Patents

Literature

96results about How to "Guaranteed differential pressure" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

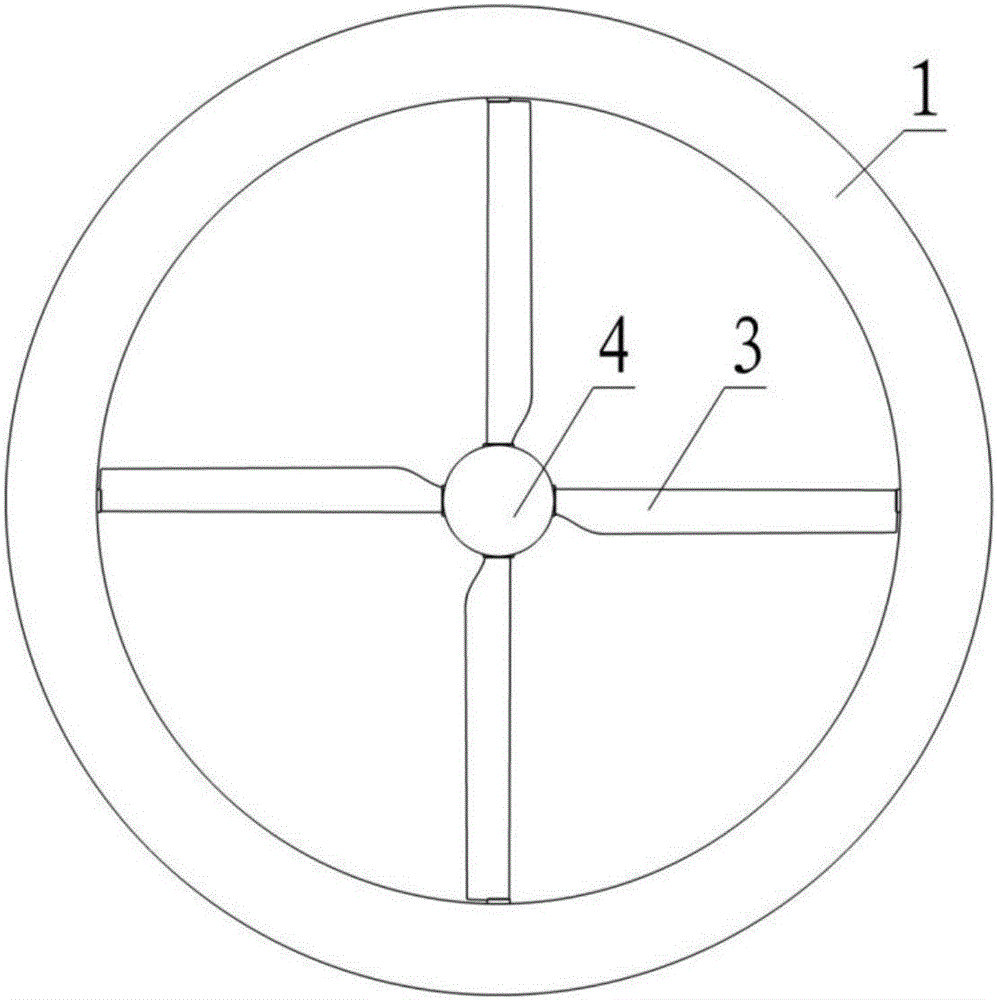

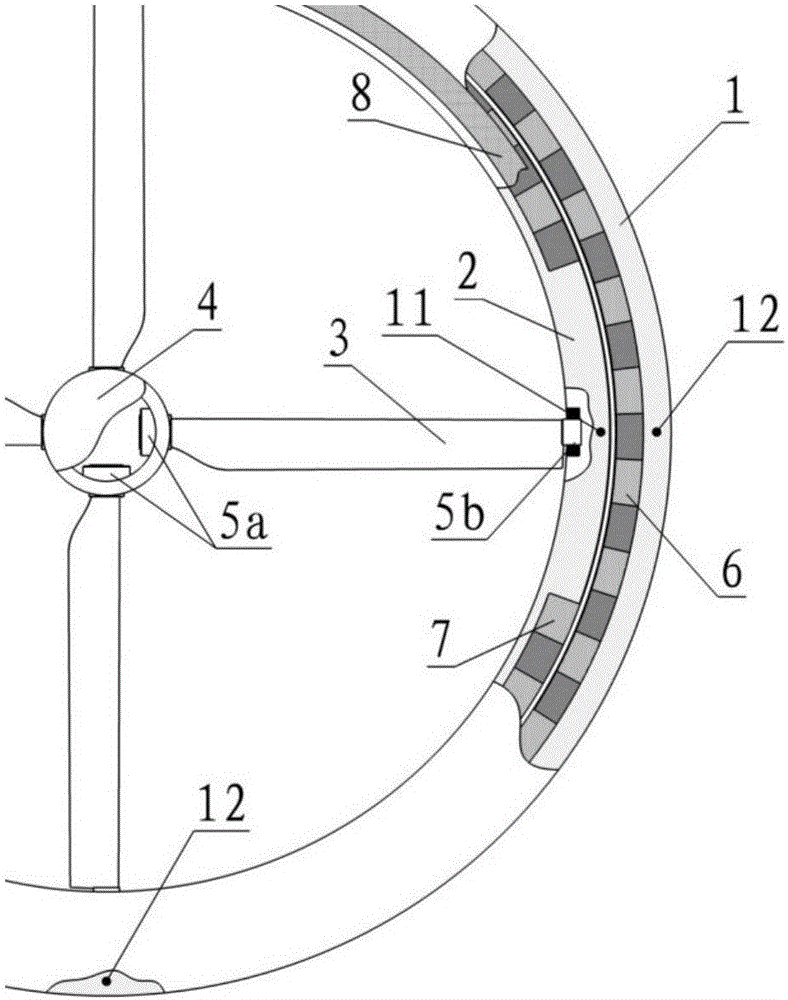

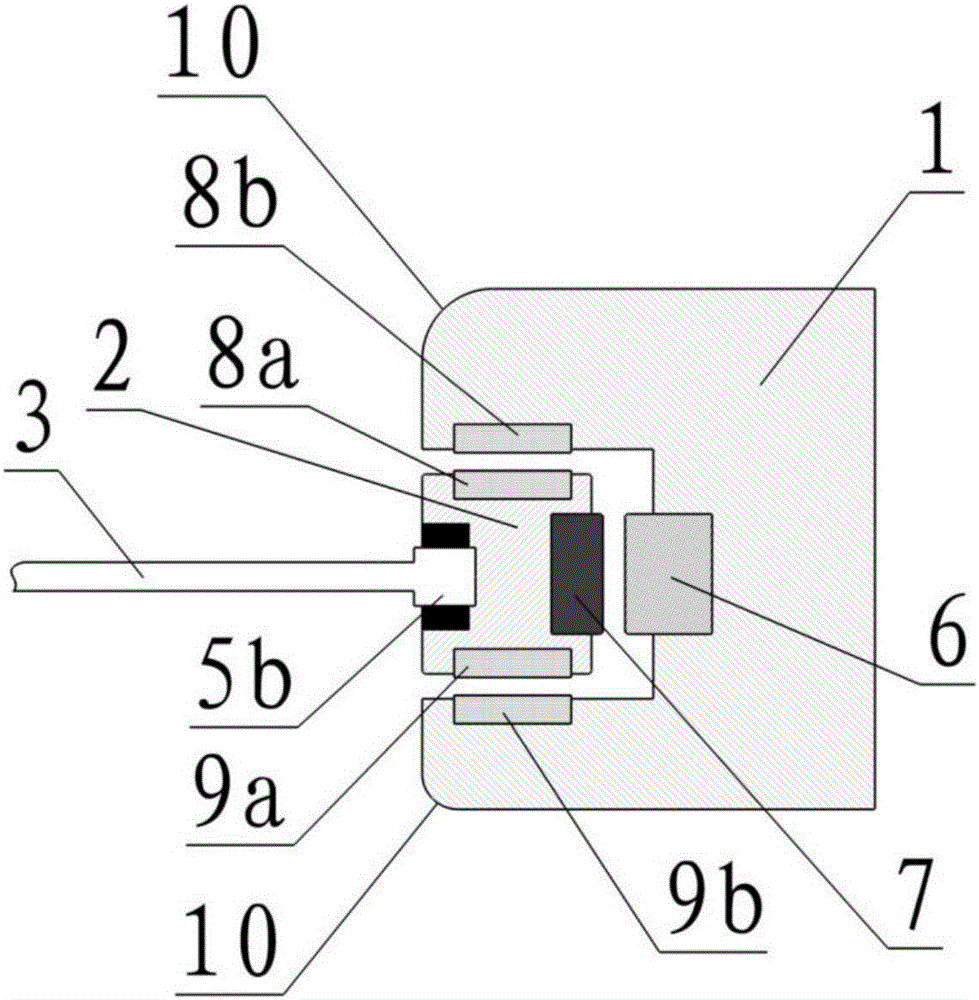

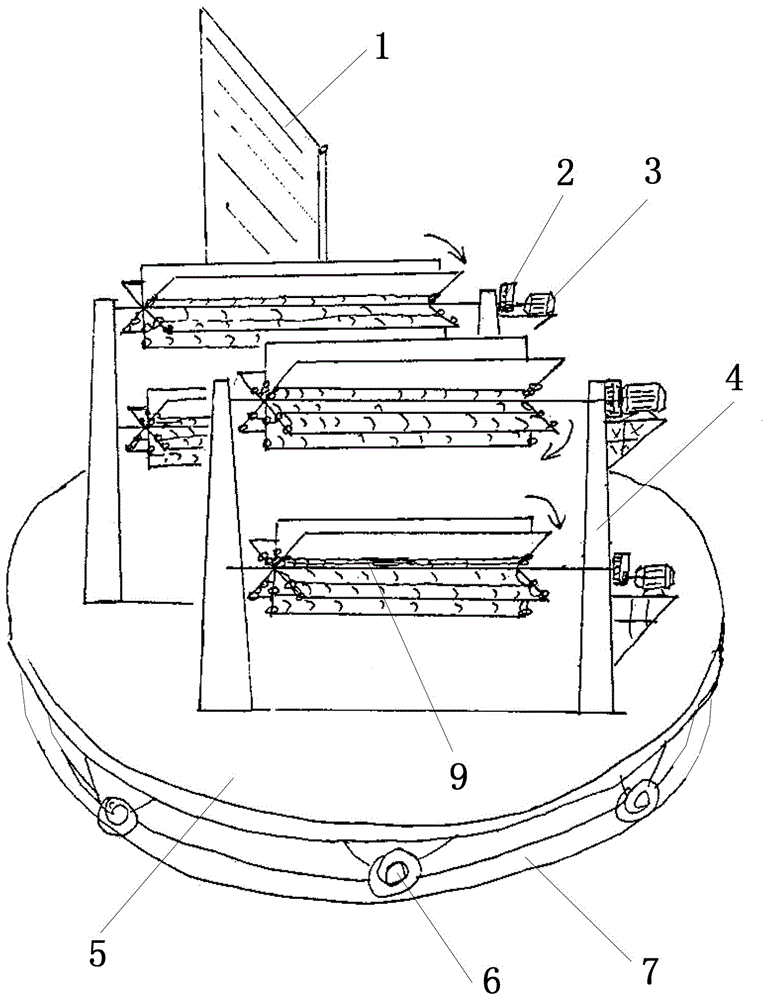

Magnetic levitation rotor wing system and helicopter with same

ActiveCN106516127AEffective consideration of strengthEffectively consider the lift effectPropellersPower plant constructionAviationPropeller

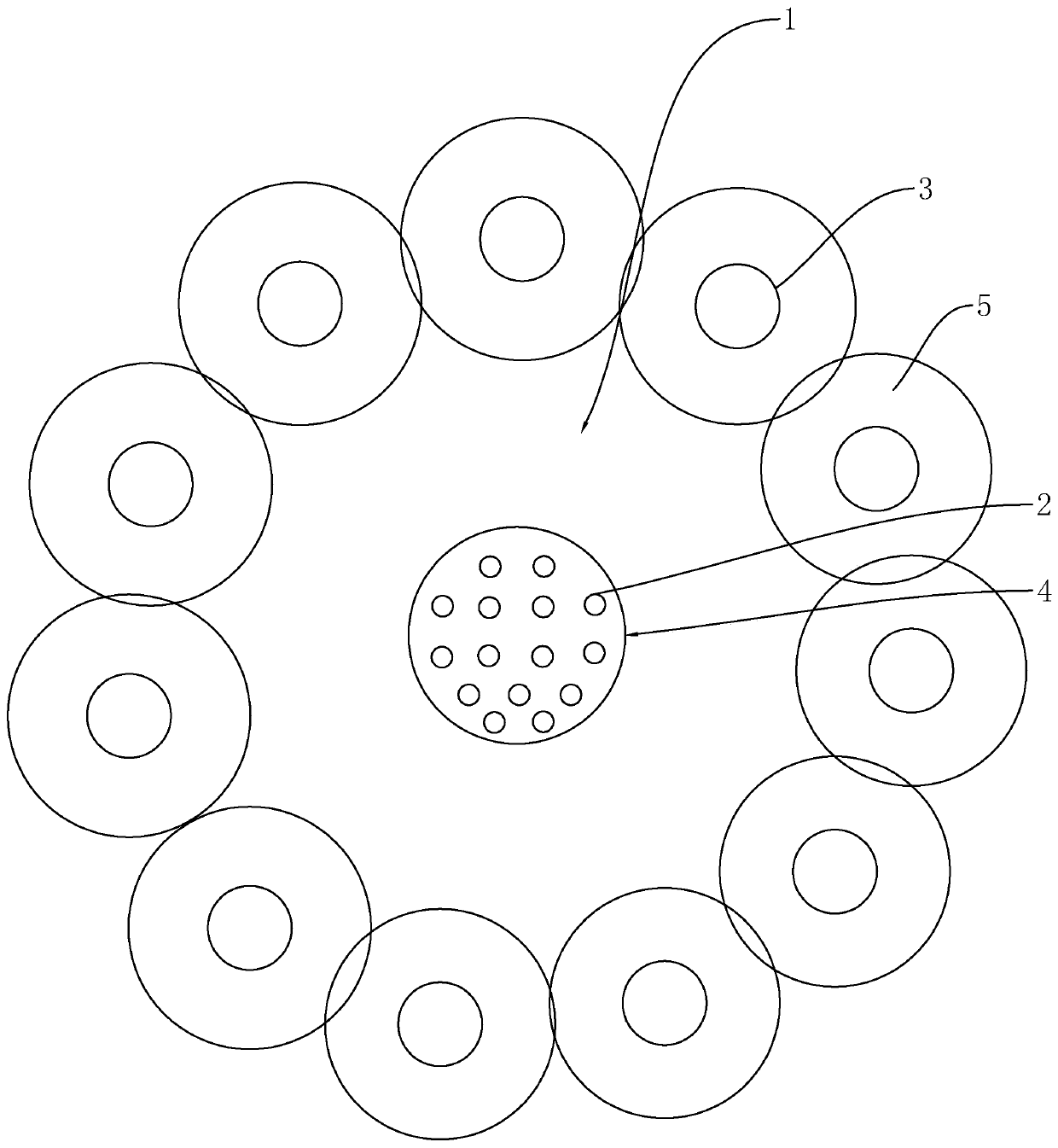

The invention relates to a magnetic levitation rotor wing system and a helicopter with the same and the field of aviation, in particular to the technical field of rotor wings. The magnetic levitation rotor wing system comprises a rotor wing ring (2) and a rail ring (1), wherein the rotor wing ring (2) is connected with a rotor wing propeller point, and the rail ring (1) provides magnetic suspension force for the rotor wing ring (2). Magnetic suspension force provided by the rail ring (1) includes a driving device capable of driving blades to rotate and a suspension device capable of enabling the propeller point to suspend. A first deflection driving mechanism is arranged on the root portions of the blades of the rotor wing so that first deflection angles of the root portions of the blades can be provided, and a second deflection driving mechanism is arranged on the rotor wing ring (2) so that second deflection angles of the points of the blades can be provided. According to the magnetic levitation rotor wing system and the helicopter with the same, only an outside rail ring is needed to drive the rotor wing ring, and the blades are connected by a central connecting component; and the requirement of independent variable pitch of the rotor wing is guaranteed, partial load of the blades is counteracted with one another through the central connecting component, integrality of the rotor wing ring is increased, and working reliability of improved.

Owner:CHINA HELICOPTER RES & DEV INST

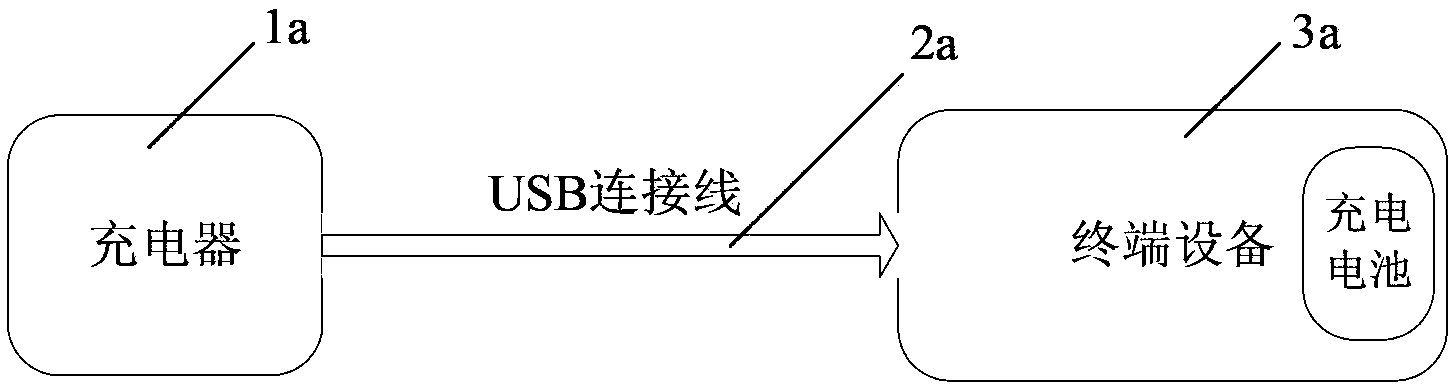

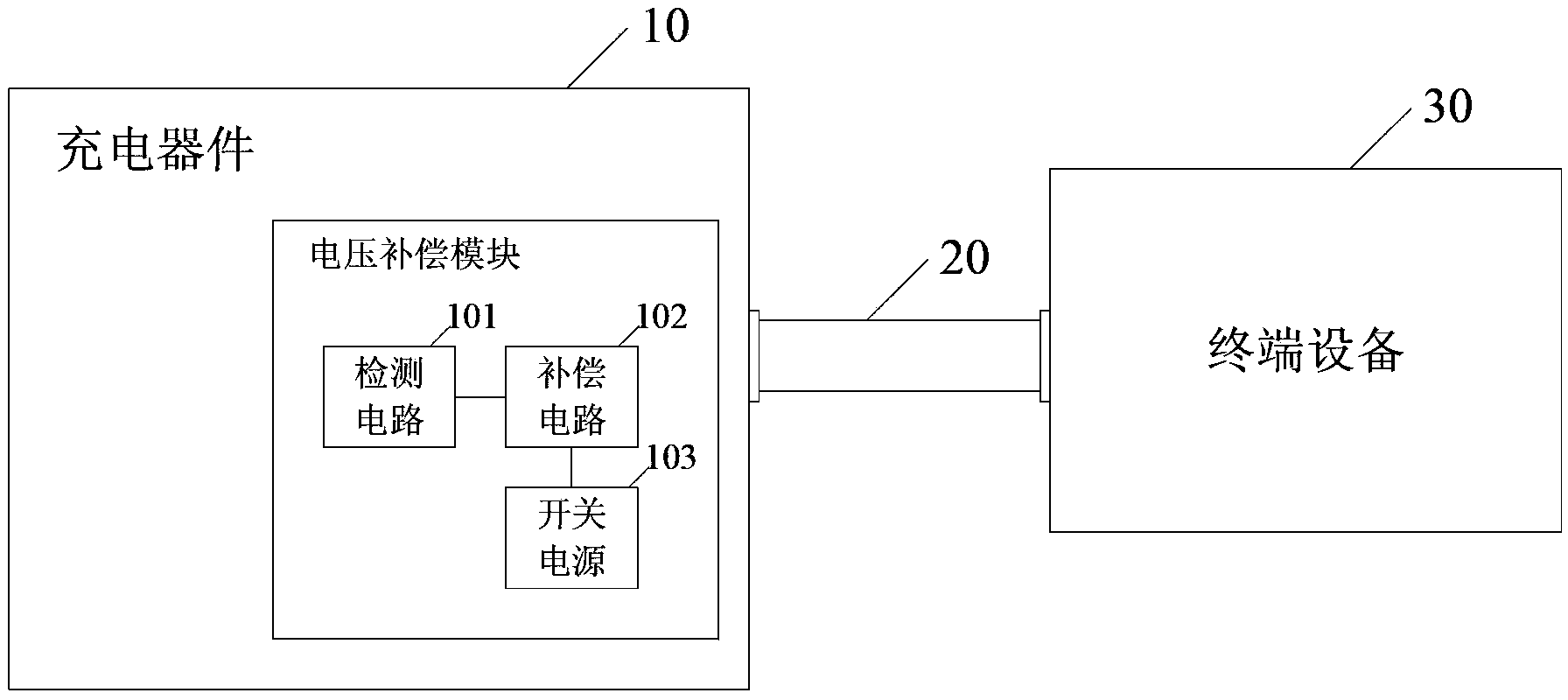

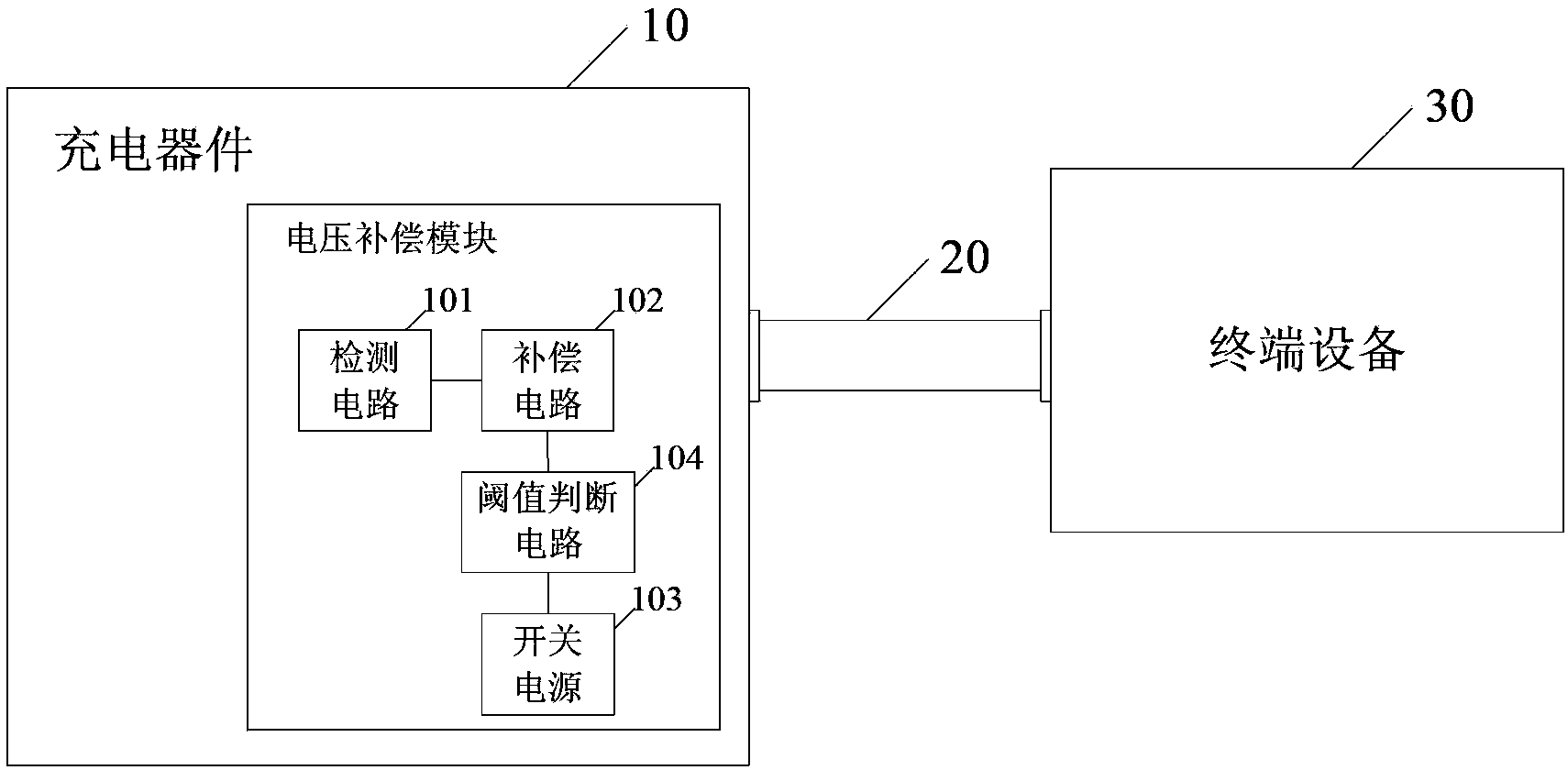

Charging equipment and power supply method thereof

ActiveCN104253461ASolve the problem of excessive pressure dropGuaranteed differential pressureBatteries circuit arrangementsElectric powerCharge currentTerminal equipment

An embodiment of the invention discloses charging equipment which comprises a voltage compensation module. The voltage compensation module comprises a detection circuit, a compensation circuit and a switch power source, the detection circuit is used for detecting output voltage of a voltage output end of the charging equipment and charging voltage reaching a charging end of terminal equipment and comparing a difference value between the output voltage and the charging voltage, the compensation circuit is used for calculating a sum of the output voltage and two times of the difference value to acquire output voltage after compensation, and the switch power source is used for adjusting the output voltage of the charging equipment to enable the output voltage to be equal to the output voltage after compensation. The embodiment of the invention further provides a charging method of the charging equipment. By the charging equipment, the problem of overlarge voltage drop on a charging cable can be solved, and charging current of a charging battery of the terminal equipment is guaranteed to be constant, so that charging efficiency is improved while charging time is reduced.

