Filter integrality detection device

A technology of integrity detection and filter, which is applied in the direction of measuring the increase and decrease rate of fluid, liquid tightness measurement by using liquid/vacuum degree, etc. High sealing requirements and other issues, to achieve the effect of reducing air leakage, reducing design and manufacturing costs, and saving space

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

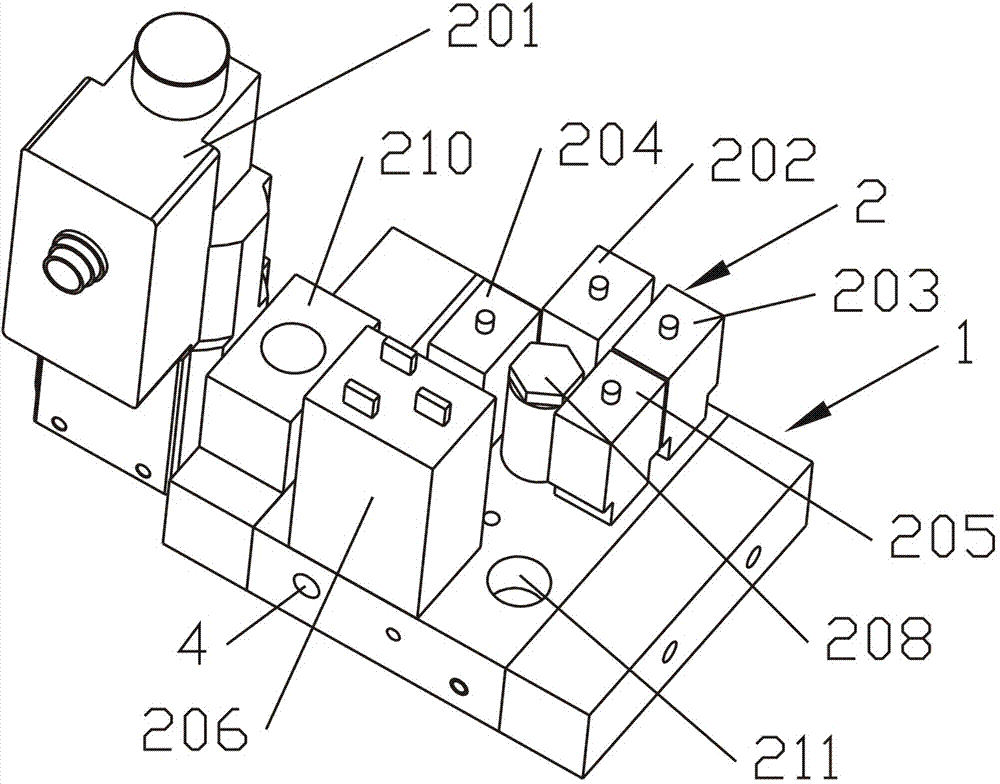

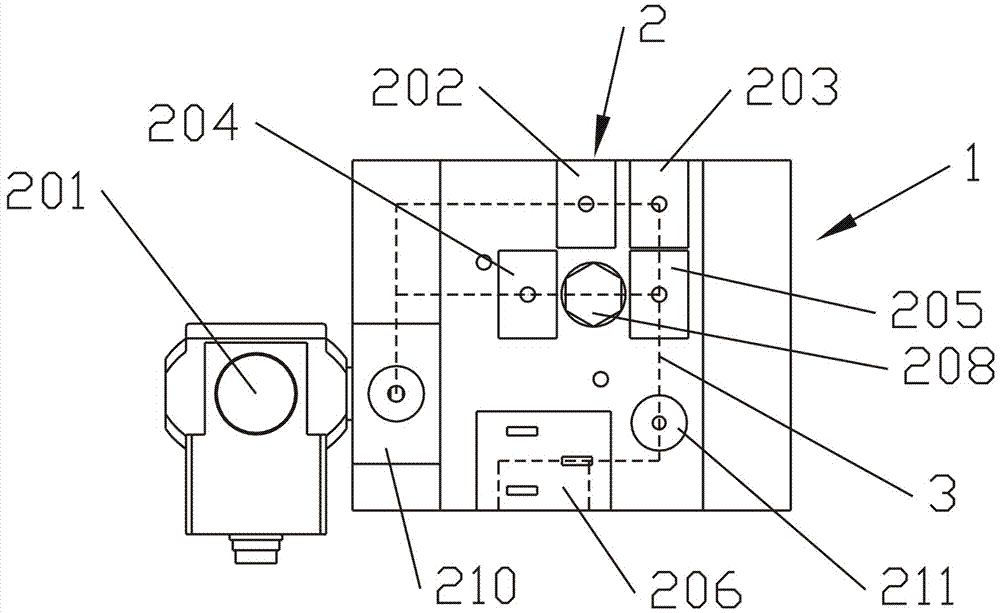

[0028] Filter integrity detection device, the filter integrity detection device is connected between the gas source and the filter to be tested, such as figure 2 , 3 As shown, it includes a solenoid valve, a pressure sensor, a reference tank, and an air circuit board 1. The solenoid valve, pressure sensor, and reference tank are arranged on the air circuit board 1. The board 1 is fixedly connected by buckles, threads and the like. The air circuit board 1 is provided with an air channel pipe 3 (i.e. image 3 The dotted line part shown), the solenoid valve, the pressure sensor, and the reference tank communicate with each other through the gas pipeline 3. In this way, all processing units are integrated on the air circuit board 1 to form an integral module.

Embodiment 2

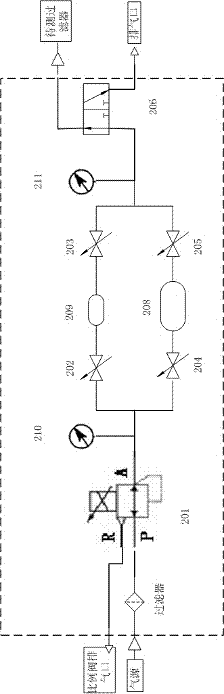

[0030] On the basis of Embodiment 1, the filter integrity detection device of the present invention includes the following components, such as figure 1 , 3 As shown, the solenoid valve includes a first solenoid valve 201, a second solenoid valve 202, a third solenoid valve 203, a fourth solenoid valve 204, a fifth solenoid valve 205, and a sixth solenoid valve 206, and the pressure sensor includes a first pressure The sensor 210 , the second pressure sensor 211 , and the reference tank include a large reference tank 208 and a small reference tank 209 .

[0031] Wherein, the first electromagnetic valve 201 is a proportional valve for adjusting the detection pressure.

[0032] The small reference tank 209 is the gas pipeline 3 connecting the second solenoid valve 202 and the third solenoid valve 203, making full use of the existing space of the gas pipeline 3 to further simplify the structure of the filter integrity detection device.

[0033] The sixth electromagnetic valve 20...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com