Preparation method of Ni-WS2 coating

A ni-ws2, coating technology, applied in coatings, electrolytic coatings, etc., can solve the problems of poor corrosion resistance, high preparation cost, unfavorable surface lubrication, etc., to enhance corrosion resistance and durability, and the preparation method is simple. , High repeatability effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0023] A Ni-WS 2 The preparation method of coating comprises the following steps:

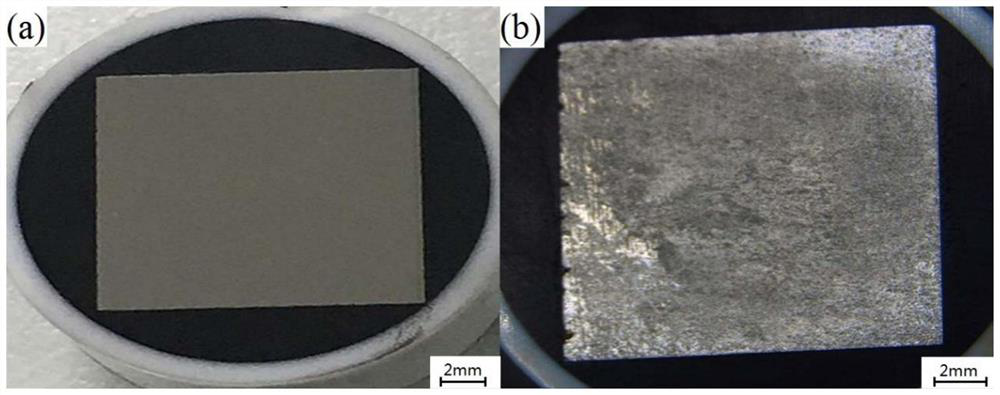

[0024] Step 1. Grind the X100 pipeline steel on 800#, 1000#, 1200#, 1500# silicon carbide sandpaper in sequence, and then polish it with polishing liquid until there is no obvious scratch on the surface of the X100 pipeline steel, and then use deionized Wash with water and acetone to remove the surface grease mixture, then drop the absolute ethanol solution on the X100 pipeline steel to remove the surface moisture, and then dry the X100 pipeline steel with electric heating to obtain the X100 matrix.

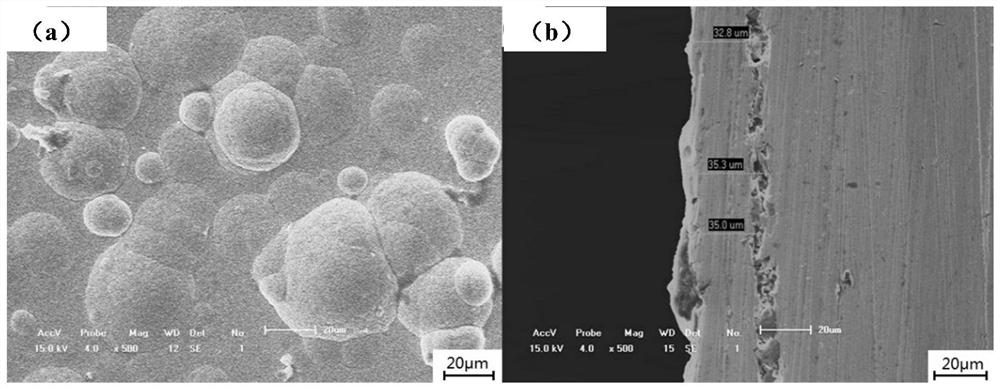

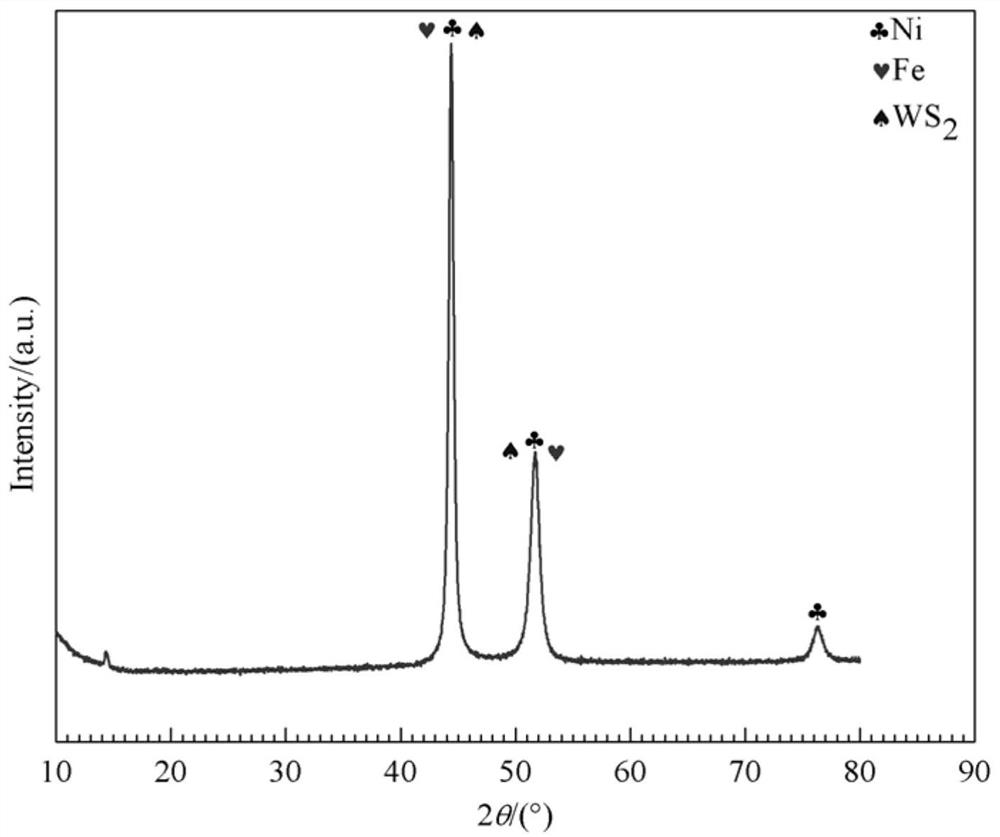

[0025] Step 2. Mix deionized water, nickel sulfate, nickel chloride, and boric acid, then adjust the pH value of the mixed solution to 3.3-3.7, and then add hexadecyltrimethylammonium bromide, saccharin, and tungsten disulfide nano Particles (the particle size of tungsten disulfide nanoparticles is preferably 40nm), brightener and wetting agent, so as to obtain the electroplating solution. In th...

Embodiment 1

[0037] A Ni-WS 2 The preparation method of coating comprises the following steps:

[0038] (1) Preparation of X100 matrix

[0039] Grind the X100 pipeline steel of 15×15mm on 800#, 1000#, 1200#, 1500# silicon carbide sandpaper in sequence, and polish it after the grinding effect reaches no large area scratches. , and then use deionized water and acetone to wash in order to remove the surface grease mixture, then drop absolute ethanol solution on the X100 pipeline steel to remove surface moisture, then dry the X100 pipeline steel with electric heating, and then seal it with a sealed bag to prevent The surface is oxidized to obtain an X100 matrix.

[0040] (2) Prepare the electroplating solution and adjust the pH value of the electroplating solution

[0041] Plating solution preparation method: add 50g of nickel sulfate, 9g of nickel chloride and 8g of boric acid into deionized water, mix and stir evenly, adjust the pH value of the mixed solution to 3.3-3.7 with dilute hydroc...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| corrosion current density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com