Owner:HONOR DEVICE CO LTD

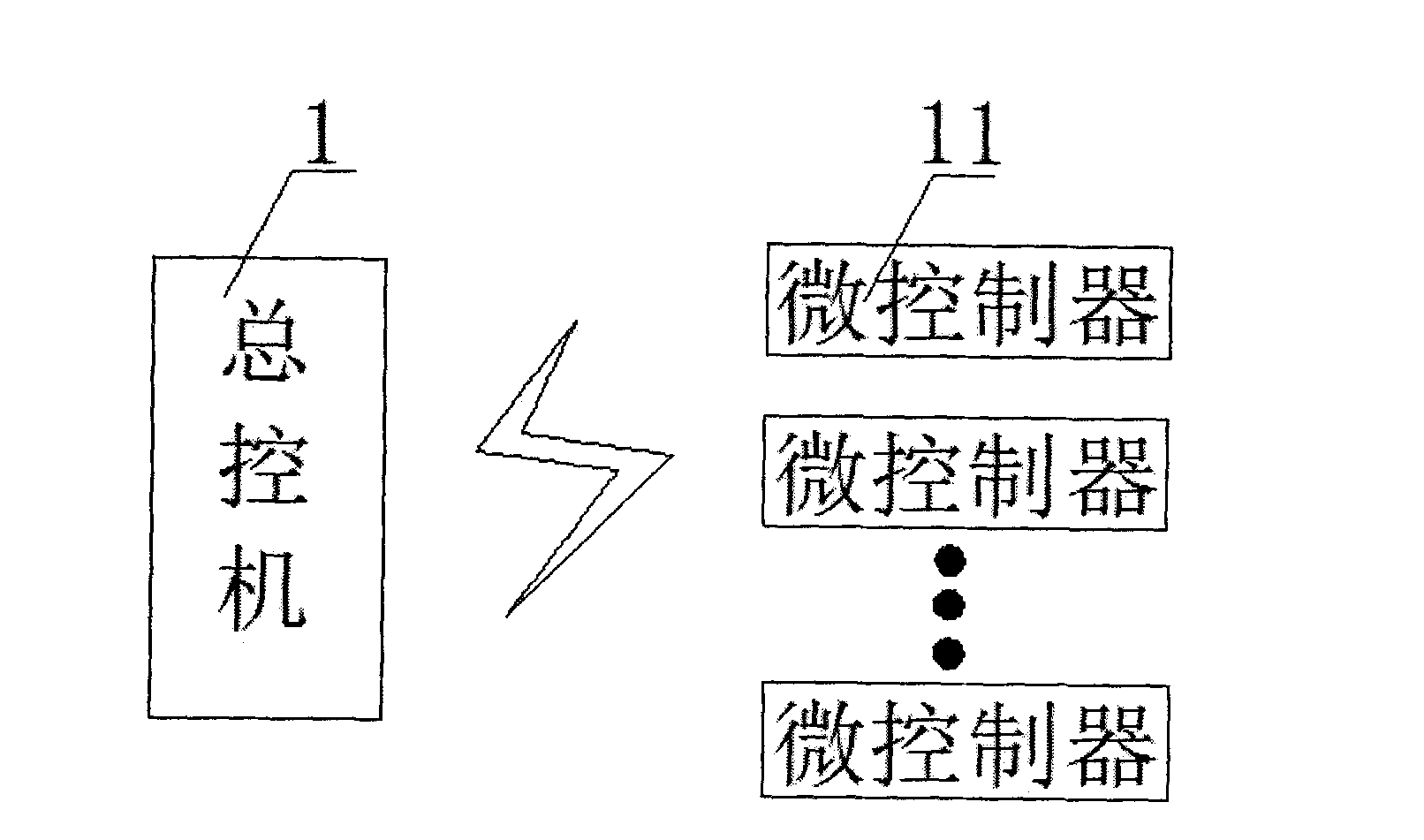

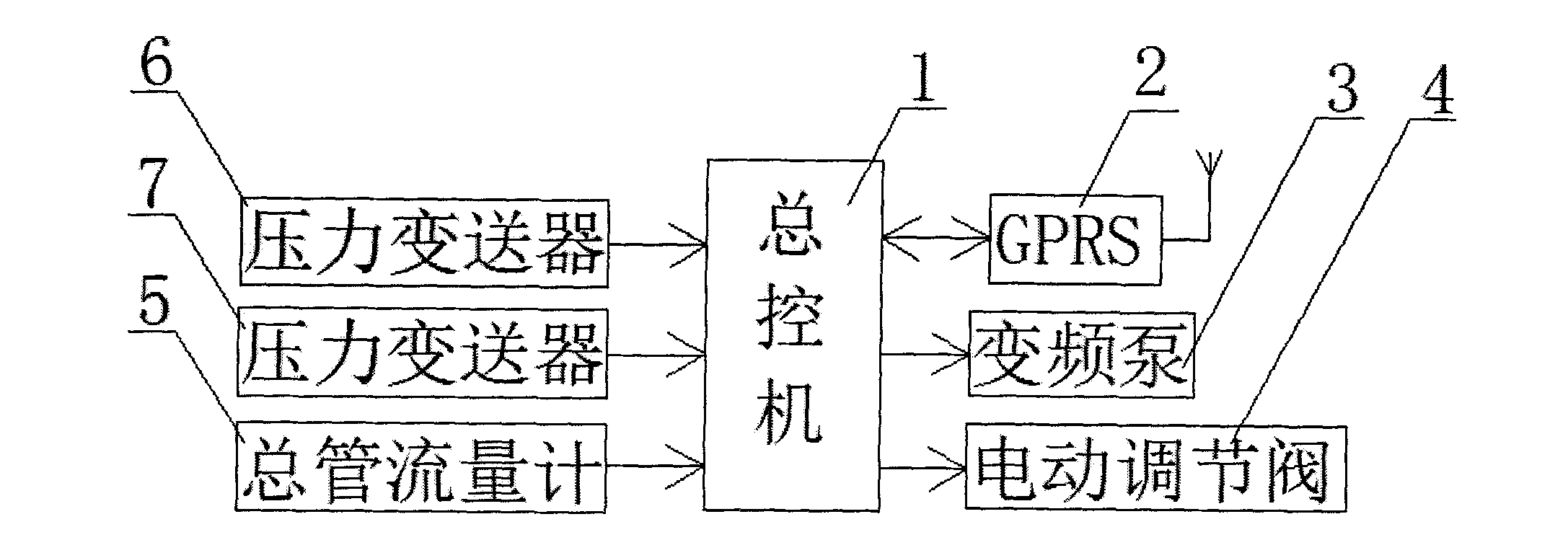

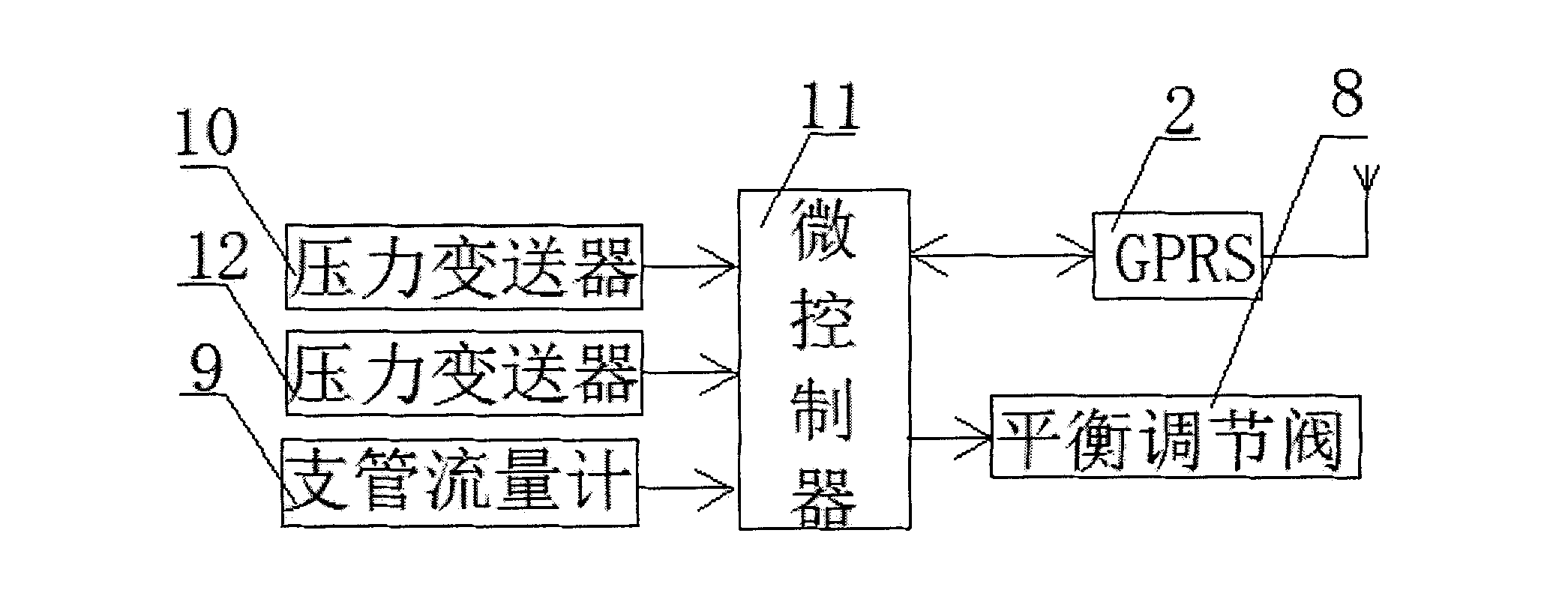

Heat supply secondary pipe network distributed balance control system and control method thereof

ActiveCN102494365ARun smoothlyAvoid vibration phenomenonLighting and heating apparatusEfficient regulation technologiesControl systemControl valves

The invention discloses a heat supply secondary pipe network distributed balance control system and a control method thereof. The system comprises a front-end control system and a tail-end control system and is provided with a master control machine and microcontrollers; and the system is characterized in that: the master control machine is connected with a plurality of microcontrollers through wireless communication; a first pressure transmitter, a second pressure transmitter, a header pipe flowmeter, a variable frequency pump, an electric control valve and a general packet radio service (GPRS) module are connected to the master control machine respectively; and a third pressure transmitter, a fourth pressure transmitter, a branch pipe flowmeter, a balancing control valve and a GPRS module are connected to the microcontrollers respectively. The invention has the advantages that: the pressure difference and flow of a pipe network in each building can be detected, pressure difference between an input end and an output end of the pipe network in each building is guaranteed, pressure difference between a heat supply header pipe and a backflow header pipe is guaranteed, and flow balance between the heat supply header pipe and a heat supply branch pipe is monitored simultaneously; and therefore, the secondary pipe network is operated stably, pipelines are prevented from vibrating, and the service life of the pipelines is prolonged.

Owner:CHONGQING WECAN PRECISION INSTR

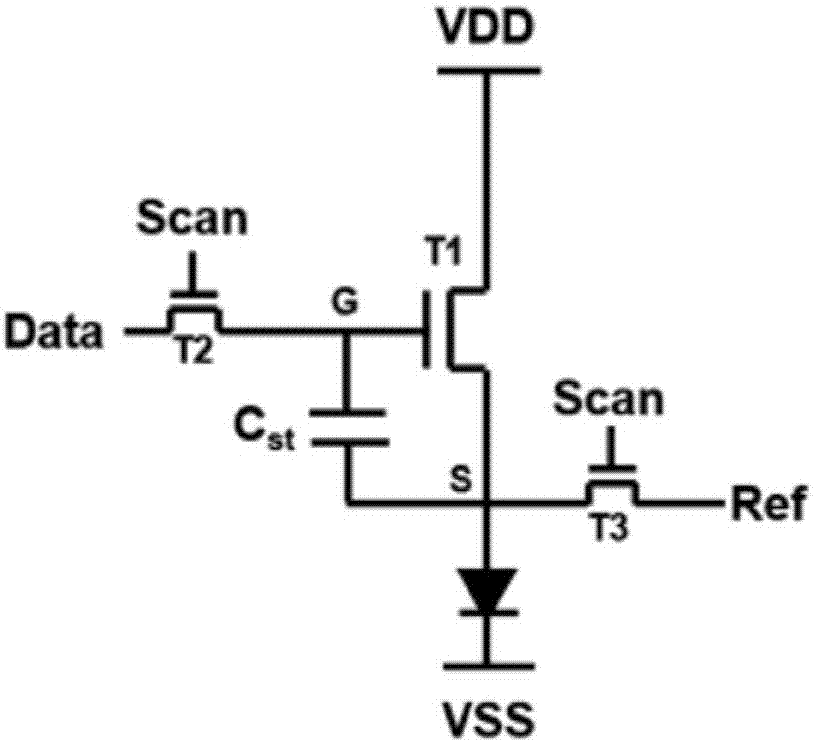

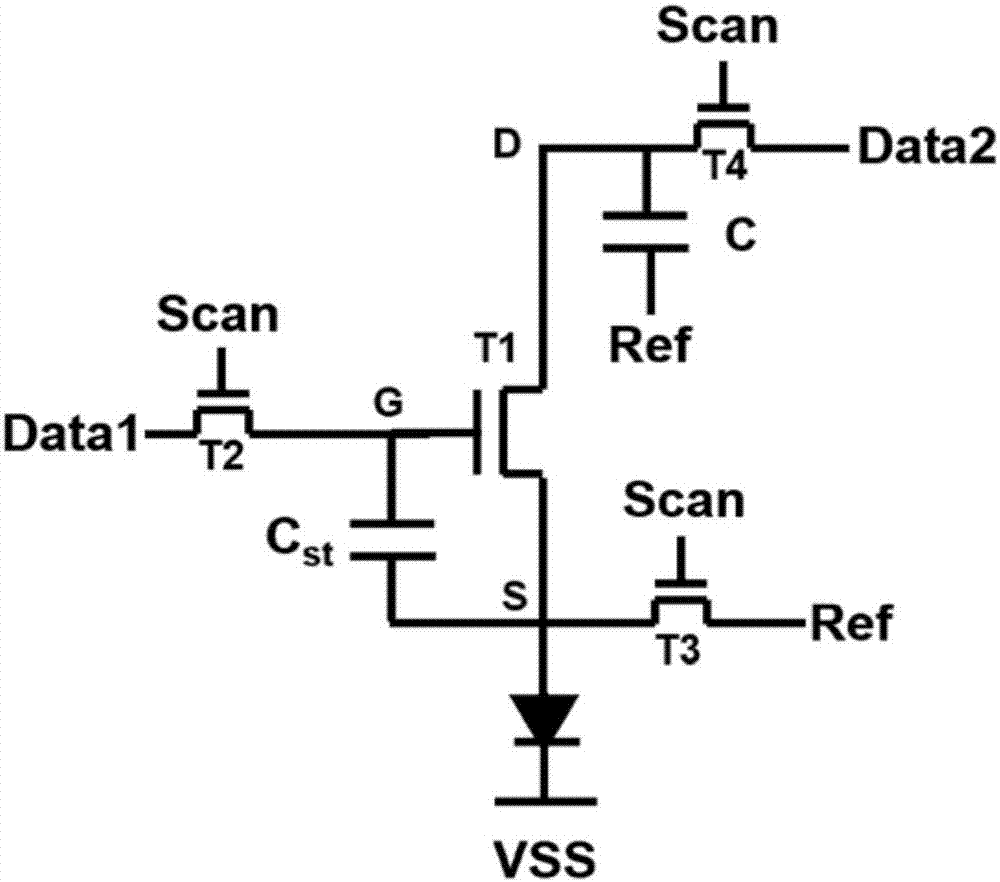

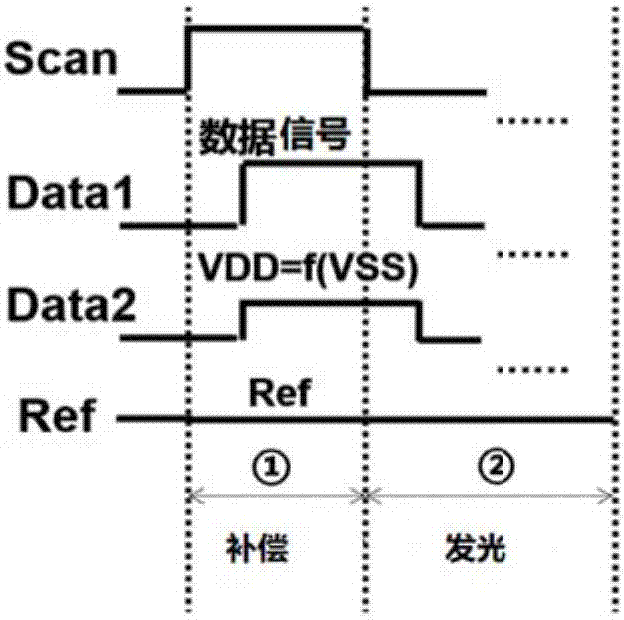

Top-emission AMOLED pixel circuit and driving method thereof

ActiveCN107393477AAvoid failureGuaranteed differential pressureStatic indicating devicesSolid-state devicesCapacitanceLow voltage

The invention relates to a top-emission AMOLED pixel circuit and a driving method thereof; the top-emission AMOLED pixel circuit comprises the following units: a first film transistor (T1) connected with a first node (G), a second node (S) and a third node (D); a second film transistor (T2) connected with a scan signal (Scan), the first node (G) and a data signal (Data1); a third film transistor (T3) connected with the scan signal (Scan), the second node (S) and a reference voltage (Ref); a fourth film transistor (T4) connected with the scan signal (Scan), the third node (D) and a power supply high voltage (Data2); a first capacitor (Cst) connected with the first node (G) and the second node (S); a second capacitor (C) connected with the third node (D) and the reference voltage (Ref); an OLED connected with the second node (S) and a power supply low voltage (VSS); the difference between the power supply high voltage (Data2) and the power supply low voltage (VSS) remains unchanged. The invention also provides the corresponding driving method. The top-emission AMOLED pixel circuit and the driving method thereof can effectively alleviate IR voltage drop caused by the transparency cathode impedance increases.

