Sheng-bast fiber raschel blanket

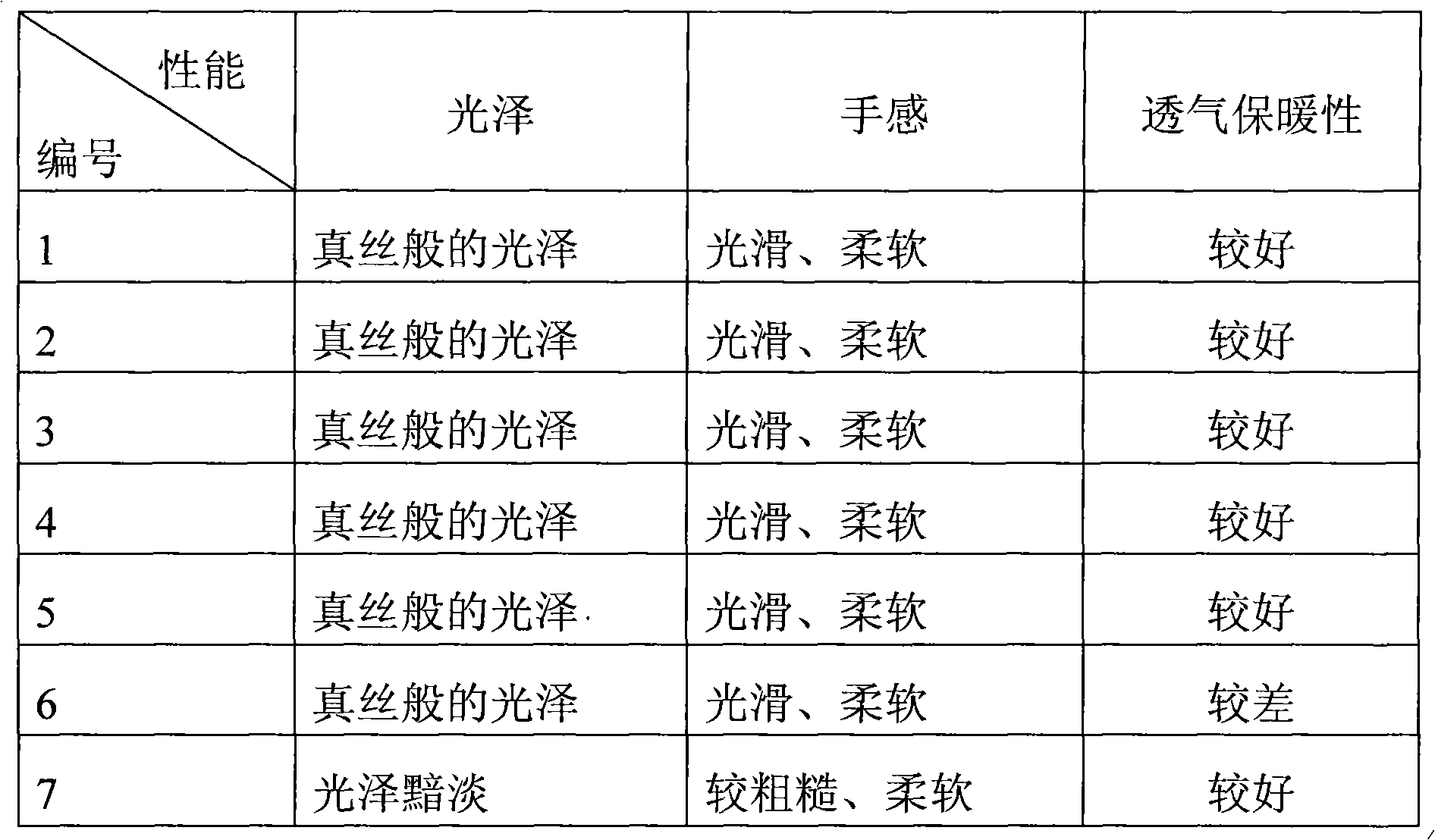

A raschel blanket and holy hemp fiber technology, applied in the field of blankets, can solve the problems of water absorption performance and hand feeling comparable, water absorption performance and hand feeling poor, color, feel and other problems, to achieve good skin affinity, soft hand feel, color bright effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

