Silicone oil defoamer for drilling fluid and production process thereof

A silicone oil defoamer and drilling fluid technology, which is applied in the direction of drilling compositions, chemical instruments and methods, etc., can solve the problems of difficult application in low temperature environment, poor defoaming persistence, and affecting defoaming ability, and achieve excellent defoaming Efficacy, outstanding defoaming performance, and the effect of reducing surface activity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

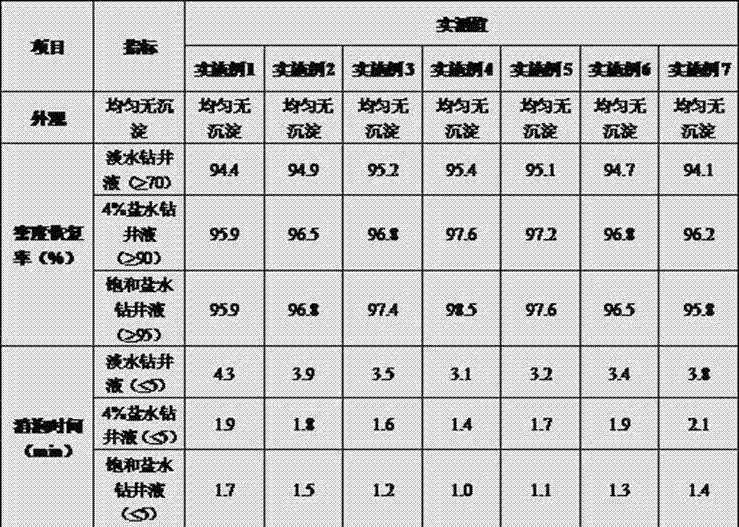

Examples

Embodiment 1

[0023] Embodiment 1: Preparation of a silicone oil defoamer for drilling fluid

[0024] (1) Accurately weigh each raw material component according to the formula: kerosene 110 kg, aluminum stearate 10 kg, emulsifier 10 kg, methyl silicone oil 5 kg, tributyl phosphate 10 kg, n-octanol 10 kg, water 5 kg kg, the emulsifier is at least one of SP-40 (Span-40), SP-60 (Span-60), SP-80 (Span-80) and T-60 (Tween-60) and / or the mixture of polyoxyethylene octylphenol ether (OP-10), weighed and placed in corresponding containers for use;

[0025] (2) Open the reactor and turn on the agitator, add the weighed kerosene and aluminum stearate into the reactor evenly and slowly, keep the temperature in the kettle at 30°C, and add the emulsifier slowly and evenly within 30 minutes In the kettle; start the heating process, after the temperature rises to 90°C, keep warm for 120 minutes, and keep stirring during the heating process to ensure that the materials are fully dissolved and mixed;

[...

Embodiment 2

[0028] Embodiment 2: the preparation of a kind of silicone oil defoamer for drilling fluid

[0029] (1) Accurately weigh each raw material component according to the formula: 120 kg of kerosene, 12 kg of aluminum stearate, 12 kg of emulsifier, 6 kg of methyl silicone oil, 13 kg of tributyl phosphate, 12 kg of n-octanol, 8 kg of water kg, the emulsifier is at least one of SP-40 (Span-40), SP-60 (Span-60), SP-80 (Span-80) and T-60 (Tween-60) and / or the mixture of polyoxyethylene octylphenol ether (OP-10), weighed and placed in corresponding containers for use;

[0030] (2) Open the reactor and turn on the agitator, add the weighed kerosene and aluminum stearate into the reactor evenly and slowly, keep the temperature in the kettle at 35°C, and add the emulsifier slowly and evenly within 35 minutes In the kettle; start the heating process, after the temperature rises to 95°C, keep warm for 130 minutes, and keep stirring during the heating process to ensure that the materials ar...

Embodiment 3

[0033] Embodiment 3: the preparation of a kind of silicone oil defoamer for drilling fluid

[0034] (1) Accurately weigh each raw material component according to the formula: kerosene 126 kg, aluminum stearate 14 kg, emulsifier 14 kg, methyl silicone oil 8 kg, tributyl phosphate 16 kg, n-octanol 14 kg, water 10 kg kg, the emulsifier is at least one of SP-40 (Span-40), SP-60 (Span-60), SP-80 (Span-80) and T-60 (Tween-60) and / or the mixture of polyoxyethylene octylphenol ether (OP-10), weighed and placed in corresponding containers for use;

[0035] (2) Open the reaction kettle and turn on the agitator, add the weighed kerosene into the reaction kettle evenly and slowly, keep the temperature in the kettle at 40°C, and slowly and evenly add the emulsifier into the kettle within 40 minutes; turn on the temperature rise During the process, after the temperature rises to 100°C, keep warm for 140 minutes, and keep stirring during the heating process to ensure that the materials are...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com