Preparation method of high-performance self-cleaning curtain fabric

A self-cleaning, high-performance technology, used in dyeing, textile material processing, biochemical fiber processing, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

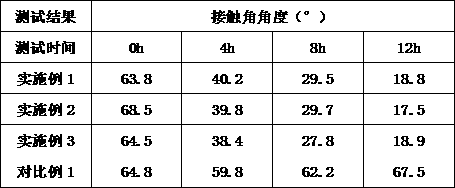

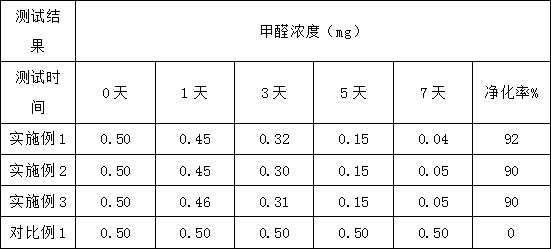

Embodiment 1

[0032] A method for preparing high-performance self-cleaning curtain fabrics includes the following steps:

[0033] S1. Pretreatment: Place the curtain grey fabric with 100% polyester to be treated in an overflow dyeing machine at 130°C for dyeing. The dyeing time is 1h, down to room temperature, washed and dehydrated to obtain pretreated fabric;

[0034] S2. Ingredients: Add water that matches the fabric to be treated in the overflow dyeing machine, and then add a photocatalyst finishing agent with a concentration of 5% and a particle size of 5nm to obtain a photocatalyst treatment liquid;

[0035] S3. Put the pretreated fabric obtained from S1 into the overflow dyeing machine of S2, and after treating for 1-2h at a temperature of 130-150℃, the fabric is dehydrated and finalized to obtain a dry photocatalyst treated fabric;

[0036] S4. Reprocessing: spray the dry fabric obtained in S3 with environmental spray, and then reprocess the fabric;

[0037] S5. Finished product: Take S4 to ge...

Embodiment 2

[0041] A method for preparing high-performance self-cleaning curtain fabrics includes the following steps:

[0042] S1. Pretreatment: Place the curtain grey fabric with polyester and linen as the main ingredient in an overflow dyeing machine at 140°C for dyeing. The dyeing time is 1.5h, down to room temperature, washed and dehydrated to obtain pretreated fabric;

[0043] S2. Ingredients: Add water that matches the fabric to be treated in the overflow dyeing machine, and then add a photocatalyst finishing agent with a concentration of 8% and a particle size of 8nm to obtain a photocatalyst treatment liquid;

[0044] S3. Put the pretreated fabric obtained from S1 into the overflow dyeing machine of S2, and treat it at 130°C for 1.5 hours, then dehydrate and finalize the shape to obtain a dry photocatalyst treated fabric;

[0045] S4. Reprocessing: spray the dry fabric obtained in S3 with environmental spray, and then reprocess the fabric;

[0046] S5. Finished product: Take S4 to get repr...

Embodiment 3

[0050] A method for preparing high-performance self-cleaning curtain fabrics includes the following steps:

[0051] S1. Pretreatment: Place the curtain grey fabric with polyester and linen as the main ingredient in an overflow dyeing machine at 150°C for dyeing. The dyeing time is 2h, and it is lowered to room temperature. After washing, it is dehydrated to obtain the pretreated fabric;

[0052] S2. Ingredients: Add water that matches the fabric to be treated in the overflow dyeing machine, and then add a photocatalyst finishing agent with a concentration of 10% and a particle size of 10nm to obtain a photocatalyst treatment liquid;

[0053] S3. Put the pretreated fabric obtained from S1 into the overflow dyeing machine of S2, and treat it at 130°C for 1.5 hours, then dehydrate and finalize the shape to obtain a dry photocatalyst treated fabric;

[0054] S4. Reprocessing: spray the dry fabric obtained in S3 with environmental spray, and then reprocess the fabric;

[0055] S5. Finished p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com