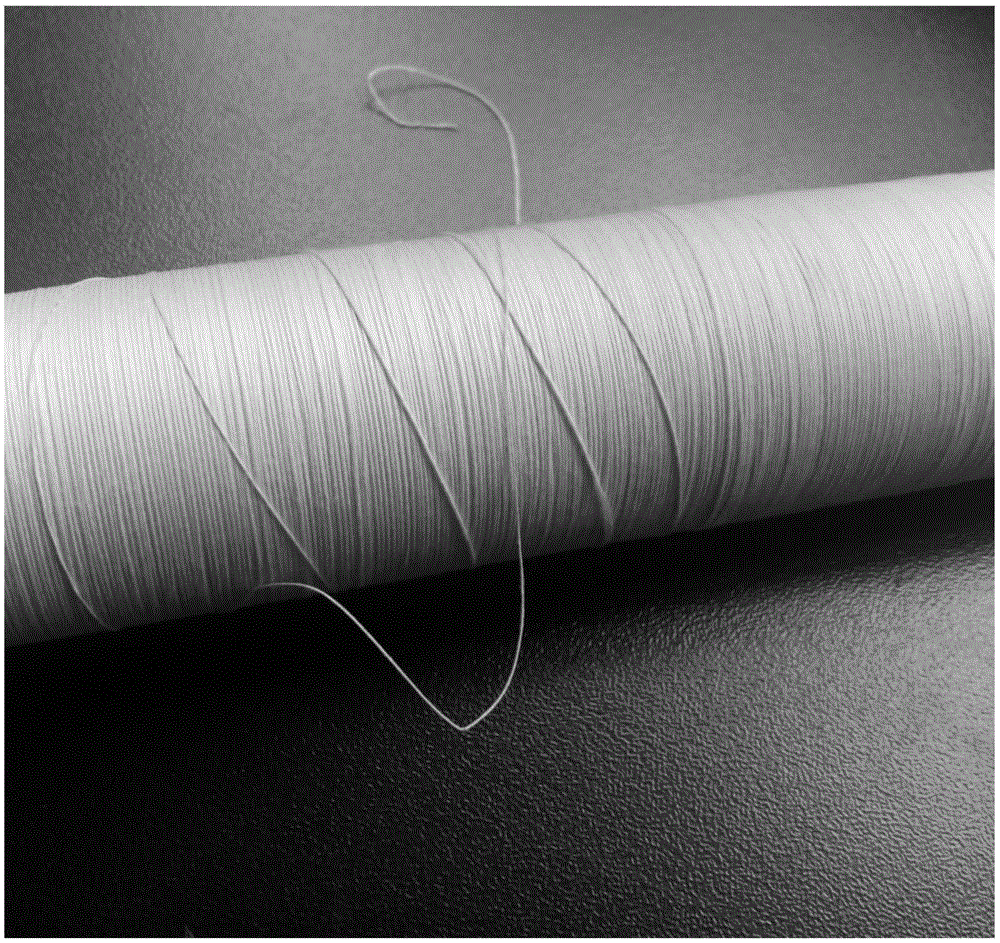

[0056] D) peeling off the polyimide nanofiber belt from the mirror transmission belt, and then drawing and twisting to obtain a polyimide nanofiber yarn.

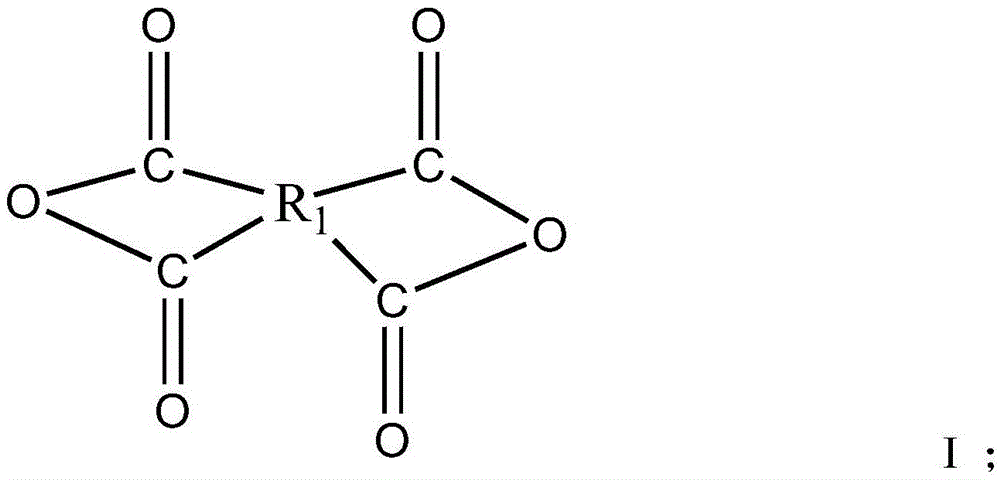

[0057] In the invention, firstly, the diluted polyimide precursor solution is electrostatically spun to obtain polyamic acid nanofibers. The present invention is not particularly limited to the dilution method of the d...

Embodiment 1

[0076] Triphenylene ether dianhydride / pyrophthalic anhydride / dimethyl benzphenyl diamine / diphenyl ether diamine / diphenoxybenzophenone diamine (HQDPA / PMDA / DMB / ODA / BABP) copolymerized polyamide Preparation of imine nanofiber yarn

[0077] Synthesis and electrospinning of polyamic acid solution: take a certain amount of triphenylene diether dianhydride (HQDPA), pyrophthalic anhydride (PMDA), and dimethyl biphenyl at a molar ratio of 0.5:0.5:0.6:0.2:0.2 Diamine (DMB), diphenyl ether diamine (ODA) and diphenoxybenzophenone diamine (BABP) monomers were added to N,N-dimethylacetamide (DMAC) solution at 5 °C Carry out the polymerization reaction under the same conditions, the reaction time is about 8 hours, to obtain a polyamic acid solution, add N,N-dimethylacetamide and tetrahydrofuran mixed solvent to adjust the solid content of the solution, and obtain a mass concentration of 18%, and tetrahydrofuran accounts for the total solvent content 50%, polyamic acid spinning solution with...

Embodiment 2

[0085] Triphenylene ether dianhydride / biphenyl dianhydride / dimethyl benzphenyl diamine / diphenyl ether diamine / biphenyl diamine (HQDPA / BPDA / DMB / ODA / Bz) copolymerized polyimide nanofiber yarn preparation of

[0086] Synthesis and electrospinning of polyamic acid solution: Take a certain amount of triphenyldiether dianhydride (HQDPA), biphenyl dianhydride (BPDA), dimethyl biphenyl at a molar ratio of 0.6:0.4:0.5:0.2:0.3 Diamine (DMB), diphenyl ether diamine (ODA) and biphenyl diamine (Bz) monomers were added to N,N-dimethylacetamide (DMAC) solution and polymerized at 5°C. The reaction time is about 8 hours, and a polyamic acid solution is obtained, and a mixed solvent of N,N-dimethylacetamide and tetrahydrofuran is added to adjust the solid content of the solution to obtain a mass concentration of 21%, tetrahydrofuran accounts for 49% of the total solvent content, and the absolute viscosity is 2.6Pa.s polyamic acid spinning solution. The polyamic acid spinning solution is elect...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| strength | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com