Owner:SHENZHEN CHINA STAR OPTOELECTRONICS SEMICON DISPLAY TECH CO LTD

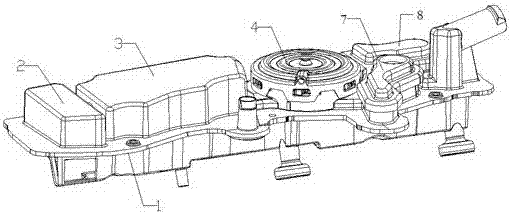

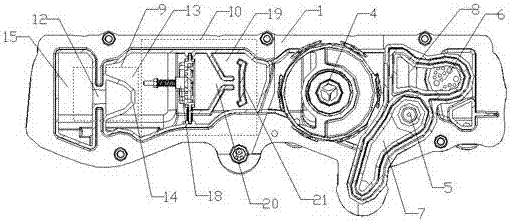

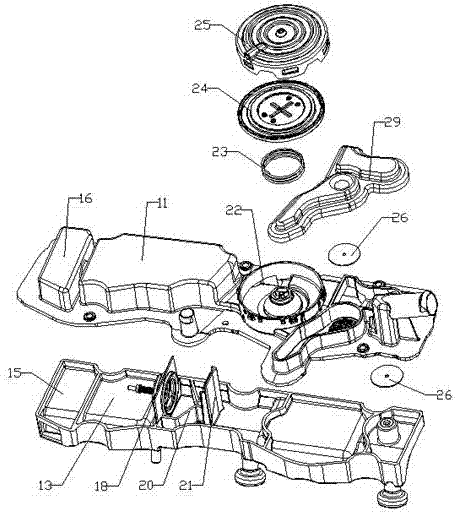

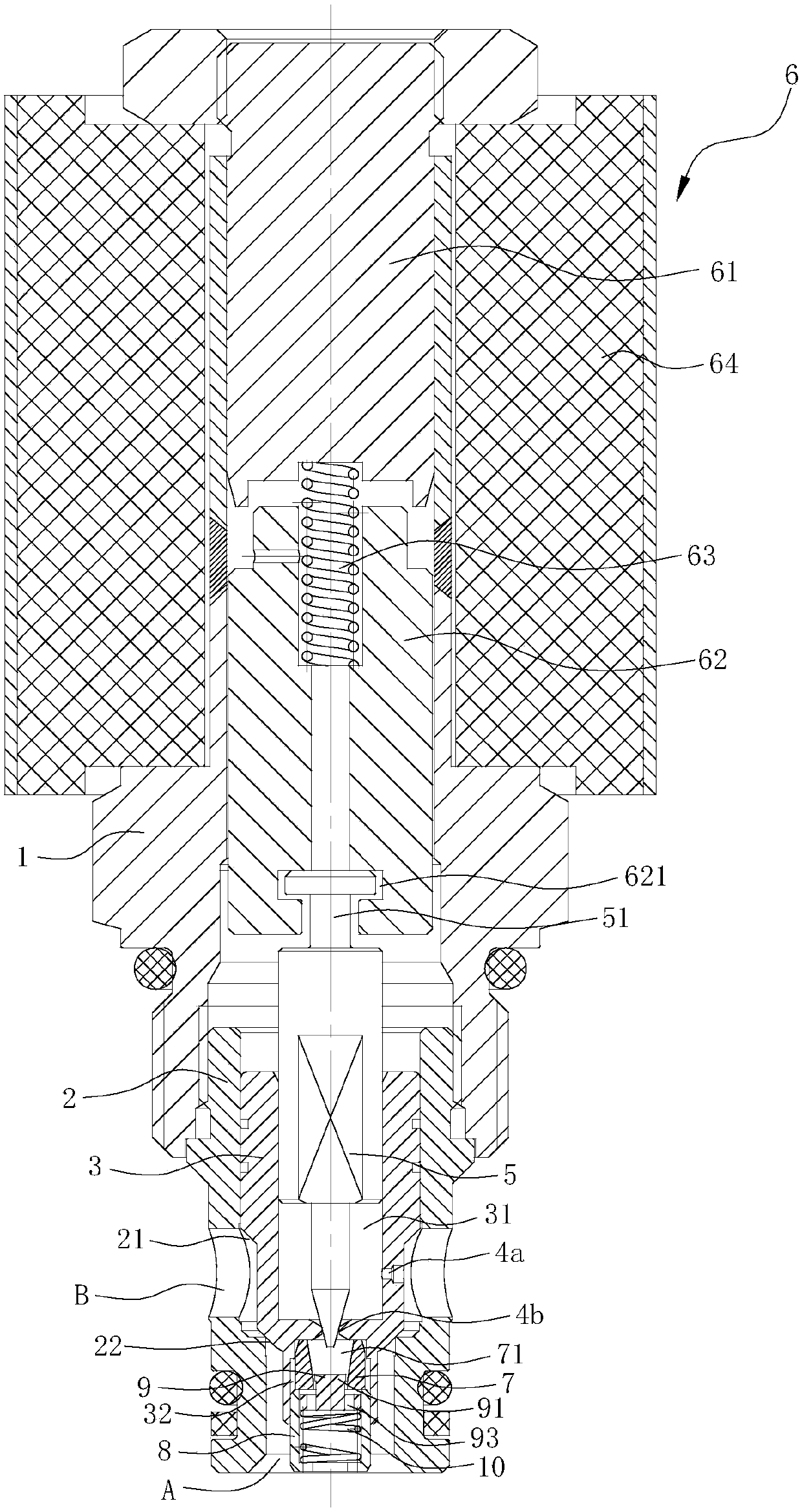

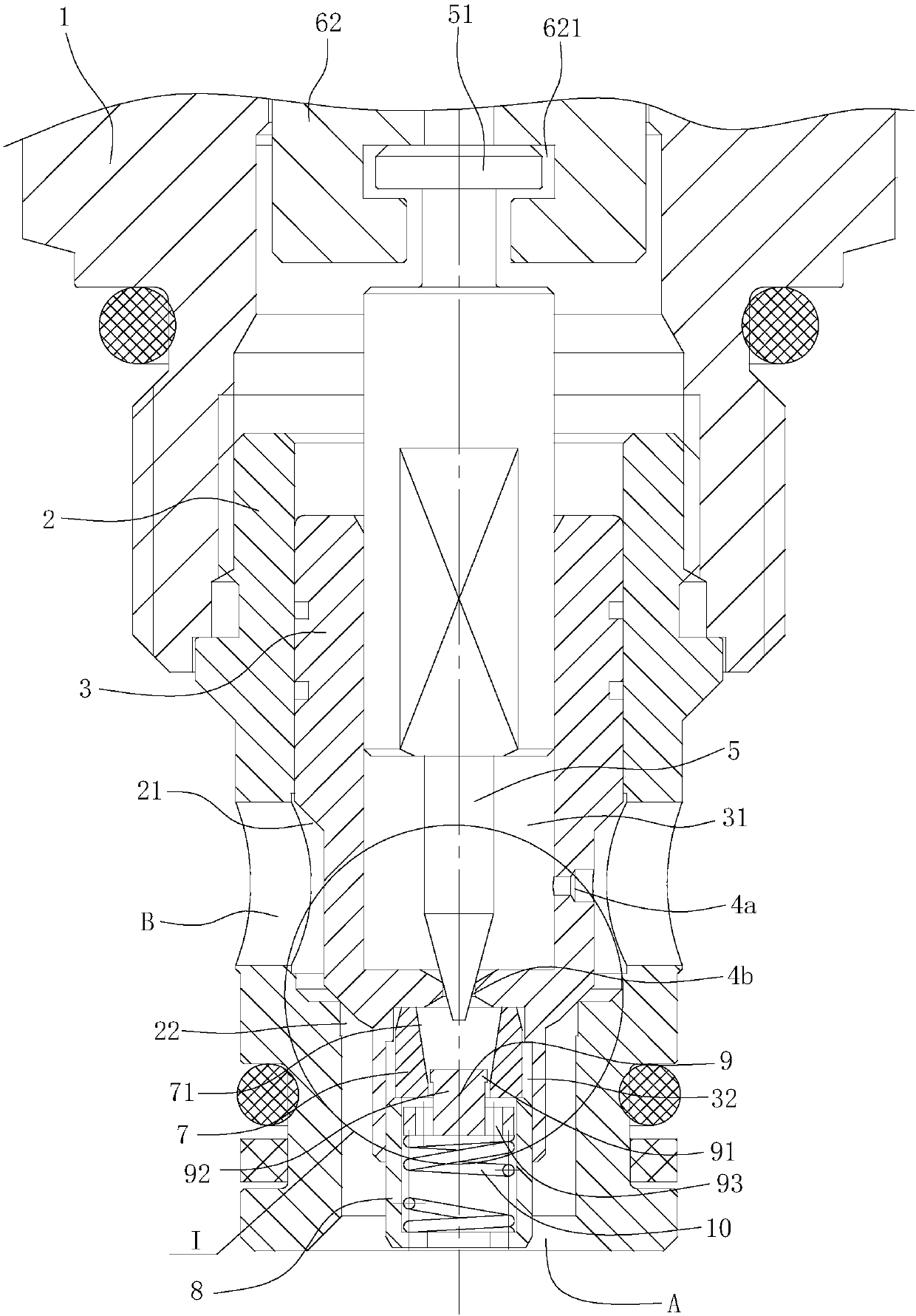

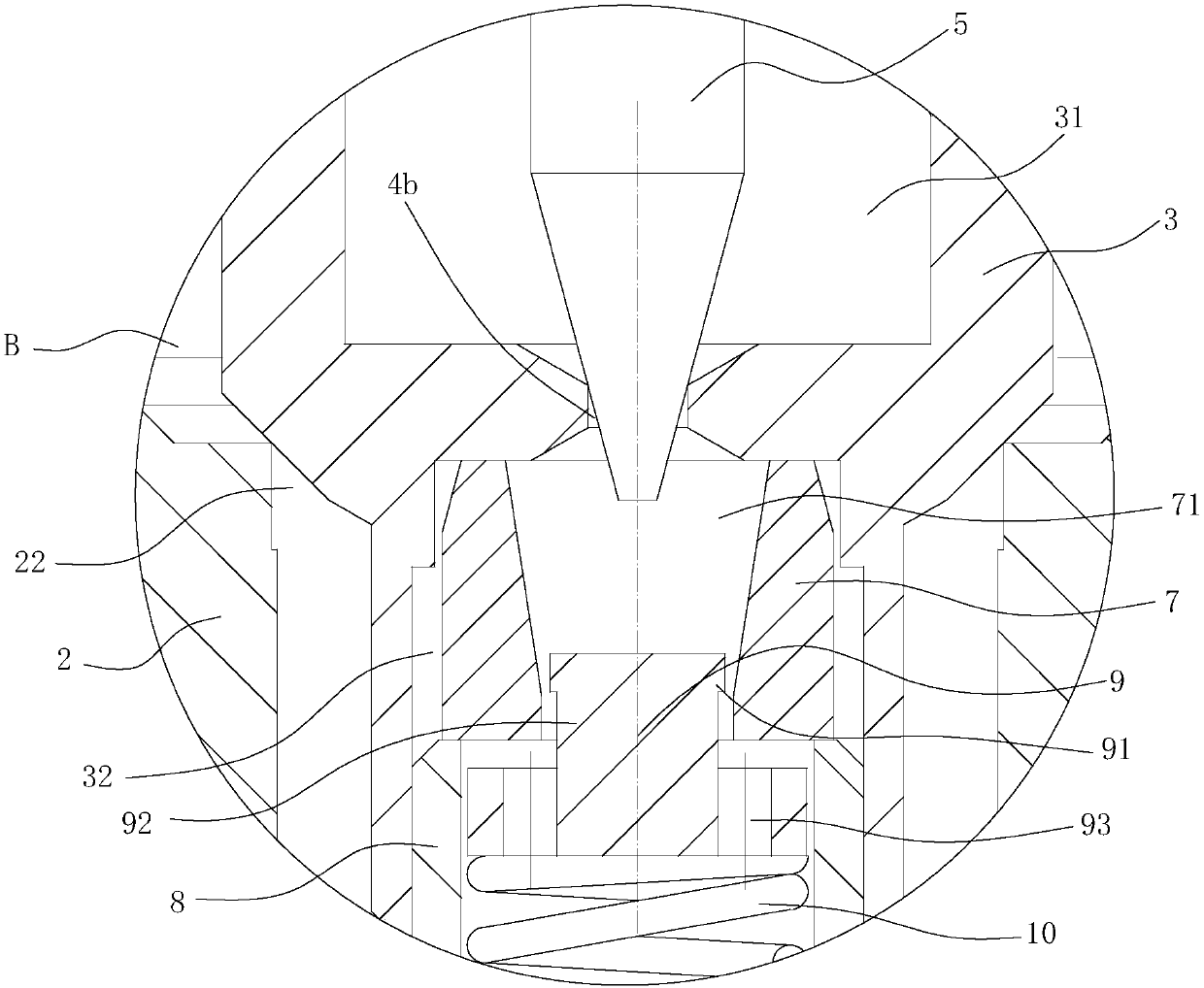

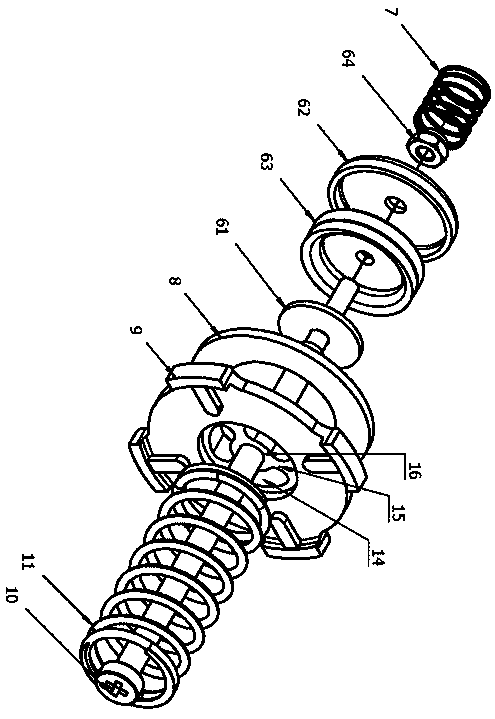

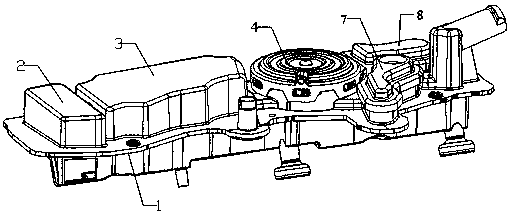

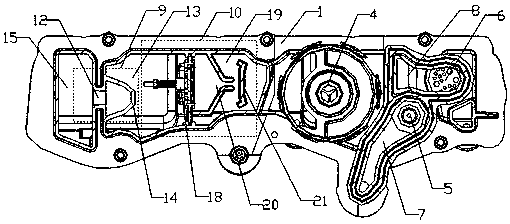

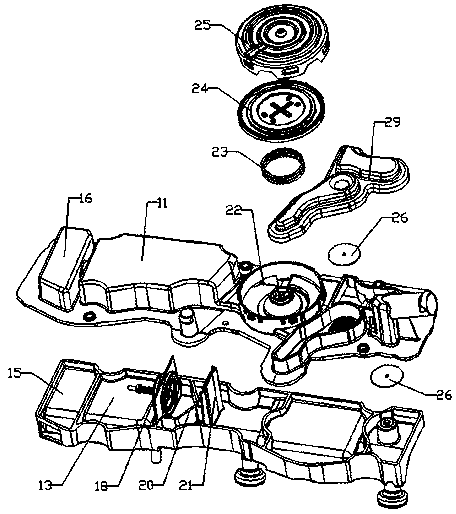

Oil-gas separator

ActiveCN107152324ASimple structureEfficient and thorough separationMachines/enginesCrankcase ventillationEngineeringPressure difference

The invention relates to an oil-gas separator, and belongs to the technical field of automobile engines. The oil-gas separator comprises a separator body, a moving gas gathering chamber, an oil-gas separating part, a pressure adjusting valve, a small load one-way valve, a large load one-way valve, a small load channel and a large load channel; the moving gas gathering chamber is arranged on the left portion of the separator body, and is connected with the oil-gas separating part, the pressure adjusting valve is arranged on the rear side of the oil-gas separating part, the small load channel and the large load channel are formed in the rear side of the pressure adjusting valve, the small load channel is provided with the small load one-way valve, and the large load channel is provided with the large load one-way valve. The one-way valves are directly integrated in the separator body, the oil-gas separating part of the special structure is arranged, oil and gas can be efficiently and thoroughly separated, the separating efficiency is improved, meanwhile,, the structure of the oil-gas separator is simplified, the manufacturing cost of the separator is reduced, the oil-gas separating efficiency is ensured, meanwhile, it is ensured that the pressure difference of the whole oil-gas separator is within the reasonable range, and the engine oil consumption is reduced.

Owner:HENGST FILTER SYST (KUNSHAN) CO LTD

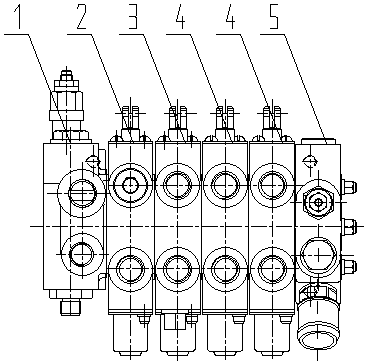

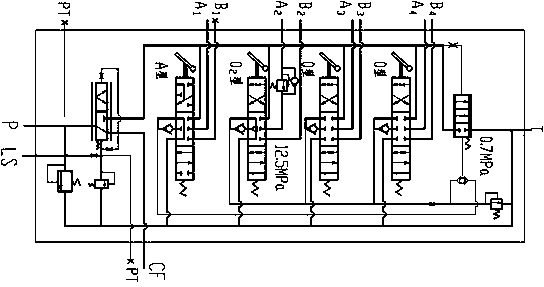

Load sensitive forklift multi-way valve

ActiveCN104141650AIncrease pressureReduce loadServomotor componentsLifting devicesInlet valveEngineering

The invention provides a load sensitive forklift multi-way valve, and belongs to the technical field of engineering machinery hydraulic components. The load sensitive forklift multi-way valve comprises an oil inlet valve piece, a lifting valve piece, an inclined valve piece, a fitting valve piece and an oil return valve piece. All the valve pieces are provided with flow control valve rods and oil inlet one-way valves respectively, the inclined valve piece is provided with a load maintaining valve, and the oil return valve piece is provided with an unloading valve core, a reset spring, a shuttle valve and a secondary overflow valve. The load sensitive forklift multi-way valve has good flow control performance, so that the speed of an executing mechanism is unrelated to the load pressure and is only associated with the stroke of the valve rods, and the pressure of a system is unrelated to flow change of oil feeding. Meanwhile, the inclined valve piece is provided with the load maintaining valve, so that the forwards leaning pressure keeps stable all the time, load on an oil cylinder is lowered, when the system flow is larger than the required flow, oil return is conducted on the redundant flow through the unloading valve core, energy consumption can be effectively reduced, and the load sensitive forklift multi-way valve is high in efficiency and less in power loss, so that fuel is saved and a hydraulic system is lower in heating quantity.

Owner:ZHEJIANG HAIHONG HYDRAULIC TECH

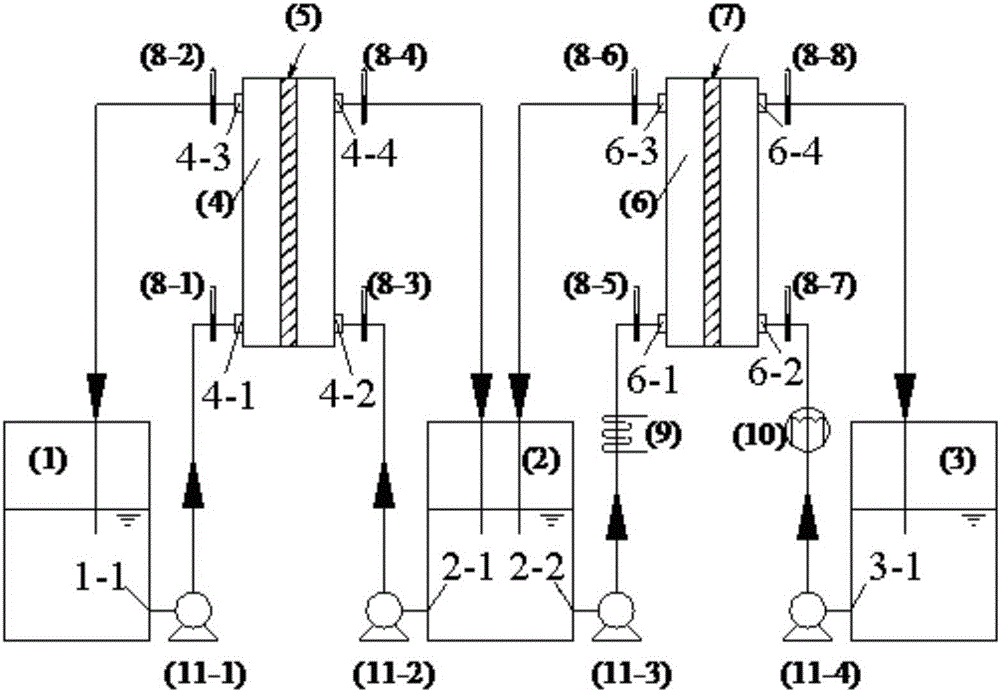

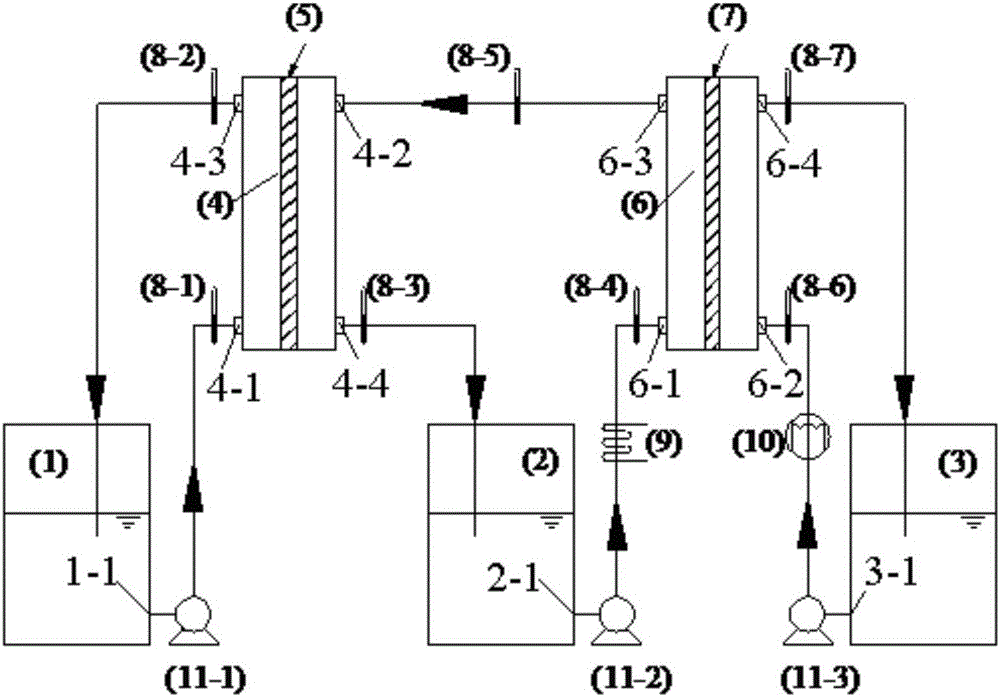

Urine source separation device based on combined membrane process and urine separation method using urine source separation device

InactiveCN105967275AGuaranteed differential pressureWater/sewage treatment bu osmosis/dialysisEnergy based wastewater treatmentMembrane distillationHeating system

A source separation urine device based on combined membrane technology and a method for separating urine by using the device, which relates to a device for separating urine and a method for separating urine by using the same. The purpose of the present invention is to solve the problems of complex process, cumbersome operation and high cost in the separation of nutrients and water in urine in the prior art. A source separation urine device based on a combined membrane process includes a source separation urine storage tank, a draw liquid storage tank, a distillate storage tank, a forward osmosis membrane module, a forward osmosis membrane, a membrane distillation module, a hydrophobic membrane, a first thermometer, Second thermometer, third thermometer, fourth thermometer, fifth thermometer, sixth thermometer, seventh thermometer, eighth thermometer, heating system, cooling system, first water pump, second water pump, third water pump and fourth water pump. The invention can obtain a source separation urine device based on combined membrane technology and a method for separating urine by using the same.

Owner:HARBIN INST OF TECH

Vortex solidification underground water remediation system and method

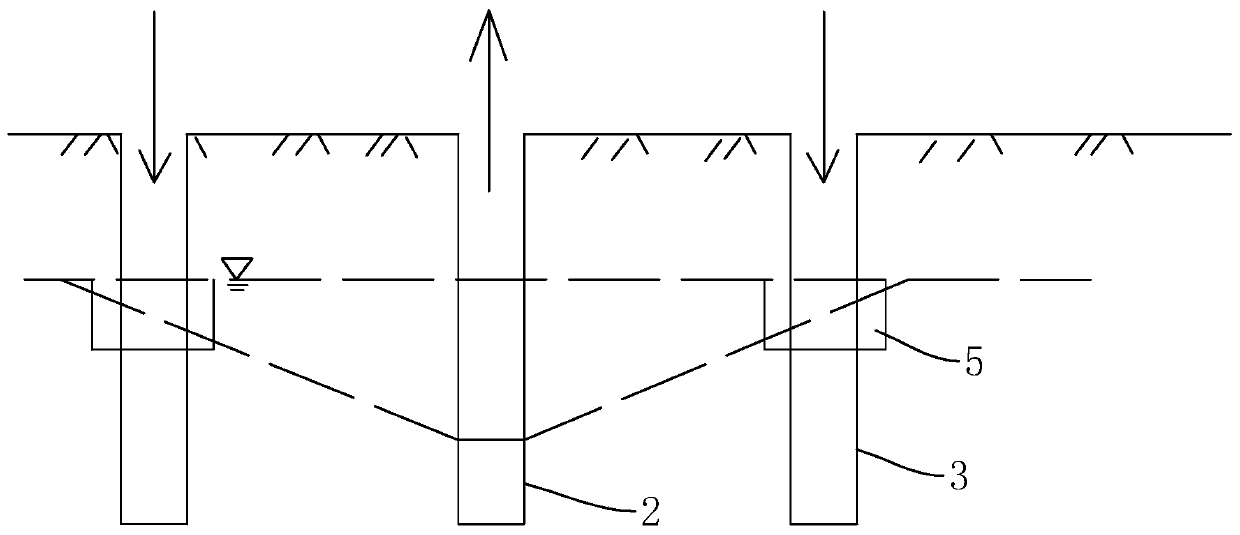

PendingCN110104892AReduce water outputShort cycleWater resource protectionTreatment involving filtrationCone of depressionGroundwater remediation

The invention relates to a vortex solidification underground water remediation system. The vortex solidification underground water remediation system is arranged in an underground water to-be-remediated area, and comprises a pumping well, water injection wells and fences. The pumping well is formed in the center of the to-be-remediated area, the multiple water injection wells are arranged at intervals along the outer contour line of the to-be-remediated area, an inorganic inert adsorption material is injected into the water injection wells, and the closed adsorption material fences are formedon the outer side of the to-be-remediated area, wherein the adsorption material fences have good water permeability, and the height of the fences is at least equal to the covering depth of polluted underground water. By performing large-drawdown pumping on the pumping well and large-flow reinjection on the water injection wells, a cone of depression is formed, and after the adsorption material adsorbs pollutants in the underground water, the pollutants are degraded and solidified, gather towards the pumping well group along with the migration of the underground water and then are pumped to thesurface through the pumping well group for surface treatment and purification. The vortex solidification underground water remediation system has the advantages of small pumping amount, short cycle and large treatment range.

