Fire fighting system using superfine dry powder as extinguishing agent and using method thereof

A fire extinguishing system and ultra-fine dry powder technology, which is applied in fire rescue, fire alarms, instruments, etc., can solve the problems of not being suitable for rooms with high temperature, poor timeliness and automation, and space occupied by high-pressure gas cylinders. Good fluidity and fluidity, accurate fire extinguishing, and wide range of fire extinguishing effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

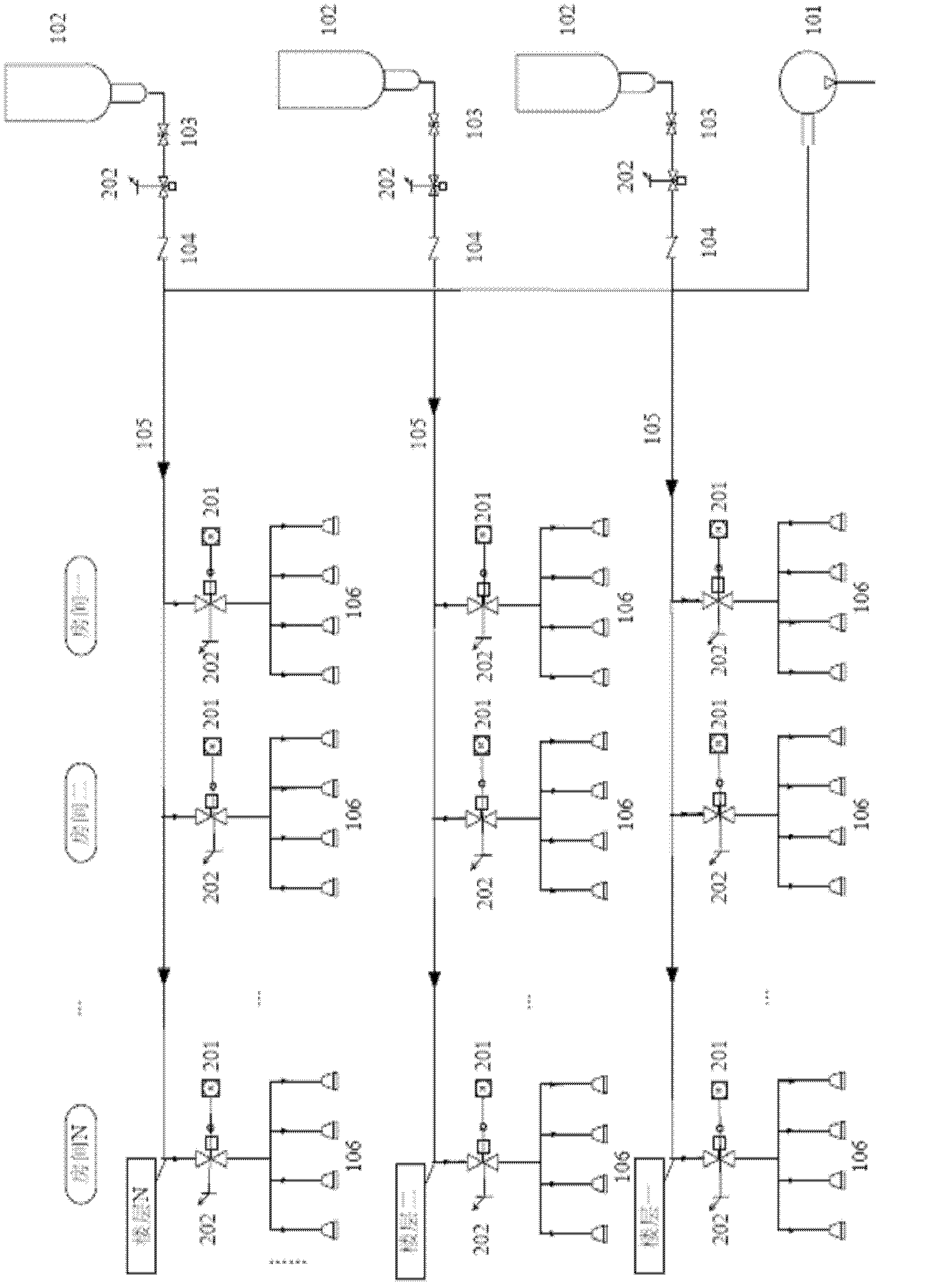

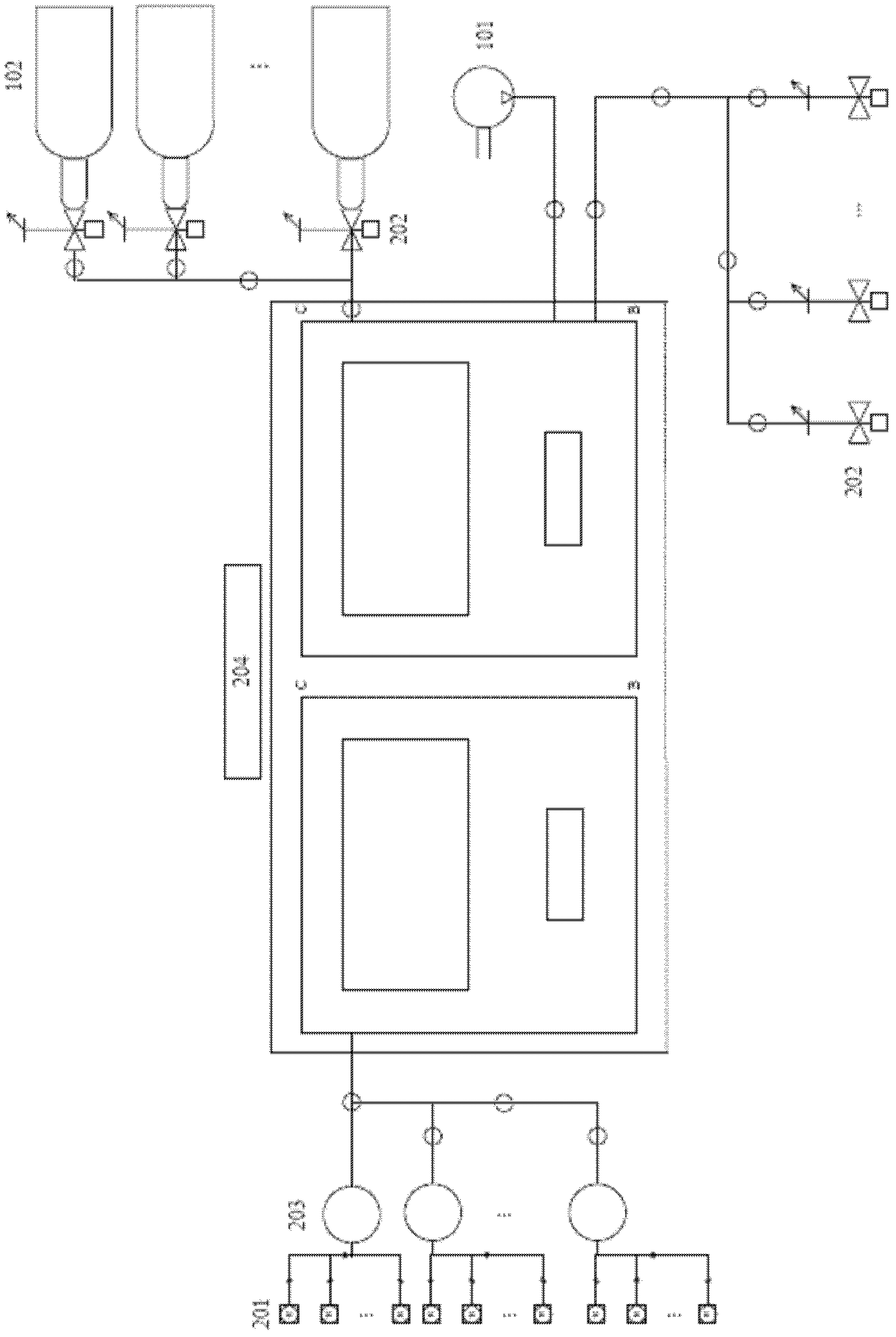

[0046] The present invention will be further described in detail with reference to the accompanying drawings and embodiments. See figure 1 , figure 2 and image 3 ,