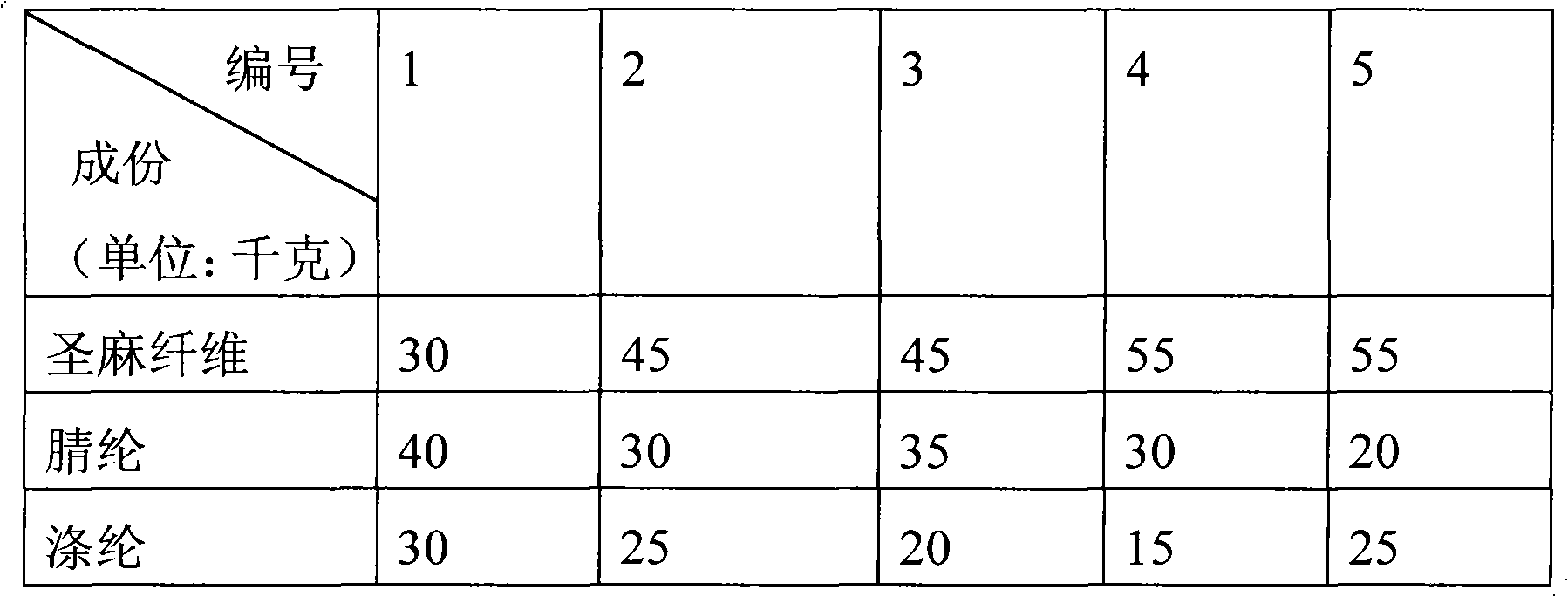

[0041]Embodiment 1: select the component described in number 1 in table 1 as raw material; Its weaving process is as follows:

[0042] One: The white gray cloth for weaving the holy hemp fiber raschel blanket:

[0043] 1) Spinning of plush yarn: firstly mix wool according to the ratio required by the process, and then warp and wool-combing-blending-first needle comb-second needle comb-three needle comb-roving-spun yarn-winding - Doubling - two-for-one twisting - inspection and storage.

[0044] 2) Warping of the woven yarn: through the HD40-21NC computer control of the Kobe warping machine, each polyester filament is wound in parallel on the pan head. The tension of each filament passing through the warping tensioner is 20CN. The line speed is 700 m / min, the flatness tolerance value of the warp yarn surface after warping is 1mm, and the difference in the peripheral length of the same group of warp beams (yarns) after warping is not more than 0.3%.

[0045] 3) Warping of inse...

Embodiment 2

[0050] Embodiment 2: select the described component of number 2 in table 1 as raw material, in the warp knitting process of its weaving process, use 32 / 2Nm specification as 3D * 102mm holy hemp fiber, 3D * 102mm acrylic fiber blended bulked yarn as Plush yarn, the specification is that 150D / 48F FDY polyester filament is used as knitting yarn, and 150D / 48FFDY polyester filament is used as inserted weft yarn, and is woven into blanket white fabric; other technological processes are the same as embodiment 1, and will not be repeated.

Embodiment 3

[0051] Embodiment 3: select the component described in No. 3 in Table 1 as raw material, in the warp knitting process of its weaving process, the 36 / 2Nm specification is 5D * 76 ~ 127mm holy hemp fiber, 2.5D * 76 ~ 127mm acrylic fiber The blended bulky yarn is used as plush yarn, the specification is 250D / 48F FDY polyester filament as the knitting yarn, and the 100D / 36F FDY polyester filament is used as the inserted weft yarn to weave blanket white fabric; other processes are the same as in Example 1, No longer.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com