Owner:北京爱地地质工程技术有限公司

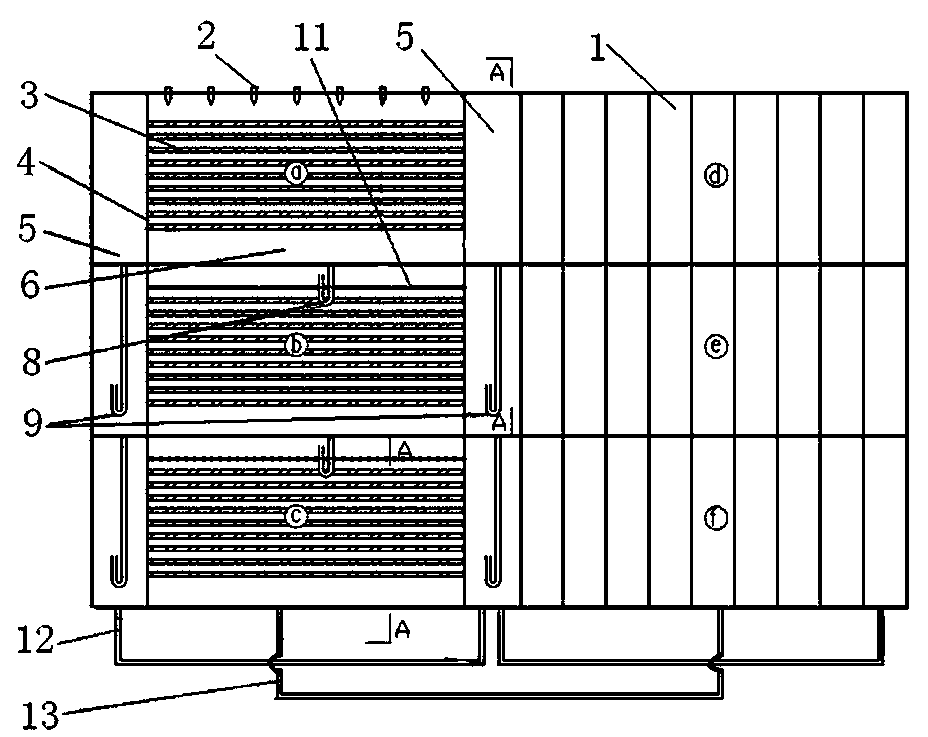

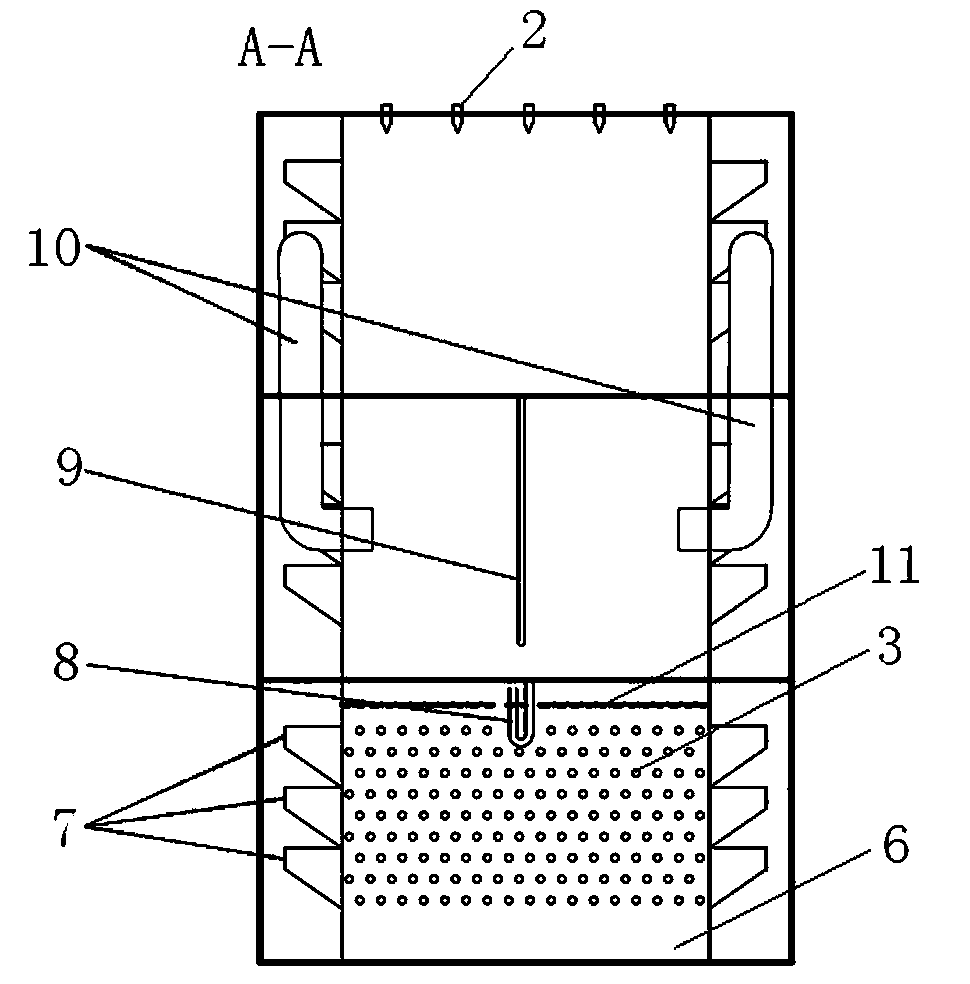

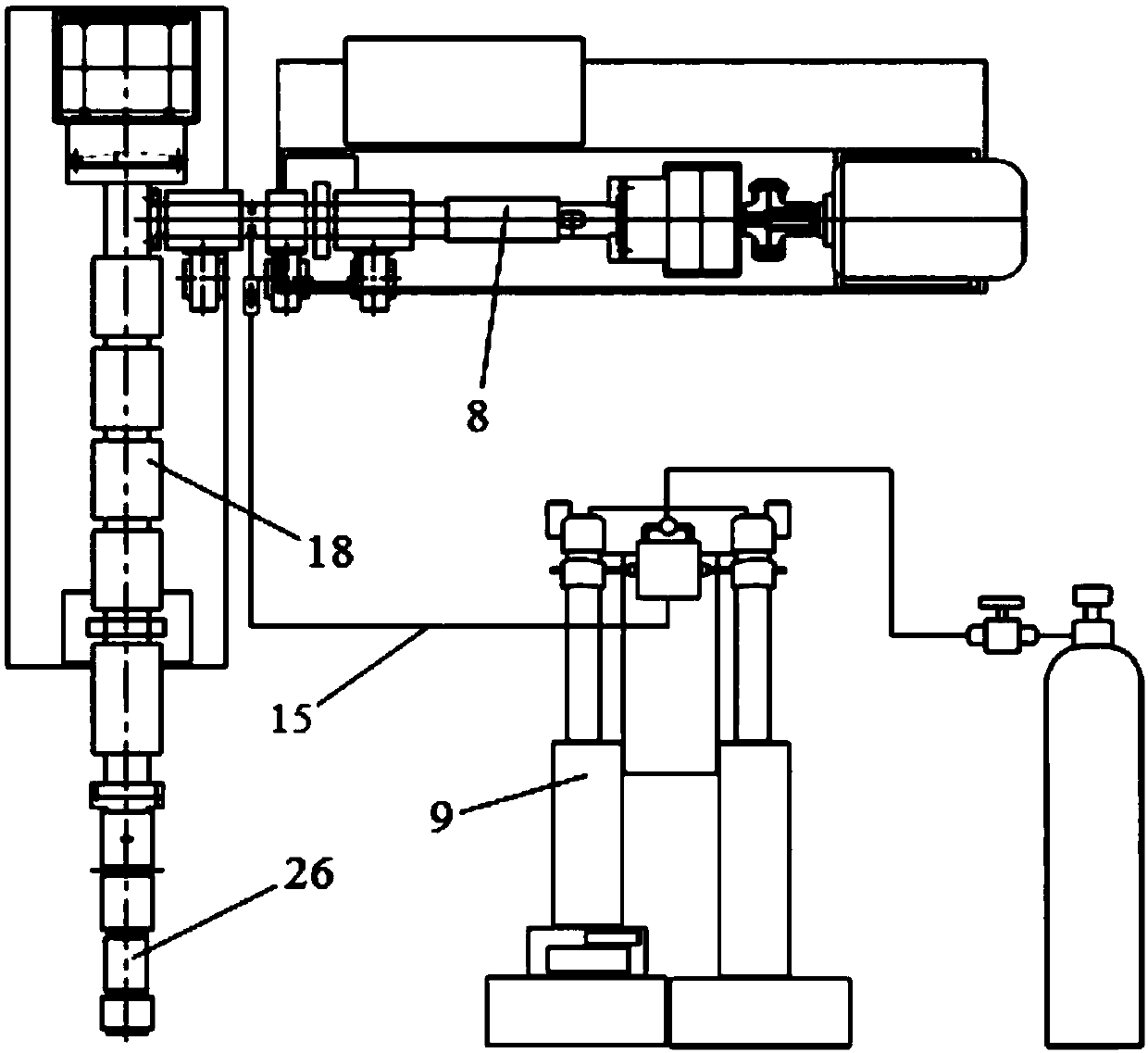

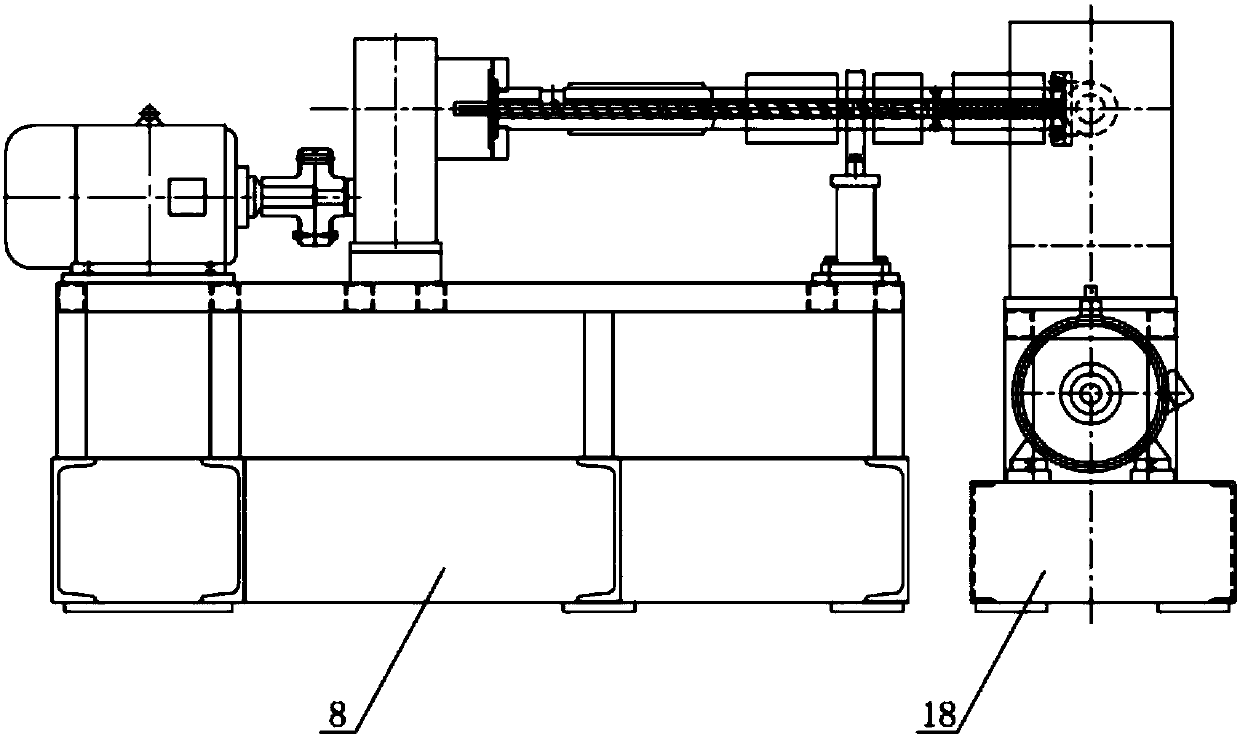

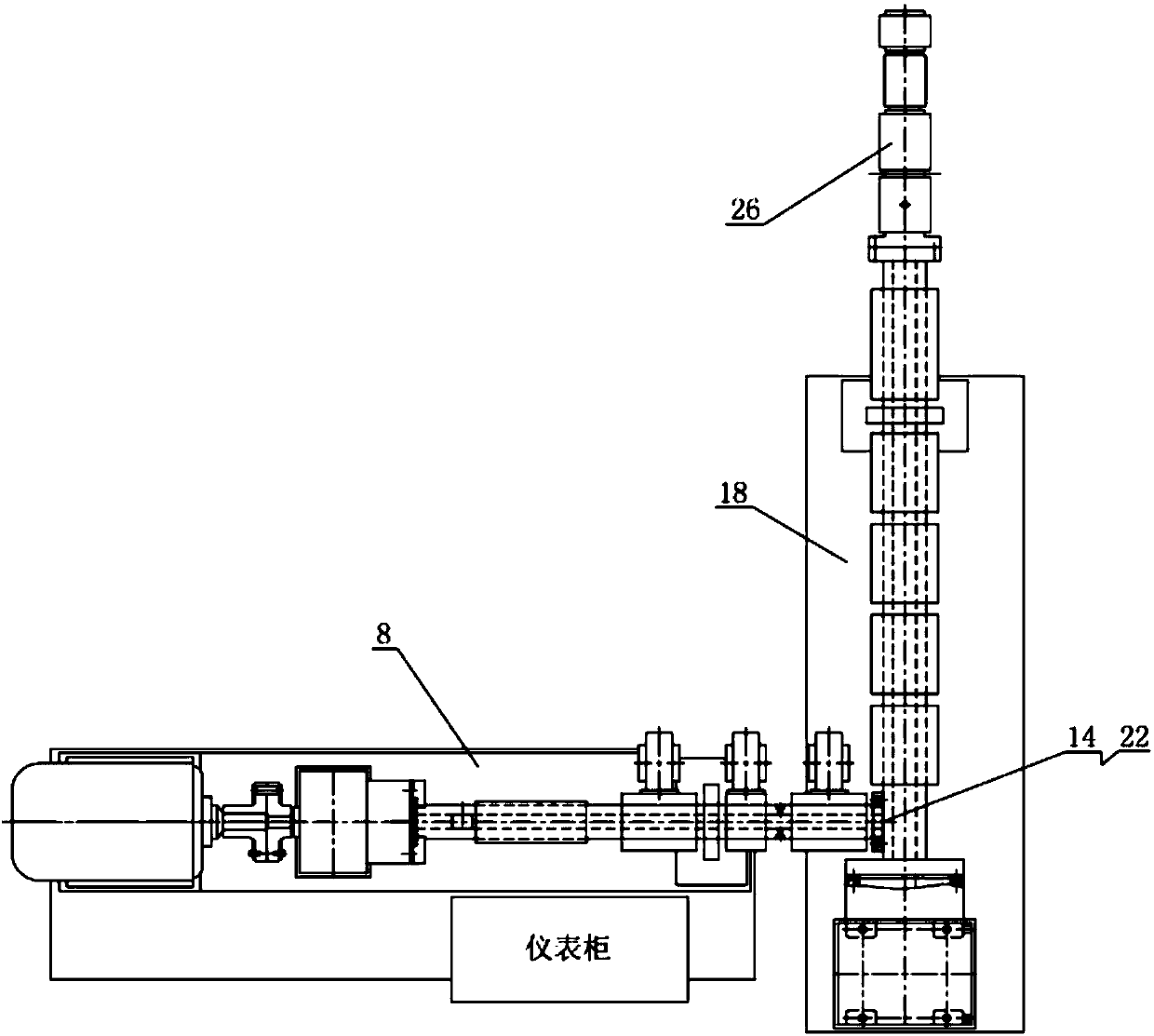

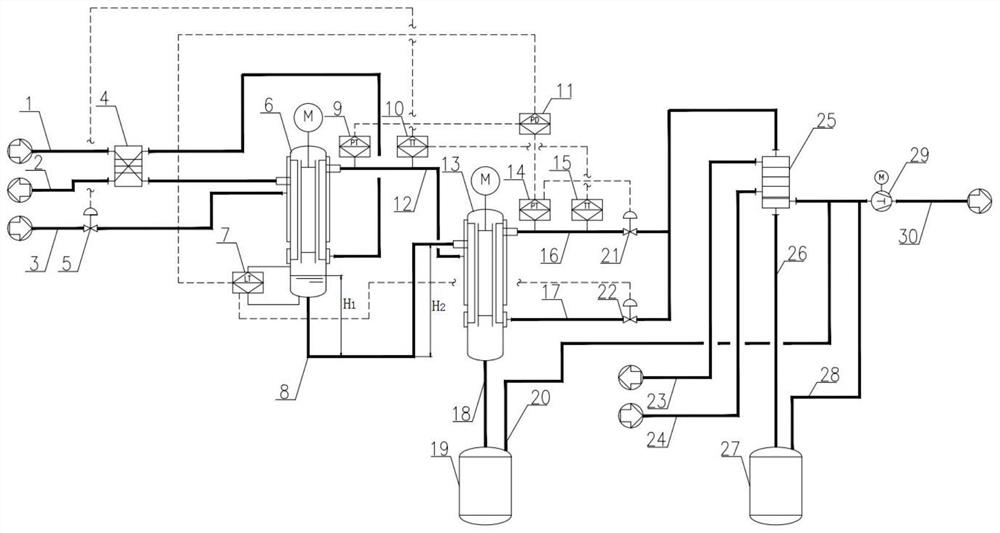

Full-automatic oil-chromatography sample feeding device for transformer and operation method

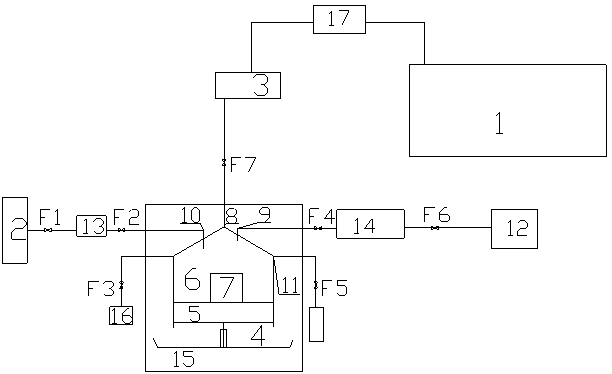

ActiveCN103412075AImprove detection efficiencyAccurately control the amount of entryComponent separationNitrogenNitrogen gas

The invention discloses a full-automatic oil-chromatography sample feeding device for a transformer. The device comprises a detection device, an oil-gas separation device, a gas tank, a gas collection device and an inspection device, wherein the oil-gas separation device comprises a degassing tank with movable bottom; a tank bottom pushing device and a gravity compensation device are connected to the tank bottom; a stirring device is arranged in the degassing tank; a gas sampling hole, a sampling hole, a nitrogen inlet and an oil discharging hole are formed in the degassing tank, the gas sampling hole is connected with the gas collection device, the sampling hole is connected with a sample, the nitrogen inlet is connected with the gas tank, and the oil discharging hole is connected with an oil collection tank. The full-automatic oil-chromatography sample feeding device aims at pretreatment processes of detecting gas components dissolved in transformer oil in a gas chromatography manner in a laboratory; the device automation is realized in operation processes originally required to be manually operated, so that the detection efficiency of an oil-immersed transformer can be improved, errors brought from pretreatment links can be reduced, the manpower can be saved, and the device is worthy of being popularized and applied.

Owner:ELECTRIC POWER SCI RES INST OF GUIZHOU POWER GRID CO LTD +1

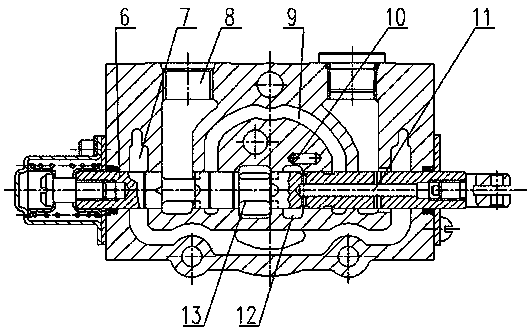

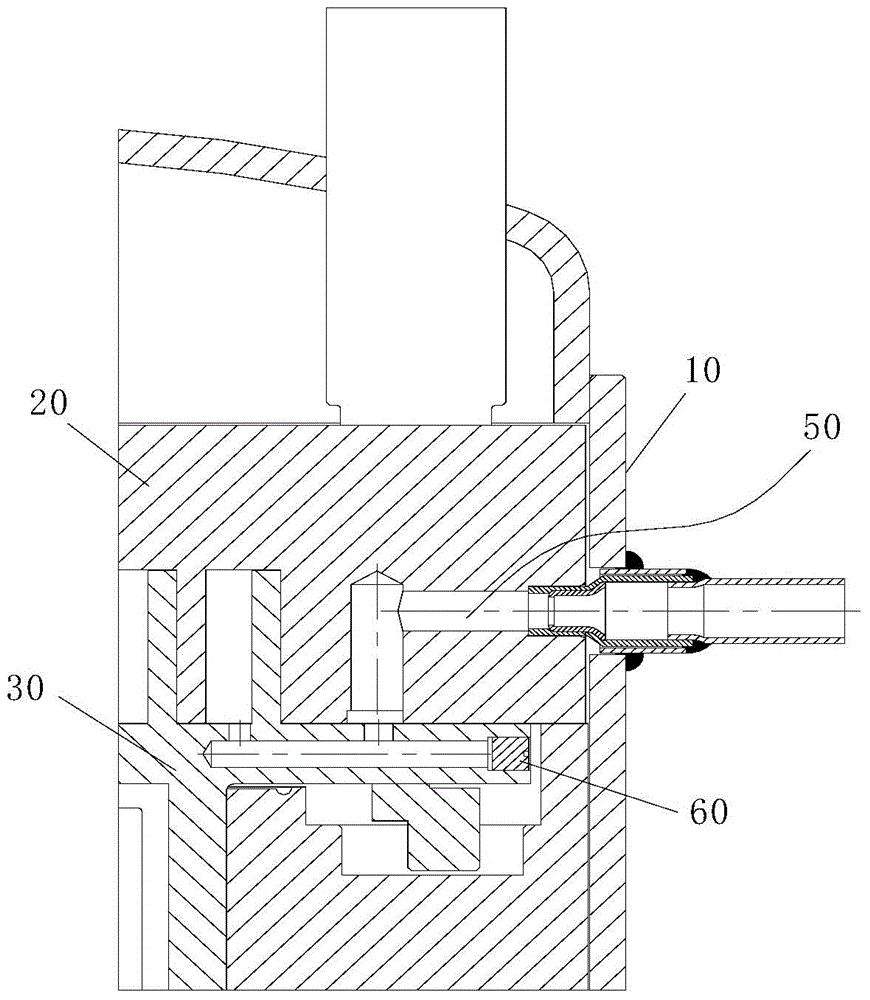

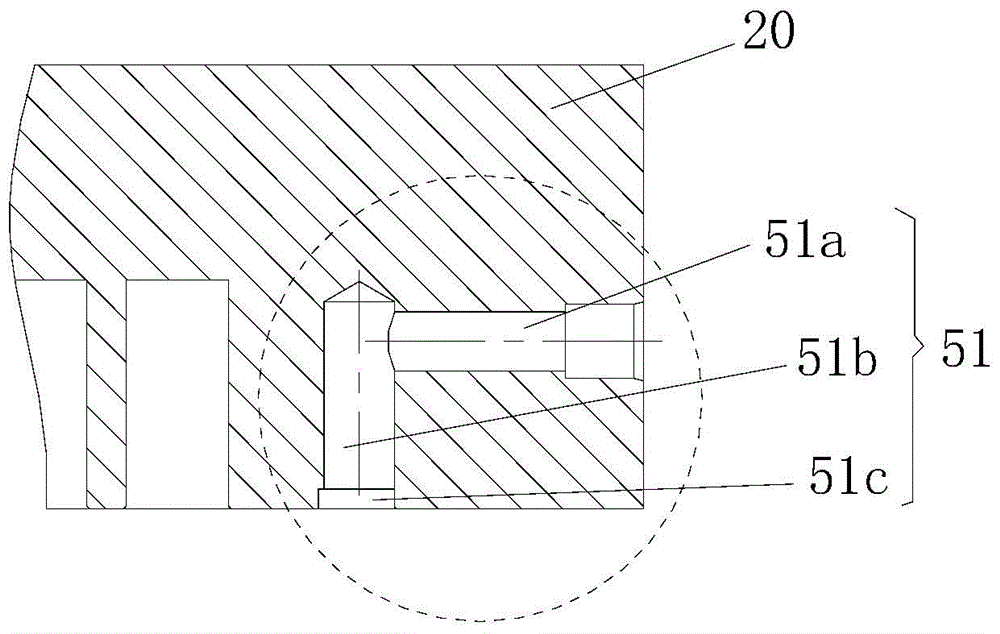

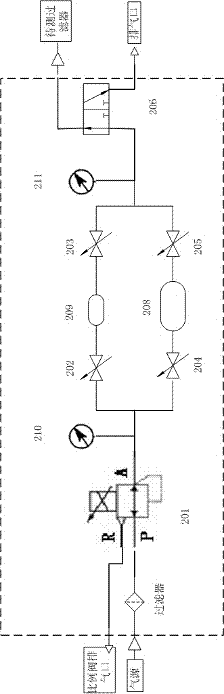

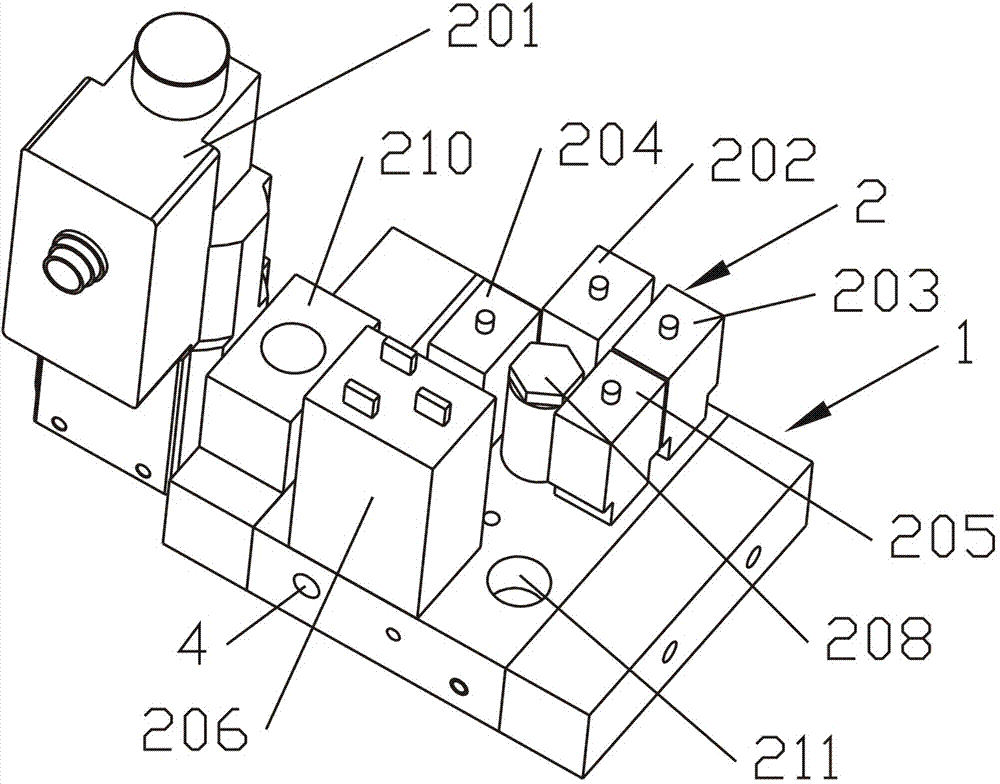

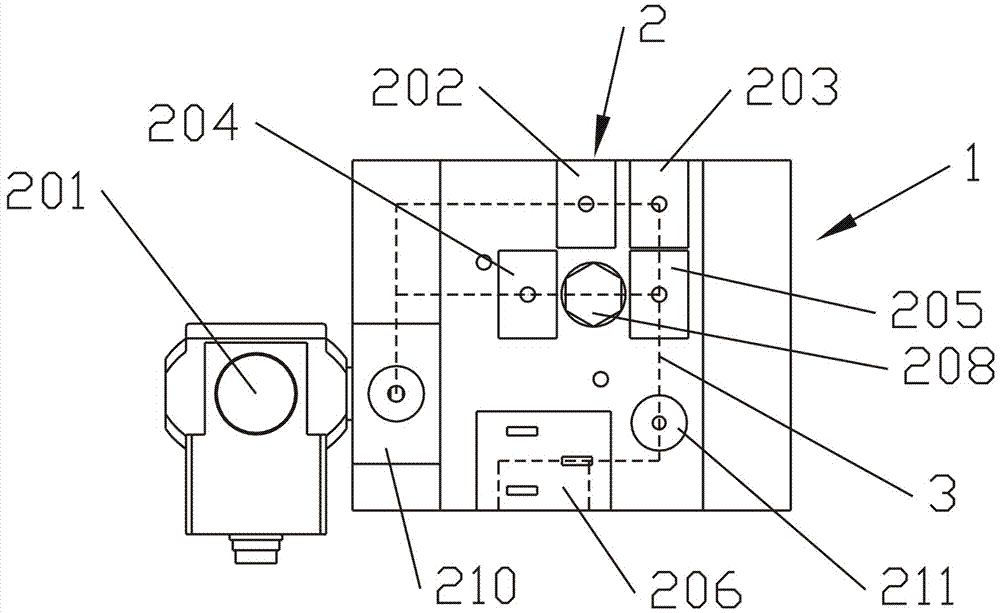

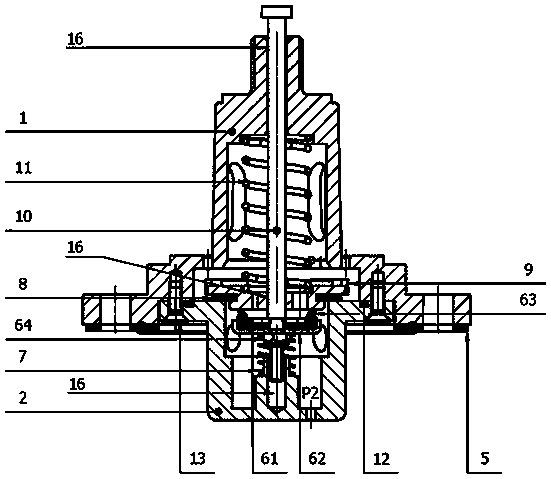

Proportional one-way flow valve with improved performance

ActiveCN107701763AGuaranteed differential pressureOperating means/releasing devices for valvesCheck valvesValve openingLow load

The invention relates to a proportional one-way flow valve with improved performance. The proportional one-way flow valve is characterized by comprising a valve body and a valve sleeve. The valve sleeve is provided with a first oil opening, a second oil opening and a valve opening. A main valve element is arranged in the valve sleeve. The periphery conical face of the main valve element is matchedwith the valve opening. A control cavity and an installing cavity are formed in the main valve element. A first damping hole is formed in the side wall of the main valve element. A second damping hole is formed in the main valve element. The hole diameter of the first damping hole is smaller than that of the second damping hole. A pilot valve element is arranged in the control cavity and controlled by a proportional electromagnet structure to be capable of moving up and down. The lower end of the pilot valve element is matched with the second damping hole. A lining and a valve seat are installed in the installing cavity. A throttling hole is formed in the lining. A throttling valve element is arranged in the valve seat. A first spring is arranged below the throttling valve element in a supporting manner. When the throttling valve element overcomes the effect of the first spring and moves downwards, a gap between the upper end of the throttling valve element and the throttling hole becomes smaller and smaller. The proportional one-way flow valve with the improved performance is more reasonable in structure, low in cost and capable of meeting the requirement for low-load use.