[0047] 1) The present invention is a fire extinguishing system using ultra-fine dry powder as a fire extinguishing agent. The system is composed of a conveying subsystem 1 and a control subsystem 2. The position connection relationship among them is: each component of the control subsystem 2 is organically connected to the conveying subsystem 1 through the pipe network.

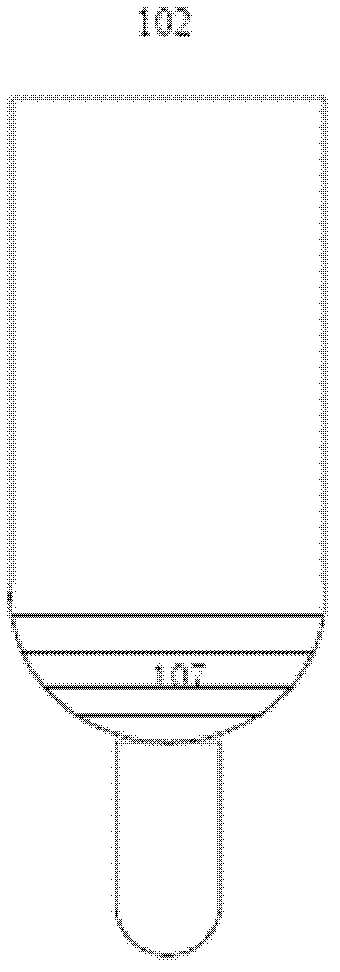

[0048] The conveying subsystem 1 includes an air compressor 101, a high-pressure gas cylinder 102, a safety valve 103, a check valve 104, a pipe network 105, a dry powder fire extinguishing agent nozzle 106, and a new superfine ammonium dihydrogen phosphate fire extinguishing powder 107. The position connection relationship between them is: air compressor 101, high-pressure gas cylinder 102, dry powder fire extinguishing agent nozzle 106 ar...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com