Owner:北京德华力通液压件制造有限公司

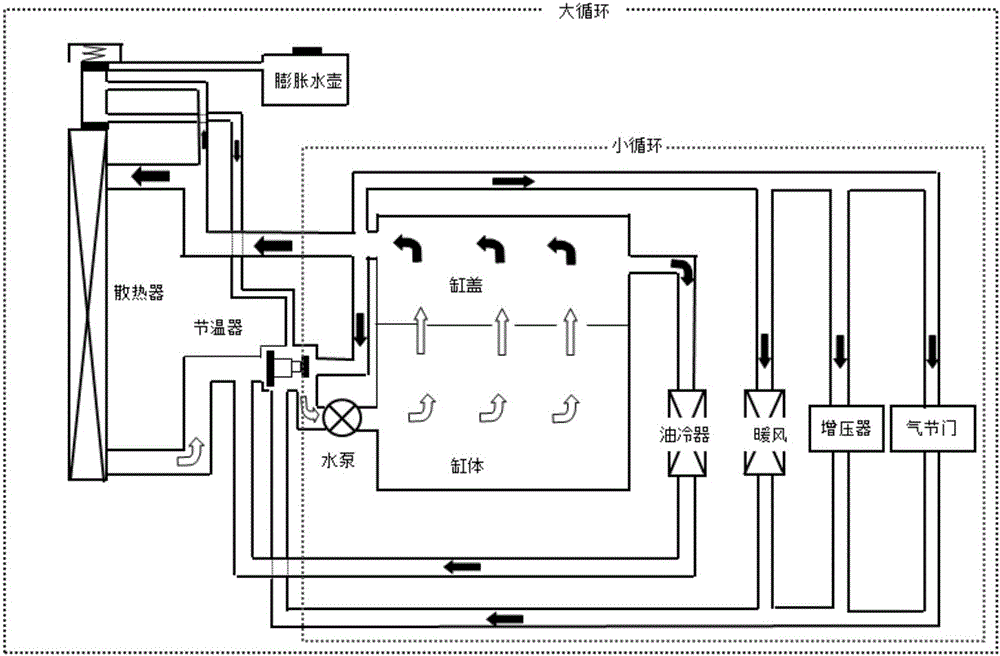

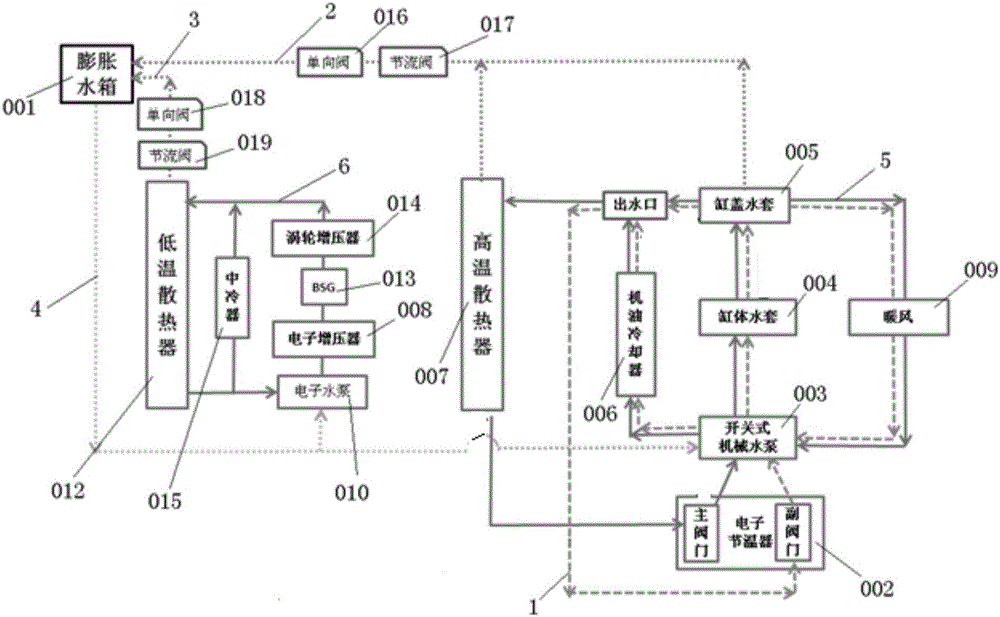

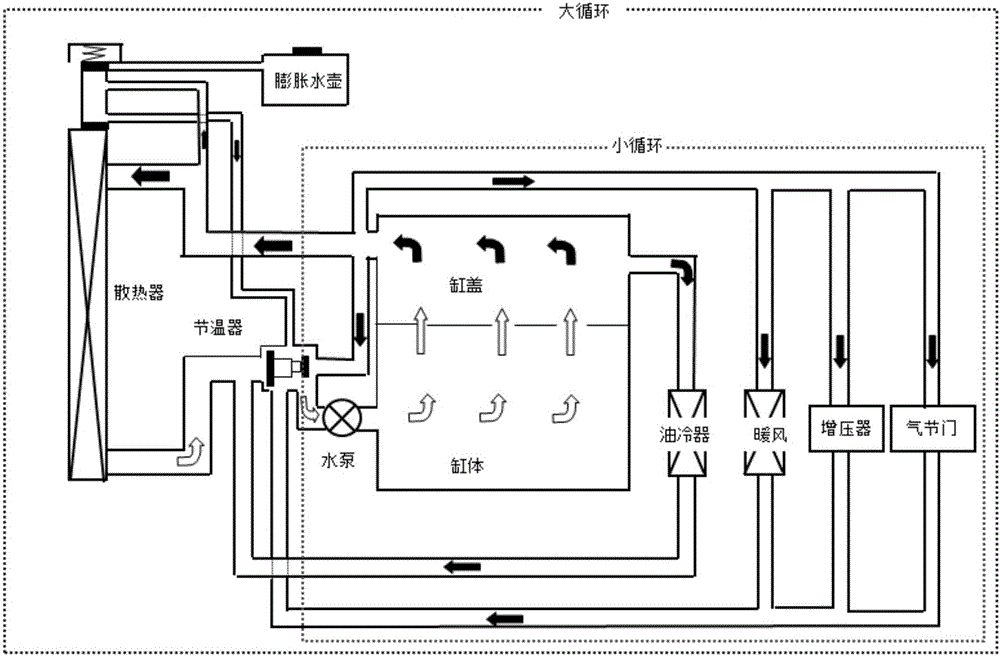

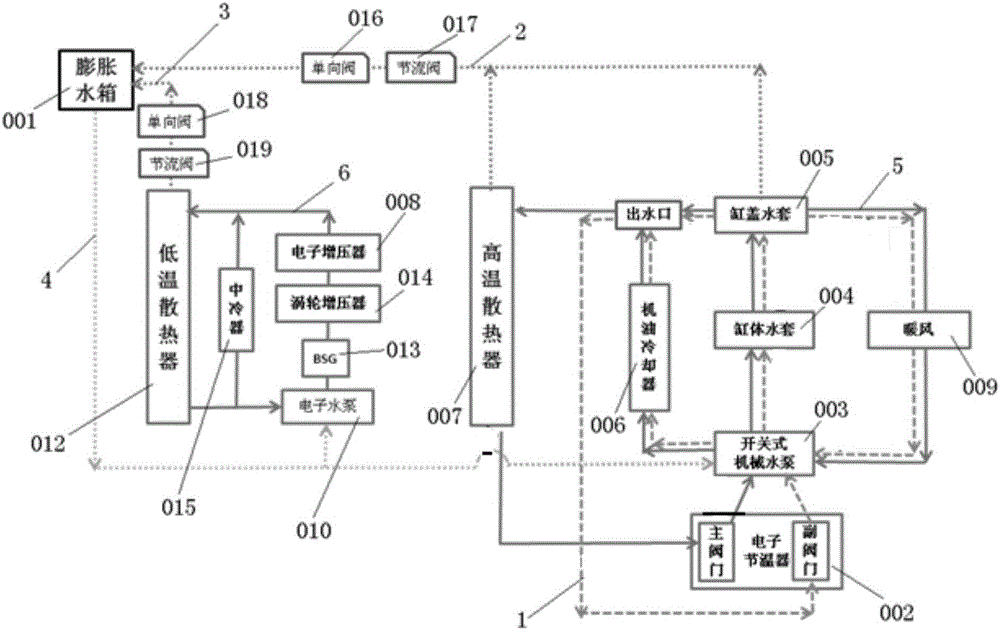

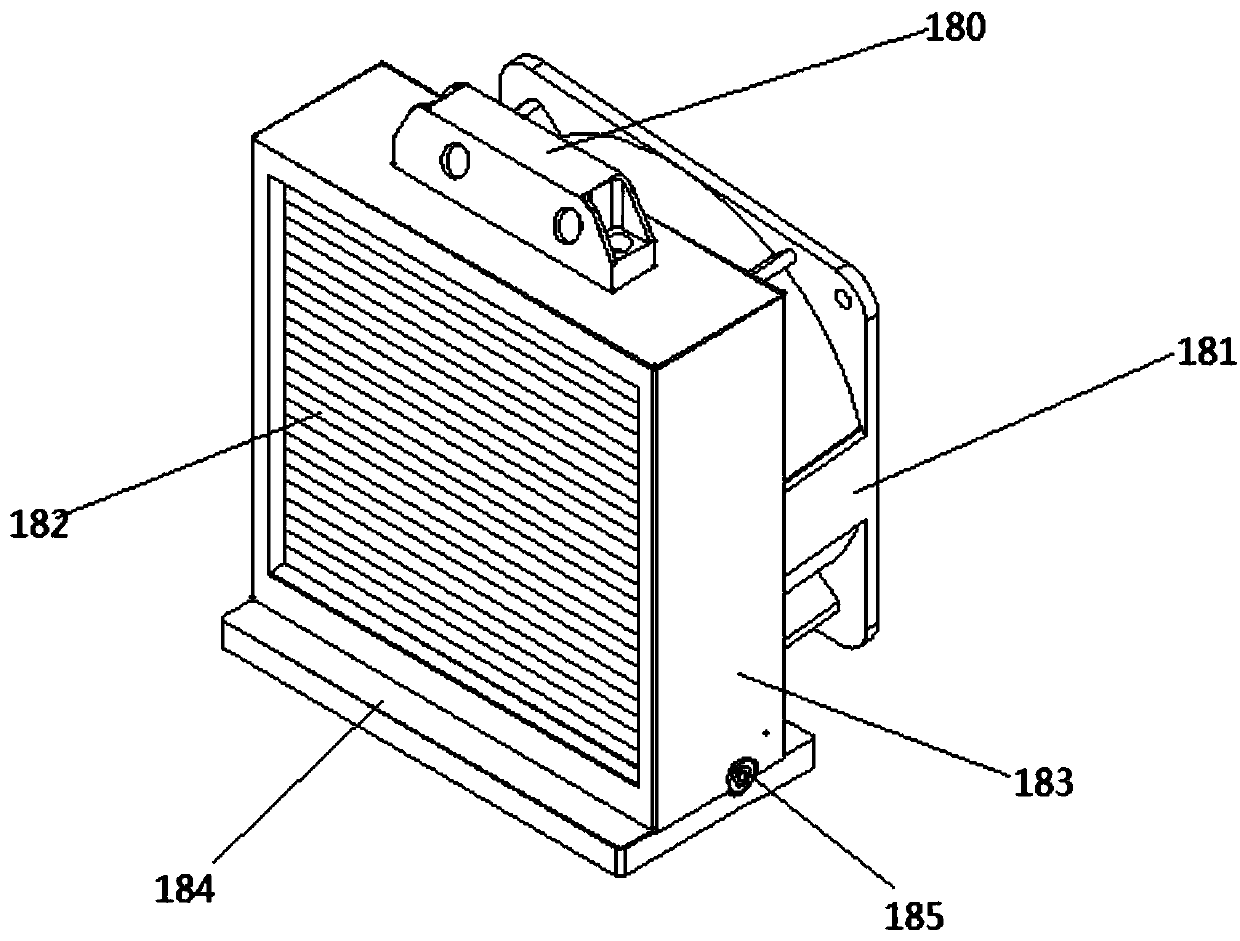

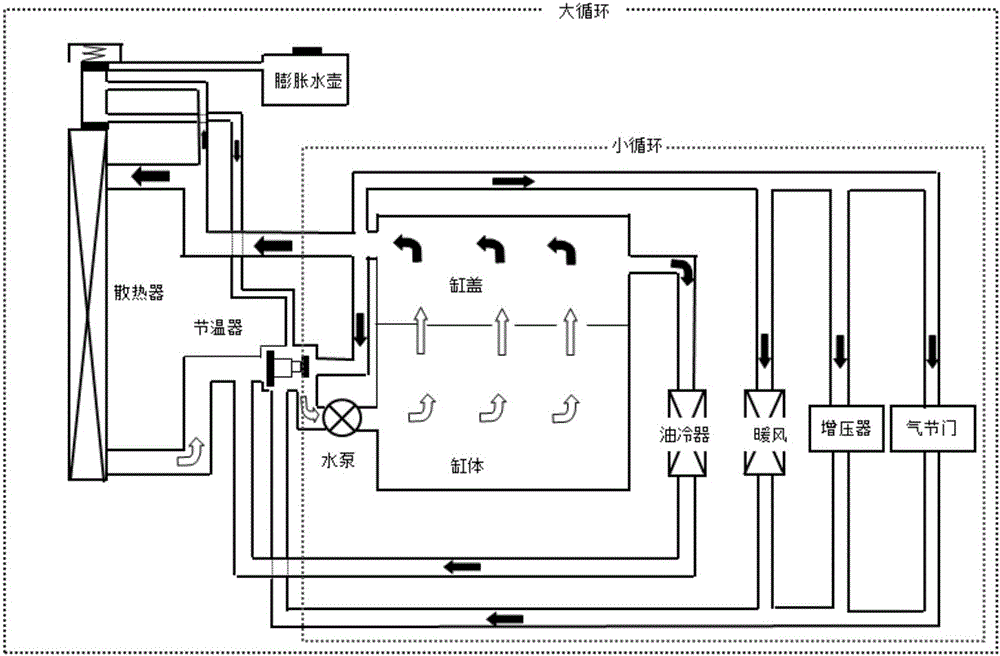

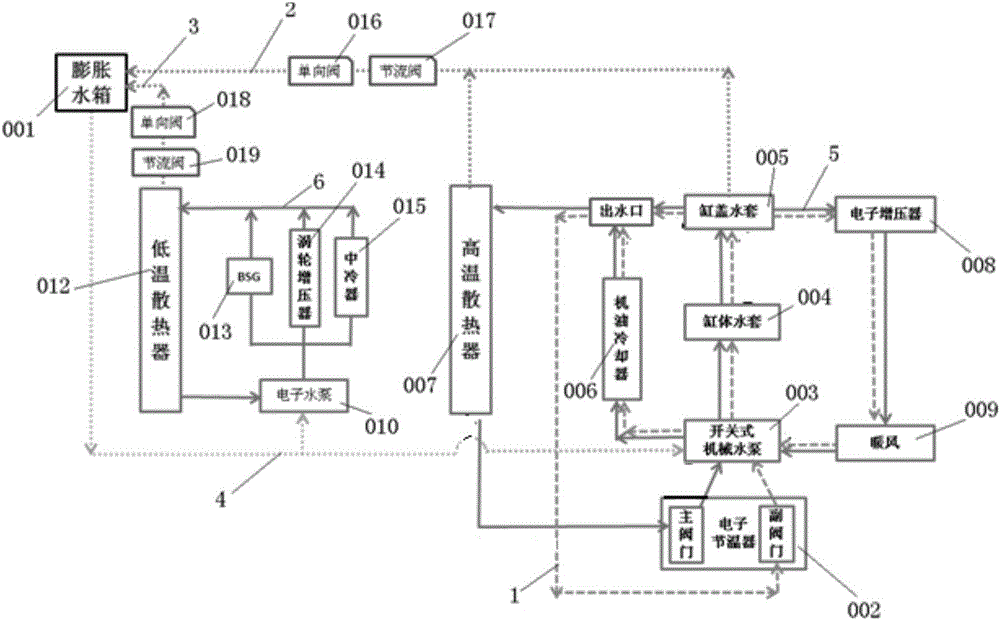

Double-water pump engine double cooling system

InactiveCN105888811AGuaranteed differential pressureGuaranteed intake air temperatureLiquid coolingAir-treating devicesExpansion tankTurbocharger

The invention relates to a double-water pump engine double cooling system. The double-water pump engine double cooling system comprises a high-temperature circulating cooling system and a low-temperature circulating cooling system; the high-temperature circulating cooling system comprises an expansion tank, a high temperature heat dissipater, an engine cooling water jacket, a first water pump, an electronic thermostat, an engine oil cooler, an electric supercharger and hot air; the low-temperature circulating cooling system comprises an expansion tank, a low temperature heat dissipater, a turbo-supercharger, a second water pump, an intercooler and a BSG. According to the system, the two circulating cooling systems are arranged, the high temperature heat dissipater and the low temperature heat dissipater are arranged so that the requirements for cooling temperature of different parts to be cooled can be effectively met, and the sizes of the cooling systems are not increased through the technical scheme. The BSG, the turbo-supercharger and the intercooler are connected in parallel in the low-temperature circulating cooling system, and therefore the stability of the pressure difference of the components is guaranteed.

Owner:ANHUI JIANGHUAI AUTOMOBILE GRP CORP LTD

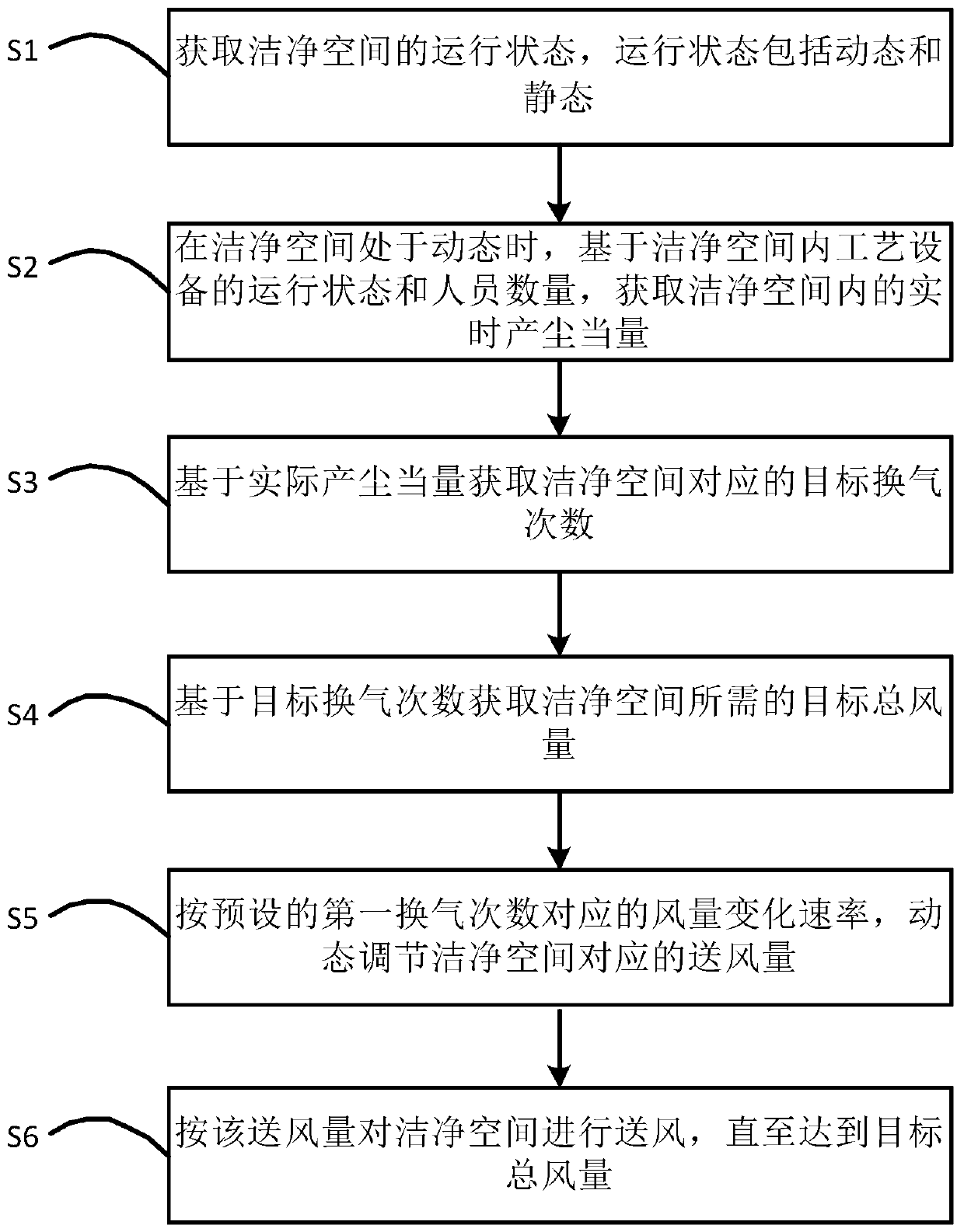

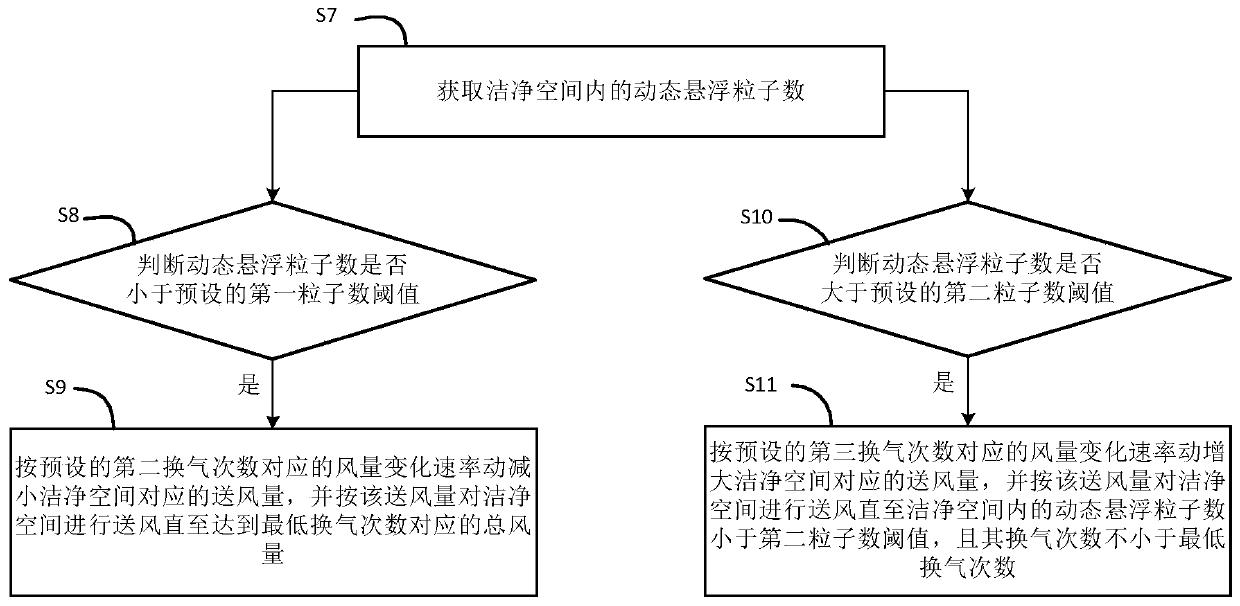

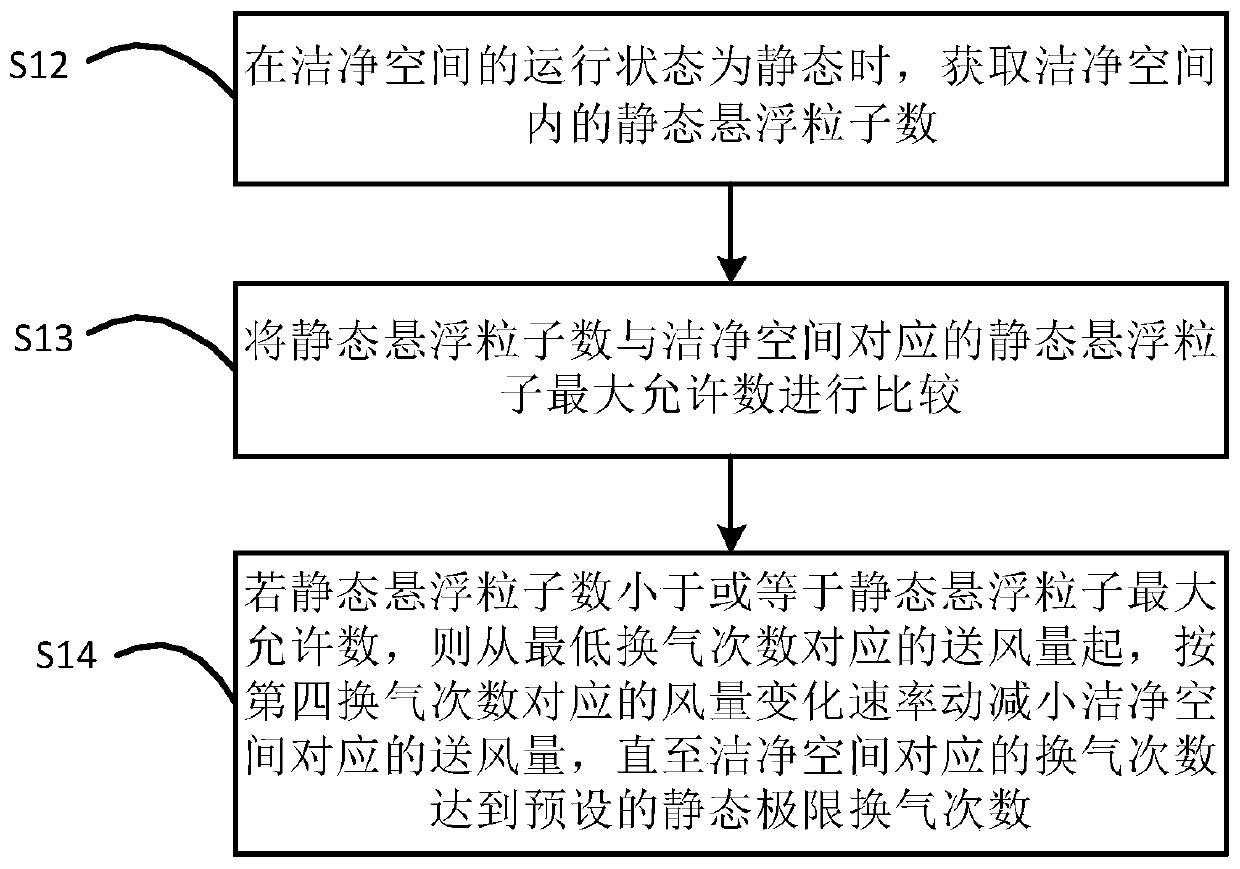

Air quantity control method and device for clean workshop

InactiveCN110057058AGuaranteed differential pressureRealize dynamic adjustmentMechanical apparatusSpace heating and ventilation safety systemsProcess equipmentEquivalent weight

The invention discloses an air quantity control method and device for a clean workshop. The clean workshop comprises a clean space. The method comprises the following steps: the running state of the clean space is obtained, and the running state comprises a dynamic state and a static state; when the clean space is in the dynamic state, a real-time dust generation equivalent weight in the clean space is obtained on the basis of the running state of process equipment in the clean space and the number of personnel; a target ventilation rate corresponding to the clean space is obtained on the basis of the real-time dust generation equivalent weight; a target total air quantity needed by the clean space is obtained on the basis of the target ventilation rate; an air supply quantity corresponding to the clean space is dynamically adjusted according to an air quantity change speed corresponding to a preset first ventilation rate; and air supply is carried out on the clean space according to the air supply quantity, until a target total air quantity is reached. The air quantity control method and device for the clean workshop are capable of dynamically adjusting the air supply quantity inthe clean space as needed, effectively guaranteeing pressure difference in the clean space, and reducing the redundant air quantity to reduce the energy consumption.

Owner:BEIJING UNION UNIVERSITY

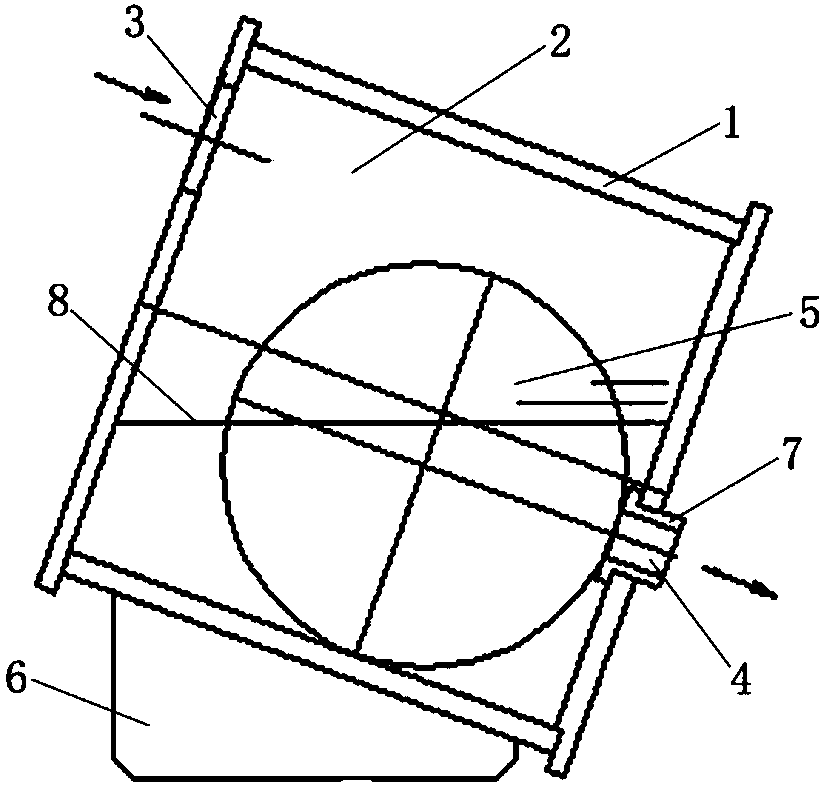

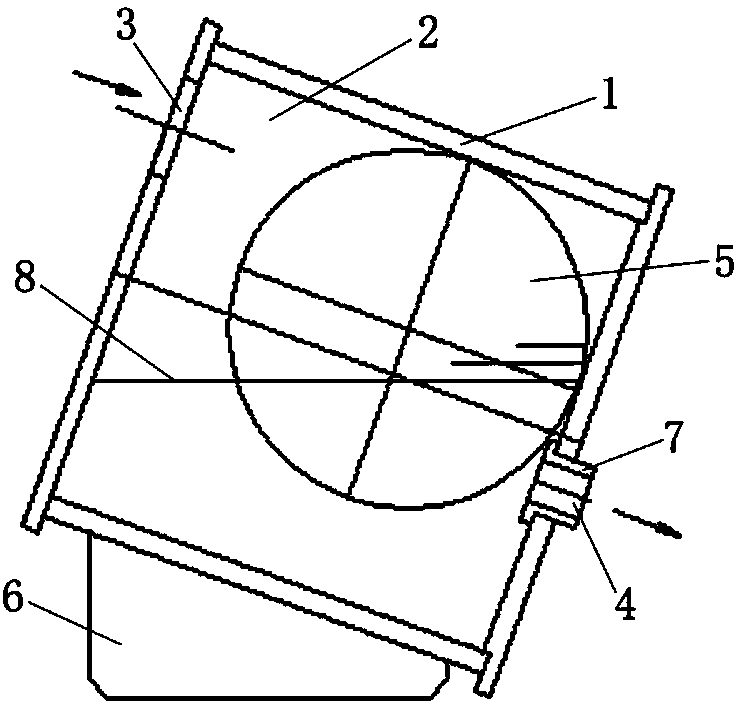

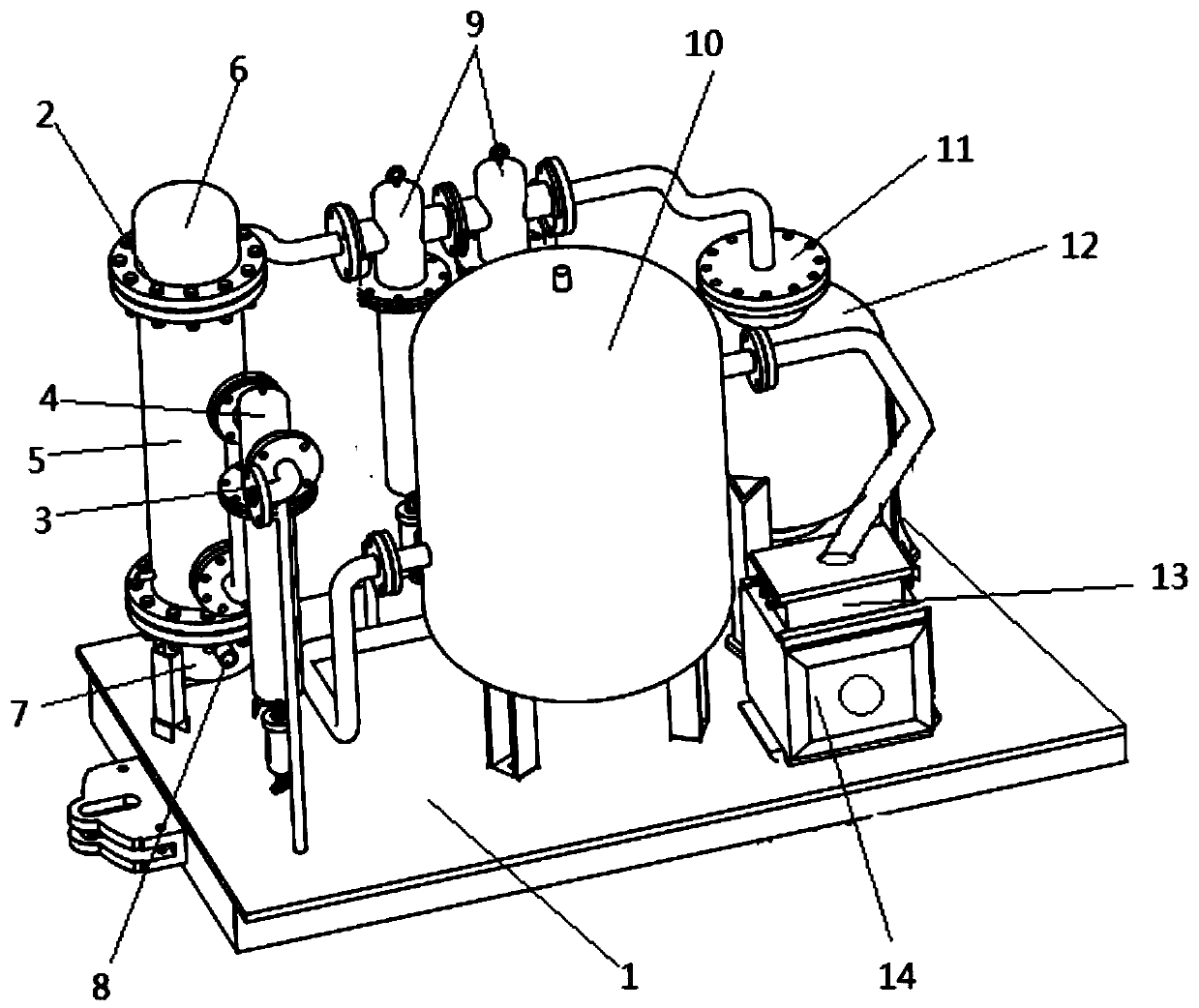

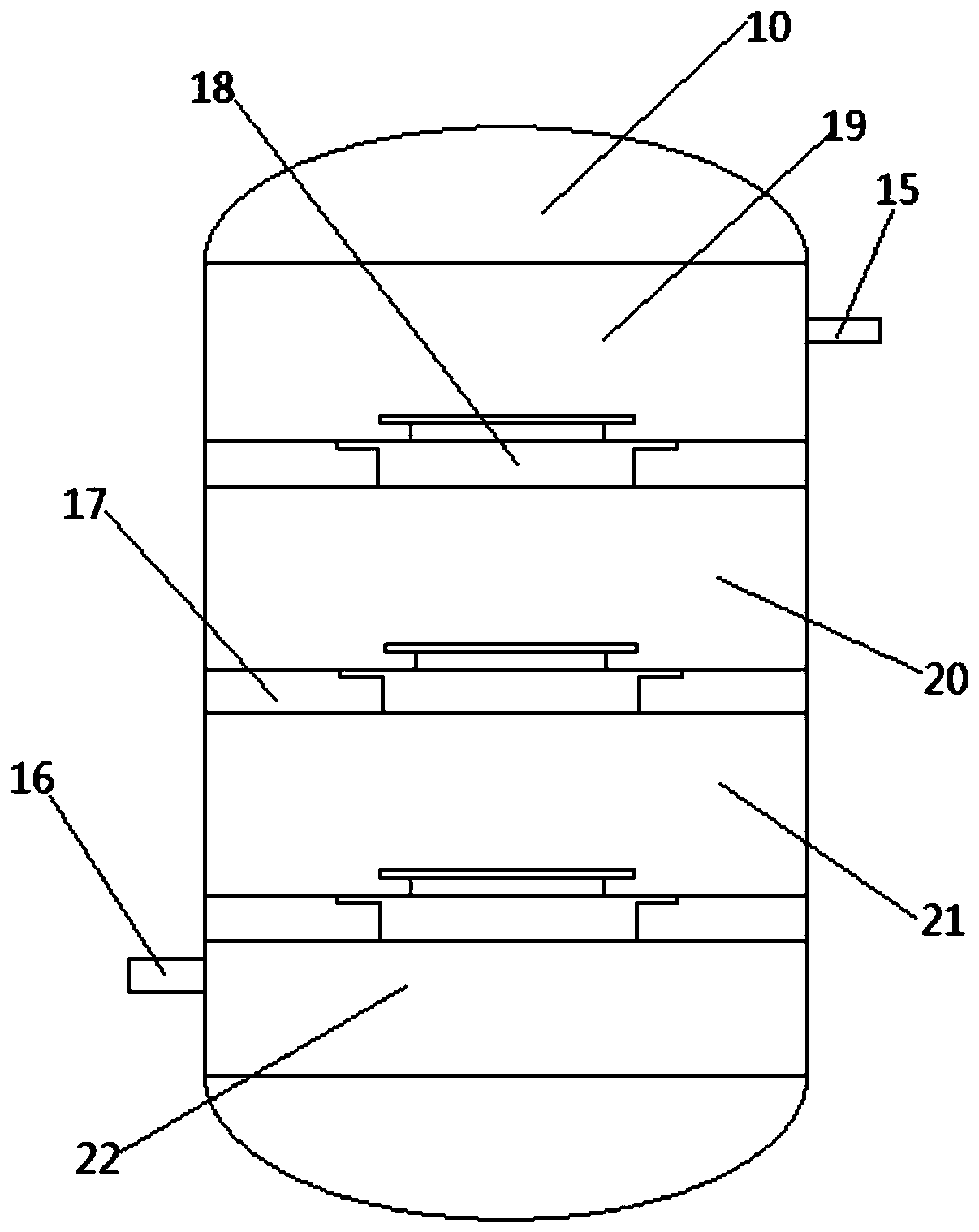

Novel low-temperature multi-effect seawater desalination evaporator

InactiveCN104370315ASave water preheating energy consumptionReduce warm-up energy consumptionGeneral water supply conservationSeawater treatmentConcentration ratioFresh water organism

The invention relates to a novel low-temperature multi-effect seawater desalination evaporator in which multi-effect evaporators are arranged up and down. The top end of each evaporation chamber is provided with a water distribution device; a water inlet end of the water distribution device of the uppermost evaporation chamber can be or not be provided with a preheater; a heat exchange tube is arranged in each evaporation chamber; the front and back ends of each heat exchange tube are respectively provided with a tube plate; the outer side of each tube plate is provided with a freshwater tank; the lower side of each heat exchange tube is provided with a concentrated water tank; every two adjacent upper and lower freshwater tanks are connected through a J-shaped inter-effect freshwater connecting tube; the concentrated water tank on the upper layer is communicated with the upper side of the water distribution device of the evaporator on the lower layer through a J-shaped inter-effect freshwater connecting tube; and secondary vapor generated by the upper evaporation chamber enters the heat exchange tube of the lower evaporation chamber through inter-effect vapor connecting tubes positioned on two sides of the back side of an evaporator tube bank to be used as an evaporation heat source. The novel low-temperature multi-effect seawater desalination evaporator can enhance the seawater concentration ratio, does not need any inter-effect pump, lowers the energy consumption for seawater desalination, and ensures that influent water of the multi-effect evaporation chamber with higher evaporation temperature is raw seawater, thereby lowering the scaling risk.

Owner:SUNRUI MARINE ENVIRONMENT ENG

Scroll compressor

ActiveCN105782032ABeneficial for ultra-low temperature refrigerationRealize the function of increasing enthalpy and replenishing gasRotary piston pumpsRotary piston liquid enginesInlet channelEngineering

The invention provides a scroll compressor. The scroll compressor comprises a shell, a static scroll plate and a dynamic scroll plate, wherein the static scroll plate is arranged in the shell, the dynamic scroll plate is movably arranged in the static scroll plate, and a first compression cavity and a second compression cavity are formed between the sidewall of the static scroll plate and the sidewall of the dynamic scroll plate. The scroll compressor further comprises an enthalpy increasing channel. The enthalpy increasing channel comprises air inlet channel bodies and air outlet channel bodies which communicate with the air inlet channel bodies. The air inlet channel bodies are formed in the static scroll plate, and the air outlet channel bodies are formed in the dynamic scroll plate. The air outlet channel bodies comprise the first air outlet channel body and the second air outlet channel body, and the first air outlet channel body and the second air outlet channel body independently communicate with the first compression cavity and the second compression cavity correspondingly. A refrigerating agent is continuously injected into the first compression cavity and the second compression cavity through the air inlet channel bodies in an alternate mode. Through the scroll compressor provided by the invention, the problem that normal use of compressors is influenced by enthalpy increasing channel structures under non-enthalpy-increasing working condition in the prior art can be solved.

Owner:ZHUHAI GREE REFRIGERATION TECH CENT OF ENERGY SAVING & ENVIRONMENTAL PROTECTION

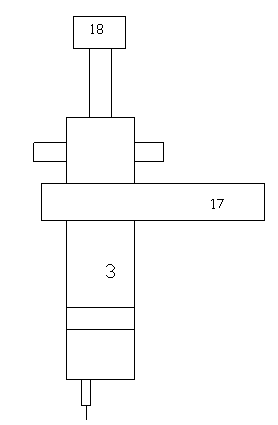

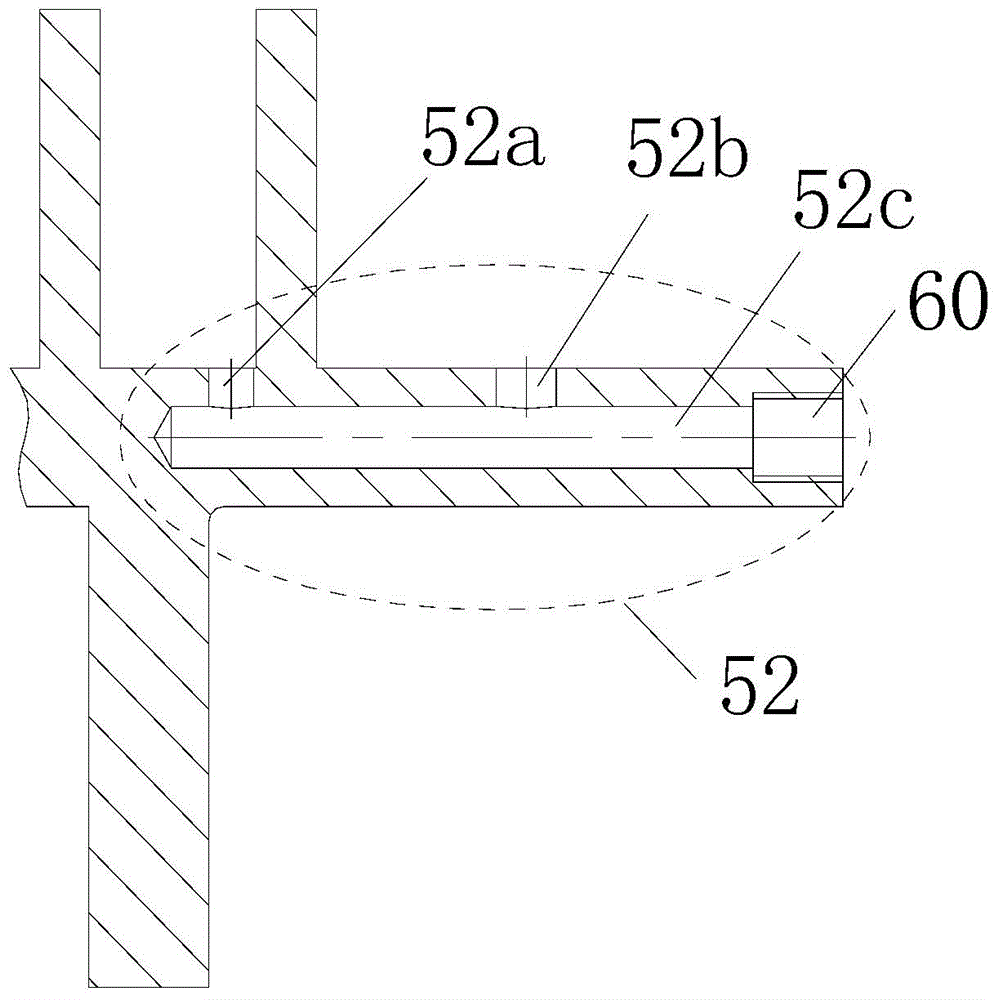

Screw rod for extrusion foaming device and extrusion foaming device

The invention discloses a screw rod for an extrusion foaming device and an extrusion foaming device, and belongs to the field of extrusion foaming devices of microcellular polymer foam materials. Aimsat solving the problems existing in an existing microcellular polymer foam material extrusion foaming device, the device provides a screw rod capable of guaranteeing effective gas injection of extrusion equipment and an extrusion foaming device composed of the screw rod, the effective injection of the foaming agent and the uniform mixing of the foaming agent and the material can be ensured, and the quality of the forming material is ensured. According to the device, during the gas injection process of the foaming agent, the gas injection section arranged on the screw rod is matched with the gas injection port arranged on the gas injection device, regularly interval gas injection is realized in the screw rod rotating process, so that the gas injection pressure of the gas injection port canbe changed regularly, the pressure of the gas injection port at each time can be increased, the material melt can be prevented from being plugged into the gas injection port, the gas injection effectis ensured, and the material melt is prevented from overflowing reversely from the gas injection port.

Owner:SICHUAN UNIV

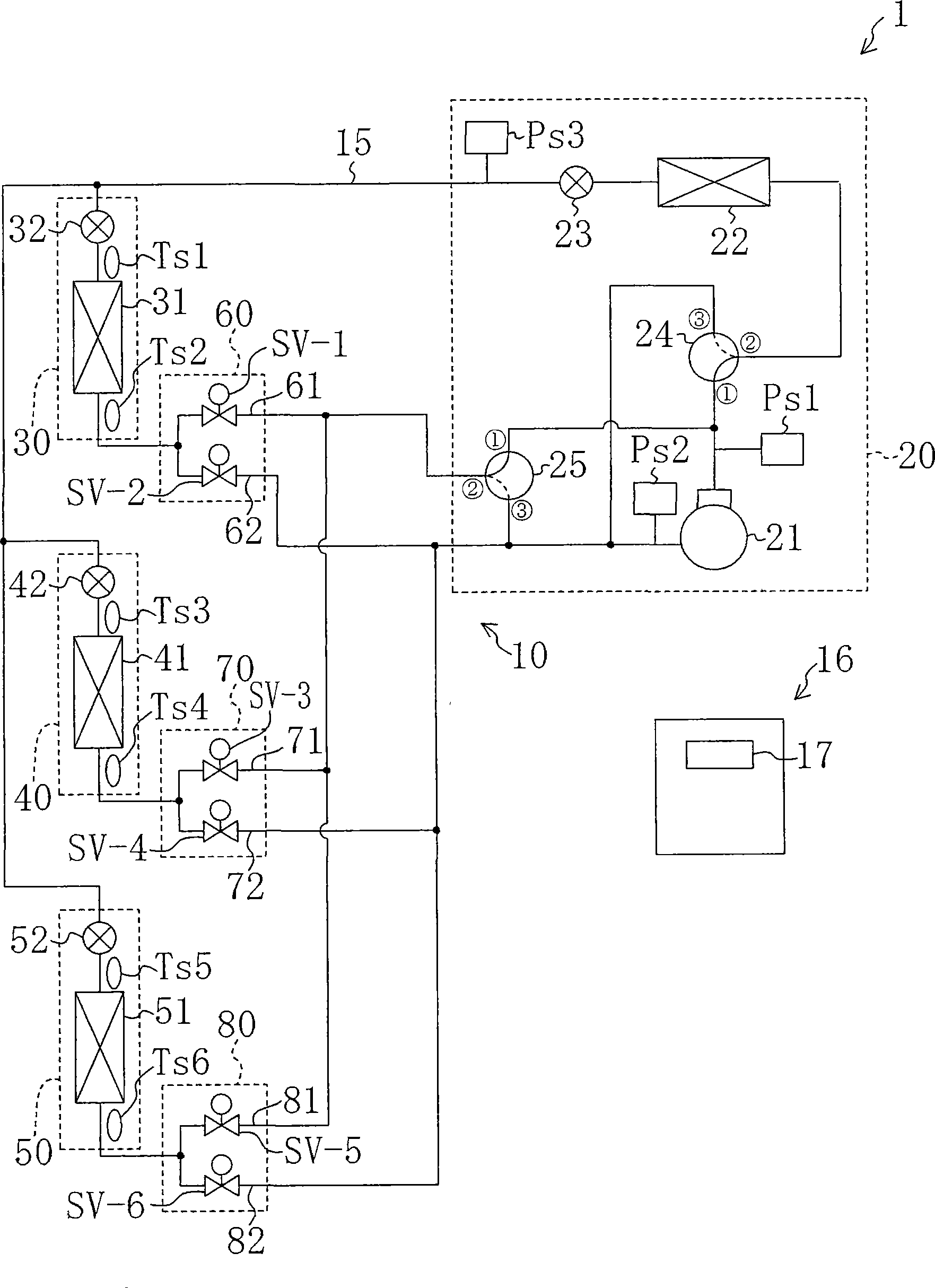

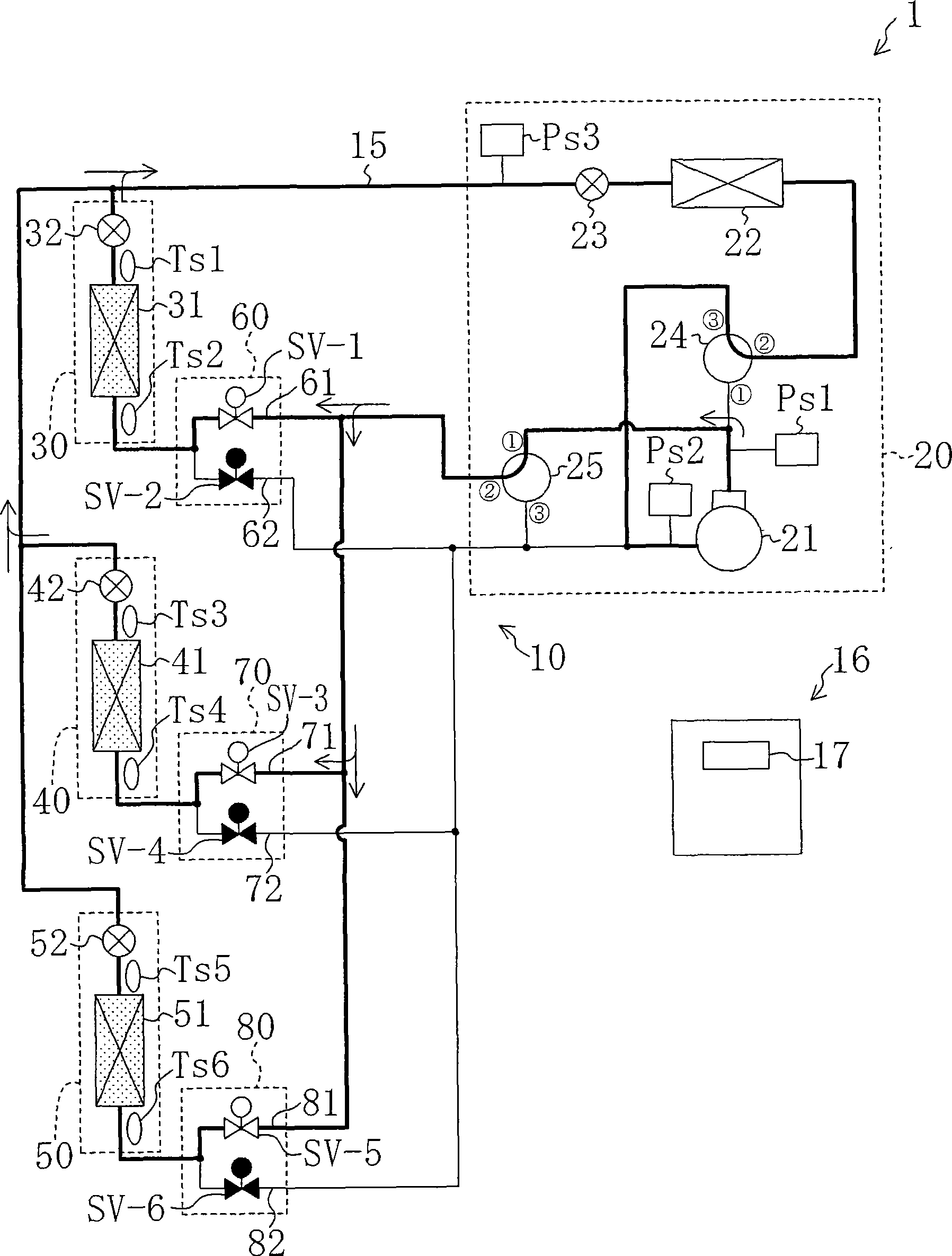

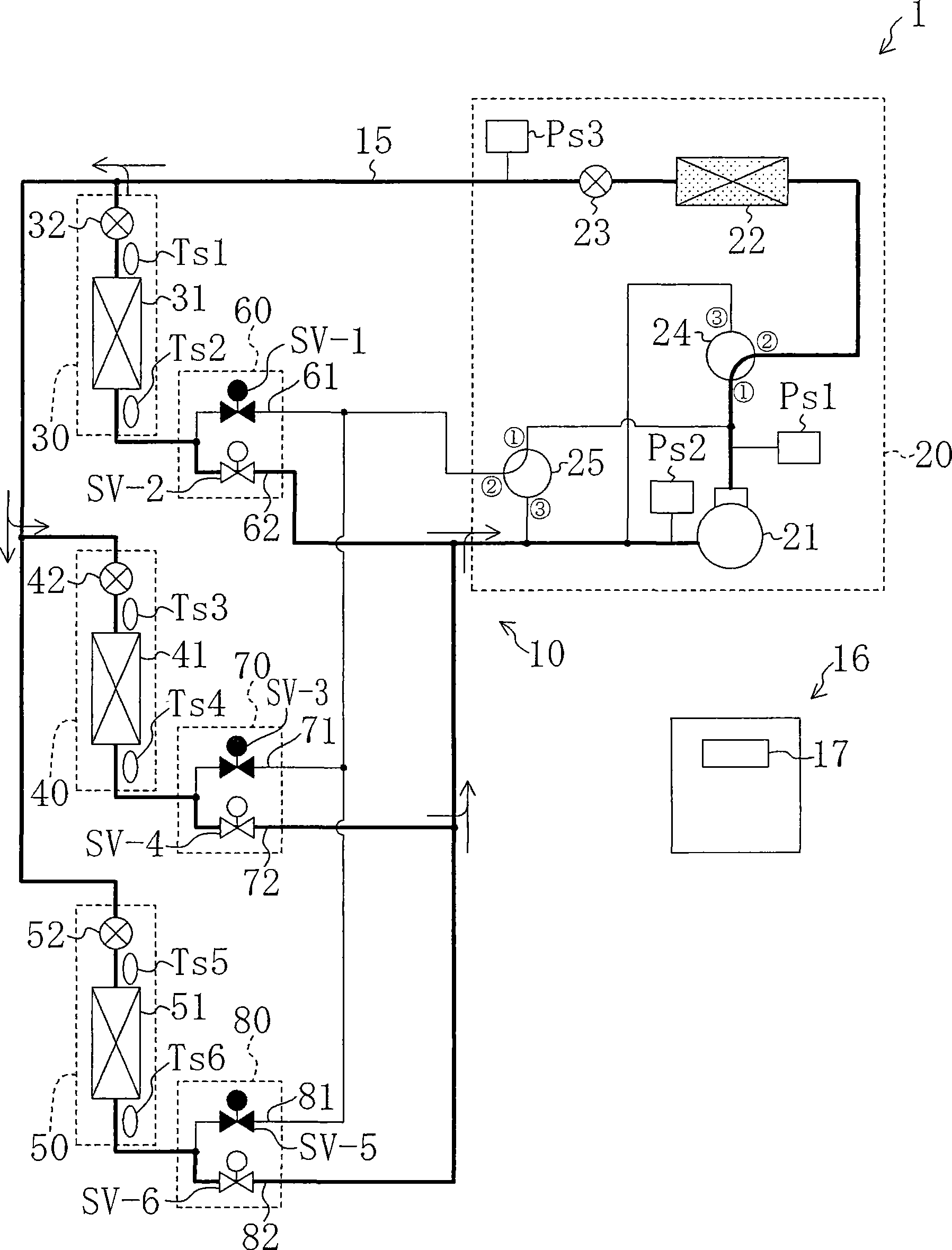

Refrigeration device

ActiveCN101535738AEnsure heat absorptionAvoid driftingSpace heating and ventilation safety systemsSpace heating and ventilation control systemsEngineeringPressure difference

A refrigeration device in which, in a coexistence operation where a refrigeration cycle using an outdoor heat exchanger (22) as a condenser and also using at least one of indoor heat exchangers (31, 41, 51) as a condenser, a pressure difference Delta between a high pressure refrigerant and a refrigerant in a liquid tube (15) is detected, and the degree of opening of an outdoor expansion valve (23) is adjusted so that the pressure difference Delta is higher than a predetermined target level.

Owner:DAIKIN IND LTD

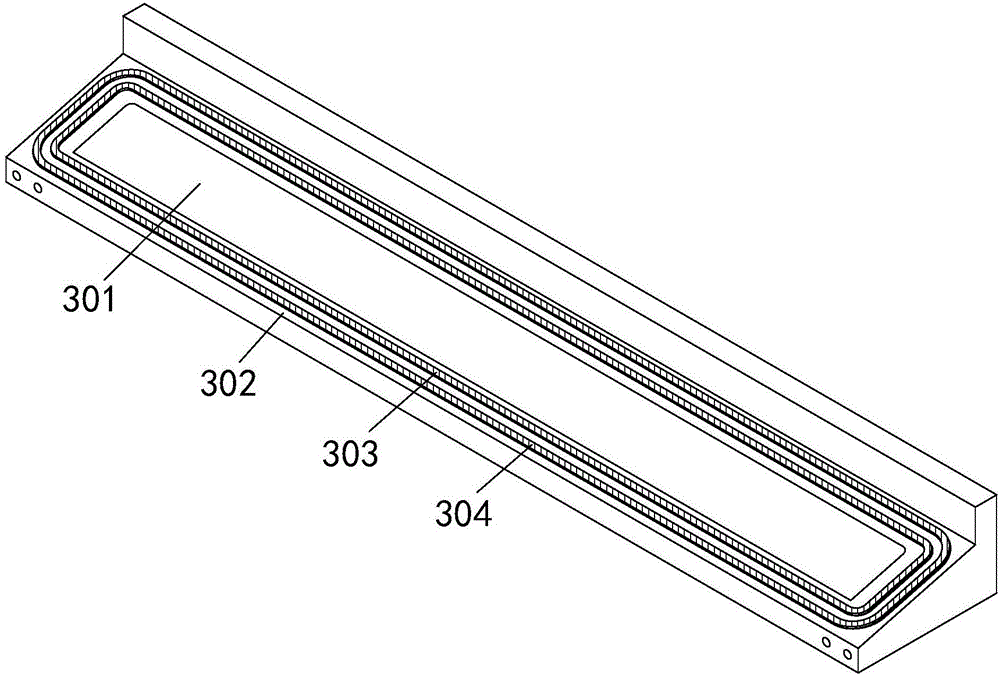

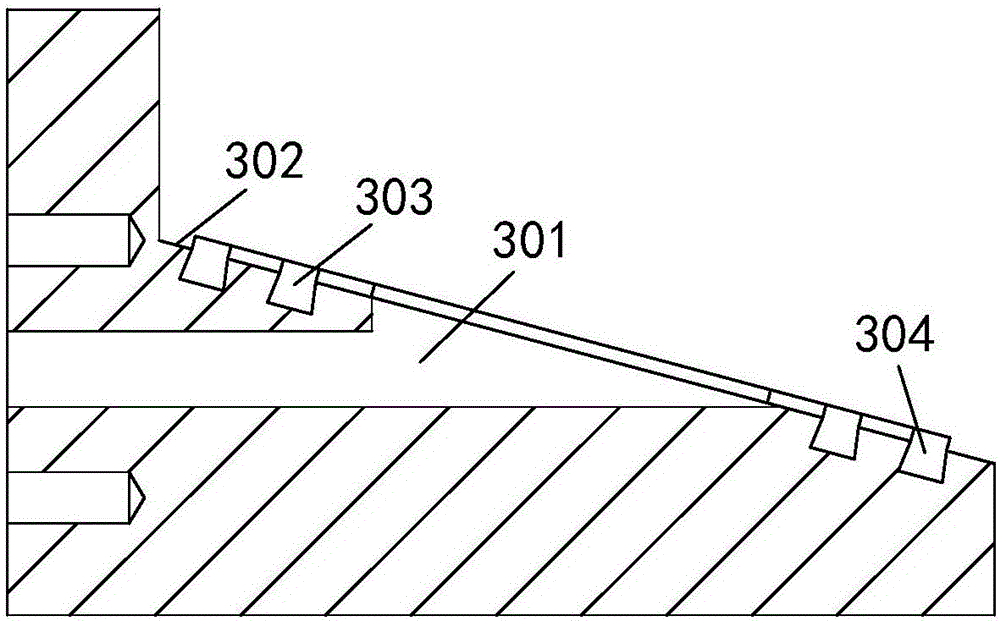

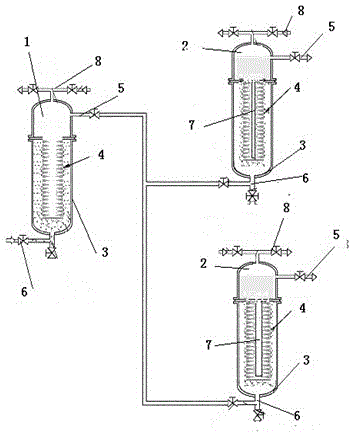

Continuous cascade film evaporator system

PendingCN112807722AGuaranteed differential pressureReduce pressure differenceMultiple-effect evaporationChemical industryControl theory

The invention discloses a continuous cascade film evaporator system which comprises a feed preheater, a first film evaporator, a second film evaporator, a tail gas condenser, a material temporary storage tank, a condensate temporary storage tank and a vacuum pump. According to the continuous cascade film evaporator system, heat can be fully utilized, and it is guaranteed that energy consumption of the system is reduced; besides, a liquid seal is arranged between the two film evaporators, so that the pressure difference between the two film evaporators is ensured, the process system is ensured to be stable by using one vacuum pump, and the system investment is reduced; meanwhile, full-automatic operation ensures the stability and efficiency of the process. According to the continuous cascade film evaporator system, the solvent recovery efficiency in the pharmaceutical chemical industry is improved, and the energy consumption and the fixed investment of solvent recovery are reduced.

Owner:SINOPEC SHANGHAI ENG +1

Filter integrality detection device

InactiveCN102829932AGood technical effectStable pressureMeasurement of fluid loss/gain rateEngineeringElectromagnetic valve

Owner:ZHEJIANG TAILIN BIOENG

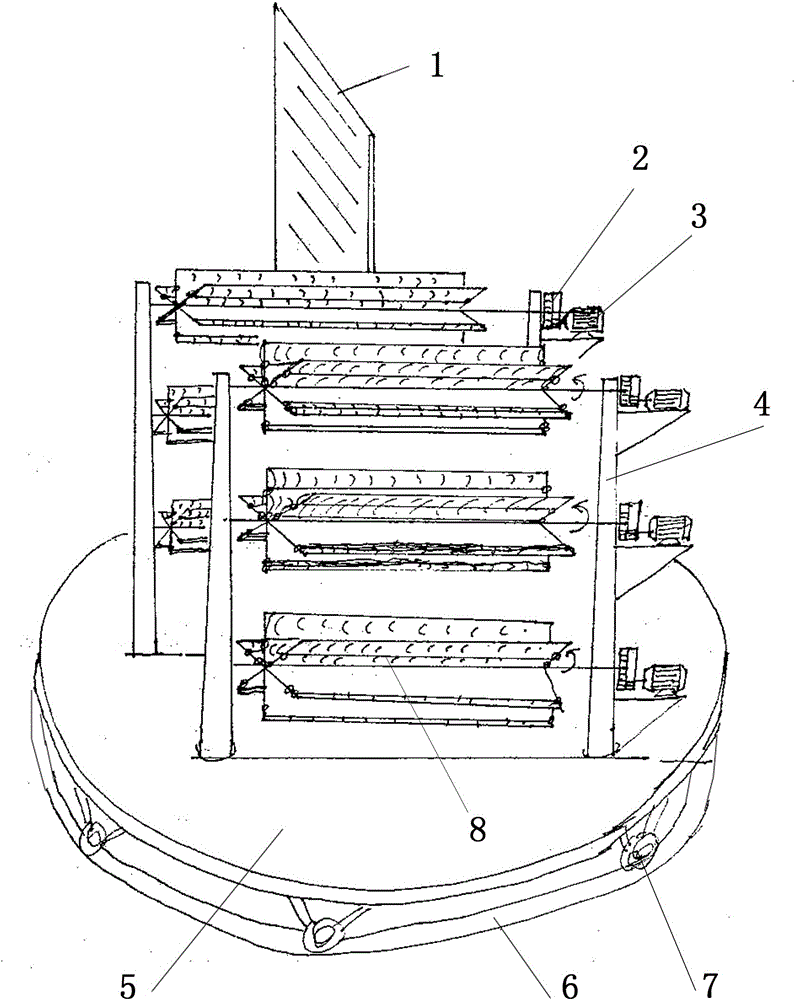

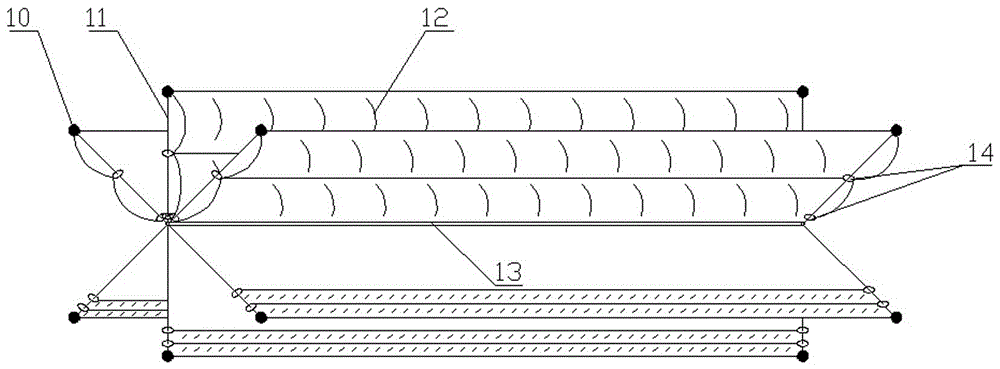

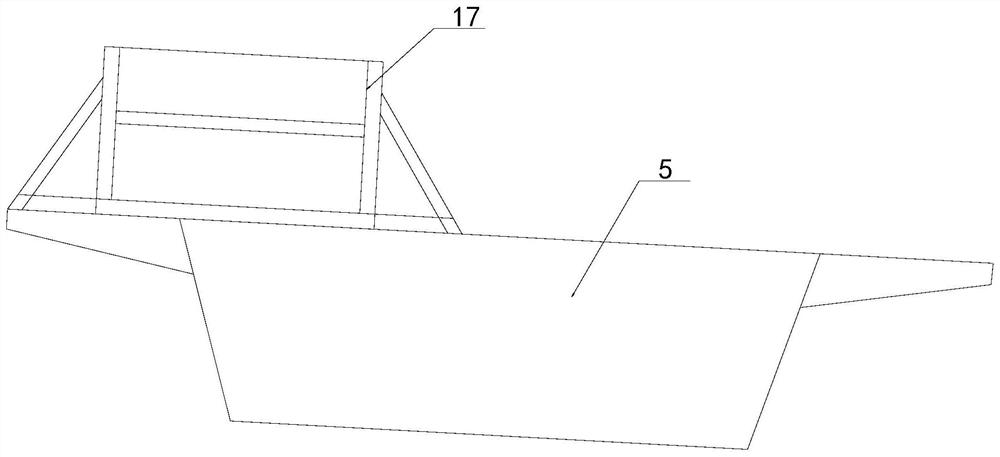

Automatic retractable wind power generating device with gravity sliding rings

PendingCN106762430AGuaranteed differential pressureWide range of external operating conditionsWind motor controlWind motor combinationsImpellerElectricity

The invention belongs to the technical field of wind power generation, and provides an automatic retractable wind power generating device with gravity sliding rings. The automatic retractable wind power generating device aims to solve the problem that an existing sailing boat type wind power generating device cannot ensure effective power generation due to the fact that a sailboard of the device is fixed in position and stress direction. The automatic retractable wind power generating device comprises a reduction gear box, a power generator, a supporting frame, a rotating disc and a plurality of fan impellers, wherein the fan impellers are arranged on the supporting frame in parallel, the lower end of the supporting frame is fixedly mounted on the rotating disc, a rail is arranged under the rotating disc in a matched mode, and universal wheels at the bottom of the rotating disc roll along the rail; and each fan impeller comprises a framework, canvas and a rotating shaft, wherein the framework is mounted on the rotating shaft and rotates around the framework, one end of the canvas is fixedly mounted at the end of the radial framework, and the other end of the canvas is slidably mounted on the radial framework through the multiple sliding rings. According to the automatic retractable wind power generating device, the fan impellers are made to rotate by the pressure difference between the canvas above the rotating shafts and the canvas below the rotating shafts, and thus power is generated; and external operation conditions of the device are wider, and the power generating function is better guaranteed.

Owner:刘俏云

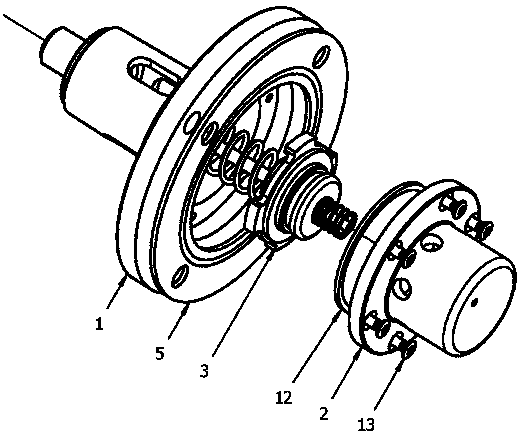

Constant-difference pressure compensation valve

PendingCN110822145AReduced differential pressure fluctuation rangeGuaranteed differential pressureOperating means/releasing devices for valvesEqualizing valvesCylinder blockPressure difference

The invention discloses a constant-difference pressure compensation valve. The constant-difference pressure compensation valve comprises an upper cylinder body, a lower cylinder body, differential pressure generators, a sealing pad I, an O-shaped ring and a countersunk screw; the upper cylinder body is fixedly connected with the lower cylinder body, the sealing pad I is arranged on the upper cylinder body, and the O-shaped ring is arranged on the lower cylinder body; the differential pressure generators are arranged on screw rods inside the upper cylinder body and the lower cylinder body; andguide holes are formed in valve seats of the upper cylinder body, the lower cylinder body and the differential pressure generators, wherein the guide holes are used for fixing the screw rods and ensuring that the valve seats move up and down on the screw rods. According to the constant-difference pressure compensation valve, the pressure difference fluctuation range can be reduced, and functions of automatic pressure compensation, differential pressure maintenance and manual emergency pressure relief can be achieved.

Owner:南通市中龙液压有限公司

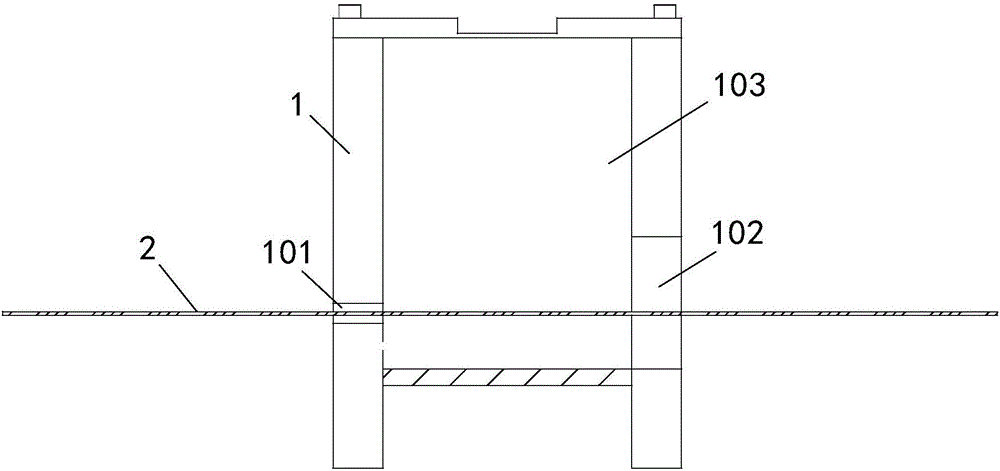

Vacuum slit valve

The invention relates to a vacuum slit valve which comprises a valve body. The valve body is provided with a channel for conveying a strip, and a vacuum accommodating cavity is disposed in the valve body. A valve body assembly and a valve plate assembly are placed in the vacuum accommodating cavity, and an executor connected with the valve plate assembly is arranged outside the valve body assembly. The valve body assembly is provided with a channel for conveying the strip, and the channel arranged on the valve body assembly is communicated with the channel arranged on the valve body, an included angle between the sealing surface of the valve body assembly and the working direction of the strip is 10-45 degrees, and at least one compressible sealing element surrounds a channel outlet of the sealing surface of the valve body assembly. An included angle between the sealing surface of the valve plate assembly and the working direction of the strip is 10-45 degrees, and the sealing surface of the valve plate assembly is provided with compressible sealing elements corresponding to the sealing elements on the sealing surface of the valve body assembly. According to the vacuum slit valve, under the conditions that the strip is not damaged, vacuum sealing of different vacuum chamber parts is achieved.

Owner:威海斡兹真空科技有限公司

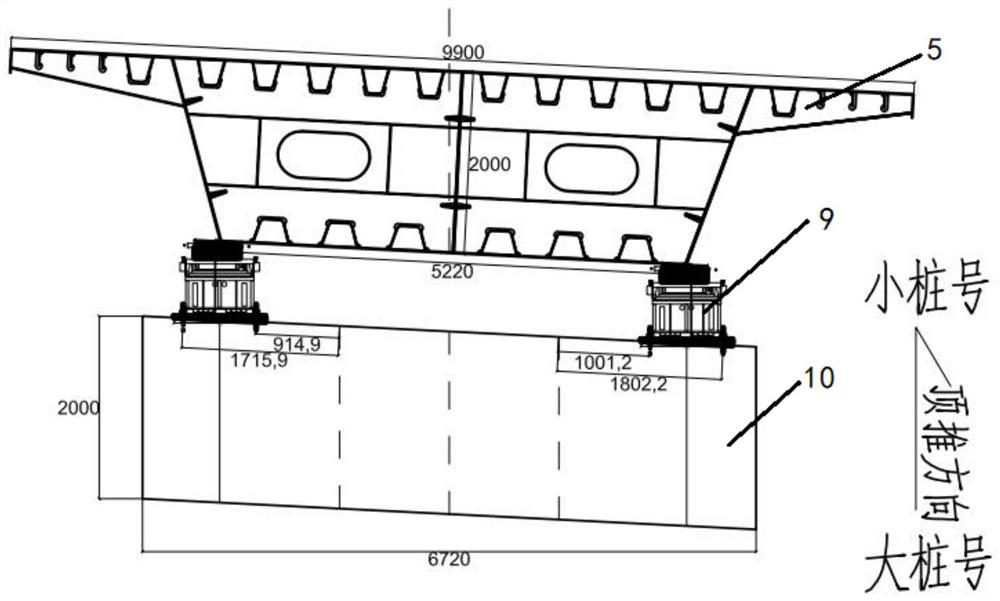

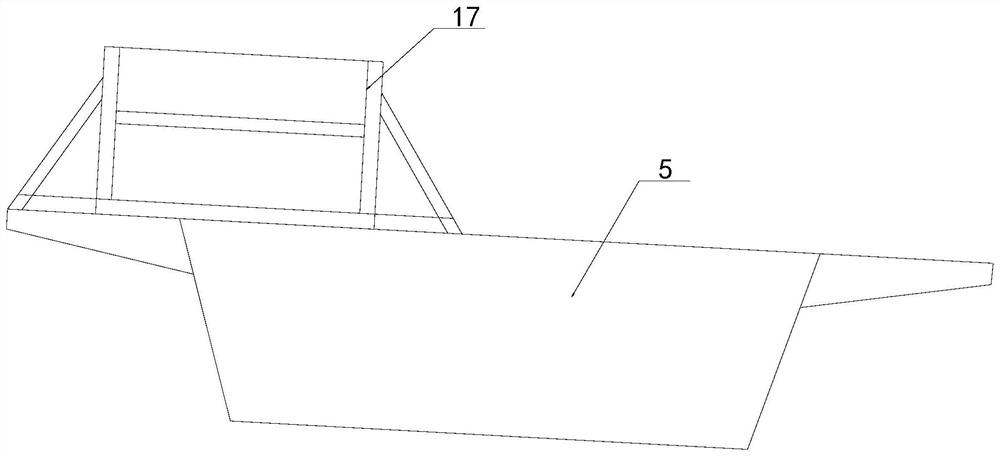

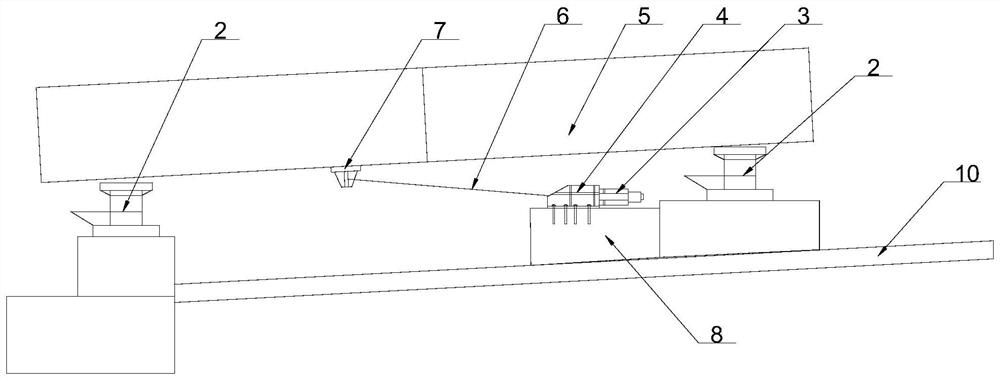

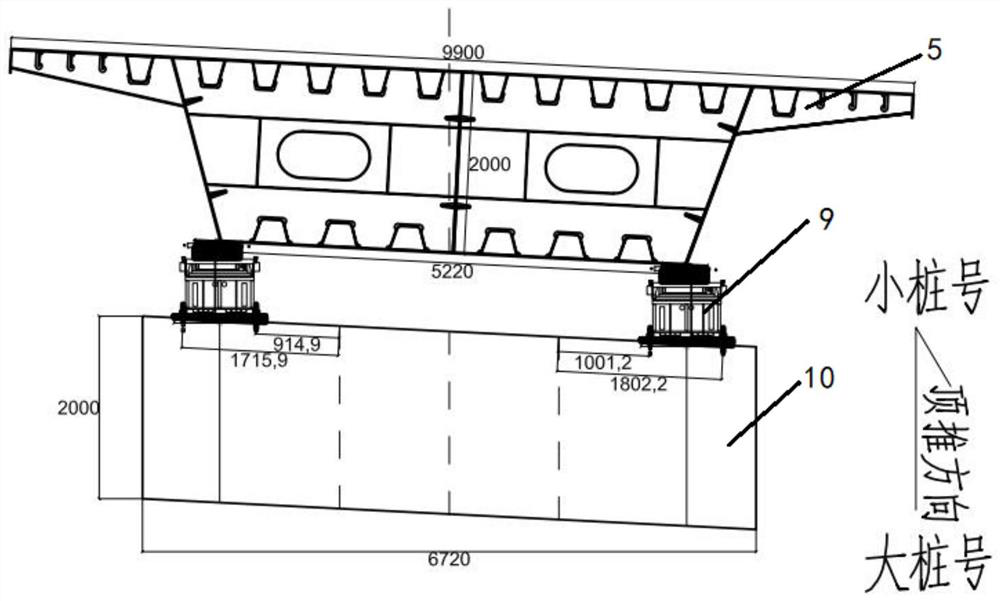

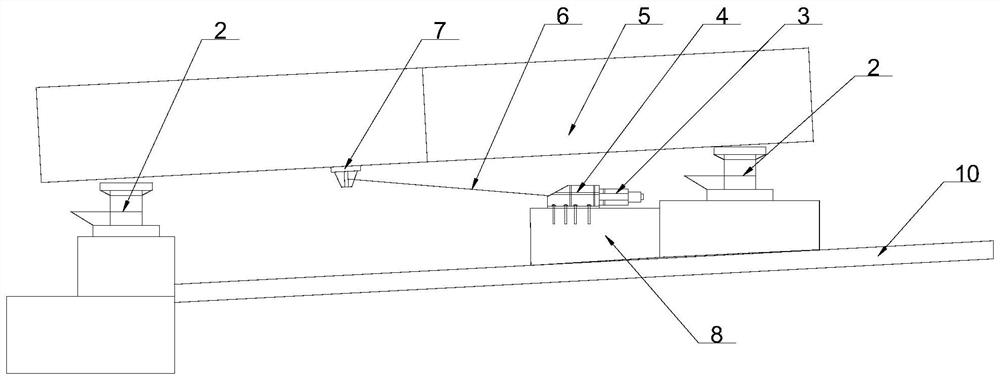

Incremental launching construction method for large, ultrahigh and small-radius circular curve steel box girder

ActiveCN113565019AAvoid voidsGuaranteed differential pressureClimate change adaptationBridge erection/assemblyArchitectural engineeringJackscrew

The invention discloses an incremental launching construction method for a large, ultrahigh and small-radius circular curve steel box girder. The incremental launching construction method comprises the following steps that walking type incremental launching equipment and a temporary bearing beam are arranged; the steel box girder is assembled according to a cross slope and a longitudinal slope which are designed according to the girder body during assembly, and the steel box girder is pushed to the temporary bearing beam on the top of an adjacent cover beam through a pushing jack on an assembly jig frame and the walking type incremental launching equipment on the top of the cover beam; curve incremental launching of the steel box girder is carried out; the deviation of the steel box girder is corrected; and incremental launching counterweight of the steel box girder is carried out, according to the segment division of the steel box girder, the walking type advancing distance of the steel box girder and the cantilever length of the steel box girder are planned, and according to the working condition calculation result of each incremental launching of the steel box girder, counterweight adjustment is carried out on the existing negative reaction force working condition and the working condition of unbalanced stress on the inner side and the outer side of the steel box girder. The purposes that the forward bending moment and torque effect of a cantilever state at the box girder end under the incremental launching state of the small-radius steel box girder is overcome, and it is guaranteed that the pressure difference between incremental launching equipment on the inner side and the incremental launching equipment on the outer side is within a certain range are achieved.

Owner:ROAD & BRIDGE INT +1

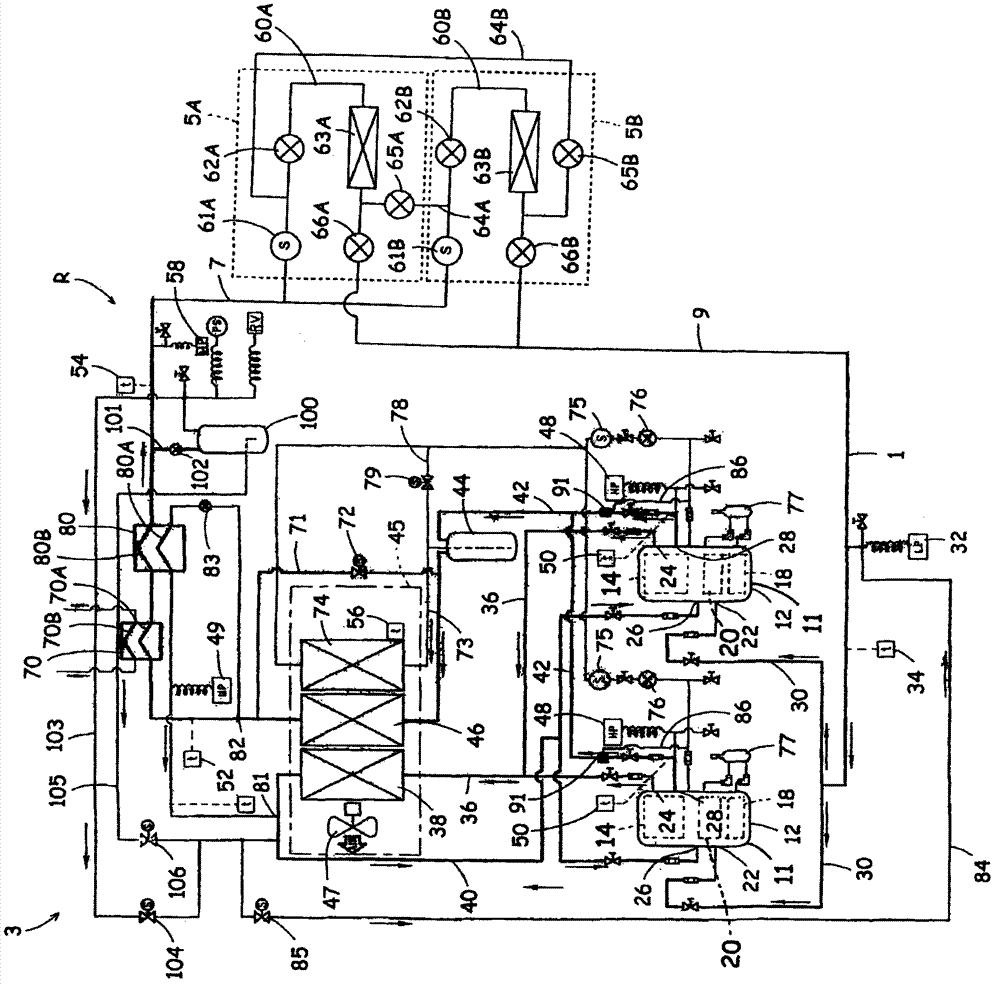

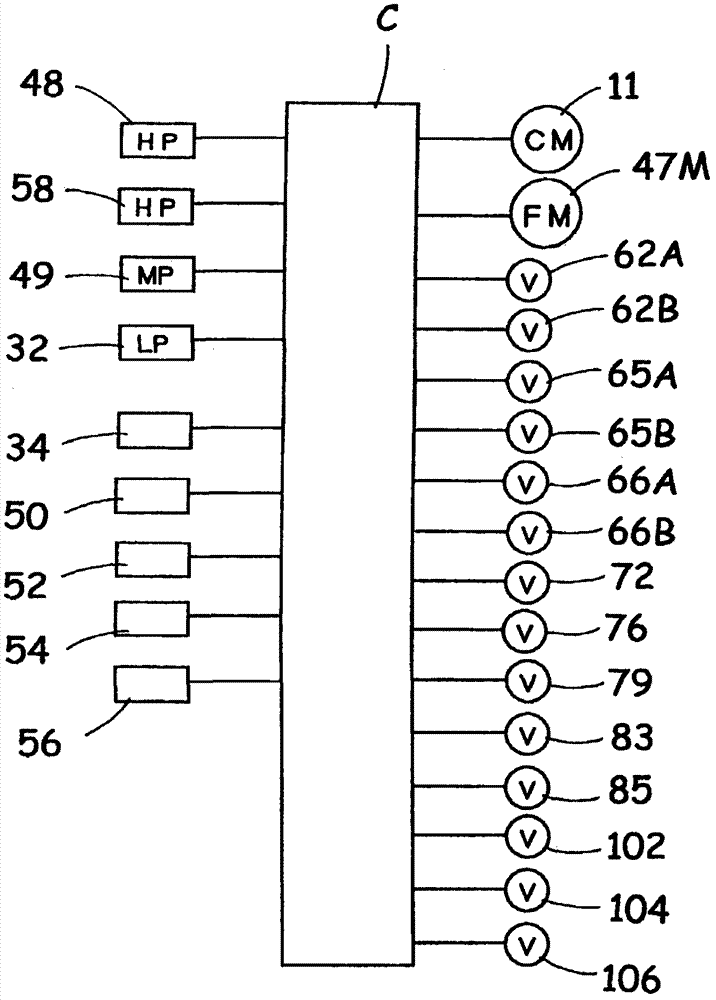

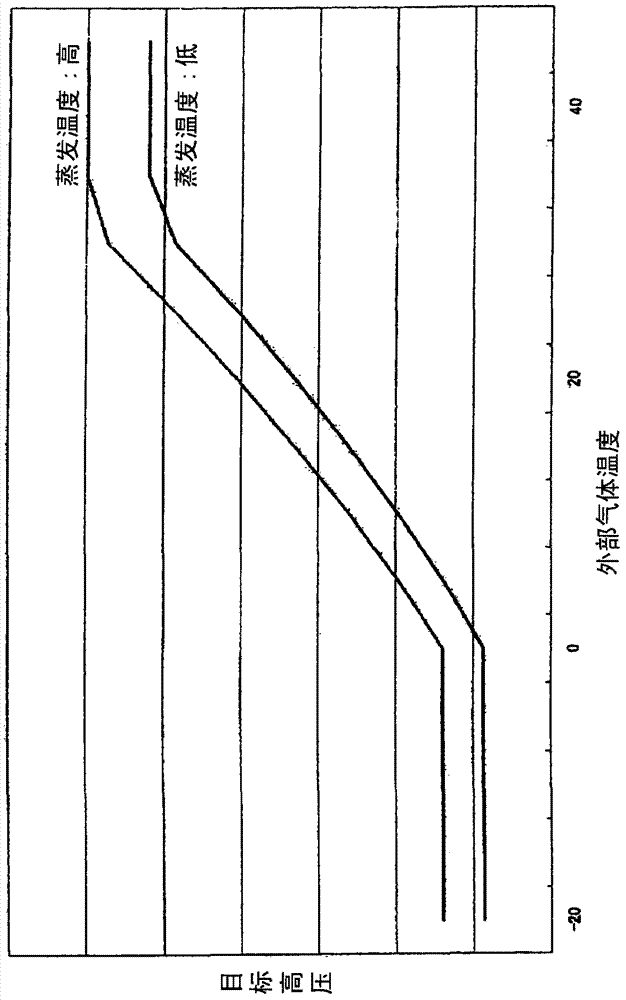

Refrigerating apparatus

ActiveCN102109260BReduced specific enthalpyReduce the amount of compression workMechanical apparatusRefrigeration safety arrangementIntermediate heat exchangerGas cooler

The present invention provides a refrigerating apparatus to obtain an adequate medium pressure of the refrigerant circuit of the refrigerating apparatus and precisely obtain the effect of a split cycle, thereby enhancing the performance of the refrigerating apparatus. The refrigerating apparatus (R) in the present invention has a split cycle device, in the refrigerating apparatus (R), an operation amount of the valve open degree of a auxiliary reducing means (83) is determined by calculating and merging from a first control amount to a third control amount, wherein the first control amount is obtained based on a discharged refrigerant temperature (DT) of the compressor (11), the second control amount is obtained based on an over-compression judgment value (MPO) and a high pressure side pressure (HP), wherein the over-compression judgment value (MPO) is obtained based on an adequate medium pressure (MP) and a low pressure side pressure (LP) of the refrigerant circuit, and the third control amount is obtained by a difference between a temperature (GCT) of the refrigerant passed through the gas cooler and a temperature (LT) of the second refrigerant flow passed through the intermediate heat exchanger.

Owner:SANYO ELECTRIC CO LTD

Refrigerant ball float valve

InactiveCN107560249ALower the liquid levelGuaranteed differential pressureMechanical apparatusFluid circulation arrangementAuto regulationEngineering

The invention provides a refrigerant ball float valve which comprises a valve body, wherein a cavity is formed in the valve body, a water inlet hole and a water outlet hole are separately formed in two sides of the cavity, a valve core is arranged in the cavity, and the valve core is in a float ball shape; the valve body is arranged obliquely, and the water inlet hole is higher than the water outlet hole; and a base is arranged in the bottom of the valve body. According to the refrigerant ball float valve provided by the invention, the openness of the valve can be adjusted at any time as required so as to ensure a needed pressure difference. When the refrigerant ball float valve operates in changed working conditions, the refrigerant ball float valve can adjust the openness of the outlet hole automatically according to changes of the amount of the refrigerant, the lowest liquid level height is in the float ball valve and is higher than the outlet hole, so that a liquid sealing action is guaranteed.

Owner:TONGFANG KAWASAKI ADVANCED ENERGY SAVING MACHINE

an oil-gas separator

ActiveCN107152324BSimple structureEfficient and thorough separationMachines/enginesCrankcase ventillationDifferential pressureEngineering

The invention relates to an oil-gas separator, and belongs to the technical field of automobile engines. The oil-gas separator comprises a separator body, a moving gas gathering chamber, an oil-gas separating part, a pressure adjusting valve, a small load one-way valve, a large load one-way valve, a small load channel and a large load channel; the moving gas gathering chamber is arranged on the left portion of the separator body, and is connected with the oil-gas separating part, the pressure adjusting valve is arranged on the rear side of the oil-gas separating part, the small load channel and the large load channel are formed in the rear side of the pressure adjusting valve, the small load channel is provided with the small load one-way valve, and the large load channel is provided with the large load one-way valve. The one-way valves are directly integrated in the separator body, the oil-gas separating part of the special structure is arranged, oil and gas can be efficiently and thoroughly separated, the separating efficiency is improved, meanwhile,, the structure of the oil-gas separator is simplified, the manufacturing cost of the separator is reduced, the oil-gas separating efficiency is ensured, meanwhile, it is ensured that the pressure difference of the whole oil-gas separator is within the reasonable range, and the engine oil consumption is reduced.

Owner:HENGST FILTER SYST (KUNSHAN) CO LTD

Anti-blocking drip irrigation filtering system

InactiveCN104941309AGuaranteed differential pressureNormal dischargeWatering devicesCultivating equipmentsDrip irrigationFilter system

The invention relates to a filtering device for farmland irrigation, and discloses an anti-blocking drip irrigation filtering system. The anti-blocking drip irrigation filtering system comprises a first-stage filter and a second-stage filter which are connected in series; each filter comprises a tank body and a filtering screen; the upper end of the tank body of each filter is provided with a water outlet, and the lower end of the tank body of each filter is provided with a water inlet. The anti-blocking drip irrigation filtering system is characterized in that the first-stage filter comprises at least one filter, and is internally provided with filter screens; the second-stage filter comprises at least two filters and is internally provided with filter screens and filter elements, and the filter elements are installed in the filtering screens, and are quartz sand filter elements; the filter screens and the water outlets of the tank bodies are connected. The anti-blocking drip irrigation filtering system can effectively prevent sediment in water from blocking a valve and a drip irrigation belt, and can be widely applied to irrigation of crops.

Owner:TIANJIN GREEN VISION ENERGY SAVING ENG EQUIP

Improved structure of dual water pump engine double cooling systems

InactiveCN105909360AGuaranteed differential pressureGuaranteed intake air temperatureLiquid coolingAir-treating devicesExpansion tankTurbocharger

The invention relates to an improved structure of dual water pump engine double cooling systems. The improved structure of the dual water pump engine double cooling systems comprises the high-temperature circulating cooling system and the low-temperature circulating cooling system. The high-temperature circulating cooling system comprises an expansion tank, a high-temperature cooler, an engine cooling water jacket, a first water pump, an electronic thermostat, an engine oil cooler and a heater. The low-temperature circulating cooling system comprises an expansion tank, a low-temperature cooler, a turbocharger, a second water pump, an intercooler, a BSG and an electronic booster. According to the improved structure of the dual water pump engine double cooling systems, the two sets of circulating cooling systems are arranged, and the high-temperature cooler and the low-temperature cooler are arranged in the two systems correspondingly, so that cooling temperature requirements of different cooling parts are effectively ensured. Further, according to the technical scheme, the size of the cooling system is not increased. At the same time, the series branch of the BSG, the turbocharger and the electronic booster and the intercooler branch are arranged in parallel in the low-temperature circulating cooling system, and stability of the differential pressure of the parts is ensured.

Owner:ANHUI JIANGHUAI AUTOMOBILE GRP CORP LTD

Coal bed gas exploiting auxiliary filter device

ActiveCN111335867AGuaranteed filtering effectGuaranteed differential pressureDispersed particle filtrationFluid removalThermodynamicsWater vapor

The invention discloses a coal bed gas exploiting auxiliary filter device. After primary simple filtering, a water vapor filtering mechanism is utilized for removing water vapor, then, a transfer tankis utilized for achieving transfer temporary storage treatment of coal bed gas, the pressure difference in a filter tank is conveniently guaranteed, a filter set is constructed into the manner that coal bed gas can flow into an upper filter partition cavity adjacent to a lower filter partition cavity from the lower filter partition cavity, the filter set can control the flow speed of the coal bedgas, and accordingly during filtering, a certain pressure difference can be achieved between the two upper-lower adjacent filter partition cavities through the filter set; and accordingly, when the filter cotton position is blocked, the coal bed gas can be gathered in the transfer tank, the filter cotton blockage situation can be judged according to the pressure intensity of the transfer tank, cleaning is conveniently conducted, the filter performance of the filter cotton during filtering can be guaranteed due to the basically constant pressure difference, the problem that dust penetrates through the filter cotton is solved, and the filtering capability and the filtering effect are improved.

Owner:濮阳市轮通机械设备修造有限公司

Double-circulation cooling system with electronic supercharger positioned in high temperature cooling system

InactiveCN105927359AIncrease temperatureImprove the warm air effectLiquid coolingAir-treating devicesExpansion tankTurbocharger

The invention relates to a double-circulation cooling system with an electronic supercharger positioned in a high temperature cooling system. The double-circulation cooling system comprises a high temperature circulating cooling system and a low temperature circulating cooling system, wherein the high temperature circulating cooling system comprises an expansion water tank, a high temperature radiator, an engine cooling water jacket, a first water pump, an electronic thermostat, an engine oil cooler, the electronic supercharger and an air heater; and the low temperature circulating cooling system comprises an expansion water tank, a low temperature radiator, a turbocharger, a second water pump, an intercooler and a BSG. According to the double-circulation cooling system, the two circulating cooling systems are arranged, and the high temperature radiator and the low temperature radiator are arranged, so that the requirements of different to-be-cooled parts on the cooling temperature are effectively guaranteed; besides, in the technical scheme, the volume of the cooling system is not increased; and in the low temperature circulating cooling system, the BSG, the turbocharger and the intercooler are arranged in parallel, so that the pressure difference of the parts is guaranteed to be stable.

Owner:ANHUI JIANGHUAI AUTOMOBILE GRP CORP LTD

Construction method of jacking for large super-high and small radius circular curved steel box girder

ActiveCN113565019BAvoid voidsGuaranteed differential pressureClimate change adaptationBridge erection/assemblyWalking distanceArchitectural engineering

This application discloses a construction method for jacking steel box girders with large, super-high and small radius circular curves, including the following steps: walking-type jacking equipment and temporary pad beam arrangement; steel box girders are assembled according to the transverse slope designed for the beam body Assembled with the longitudinal slope, the steel box girder is pushed to the temporary pad beam on the top of the adjacent cover beam by the jacking jack on the assembled tire frame and the walking-type jacking equipment on the top of the cover beam; the curved steel box girder is pushed ;Steel box girder deflection correction; steel box girder push counterweight, according to the section division of steel box girder, plan the walking distance of steel box girder and the cantilever length of steel box girder, and push the steel box girder each time According to the calculation results of the working conditions, the counterweight is adjusted for the existing negative reaction force working conditions and the unbalanced working conditions of the inner and outer sides of the steel box girder. The application achieves the purpose of overcoming the positive bending moment and torque effect of the cantilever state at the end of the box girder under the pushing state of the small-radius steel box girder, and ensuring that the pressure difference between the inner and outer pushing devices is within a certain range.

Owner:ROAD & BRIDGE INT +1

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com